Automobile part stamping die

A technology for stamping dies and auto parts, applied to forming tools, manufacturing tools, metal processing equipment, etc., can solve problems such as unusable, increased production costs of auto parts, deformation of forming dies, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

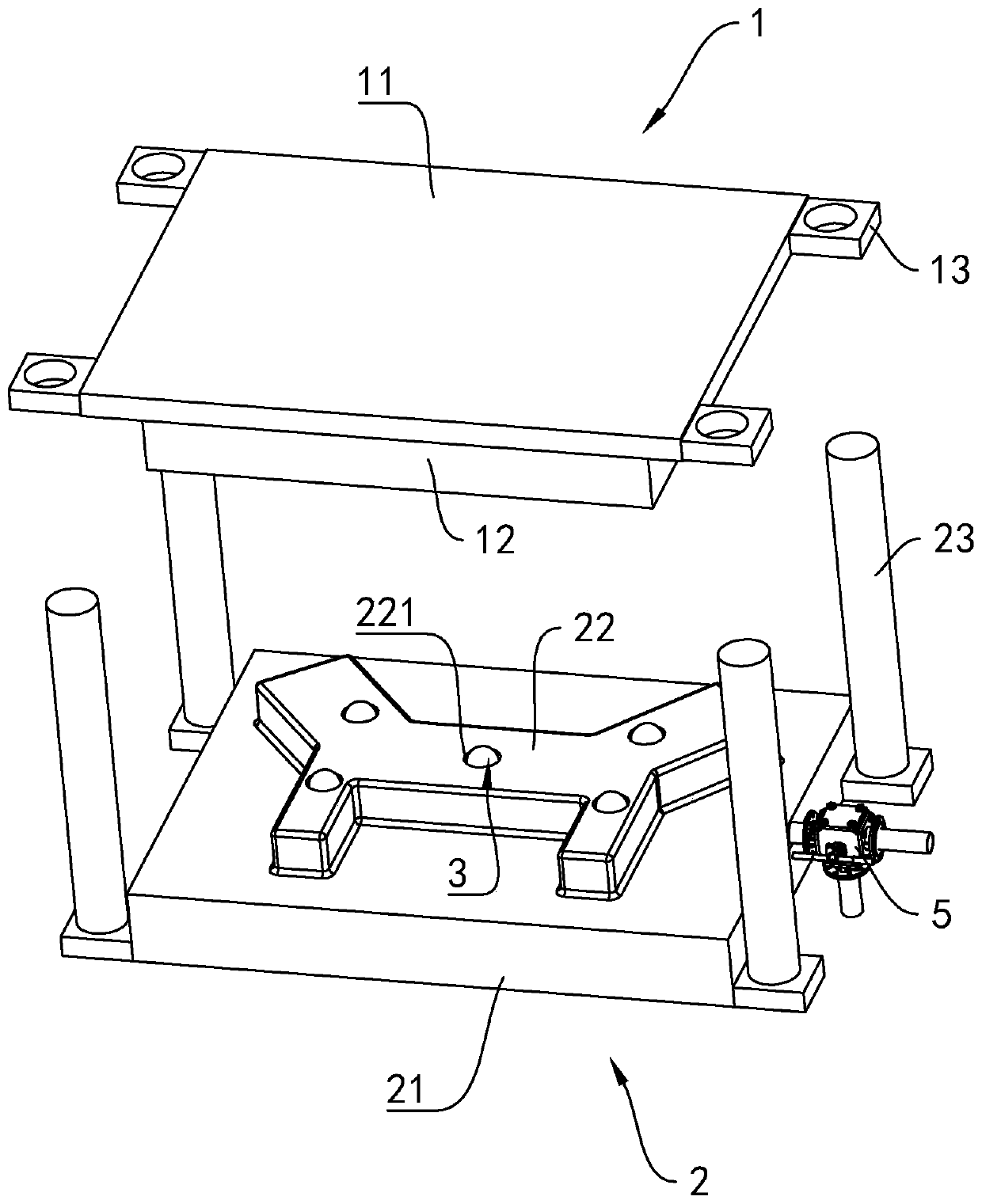

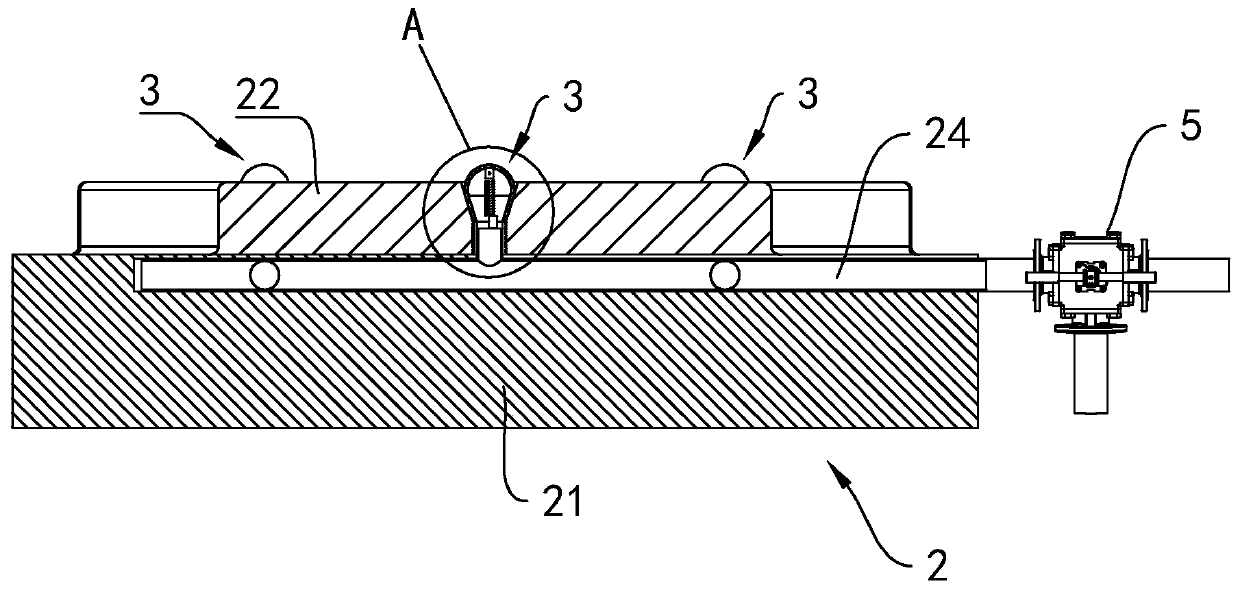

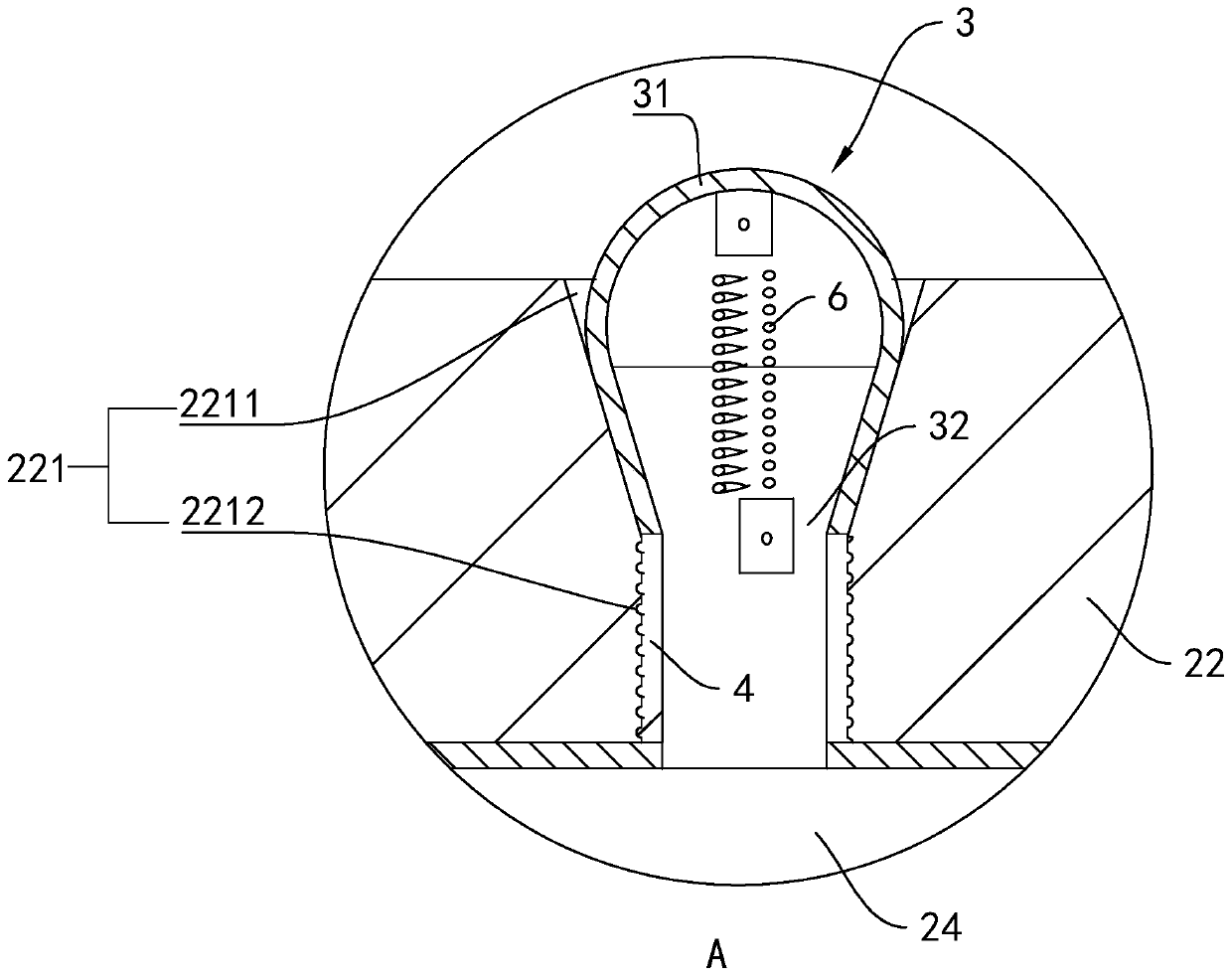

[0037] refer to figure 1 , is a stamping die for auto parts disclosed in the present invention, comprising an upper die 1 and a lower die 2 that are opposite up and down. The upper mold 1 includes an upper mold base 11 and a concave mold 12 located on the bottom surface of the upper mold base 11 , and the concave mold 12 is integrally formed with the upper mold base 11 . The lower mold 2 includes a lower mold base 21 and a punch 22 located on the top surface of the lower mold base 21 , and the punch 22 and the lower mold base 21 are integrally formed. The die 12 and the punch 22 on the upper die 1 and the lower die 2 are arranged oppositely. On opposite sides of the lower mold base 21, vertically arranged guide rods 23 are arranged, and the guide rods 23 are fixedly connected with the lower mold base 21. A sliding sleeve 13 is fixed at a position opposite to the guide rod 23 on the upper die base 11 , and the top end of the guide rod 23 runs through the sliding sleeve 13 and...

Embodiment 2

[0048] refer to Figure 5 , is a stamping die for auto parts disclosed by the present invention. The difference between Embodiment 2 and Embodiment 1 is that a counterweight 7 is arranged inside the inflatable airbag 3 , and the counterweight 7 is fixed on the closed end of the inflatable airbag 3 . Due to the weight of the counterweight 7 , during the deflation process of the inflatable airbag 3 , the counterweight 7 falls under gravity, so that the inflatable airbag 3 is quickly retracted into the accommodation hole 221 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com