System and technology used for double furnace double kettle stripping flash evaporation production of modified asphalt

A technology for modifying asphalt and asphalt, which is applied in the direction of processing tar asphalt/petroleum asphalt/natural asphalt with chemical methods, which can solve problems such as failure of measuring instruments, long maintenance time, and blockage of liquid level indicators, so as to ensure accuracy and The effects of stability, convenient replacement and maintenance, and easy liquid level control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

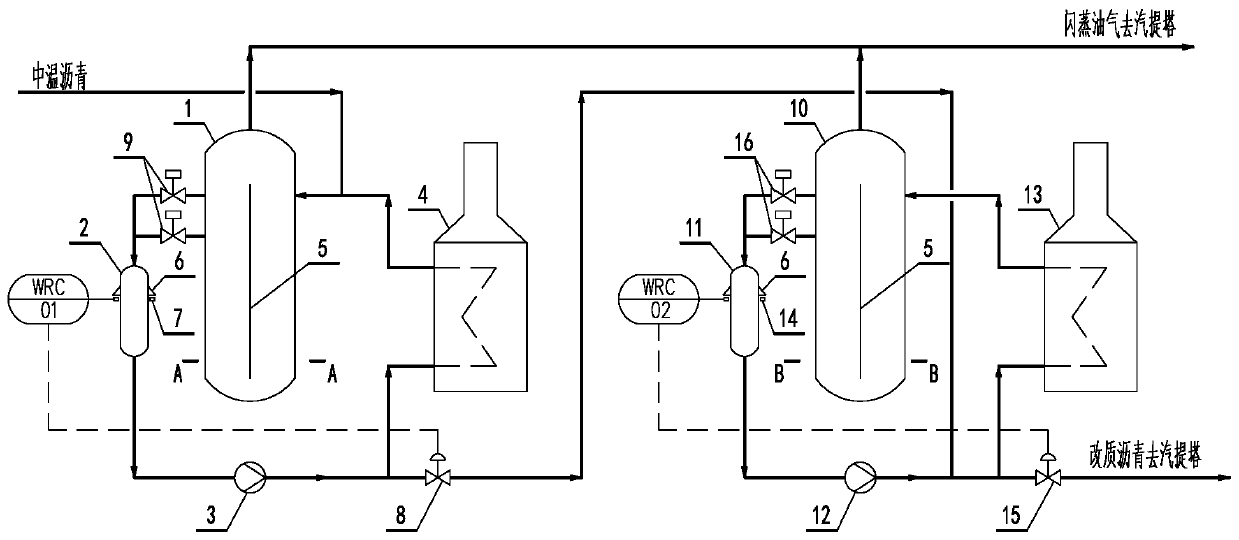

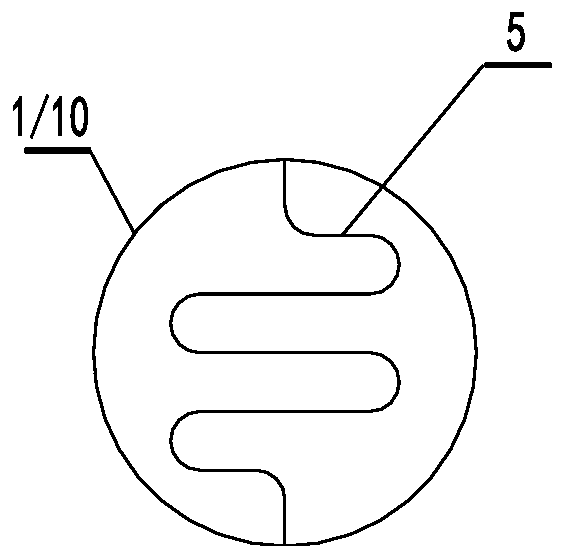

[0031] Such as figure 1 As shown, a system for producing modified asphalt by stripping and flashing with double furnaces and double kettles according to the present invention includes 1# reactor 1, 1# full flow buffer tank 2, 1# tubular furnace 4, the first asphalt circulation Loop, 2# reactor 10, 2# full-flow buffer tank 11, 2# tubular furnace 13 and the second asphalt circulation circuit; Serpentine flexible baffle 5 (such as figure 2 shown), the 1# reactor 1 / 2# reactor 10 is divided into 2 independent reaction areas, and the asphalt flow channel under the flexible baffle 5 is communicated between the 2 reaction areas; The upper part of 1# reactor 1 / 2# reactor 10 is provided with an asphalt feed inlet, and the upper part of 1# reactor 1 / 2# reactor 10 on the other side of the flexible baffle 5 is provided with an asphalt full flow port; The f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap