Method for selectively synthesizing 3-nitrosalicylic acid in continuous flow region

A technology of nitrosalicylic acid and salicylic acid, which is applied in chemical instruments and methods, preparation of nitro compounds, preparation of organic compounds, etc., can solve the problem of long post-treatment time of 3-nitrosalicylic acid and failure to meet the aging requirements Requirements, easy to generate other by-products and other issues, to achieve the effect of less side reactions, fast reaction speed, improved yield and purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1, the method for continuous flow regioselective synthesis of 3-nitrosalicylic acid of the present invention

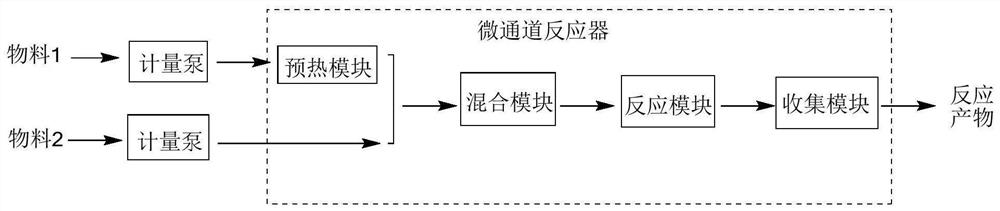

[0048] refer to figure 1 As shown in the process flow diagram, a microchannel reactor is utilized to synthesize 3-nitrosalicylic acid. Specific steps are as follows:

[0049] 1) Measure 900mL 99% acetic acid, 2.5g Prussian blue, and 100g salicylic acid into 2L beaker A respectively to obtain material 1; weigh 104.4g of concentrated nitric acid with a mass fraction of 65% and pour into 200mL beaker B to obtain Material 2.

[0050] 2) Connect beaker A and beaker B to metering pump P1 and metering pump P2 respectively; start metering pump P1 first, feed material 1 to the preheating module, and preheat at 50°C for 1 minute.

[0051] 3) Then start the metering pump P2, feed the material 2 and the preheated material 1 to the mixing module at the same time, and obtain the material 3 after mixing evenly in the mixing module; the temperature of the mixing ...

Embodiment 2

[0054] Embodiment 2, the method for continuous flow regioselective synthesis of 3-nitrosalicylic acid of the present invention

[0055] refer to figure 1 As shown in the process flow diagram, a microchannel reactor is utilized to synthesize 3-nitrosalicylic acid. Specific steps are as follows:

[0056] 1) Measure 900mL 99% acetic acid, 2.5g Prussian blue, and 100g salicylic acid into 2L beaker A respectively to obtain material 1; weigh 104.4g of concentrated nitric acid with a mass fraction of 65% and pour into 200mL beaker B to obtain Material 2.

[0057] 2) Connect beaker A and beaker B to metering pump P1 and metering pump P2 respectively; start metering pump P1 first, feed material 1 to the preheating module, and preheat at 35°C for 1 minute.

[0058] 3) Then start the metering pump P2, feed the material 2 and the preheated material 1 to the mixing module at the same time, and obtain the material 3 after mixing evenly in the mixing module; the temperature of the mixing ...

Embodiment 3

[0061] Embodiment 3, the method for continuous flow regioselective synthesis of 3-nitrosalicylic acid of the present invention

[0062] refer to figure 1 As shown in the process flow diagram, a microchannel reactor is utilized to synthesize 3-nitrosalicylic acid. Specific steps are as follows:

[0063] 1) Measure 900mL of 99% acetic acid, 2.5g of zirconia-silicotungstic acid, and 100g of salicylic acid into 2L beaker A to obtain material 1; weigh 104.4g of concentrated nitric acid with a mass fraction of 65% and pour into a 200mL beaker In B, material 2 was obtained.

[0064] 2) Connect beaker A and beaker B to metering pump P1 and metering pump P2 respectively; start metering pump P1 first, feed material 1 to the preheating module, and preheat at 50°C for 1 minute.

[0065] 3) Then start the metering pump P2, feed the material 2 and the preheated material 1 to the mixing module at the same time, and obtain the material 3 after mixing evenly in the mixing module; the temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap