Reciprocating type electrochemical frictional wear experimental instrument and use method thereof

A kind of friction and wear, electrochemical technology, applied in the direction of scientific instruments, instruments, testing wear resistance, etc., can solve the problems of data collection and integration deviation, result and real result deviation, can not satisfy the analysis and research, and achieve the integration of precise Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

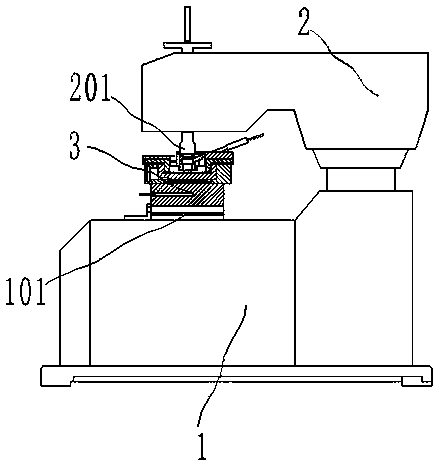

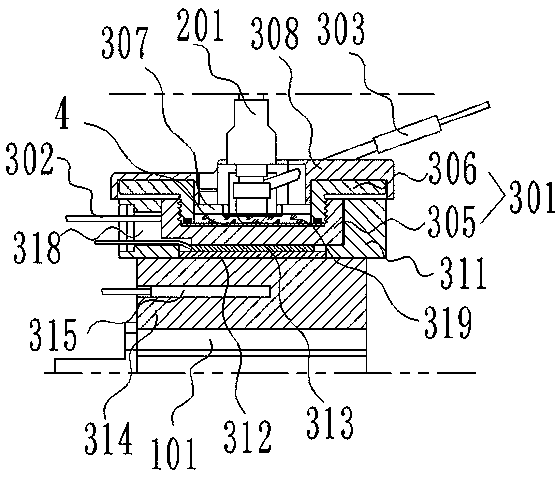

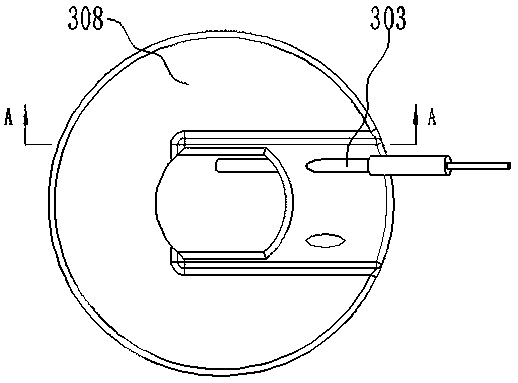

[0032] The present invention will be described in detail below in conjunction with accompanying drawing and specific embodiment: a kind of reciprocating electrochemical friction and wear tester and using method thereof, comprise reciprocating frame 1, dynamometer head 2 and electrochemical cell 3, dynamometer head 2 Connected to the top of the reciprocating machine base 1, the reciprocating machine base 1 is provided with a reciprocating mechanism 101, the reciprocating mechanism 101 is connected to the electrochemical cell 3, the electrochemical cell 3 reciprocates with the reciprocating mechanism 101, and the detection part 4 is set on the electrochemical cell 3, the surface of the detection piece 4 is in contact with the force measuring part 201 of the dynamometer head 2, and the electrochemical cell 3 is effectively combined with the reciprocating friction and wear tester, and the detection piece 4 passes through the reciprocating mechanism 101 in the electrochemical cell 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com