Mine hoist rope looseness detecting device

A mine hoist and slack rope detection technology, which is applied to mine hoisting equipment, elevators, transportation and packaging, etc., can solve the problems of high cost and complex structure, and achieve the effect of fast speed, sensitive action, and no wear of action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

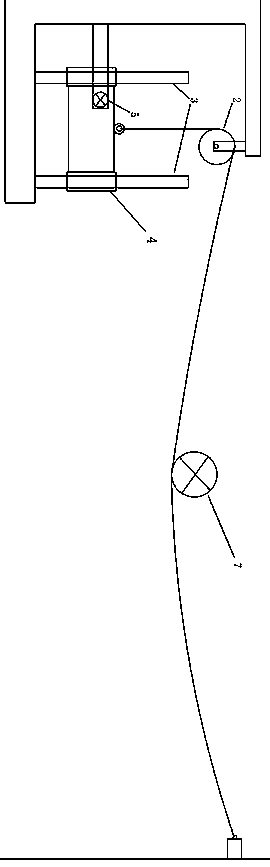

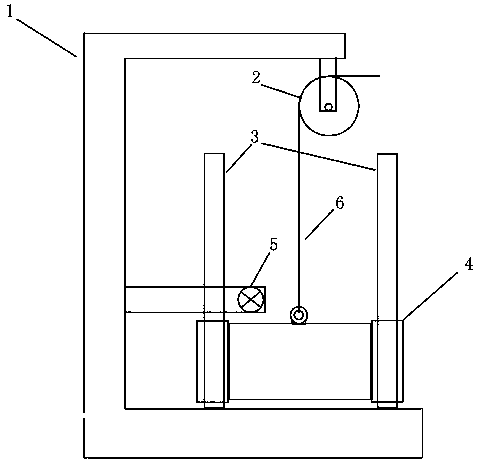

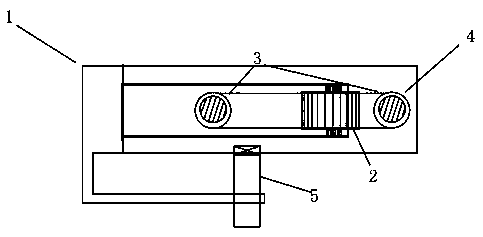

[0023] Embodiment 1, the main body support 1 is fixed on the side wall of the rope outlet of the mine hoist with expansion bolts, and one end of the steel wire rope 6 with a diameter of 8 mm is fixed at the upper end connection of the counterweight 4. After passing through the pulley 2, the steel wire rope 6 pieces Tighten and fix the other end to the opposite wall. The counterweight 4 can slide longitudinally along the guide rail 3 . The normally open proximity switch 5 is a metal induction normally open switch. When there is metal close to its end, the normally open point is closed, and when no metal is close, the normally open point is disconnected. The corresponding frequency is 100 times / second. When the hoist main rope 7 was slack, the hoist main rope 7 hung down on the steel wire rope 6, and the counterweight 4 was lifted by the steel wire rope 6. Counterweight 4 is a metal material and adopts a cast iron structure. When counterweight 4 rises along guide rail 2 and its...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com