Combined type high-voltage-stabilization-precision non-contact voltage stabilizer main circuit and non-contact voltage stabilizer

A voltage-stabilizing precision, non-contact technology, applied in the direction of instruments, adjusting electrical variables, control/regulation systems, etc., can solve the problems of taps that are difficult to deal with, and achieve simplified manufacturing processes, enhanced reliability and working life, and the number of combinations many effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention is further described below in conjunction with embodiment.

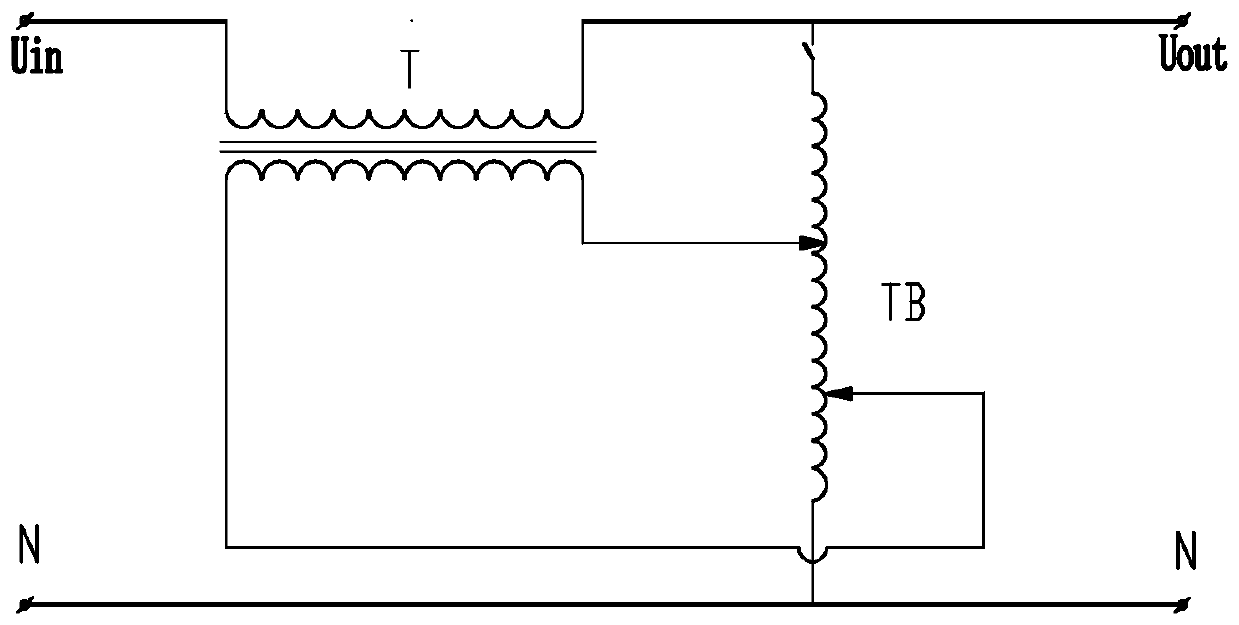

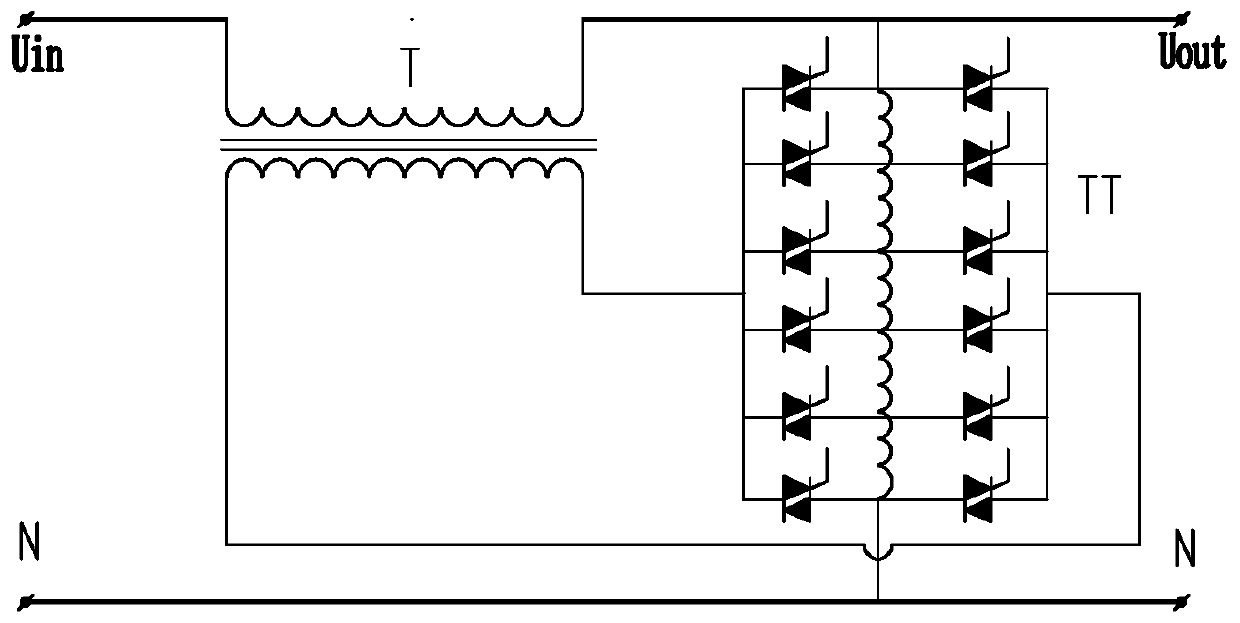

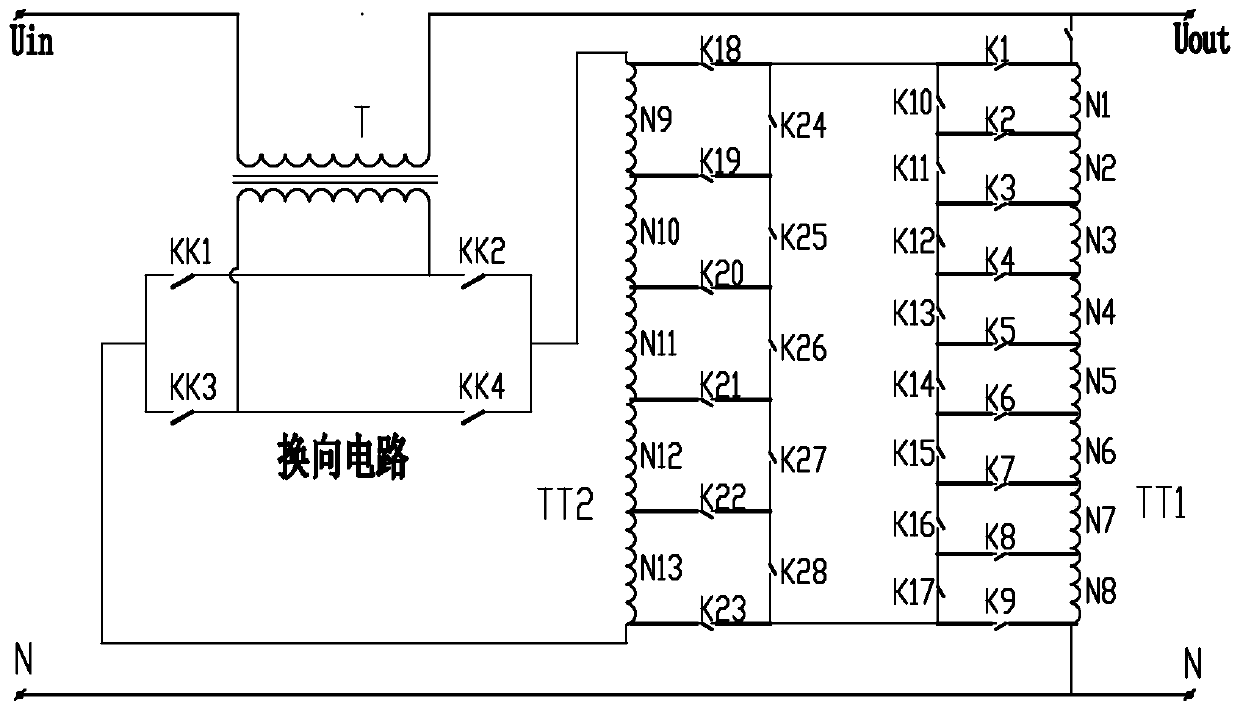

[0027] Such as image 3 Shown is the main circuit of the combined non-contact voltage stabilizer with high voltage stabilization precision of this embodiment, which includes a compensation transformer T, a first autotransformer TT1, a second autotransformer TT2, a first contactor switch K1- K9, second contactor switches K18-K23, third contactor switches K10-K17, K24-K28 and commutation circuits.

[0028] The first autotransformer TT1 is provided with two first lead-out terminals respectively located at both ends and m first taps located between the two first lead-out terminals, and the two first lead-out terminals are connected to the first autotransformer TT1 respectively. The two ends of the main coil are connected, and the two first lead-out terminals and the m first taps are respectively connected in parallel with a first parallel wire through the first contactor switches K1-K9. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com