A method for the determination of furfural content in transformer oil by high performance liquid chromatography

A high performance liquid chromatography and transformer oil technology, applied in the field of transformers, can solve the problems of inability to extract furfural and low accuracy of furfural detection, and achieve the effects of simple implementation, shortening manpower and time costs, and significant social and economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

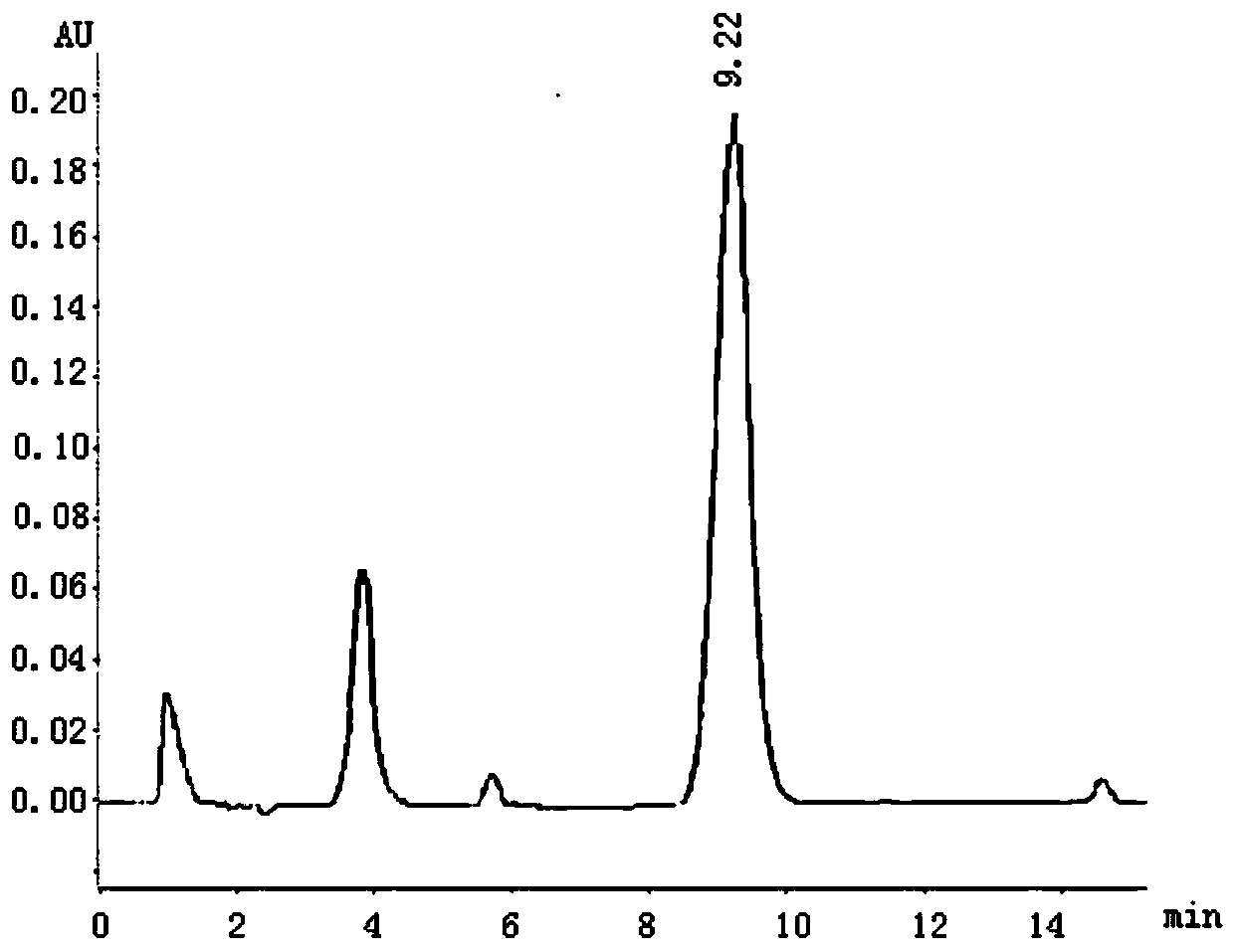

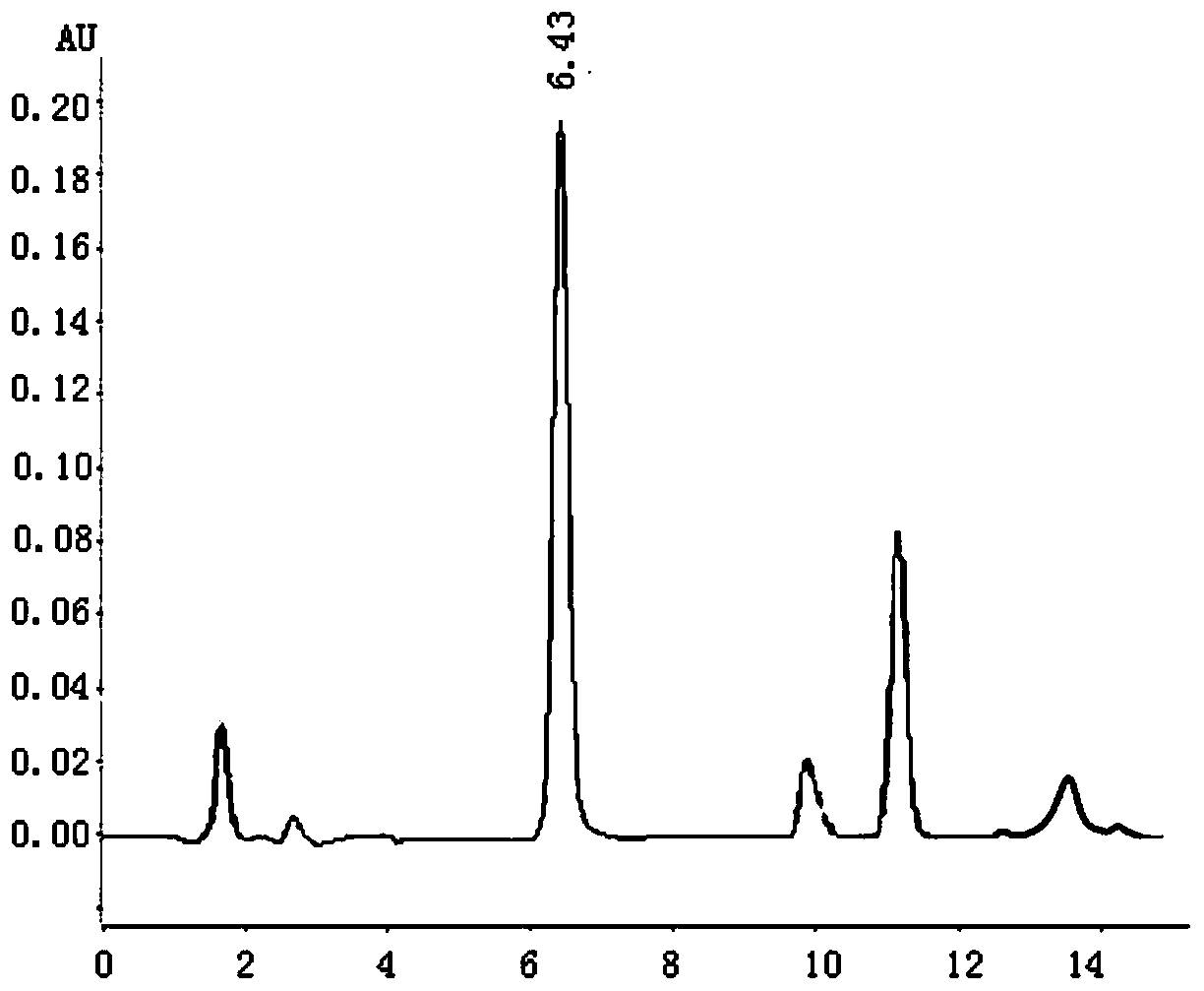

[0070] Example 1 Exploration of chromatographic conditions

[0071] 1. The choice of mobile phase

[0072] (1) Select a phenylpropyl bonded silica gel column (5μm, Φ4.6×150mm);

[0073] Sample: The ethanol solution of oxidized furoic acid is used, and potassium permanganate is used for oxidation. Refer to Example 2.

[0074] Choose the following mobile phases when exploring, the following are just typical examples:

[0075] The volume ratio of methanol: water = 30: 70, chromatographic behavior: no chromatographic peak tailing phenomenon, but the column efficiency is poor;

[0076] Acetonitrile: water volume ratio = 30: 70, chromatographic behavior: chromatographic peak tailing;

[0077] The volume ratio of methanol:0.05mol / L sodium acetate aqueous solution=30:70, chromatographic behavior: chromatographic peaks appear bifurcated;

[0078] Methanol: 0.05mol / L sodium citrate (monosodium citrate, pH4.5) aqueous solution volume ratio=30:70, chromatographic behavior: chromatographic peak shape a...

Embodiment 2

[0118] Choice of oxidation method:

[0119] Before determining the oxidation method most suitable for the present invention, the present invention has been studied and explored through various oxidation methods. Among them, experiments have verified that the Conicano method produces a large amount of other by-products while preparing furoic acid, which increases the difficulty of chromatographic separation; the oxidation efficiency of the catalyst oxidation method is low, and it cannot completely oxidize furfural. Furoic acid, which is not conducive to the detection of furoic acid. Using the oxidant oxidation method, the present invention first found that in transformer oil containing furfural in a certain concentration range (between 5.2μg / L~5mg / L), the transformer oil is oxidized by the oxidant method, and the furoic acid reaction yield is certain Yes, and the present invention adopts oxidant oxidation method, which has higher yield and fewer by-products.

[0120] Take the pref...

Embodiment 3

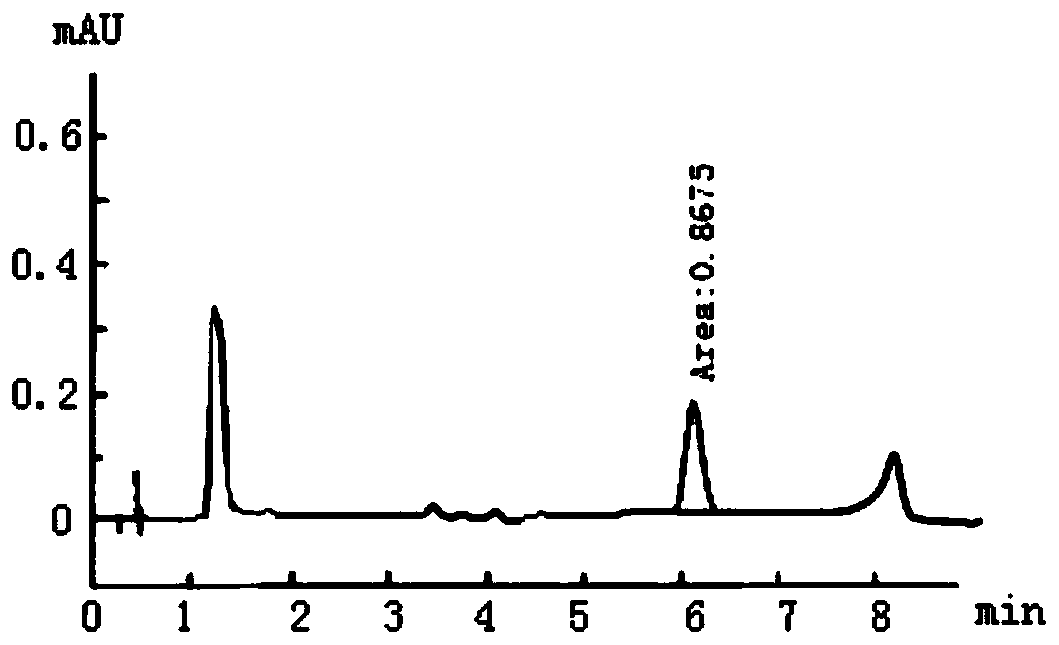

[0124] (1) Selection of extractant types:

[0125] Select methanol, ethanol, water, methanol: water volume ratio of 1:1, ethanol and water volume ratio of 1:1 as extractants.

[0126] experimental method:

[0127] Dissolve 0.010g furoic acid and 0.010g furfural in 10ml blank transformer oil and mix them thoroughly; then select the above 5 extractants for extraction, the pH of the extractant is 6.5, and the volume ratio of extractant: blank transformer oil is 10 : 3. During extraction, vibrate the sample on a mechanical vibrator for 5 minutes and let the sample stand until the extraction phase and the oil phase are completely separated.

[0128] The experimental results are shown in the table. From Table 4, the extraction efficiency of furoic acid and furfural is different for different extractants. Among them, when ethanol is used as the extractant, furoic acid has the highest extraction efficiency, while furfural has the lowest extraction efficiency.

[0129] Table 4 The extraction r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com