Foundation pit supporting device for civil engineering

A technology of foundation pit support and civil engineering, applied in the direction of infrastructure engineering, excavation, construction, etc., can solve the problems of low reuse efficiency and narrow application range of support devices, and achieve high reuse rate and wide application range Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

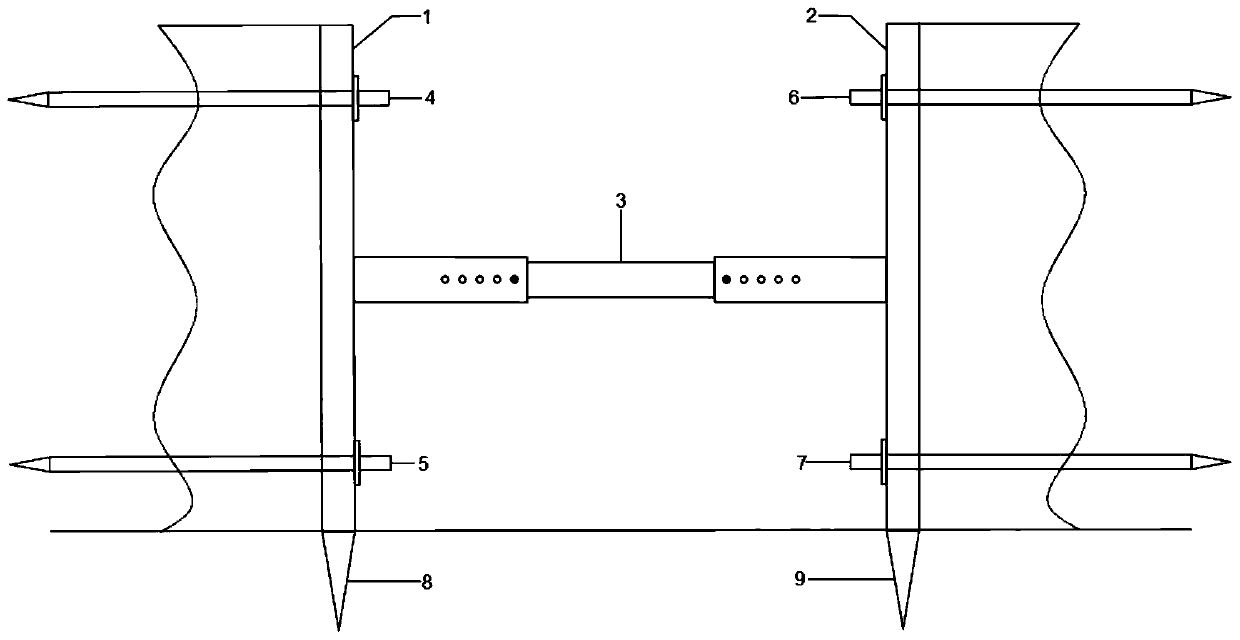

Embodiment 1

[0025] Embodiment 1: refer to Figure 1-2 , including a flat plate one 1 vertically close to the side wall of the foundation pit, a flat plate two 2 vertically close to the side wall of the foundation pit, and a telescopic rod 3 horizontally connecting the flat plate one 1 and the flat plate two 2, the flat plate one 1 Anchor rod one 4 and anchor rod two 5 are horizontally inserted in the upper and lower parts, respectively, for horizontal reinforcement of plate one, and anchor rod three 6 and anchor rod four 7 are horizontally inserted in the upper and lower parts of said plate two 2, respectively, for horizontal reinforcement. Reinforce the plate two, the bottom of the plate one 1 is provided with a sharp cone one 8, which is used to vertically reinforce the plate one, and the bottom of the plate two 2 is provided with a sharp cone two 9, which is used for vertically reinforcing the plate two.

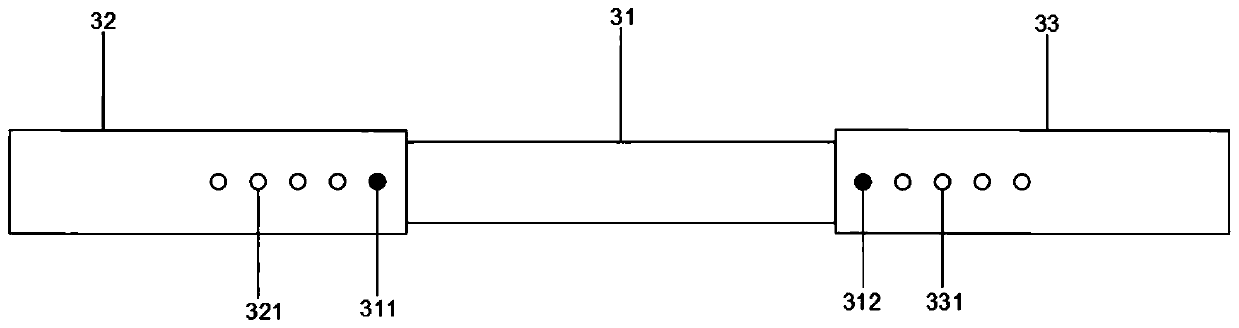

[0026] The structure of the first plate 1 is the same as that of the second plat...

Embodiment 2

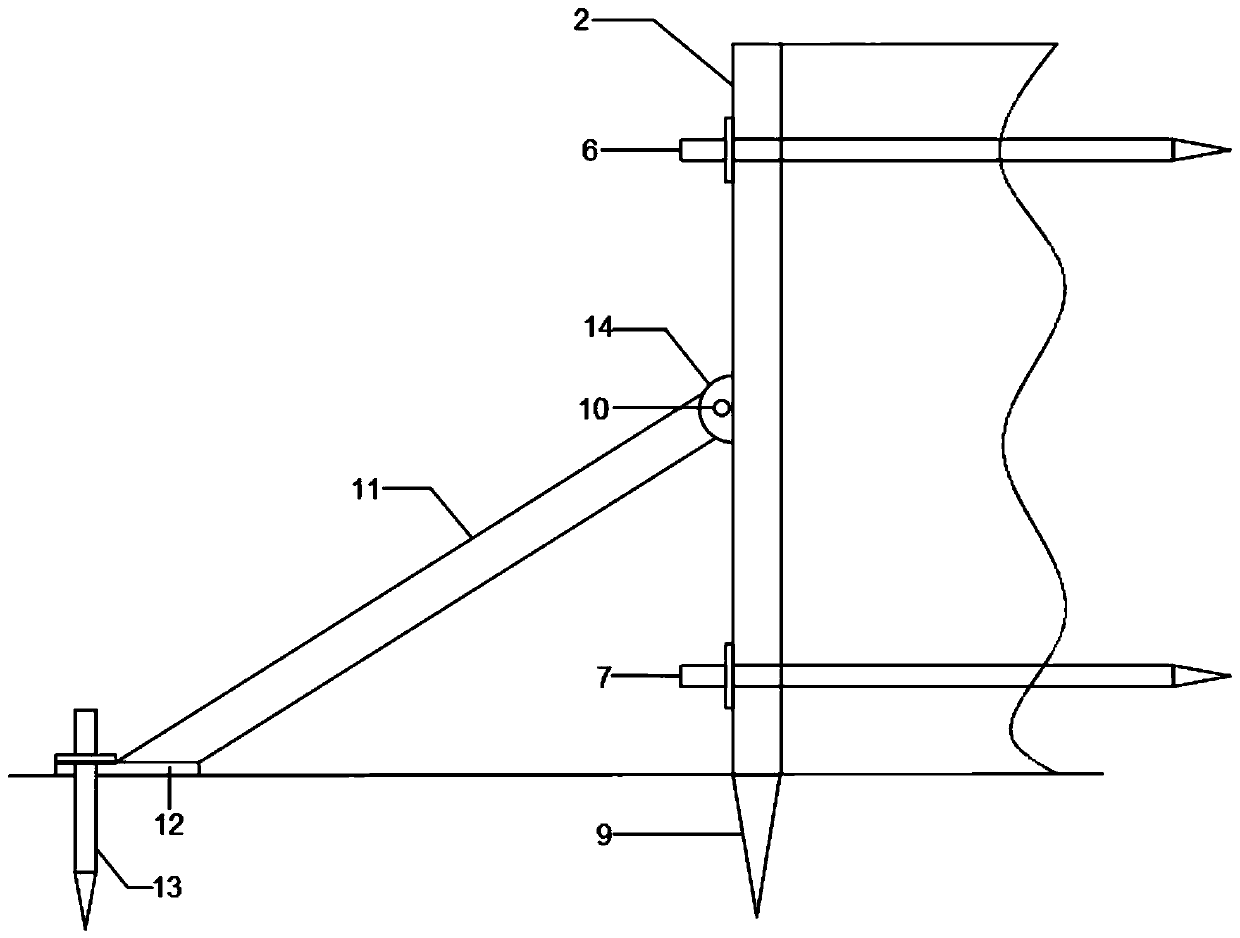

[0028] Embodiment 2: refer to image 3 , the difference from the above embodiment is that a base 14 is provided in the middle of the plate two 2, and the base 14 is hinged to the rotating rod 11 through the rotating shaft one 10 to adjust the inclination angle of the rotating rod 11. The end of the rod 11 is horizontally fixed to the support plate 12, and the side of the support plate 12 away from the rotating rod 11 is vertically inserted with an anchor rod 5 13 for vertically reinforcing the support plate 12 on the ground.

Embodiment 3

[0029] Embodiment 3: The upper part of the flat plate 1 is provided with a connecting column 17, the lower part of the flat plate 1 is provided with a groove 1 compatible with the connecting column 17, and one side of the flat plate 1 is provided with a connecting column 1. The second column 18, the other side of the first plate 1 is provided with a groove 2 matching the second connecting column 18. The sectional view of the first connecting column 17 and the sectional view of the second connecting column 18 are T-shaped or elliptical, and the sectional view of the groove one and the sectional view of the groove two are connected with the connection The sectional view of the first column 17 matches the sectional view of the second connecting column 18 . The upper part of the plate one 1 is provided with a lock one 19, and the lower part of the plate one 1 is provided with a lock two 20 matched with the lock one 19, which is used for locking a plurality of plates spliced toge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com