Corrugated skid with optimum support

A corrugated and blank technology, which is applied in the field of corrugated sliding devices with optimal support, can solve the problems of reducing the stability of cargo shipping, reducing the load transport capacity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

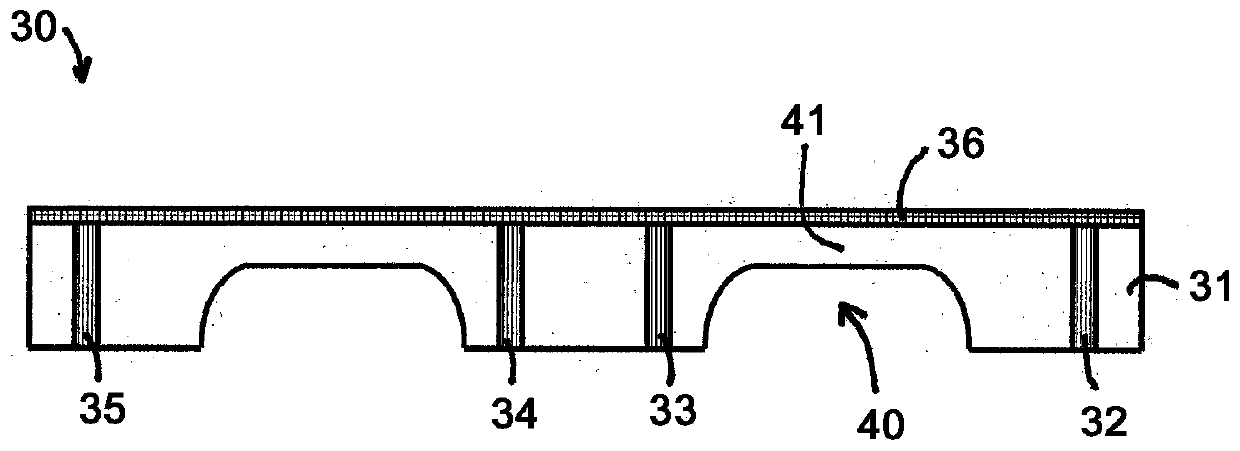

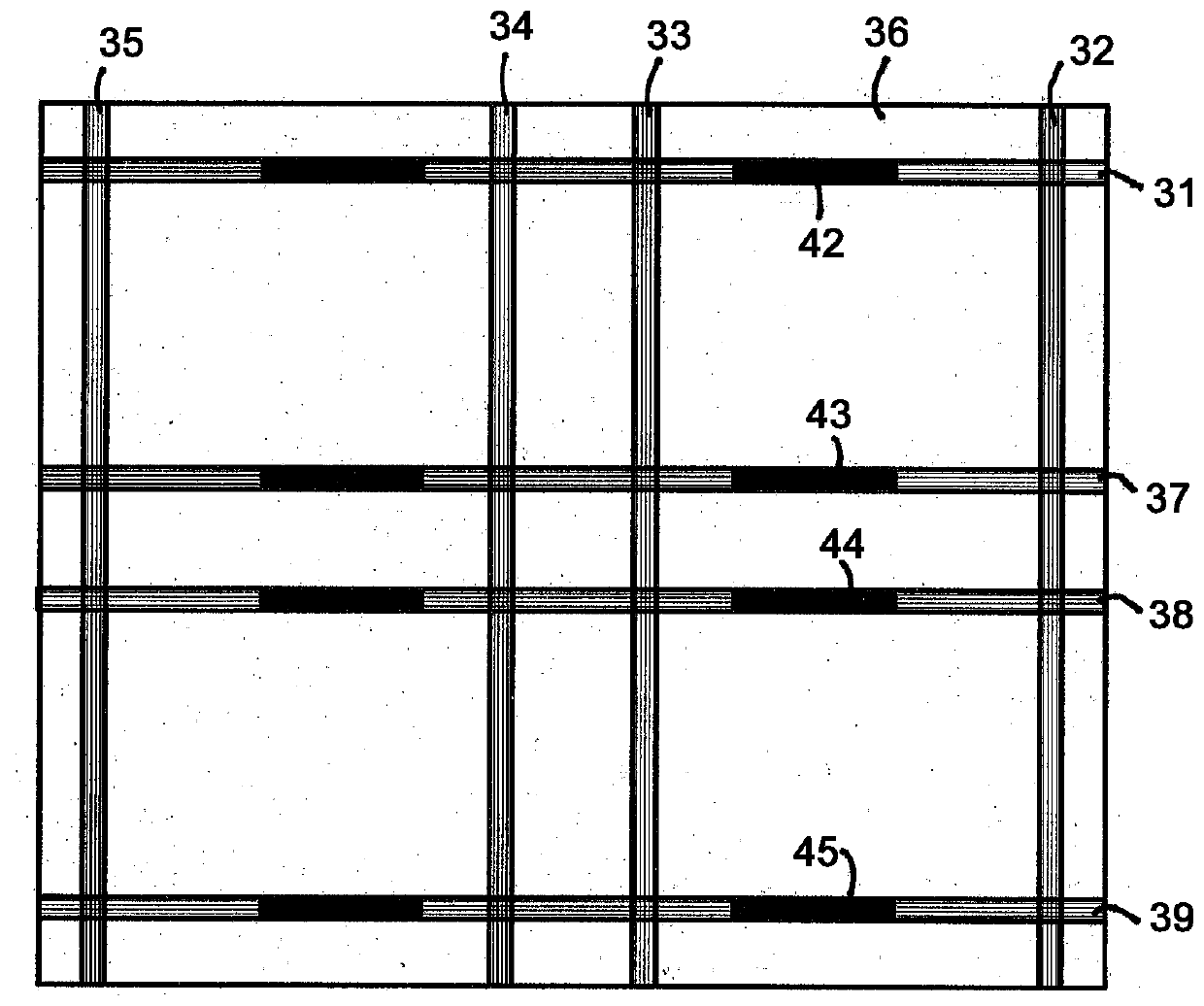

[0040] Turning to the drawings, in which like reference numerals indicate the same or corresponding parts, Figures 1A and 1B are side and bottom views of a beam and platform type corrugated sliding device of the prior art. Although this type of corrugated board sliding device has been in the market for quite some time, it is not desirable because of the need to use a large number of boards and the inherent cost. The sliding device 30 is composed of notched stacked corrugated beams 32, 33, 34, and 35 assembled with the crossed beams 31, 37, 38, and 39 and a platform plate 36 adhered to the top. The beams 31, 32, 33, 34, 35, 37, 38, 39 have a fork channel 40 to allow lifting by a pallet truck or forklift, and a continuous beam portion 41 on the channel. Since the beam 41 must be continuous on the fork channel 40, the skid device 30 needs to use an additional plate which is higher than desired. When the sliding device 30 is raised, the lifting forks act on the concentrated areas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com