Production equipment and process of a moisture-absorbing and sweat-wicking Lixin cloth

A technology for moisture absorption and perspiration production equipment, applied in textiles and papermaking, knitting, flat warp knitting machines, etc., can solve problems such as affecting the health of workers, inability to adjust Lixin cloth, fiber floating, etc., to avoid floating dust and Too many floating fibers, easy to store and take out, safe and convenient to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

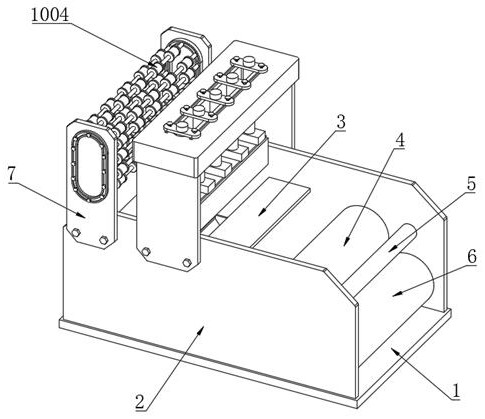

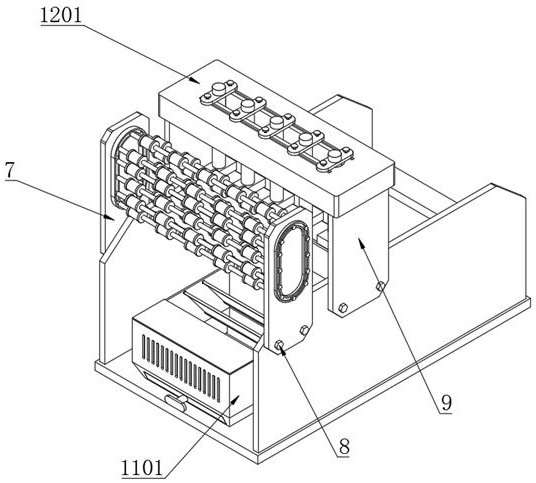

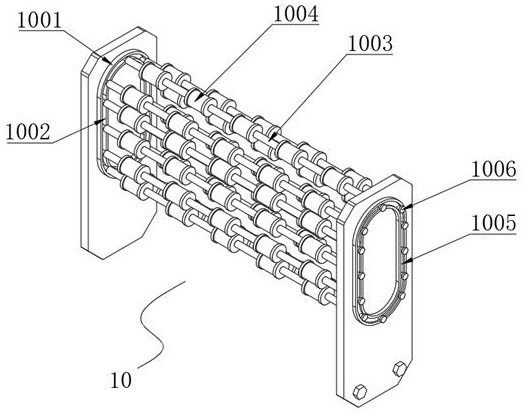

[0043] Embodiment 1: as Figure 1-5As shown, the present invention provides a technical solution, a production equipment for moisture-absorbing and sweat-wicking Lixin cloth, including a loom bottom plate 1, and a loom side plate 2 is symmetrically installed on the top of the loom bottom plate 1, and the loom side plate The inner wall of the board 2 is connected with the inner table 3 of the loom, and the inner wall of the loom bottom plate 1 corresponds to the inner table 3 of the loom. A cloth transmission roller 4 is installed at a position on one side, and the inner wall of the loom bottom plate 1 corresponds to the cloth transmission roller 4 A guide roller 5 is installed at one side position, and the inner wall of the loom bottom plate 1 is connected with a cloth bundle roller 6 at a position below the corresponding guide roller 5, and one end of the loom side plate 2 is connected with a silk thread to place a side plate 7, and the weaving machine One end of the side pla...

Embodiment 2

[0054] Embodiment 2: as Image 6 As shown, the present invention provides a technical solution, a production process of moisture-absorbing and sweat-wicking Lixin cloth, comprising the following steps:

[0055] S1. Silk thread cleaning: select yarn and polyester thread, rinse with clean water, and curl them on the silk thread storage roller after drying;

[0056] S2. Yarn arrangement: select yarn and polyester yarn, place them alternately, and set them as warp yarn and weft yarn;

[0057] S3, cloth weaving: adjust the angle of warp and weft, and use the loom to weave Lixin cloth;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com