Assembly machine for retainer ring and screw of shield assembly of cutting and grinding machine

A technology for assembling machines and shields, which is applied to conveyor objects, transportation and packaging, and metal processing. It can solve problems such as poor reliability, unstable quality, and low production efficiency, and achieve product quality improvement, production efficiency improvement, and savings. Effects of assembly operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

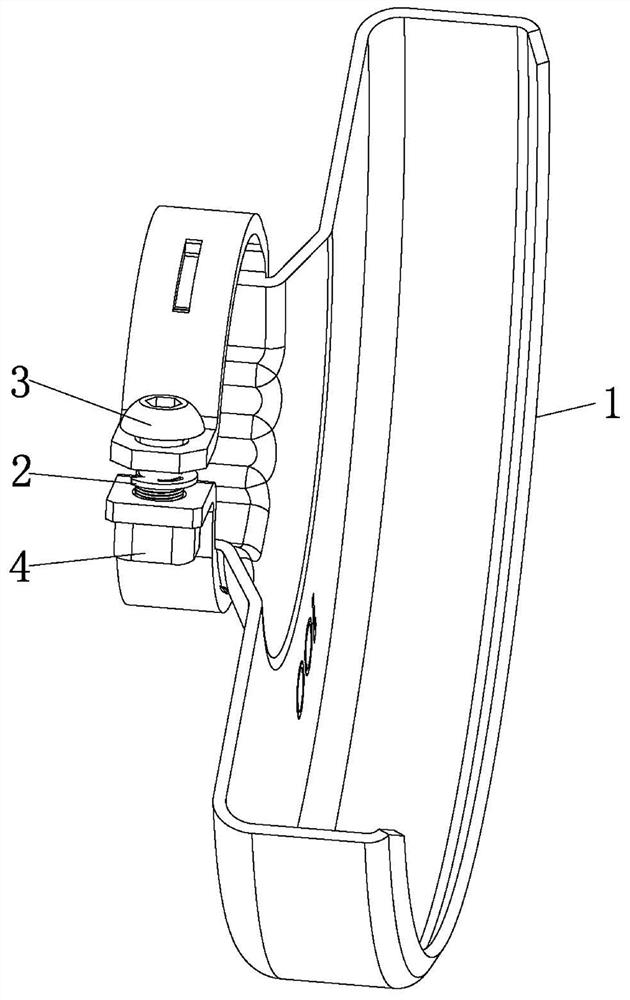

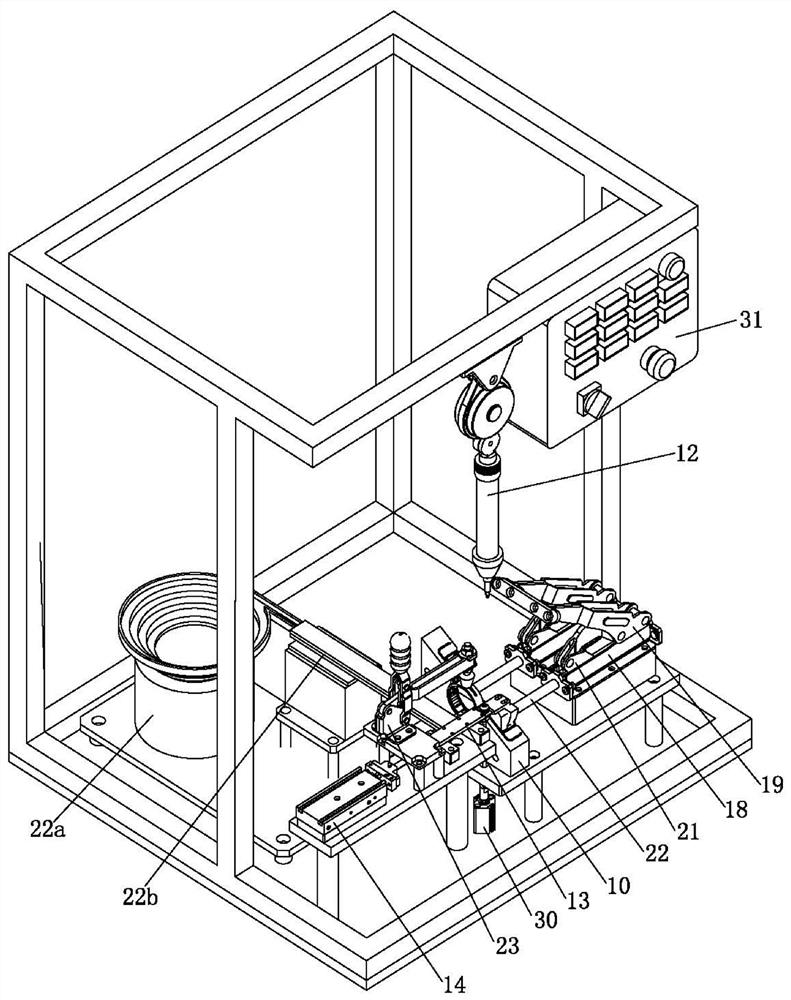

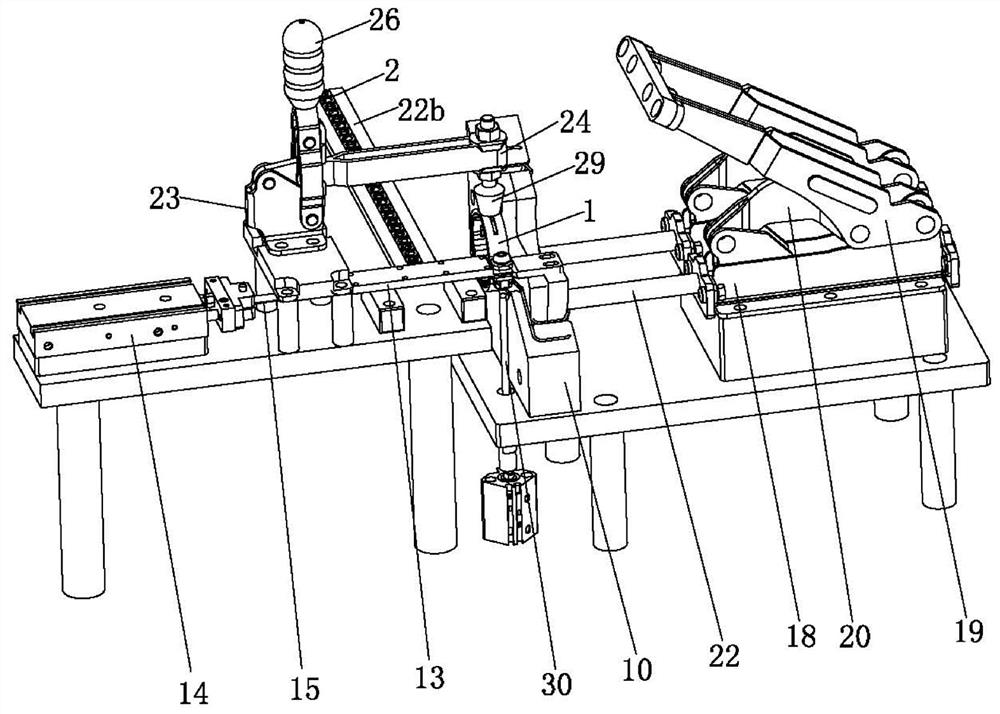

[0023] Combine below Figure 1 to Figure 7 The present invention will be described.

[0024] The assembly machine for the collar and the screw of the shield assembly of the cutting mill of the present invention includes an assembly seat 10 cooperating with the shield 1, an electric screwdriver 12, a pushing mechanism, a first positioning mechanism, a bearing seat 11, a detection mechanism, a control The following is a detailed description of each part and the relationship between them:

[0025] The fitting seat 10 is provided with a matching groove 10a, and the fitting seat 10 forms a supporting effect on the shield 1 after the shield 1 is matched with the fitting groove 10a. The shape of the fitting groove 10a matches the shape of the shield 1, therefore, the fitting groove 10a is an open groove instead of an annular groove.

[0026] The pushing mechanism pushes the received collar 2 to a position where it is assembled with the screw 3 , that is, pushes the collar 2 onto th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com