Clothes treatment device

A technology of clothes processing equipment and filtering device, which is applied to other washing machines, household clothes dryers, washing machine control devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

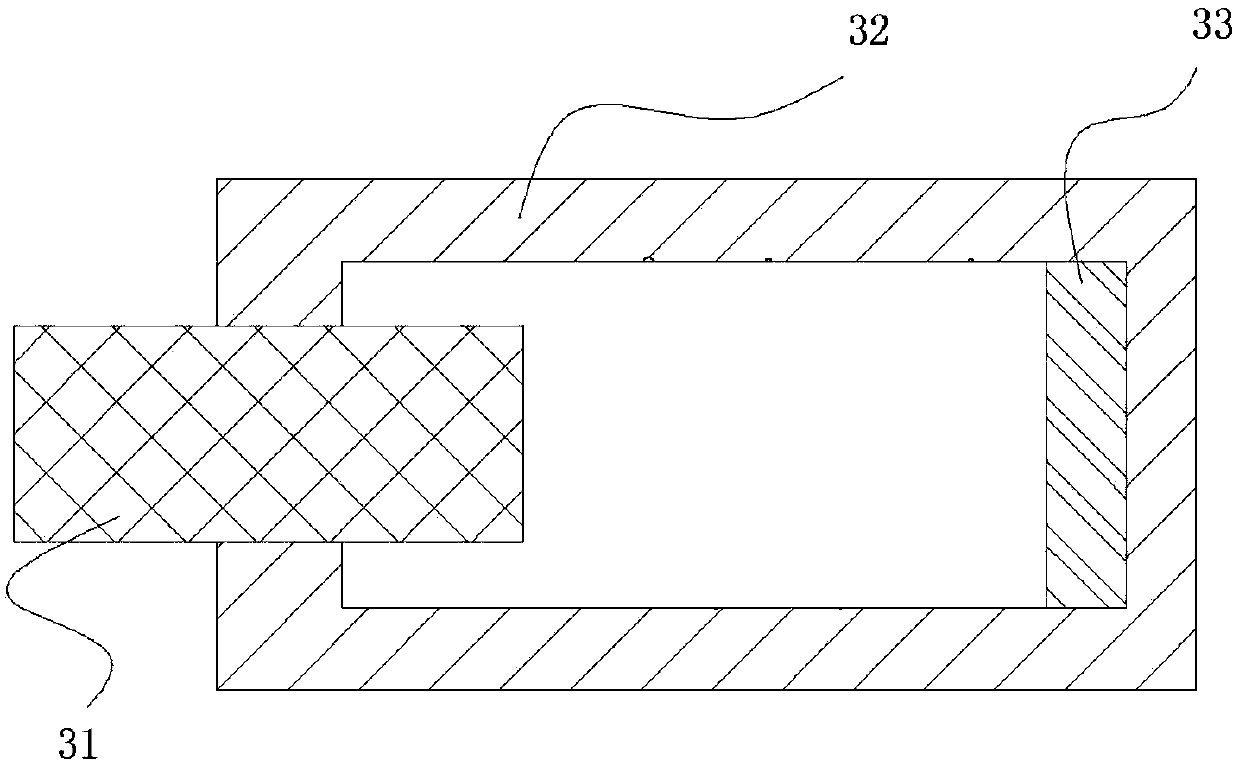

[0117] Such as figure 1 As shown, in the laundry processing equipment described in this embodiment, the lint filtering device is arranged on the laundry processing equipment through the installation part; the installation part includes a first A part 31 and a second part 32 of the mounting part arranged on the laundry processing equipment, and a mounting part adjustment unit 33 for controlling the connection relationship between the first part 31 of the mounting part and the second part 32 of the mounting part; The first piece 31 of the installation part and the second piece 32 of the installation part can be connected in cooperation, and the connection state and degree of the two are controlled by the adjustment unit 33 of the installation part; the first piece 31 of the installation part can Slide along the second piece 32 of the installation part in the axial direction; the installation part adjustment unit 33 is arranged at a position between the first part 31 of the insta...

Embodiment 2

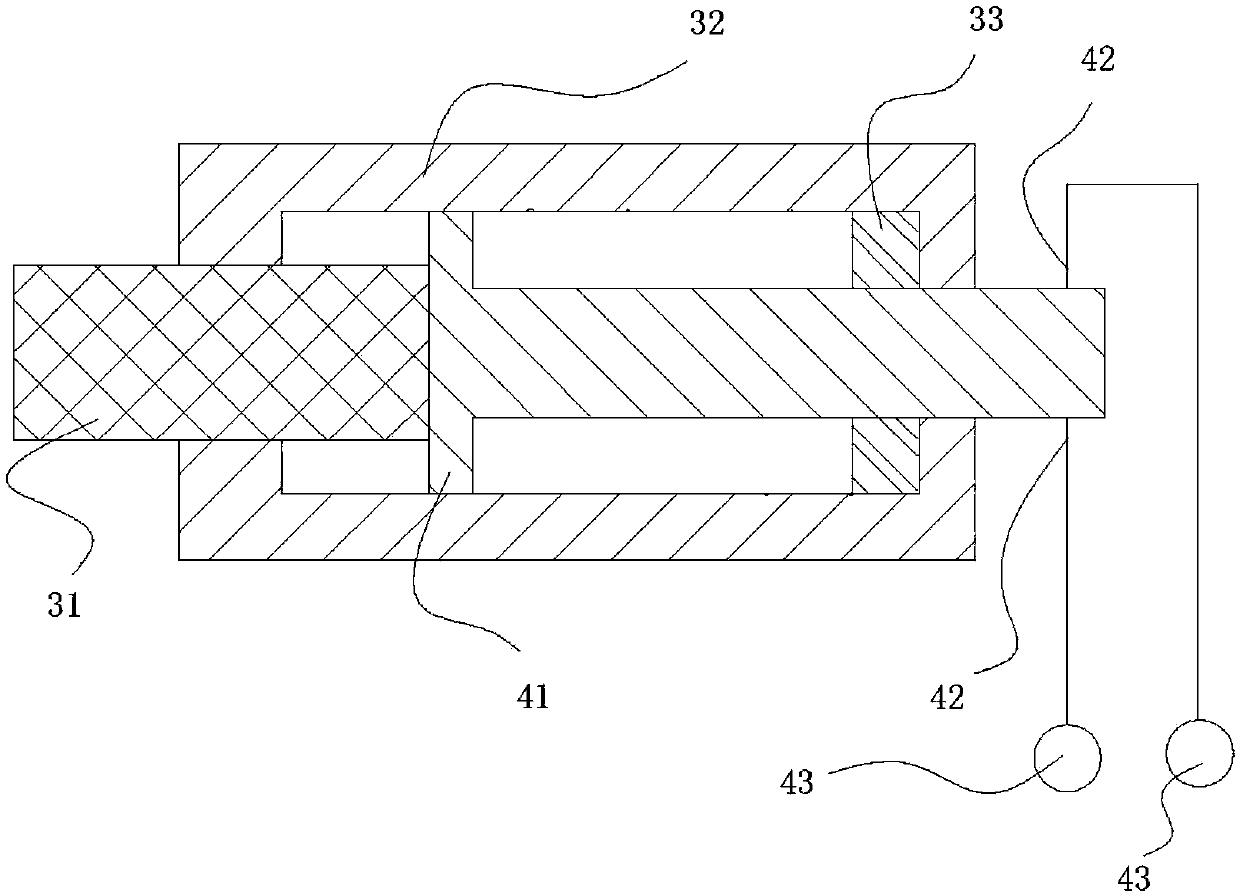

[0123] Such as figure 2 As can be seen, the difference between the laundry processing device described in this embodiment and the above-mentioned embodiments lies in that: the detection communication part is used to obtain the relative positional relationship between the first part of the installation part and the second part of the installation part.

[0124] The position detection device includes a detection connection part 41, a first detection point 42, and a controller 43 that cooperate with each other; the detection connection part 41 obtains the relative positional relationship between the lint filtering device and the clothes processing equipment, and mainly Based on this, control the communication relationship between the first detection point 42 and the controller 43 to generate corresponding signals, and then realize the detection of the position and state of the lint filtering device. between one piece and the second piece of the installation part, and can be move...

Embodiment 3

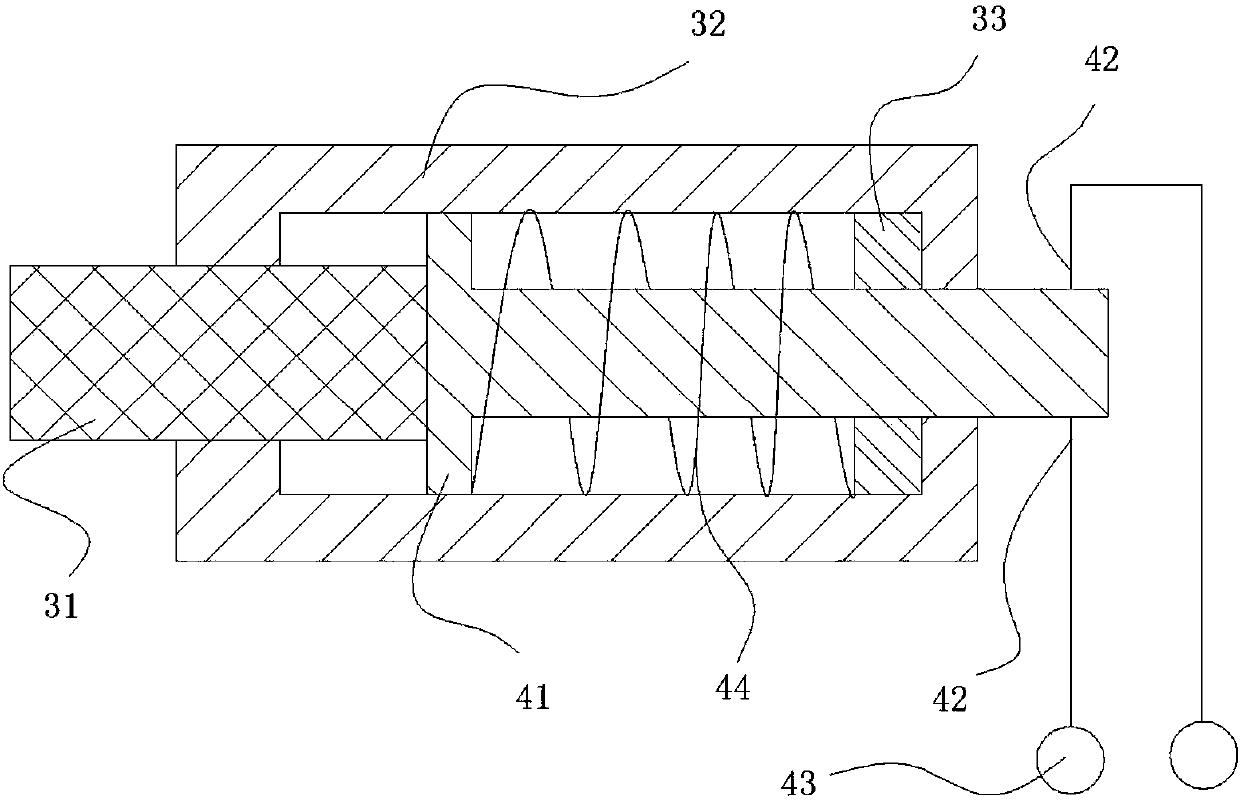

[0128] Such as image 3 As shown, the difference between the clothes processing equipment described in this embodiment and the above embodiments is that the position detection device in this embodiment includes a reset member 44, which is used to restore the detection connecting member 41 to the original position, so that the first detection point 42 is disconnected from the controller 43, and generates corresponding signals;

[0129] Preferably, the reset member 44 can axially make the detection communication member 41 slide along the axial direction of the second part 32 of the installation part, so as to restore the relative relationship between the detection communication part 41 and the second part 32 of the installation part. position, thereby disconnecting the first detection point 42 from the controller 43;

[0130] Further preferably, the reset member 44 is a spring.

[0131] Through the laundry processing equipment introduced in the present invention, a reset devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com