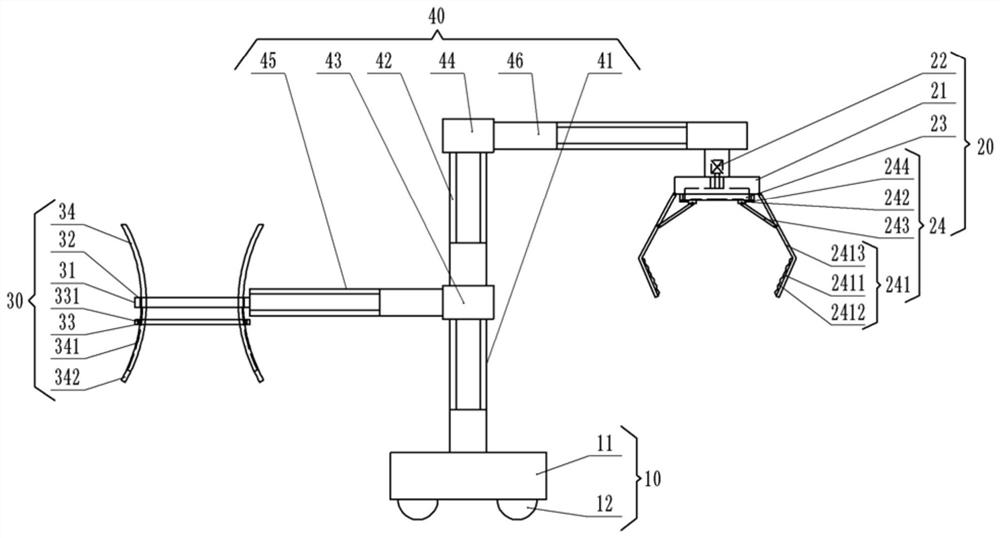

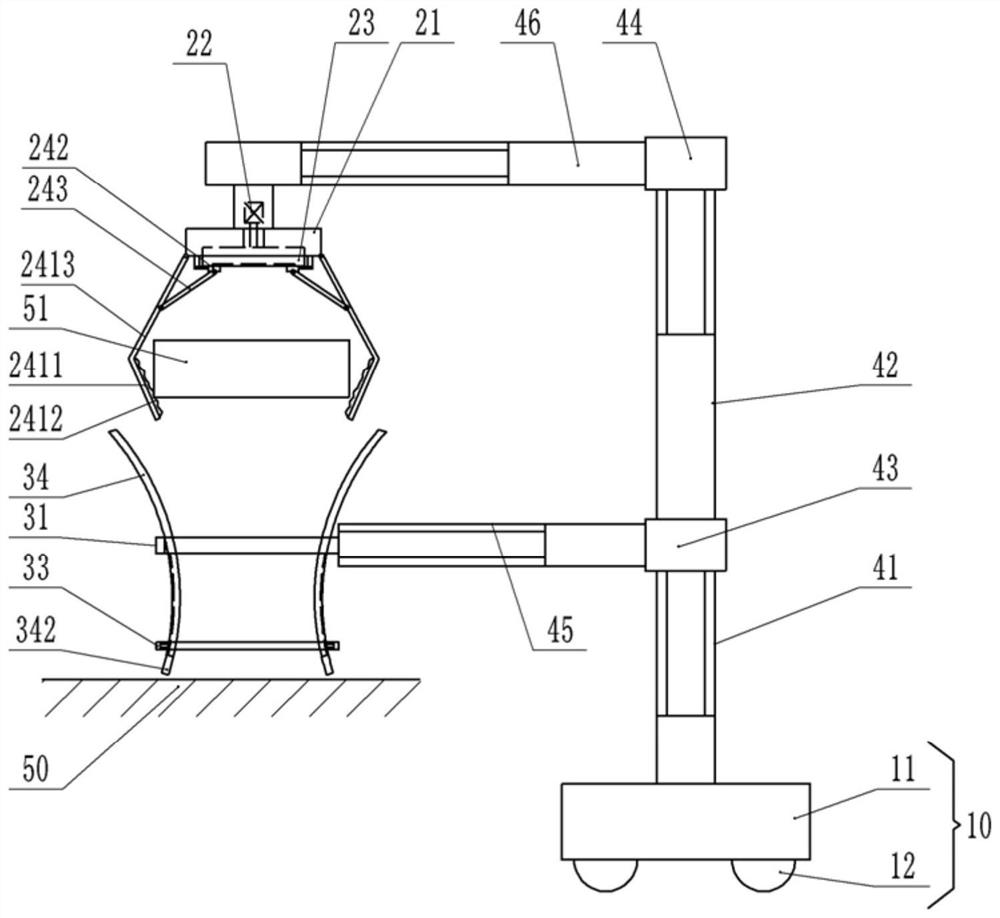

Intelligent feeding robot

A feeding robot and intelligent technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of time-consuming, labor-intensive, and potential safety hazards, and achieve the effect of avoiding potential safety hazards and saving time and energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

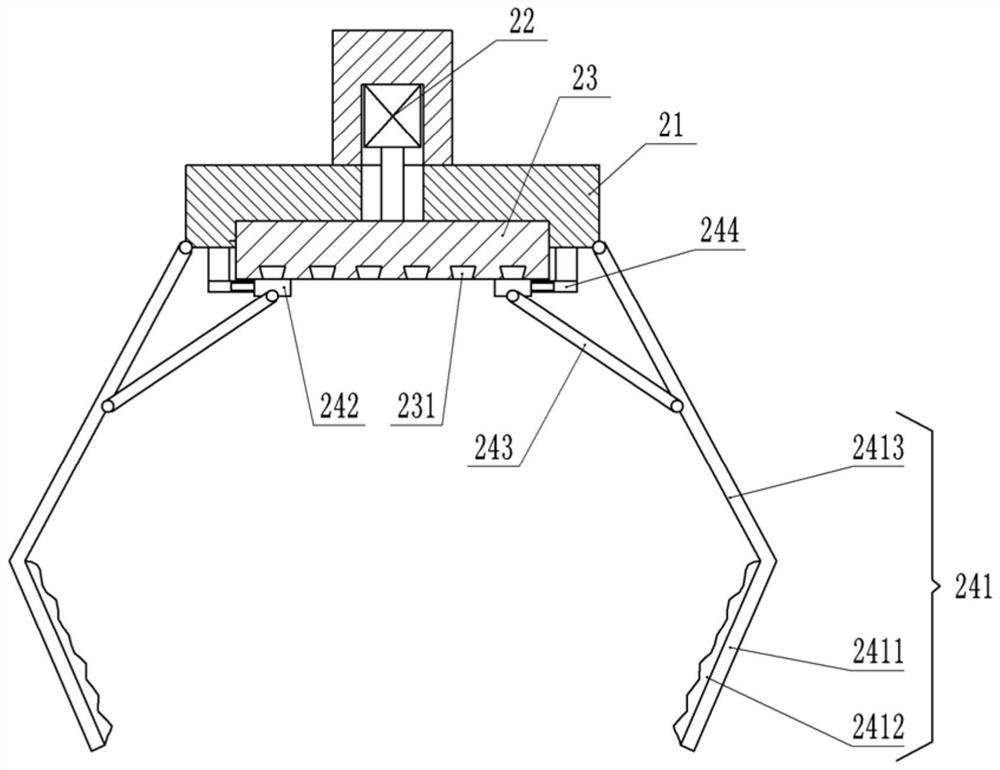

[0046] The difference between this embodiment and embodiment 1 is that, as Figure 5 As shown, a telescopic unit 25 is arranged between the clamping claw 241 and the support plate 21. The telescopic unit 25 includes a cylinder body 251 fixed to the support plate 21 and a piston rod 252 connected to the clamping claw 241. The piston rod 252 is connected in a sliding and sealed manner. In the cylinder body 251 , a driving part 253 for controlling the sliding of the piston rod 252 is provided on the support plate 21 . In this embodiment, the driving part 253 includes a cavity block 2531 fixed on the support plate 21, four column cavities 2532 are arranged on the cavity block 2531, and the four column cavities 2532 communicate with the four cylinder bodies 251 respectively through pipelines; On the block 2531, a screw rod 2533 is set on the side away from the support plate 21. The screw rod 2533 is threadedly connected with a nut 2534. The screw rod 2533 is located between the nut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com