Disinfection cabinet

A technology of disinfection cabinet and inner tank, applied in the field of disinfection cabinet, can solve the problems of ineffective volatilization, rot and mildew of the cabinet, etc., and achieves the effect of convenient operation and avoiding leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

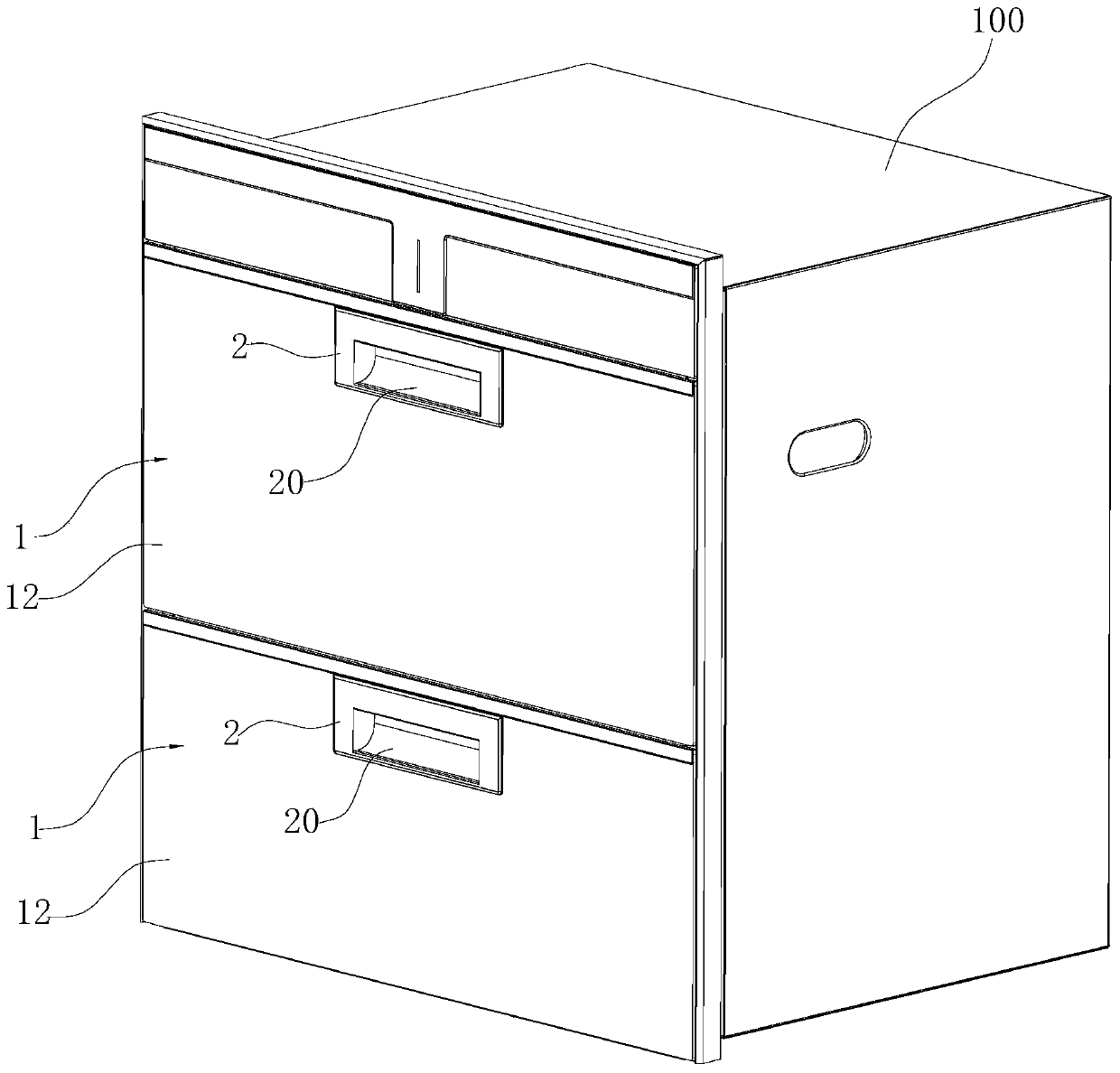

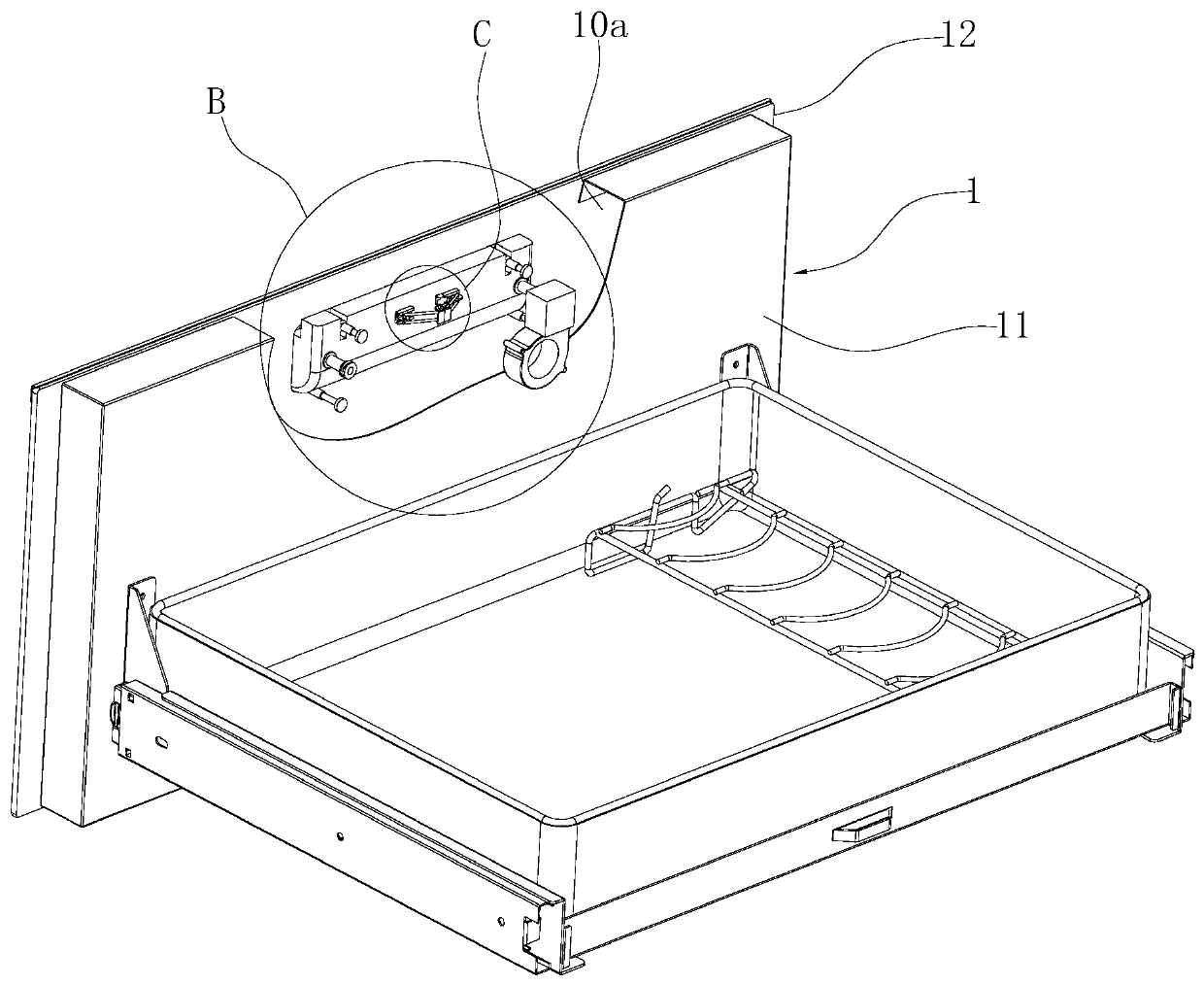

[0029] Such as Figure 1-10As shown, a disinfection cabinet includes a cabinet body 1, the front of which is open and its inner cavity is the inner container of the disinfection cabinet. In this embodiment, two drawers 10 are arranged above and below the inner container, and the drawer panels of each drawer 10 respectively constitute the door body 1 of the disinfection cabinet and cover the opening of the inner container. Each door body 1 includes a box-shaped door frame 11 and a panel 12, the panel 12 covers the opening of the door frame 11, and the panel 12 is provided with an installation opening 121, and a handle 2 is embedded in the installation opening 121, The panel 12 and the door frame 11 enclose a space 10a capable of accommodating the above-mentioned handle 2 .

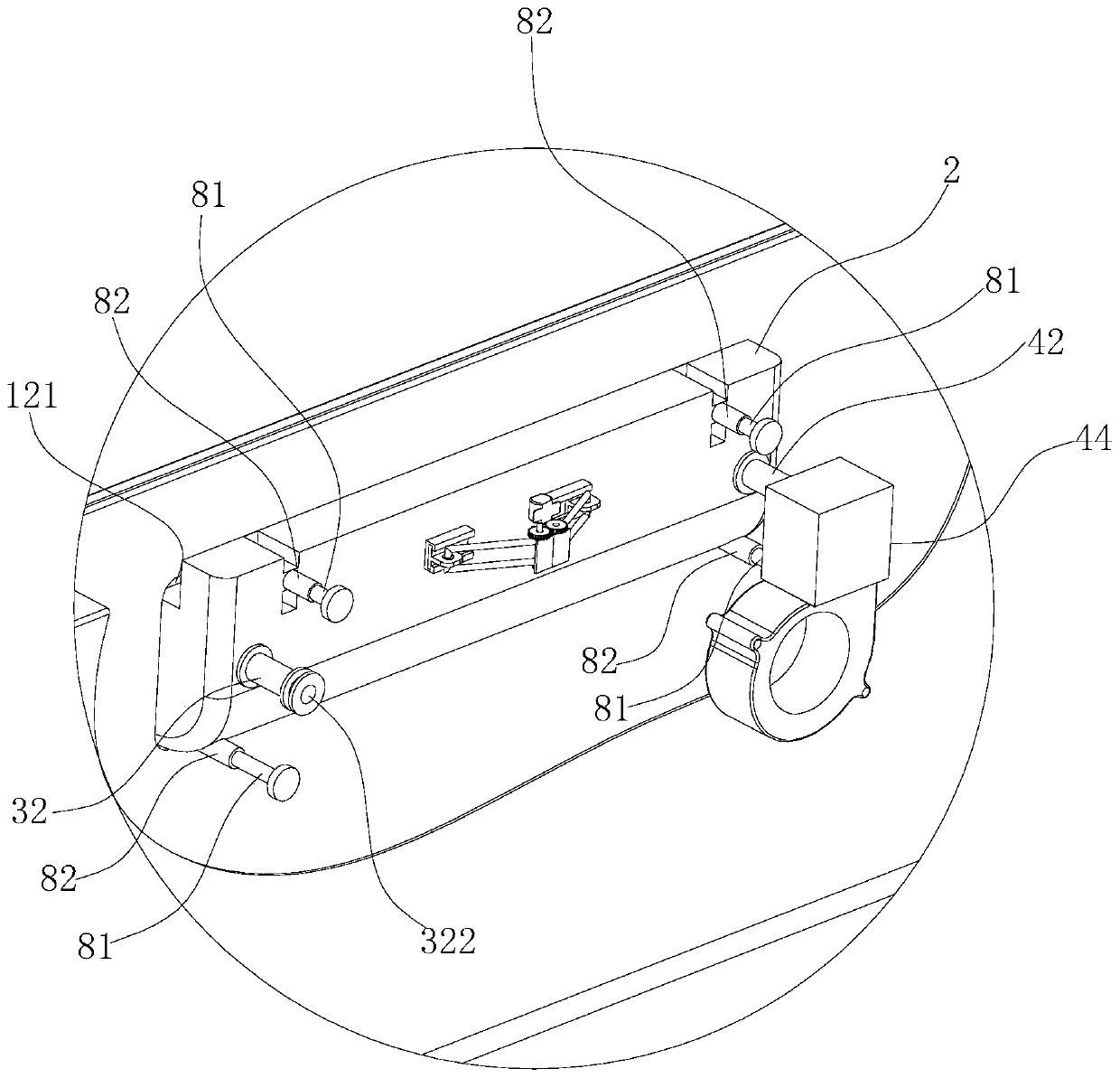

[0030] The above-mentioned handle 2 is respectively provided with an air intake mechanism 3 and an exhaust mechanism 4, wherein the air intake mechanism 3 includes an air intake chamber 31 with an air inle...

Embodiment 2

[0036] Such as Figure 11 and 12 As shown, the difference from Embodiment 1 is that in this embodiment, the upper locking ejection mechanism 6 includes a motor 61, a first connecting rod 64, a second connecting rod 65, a first slide rail 661 and a second slide rail 662. The first slide rail 661 and the second slide rail 662 are respectively fixed on the handle 2, the first hinge seat 691 and the second hinge seat 692 are respectively fixed on the above-mentioned door frame 11, and the above-mentioned first connecting rod 64 and the second connecting rod 65 are opposite to each other. Set, the first end of each connecting rod is respectively hinged with the first hinged seat 691 and the second hinged seat 692, and the second end of each connecting rod is respectively hinged with the first slider 671 and the second slider 672, the first The slider 671 and the second slider 672 are respectively embedded in the above-mentioned first slide rail 661 and the second slide rail 662 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com