Self-propelled wire boring device for inner wall of through pipe

A wall boring and self-advancing technology, which is applied in the field of self-advancing through-pipe inner wall boring devices, can solve the problem of low degree of automation and achieve the effect of wide application range and easy pick and place.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

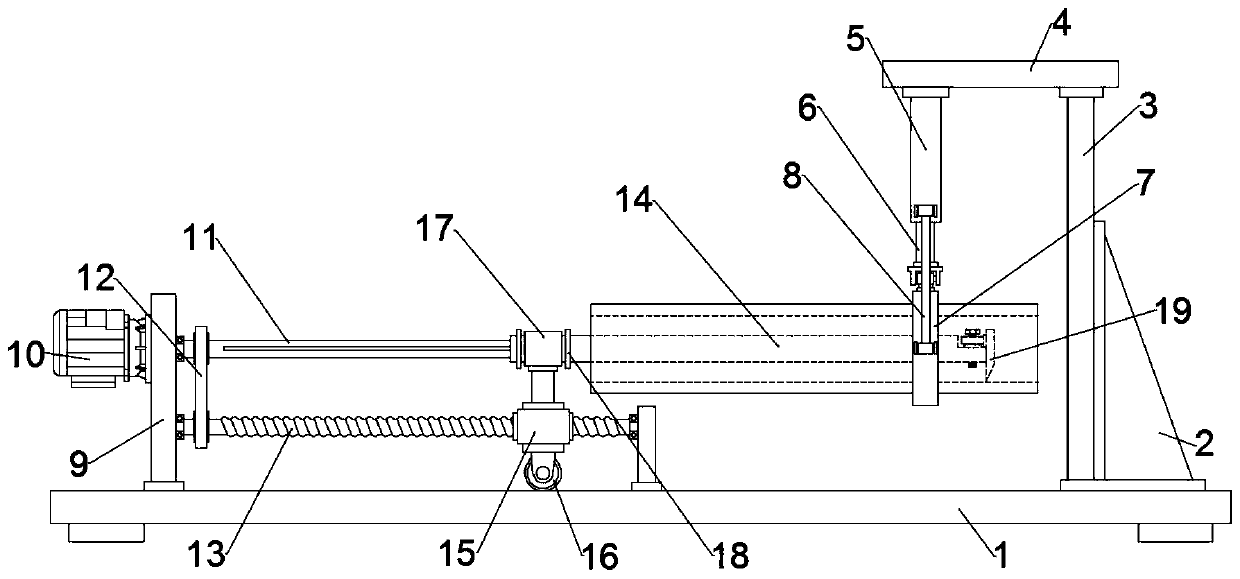

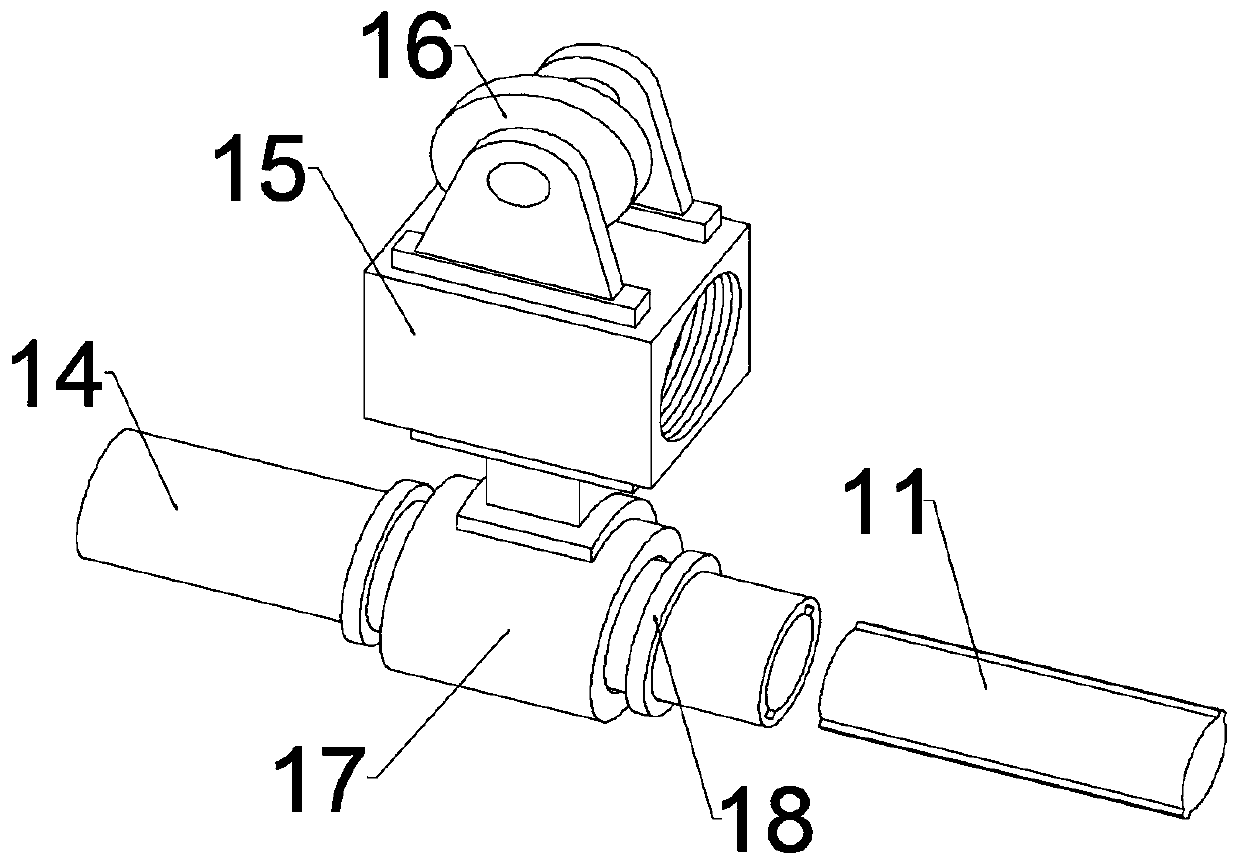

[0021] see Figure 1~3 , in an embodiment of the present invention, a self-propelled through-pipe inner wall boring device includes a workbench 1, a clamping device installed above one side of the workbench 1 for fixing the through-pipe, a tapping assembly and a push tapping Traveling mechanism for component travel;

[0022] Specifically, the clamping device is fixed below the top plate 4, the top plate 4 is fixed on one side of the workbench 1 through the support plate 3, and a reinforcing rib 2 is fixed at the connection between the workbench 1 and the support plate 3, and the clamping The device suspends and fixes the through pipe, which is convenient for processing; on the side of the workbench 1 opposite to the support plate 3, a mounting plate 9 for flange mounting of the servo motor 10 is fixed, and the servo motor 10 is connected to the power supply and the switch through a wire, and the servo motor The output end of 10 is connected to the drive shaft 11. It should be...

Embodiment 2

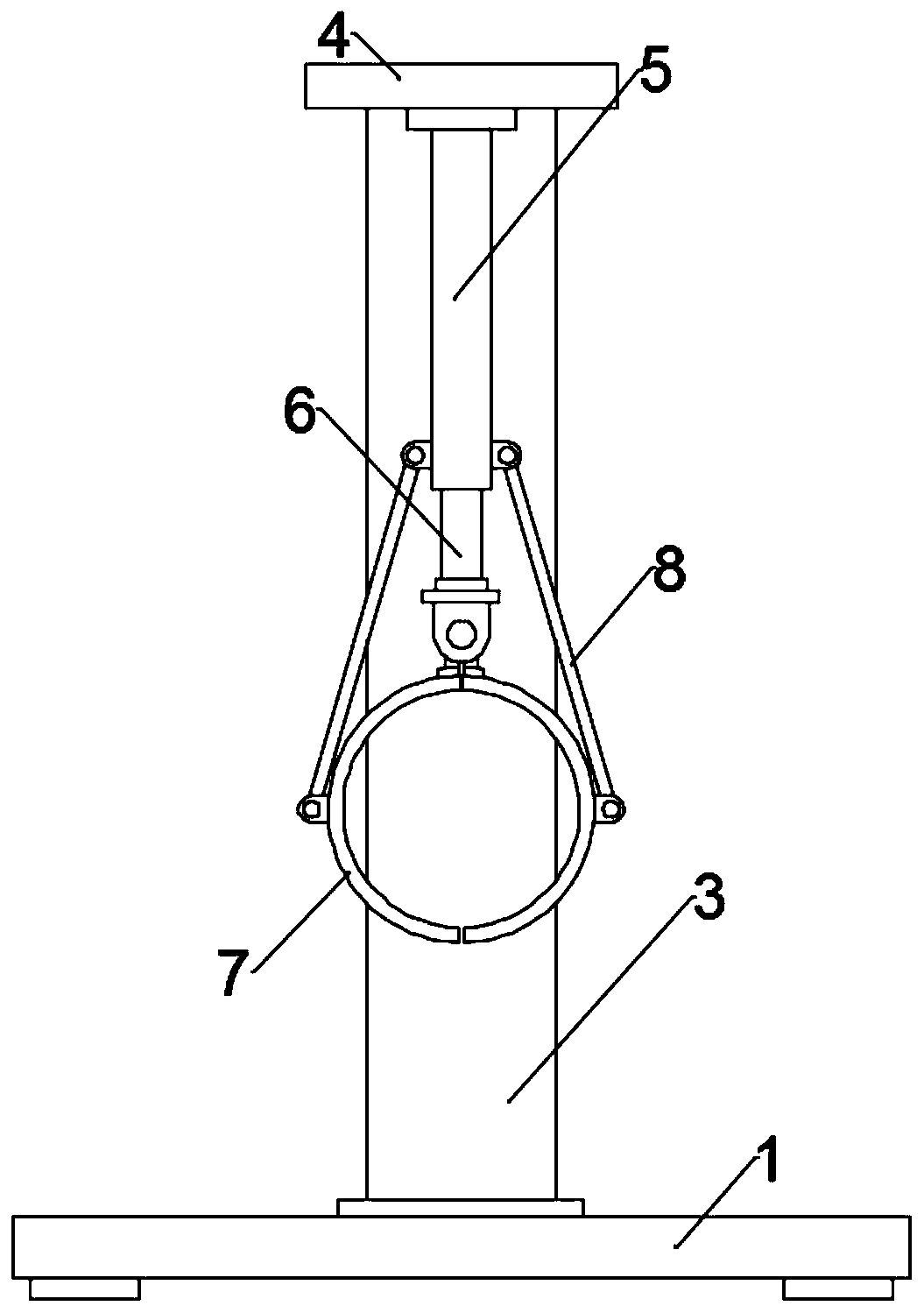

[0026] In order to further describe the clamping device in the above-mentioned embodiment in detail, the present application provides another embodiment, a self-propelled through-pipe inner wall boring device, the clamping device includes a driving mechanism fixed on the top plate 4, The piston rod 6 slidably connected to the lower part of the driving mechanism, and the two clamping claws 7 hinged at the lower end of the piston rod 6. Preferably, the driving mechanism is a cylinder 5. Obviously, the driving mechanism is not limited to the cylinder 5, and can also be a hydraulic cylinder, etc. , the lower end of the connecting rod 8 is hinged at the middle part of the outer wall of the clamping turn 7, and the upper end of the connecting rod 8 is hinged on the outer wall of the lower part of the cylinder 5. stretching, thereby driving the upper hinge of the clamping claw 7 to move, and under the action of the connecting rod 8, the clamping claws 7 on both sides are driven to ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com