Bolt assembling and dismantling mechanical wrench for transmitting large torque in long and narrow space

A loading and unloading machine, in-space technology, used in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of not meeting the operating requirements of long and narrow spaces, easy to break, low transmission efficiency, etc., to meet the requirements of long and narrow operating spaces, continuous Tightening and loosening, increasing the effect of transmitted torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0032] The bolt loading and unloading mechanical wrench of the present invention is mainly used in narrow and long space environments.

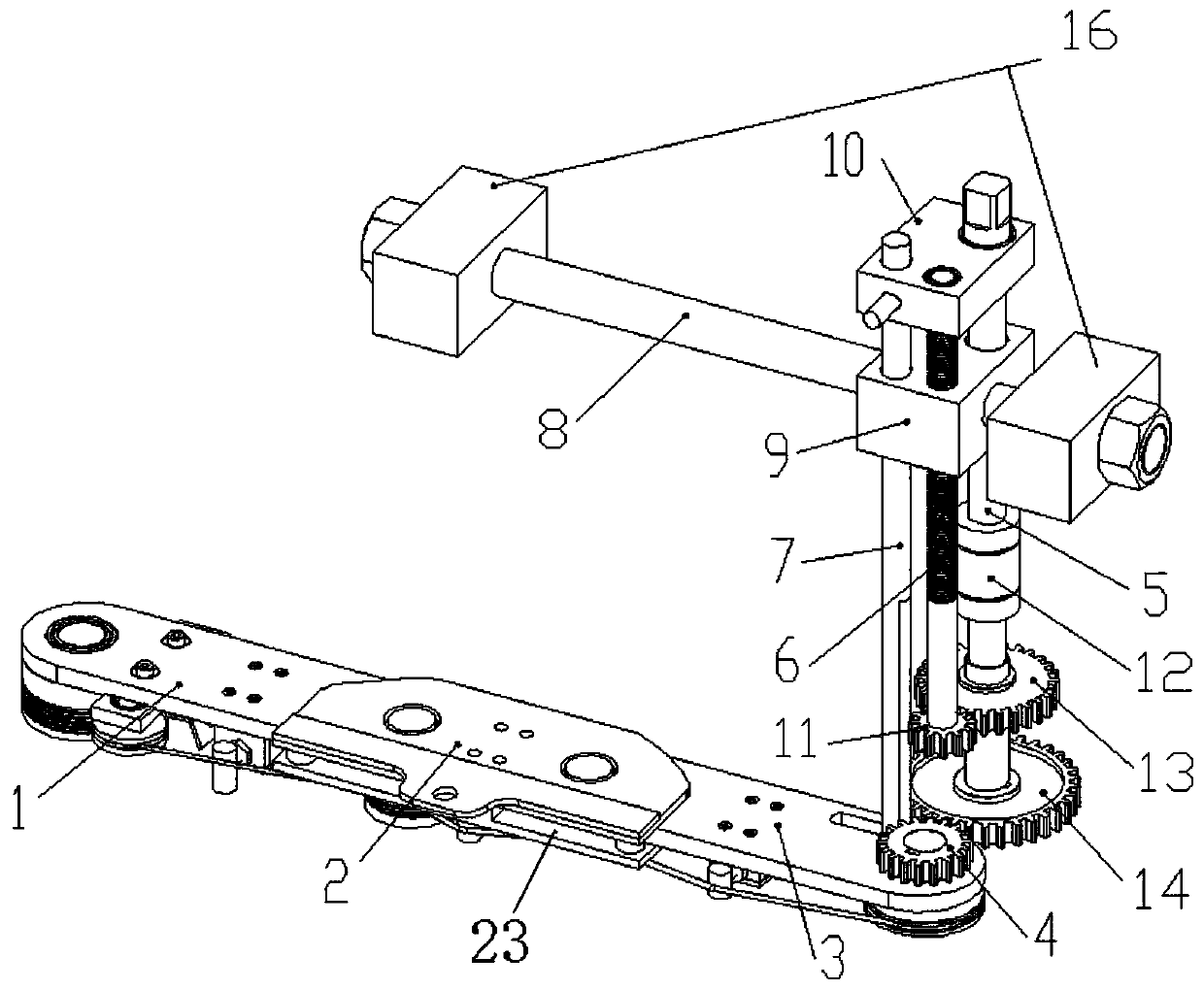

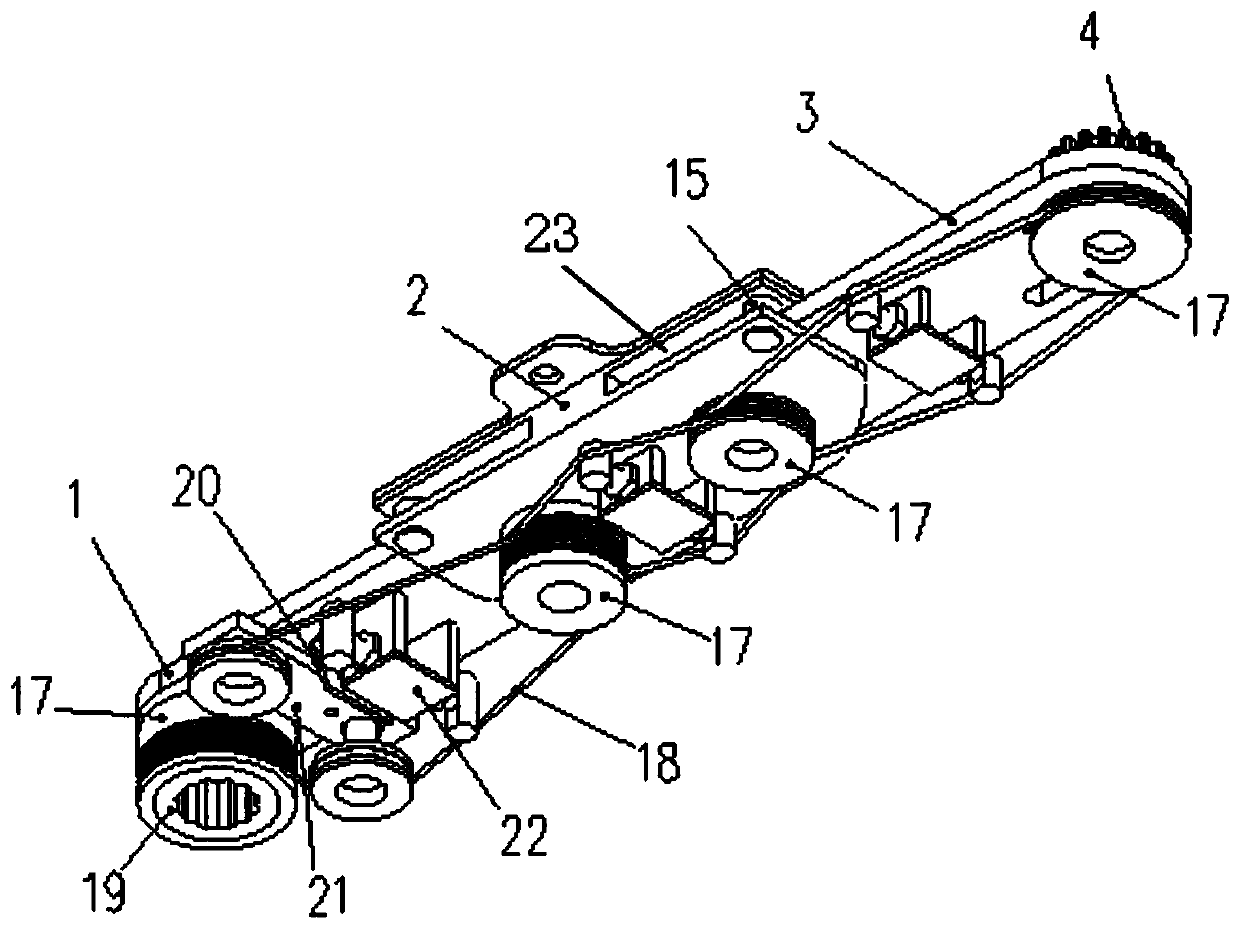

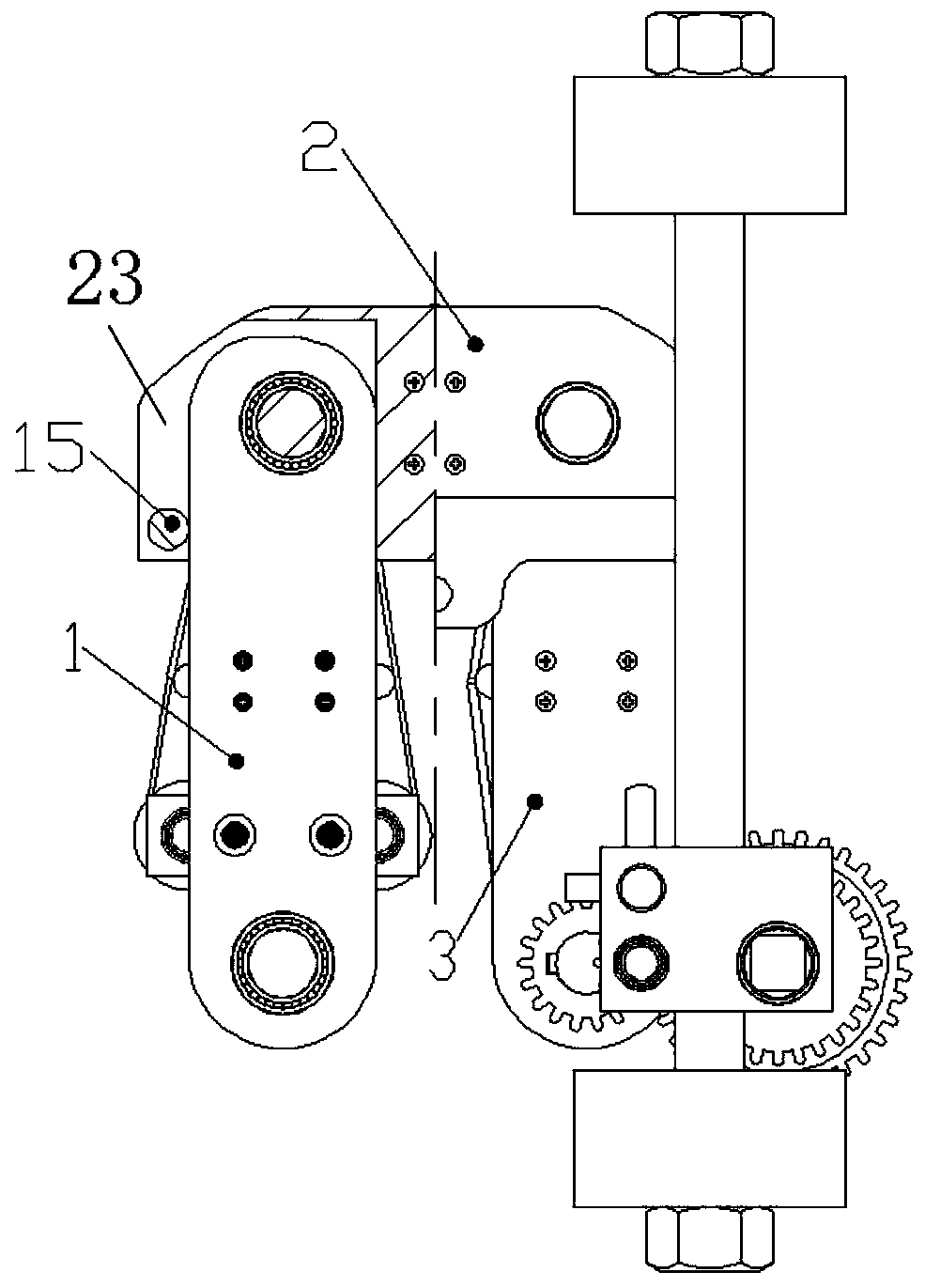

[0033] combine figure 1 , figure 2 , image 3 As shown, the bolt loading and unloading mechanical wrench includes a linear guide assembly, a transmission arm assembly, a multi-stage flexible rope transmission mechanism, a lifting assembly, a pull rod 7, a rotating arm 5, a transmission gear set and a nut sleeve 19;

[0034] The linear guide assembly includes a linear slide rail 8 arranged horizontally, a slider 9 installed on the linear slide rail 8, and the slider 9 can slide reciprocally along the rail length direction of the linear slide rail 8;

[0035]The transmission arm assembly is installed below the linear guide assembly, which can be unfolded into a straight structure and folded into a U-shaped structure. When the transmission arm assembly is unfolded into a straight structure, it is parallel to the linear slide rail 8; the trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com