Steel pipe thread burr grinding machine

A grinding machine and thread technology, which is applied in the direction of grinding frame, machine tools suitable for grinding the edge of workpieces, grinding machines, etc., can solve the problems of defective steel pipes, thread wear, and insufficient contact force between handle impeller and thread. equality problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

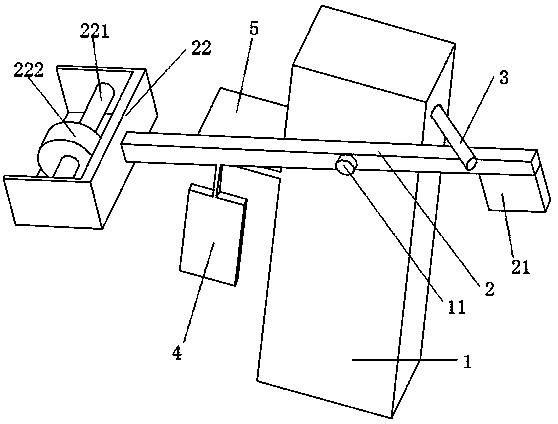

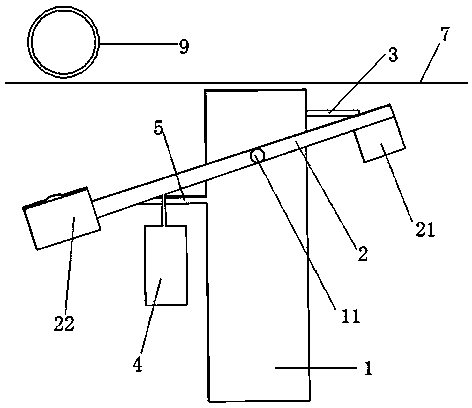

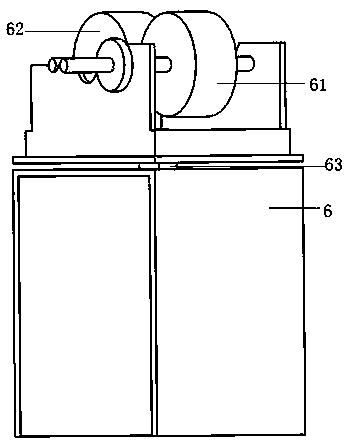

[0024] refer to Figure 1~Figure 5 : A steel pipe thread burr grinding machine, comprising a lever 2 and a bracket 1, the middle part of the lever 2 is axially connected to the upper end of the bracket 1, one end of the lever 2 is provided with a grinding platform 22, and the other end of the lever 2 is provided with a first fitting A weight 21, the grinding platform 22 is provided with a shank impeller 222, and the weight of the first counterweight 21 is 10kg-40kg.

[0025] In the present embodiment, the grinding machine is installed on one side of the platform 7, and the platform 7 is provided with a conveyor belt 8 with the same width, there is a gap between the conveyor belt 8 and the conveyor belt, and a steel pipe 9 is placed on the conveyor belt. The steel pipe is transported, and the threads at both ends of the steel pipe extend out of the stan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com