A semi-automatic continuous assembly machine for electromagnetic clutch

An electromagnetic clutch and semi-automated technology, applied in hand-held tools, manufacturing tools, etc., can solve the problems of low work efficiency, low degree of automation, high error rate, etc., and achieve the effect of saving labor costs and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The embodiments of the present invention will be described in detail below. Examples of the embodiments are shown in the accompanying drawings, wherein the same or similar reference numerals indicate the same or similar elements or elements with the same or similar functions. The embodiments described below with reference to the accompanying drawings are exemplary, and are intended to explain the present invention, but should not be construed as limiting the present invention.

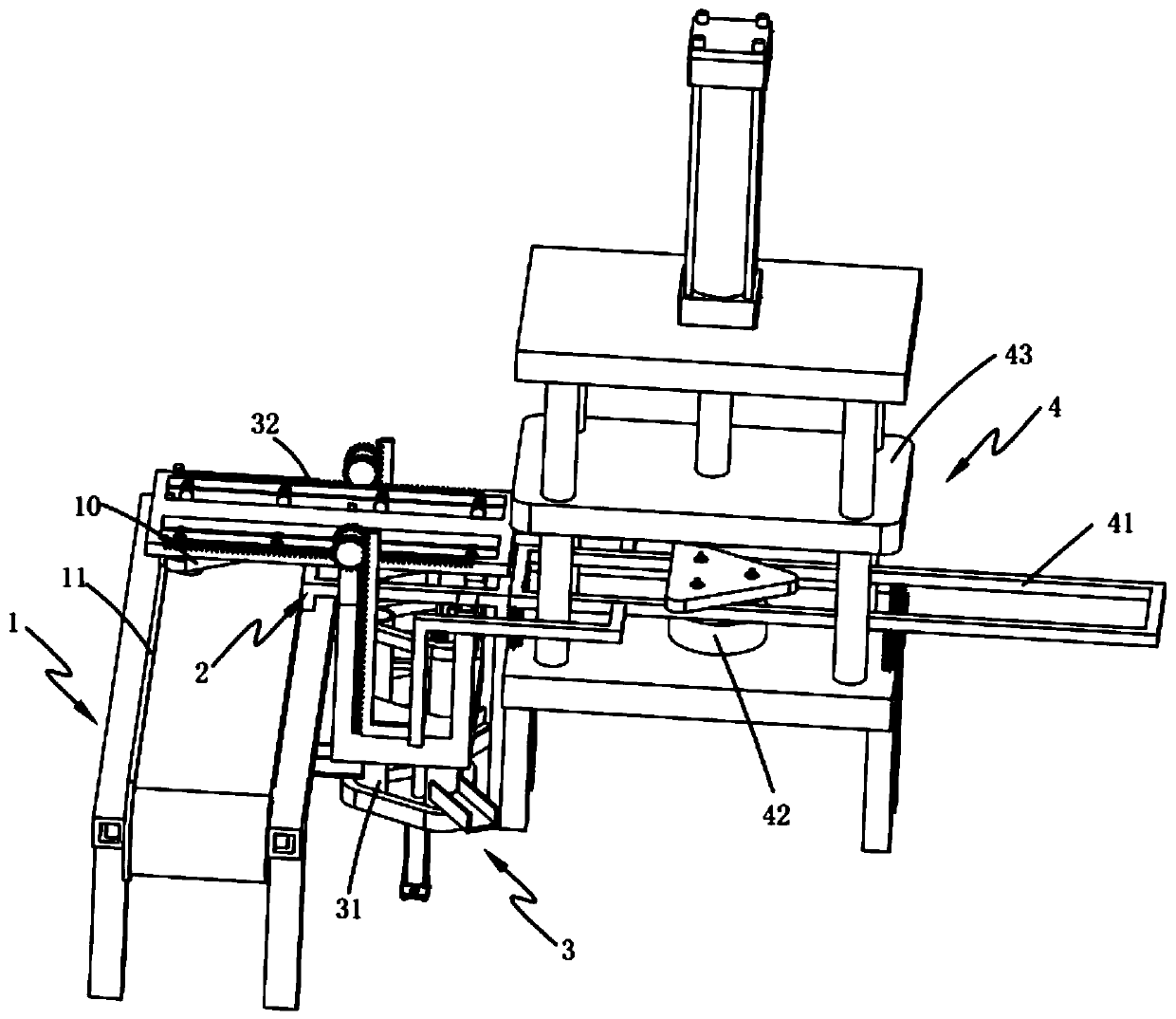

[0055] Such as Figure 1~15 As shown, an electromagnetic clutch semi-automatic continuous assembly integrated machine includes a triangular chassis conveying mechanism 1 and a triangular chassis conveying track 2 provided on one side of the triangular chassis conveying mechanism 1, and further includes:

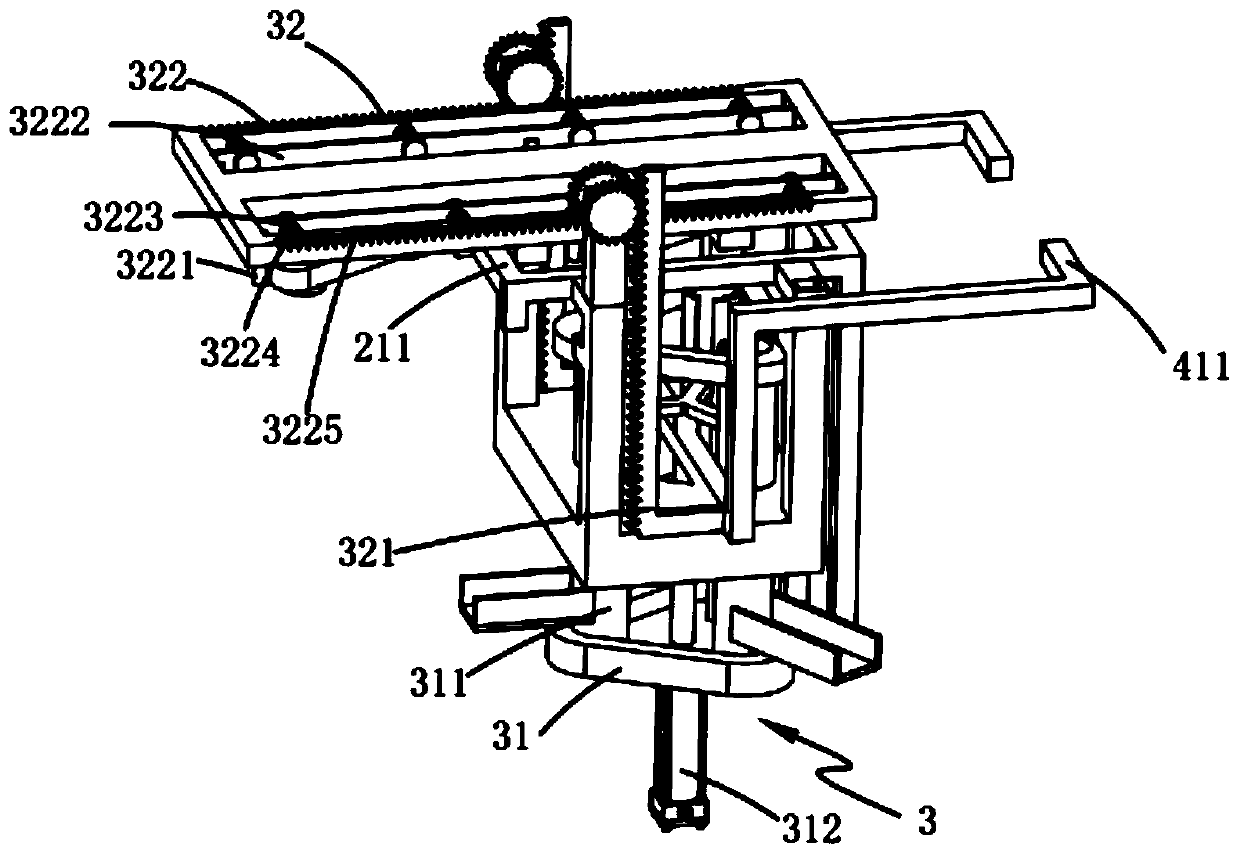

[0056] The round cap placing mechanism 3 is arranged on the triangular chassis transmission track 2, and the round cap placing mechanism 3 includes a round cap blanking assembly 31 and a triangular ...

Embodiment 2

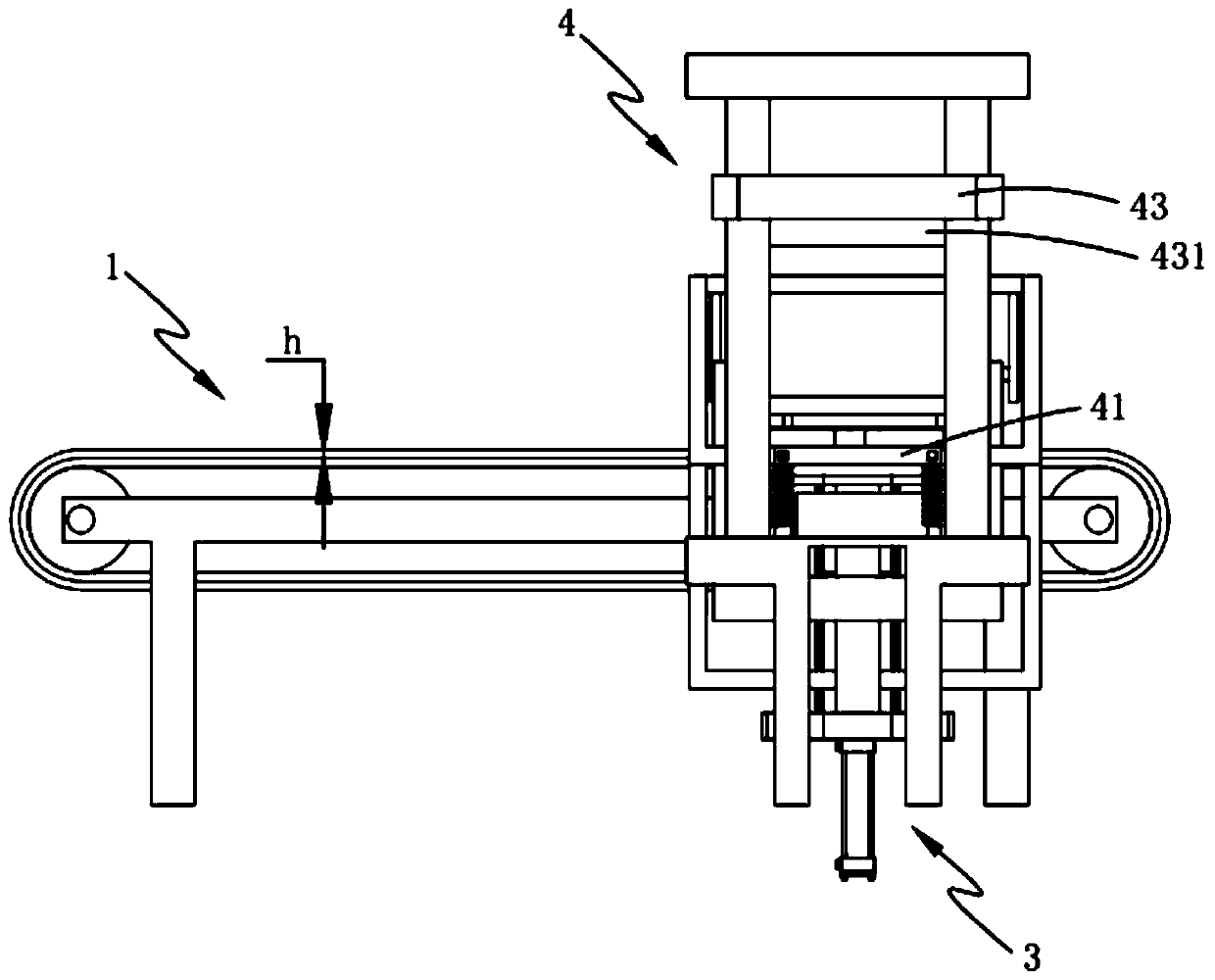

[0084] figure 2 It is a schematic structural diagram of the second embodiment of an electromagnetic clutch semi-automatic continuous assembly machine of the present invention; figure 2 As shown, the components that are the same as or corresponding to the first embodiment use the reference numerals corresponding to the first embodiment. For simplicity, only the differences from the first embodiment are described below. The difference between the second embodiment and the first embodiment shown in the figure is:

[0085] The conveyor belt of the triangular chassis conveying mechanism 1 is provided with a limiting protrusion 11 on the side away from the round cap laying mechanism 3, and the relationship between the height h of the limiting protrusion 11 and the thickness H of the triangular chassis 10 satisfies , H<H.

[0086] It should be noted that by setting the limit bump 11 on the side of the conveyor belt on the triangular chassis conveying mechanism 1 away from the round cap ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com