Method for preparing light olefins from alcohols

A technology for low-carbon olefins and compounds, which is applied in the field of preparing low-carbon olefins from alcohol compounds, can solve the problems of reduced methanol conversion rate, influence on methanol dehydration reaction, etc. acrylic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

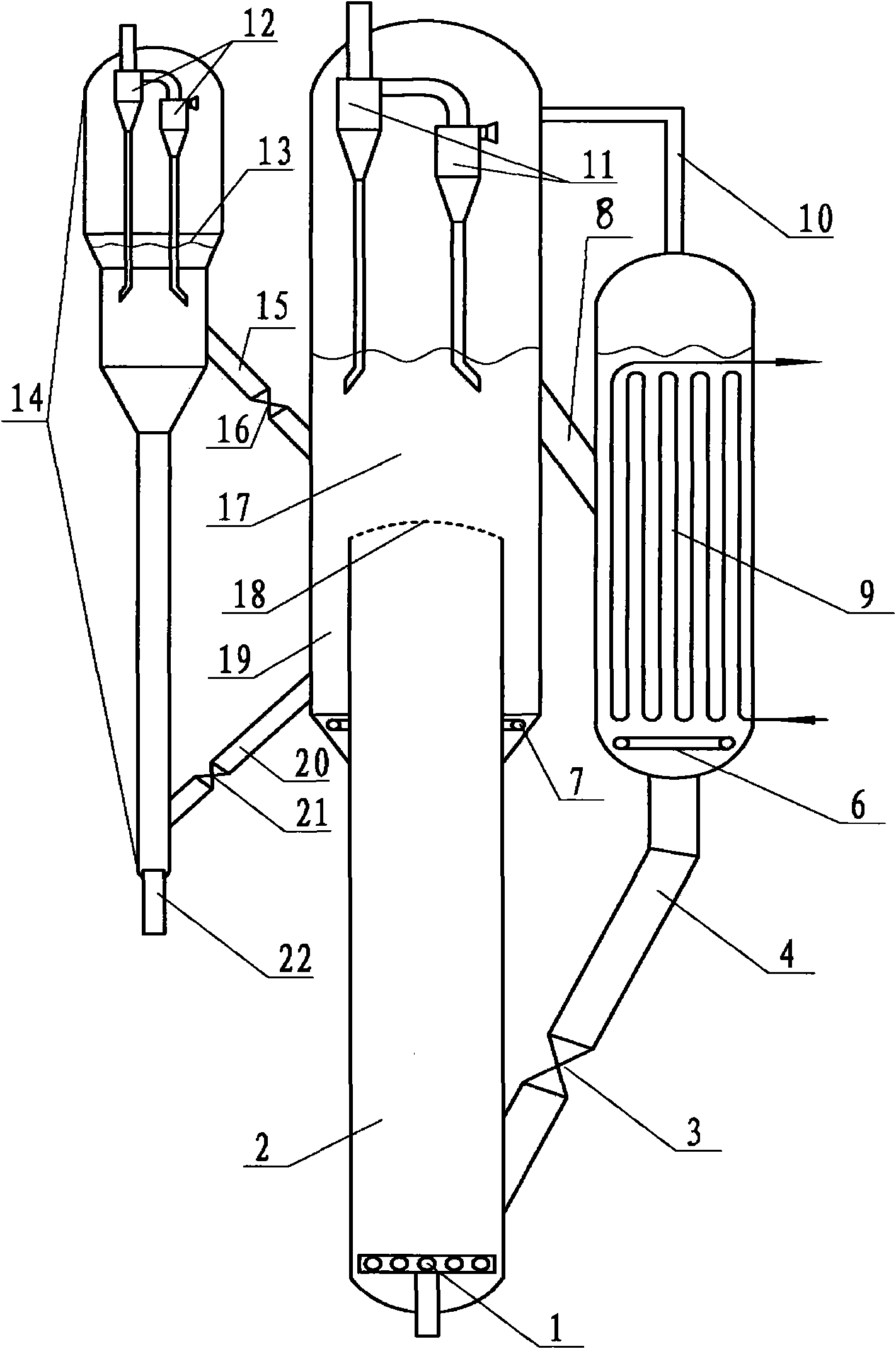

[0050] Example 1 illustrates the effect of using the method provided by the invention to carry out catalytic conversion of methanol to produce light olefins.

[0051] The methanol conversion experiment was carried out on a medium-sized device with continuous reaction-regeneration operation. The reactor form adopts the riser + fluidized bed mode, and the catalyst is MMC-2. The lower first reaction zone of the fluidized bed reactor is a riser reactor with an inner diameter of 16 mm and a height of 4 meters; the outlet of the riser reactor is located at the bottom of the dense phase bed in the upper second reaction zone, and the inner diameter of the second reaction zone is It is 64 mm and the height is 2.5 meters. The catalyst cooler has a diameter of 70mm and a height of 3m.

[0052] The catalyst and raw materials used are the same as those in the comparative example. The catalyst after reaction at 430°C from the second reaction zone first passes through the catalyst cooler, c...

Embodiment 2

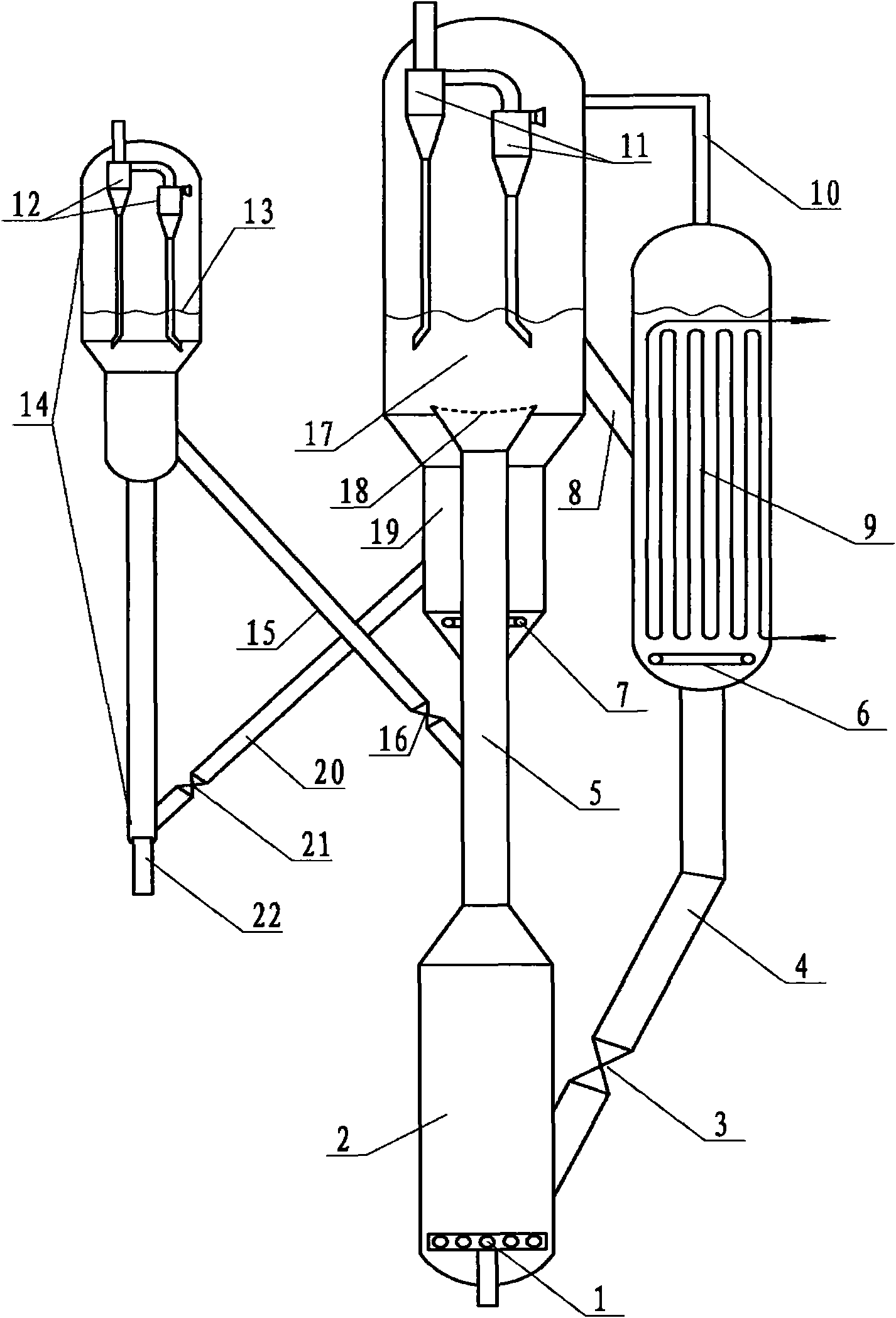

[0054] Example 2 illustrates the effect of using the method provided by the invention to carry out catalytic conversion of methanol to produce light olefins.

[0055] With MTO-100 as the catalyst, the form of the fluidized bed reactor is: the first reaction zone is a fast fluidized bed reactor, the diameter of the dense phase fluidized section is 50 mm, and the length is 4 meters. The reaction in the first reaction zone The temperature is 280°C and the bed weight hourly space velocity is 10h -1 . The structure of the second reaction zone is the same as in Example 1, the reaction temperature is 380°C, and the bed weight hourly space velocity is 3h -1 , The reaction pressure is 0.15MPa (gauge pressure). Water vapor is injected at the bottom of the second reaction zone to reduce the partial pressure of the reacted hydrocarbons, and the weight ratio of injected water to methanol is 50:50. All the other test conditions are the same as in Example 1, and the test results are shown...

Embodiment 3

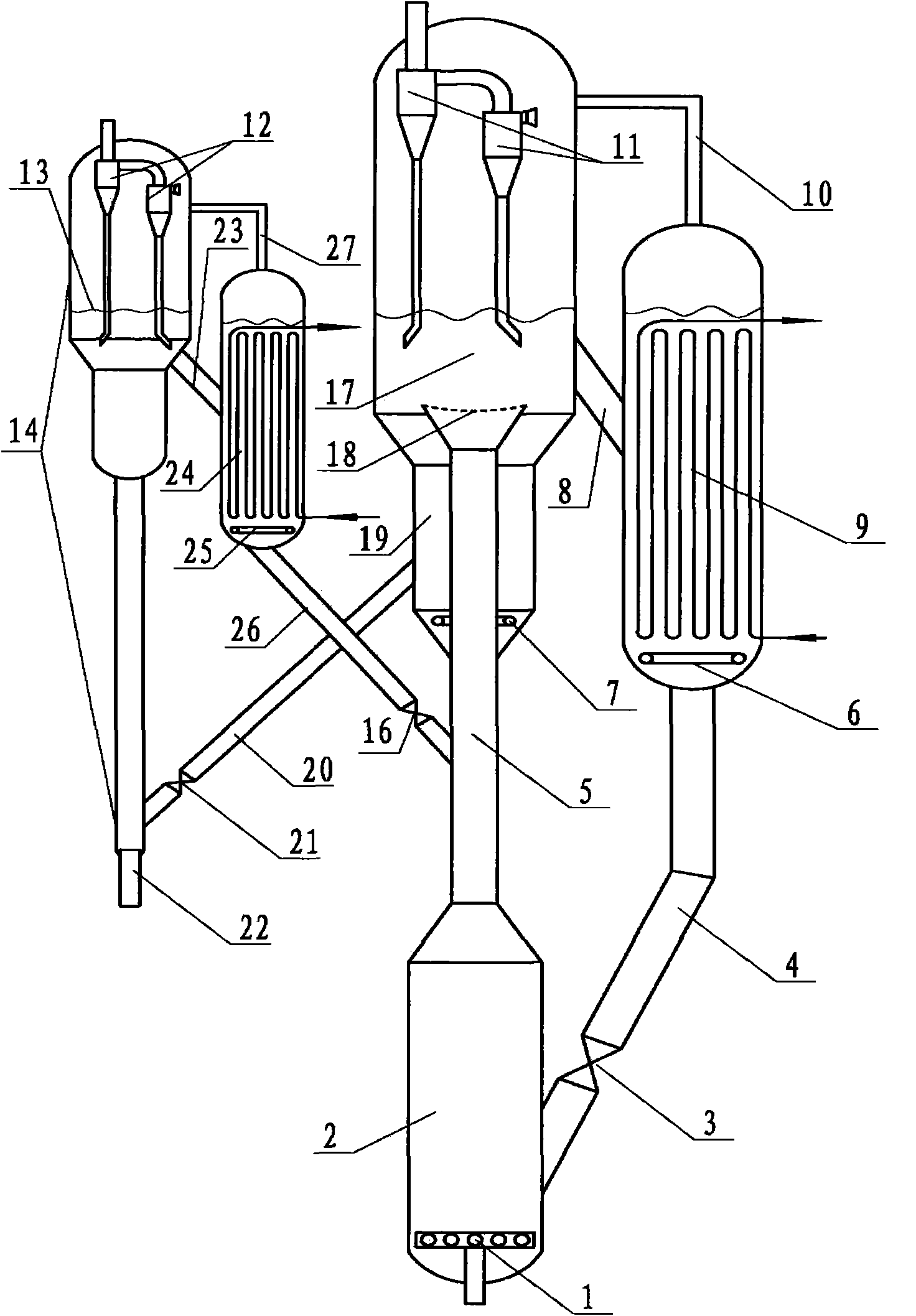

[0057] Example 3 illustrates the effect of using the method provided by the invention to carry out catalytic conversion of methanol to produce light olefins.

[0058] With MTO-100 as the catalyst, the form of the fluidized bed reactor is: the first reaction zone is a fast bed with a bed diameter of 50 mm and a bed height of 1.5 meters; the outlet of the fast bed reactor passes through a section with a diameter of 16 mm and a height of 2.5 The dilute-phase conveying pipe of m is in fluid communication with the bottom of the dense-phase bed in the upper second reaction zone, and an open-hole distribution plate is set at the outlet of the dilute-phase conveying pipe, and the superficial gas velocity of the gas passing through the open-hole distribution plate is 8m / s; the structure of the second reaction zone is basically the same as that of Example 1, except that the regenerated catalyst does not directly enter the dense phase bed of the second reaction zone but enters the middle...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com