Control method of clothes treating apparatus and clothes treating apparatus

A technology of clothes treatment equipment and control method, which is applied in the field of clothes treatment equipment control and clothes treatment equipment to achieve the effect of position stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

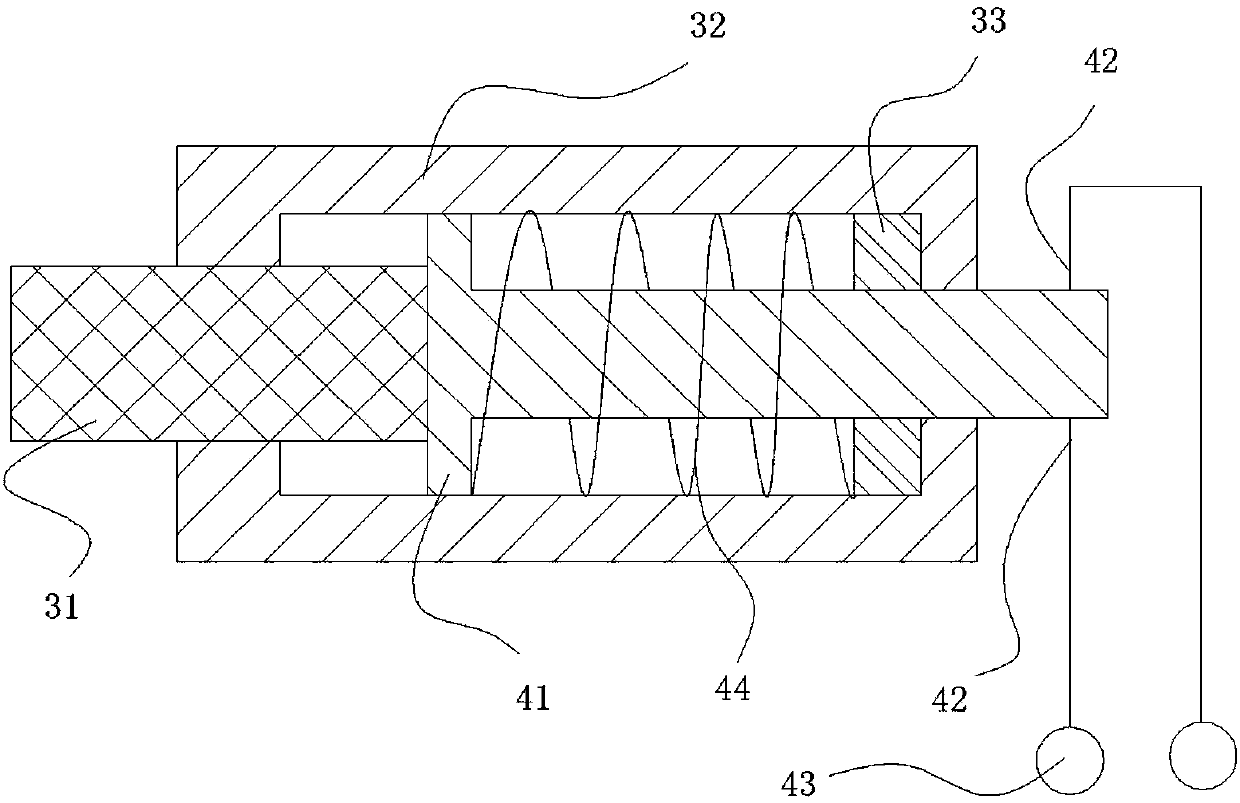

[0076] In the method for controlling laundry processing equipment and the laundry processing equipment described in this embodiment, the evaluation object includes the number of areas where the position of the lint filtering device is evaluated. Further, the number of said regions in this embodiment is one or at least two, and said at least two said regions are dispersedly distributed on said lint filtering device.

[0077] Further, the evaluation object in this embodiment is determined based on the amount of laundry to be treated in the laundry treatment device. When the amount of the laundry to be processed reaches a specific value, the selection of the evaluation object is adjusted; more preferably, when the amount of the laundry to be processed reaches a specific value, the evaluation object is adjusted to at least two of said regions.

[0078] According to the control method of the clothes treatment equipment and the clothes treatment equipment introduced in the present ...

Embodiment 2

[0082] The difference between the method for controlling the laundry treatment equipment and the laundry treatment equipment described in this embodiment and the above-mentioned embodiments is that: the evaluation index includes the distance that the lint filter device deviates from its ideal installation position. The evaluation index includes the distance that a certain area / at least two areas of the lint filter device deviate from its ideal installation position. The equipment in this embodiment includes a position detecting device for detecting the position state of the lint filtering device during its operation, and the position detecting device is used for detecting the distance of the lint filtering device from its ideal installation position.

[0083] Further, the method for controlling laundry processing equipment and the evaluation index of the laundry processing equipment in this embodiment also include the humidity of the air intake of the equipment; the laundry pro...

Embodiment 3

[0087] The difference between the method for controlling laundry processing equipment and the laundry processing equipment described in this embodiment and the foregoing embodiments lies in that: the way of obtaining the state score is different according to the evaluation object. When the state score reaches a certain value, the position of the lint filtering device is adjusted accordingly.

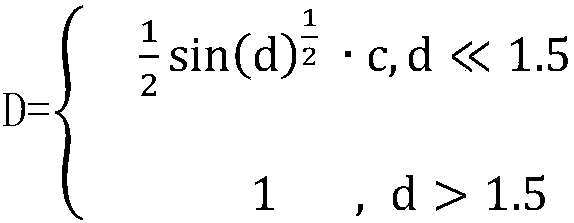

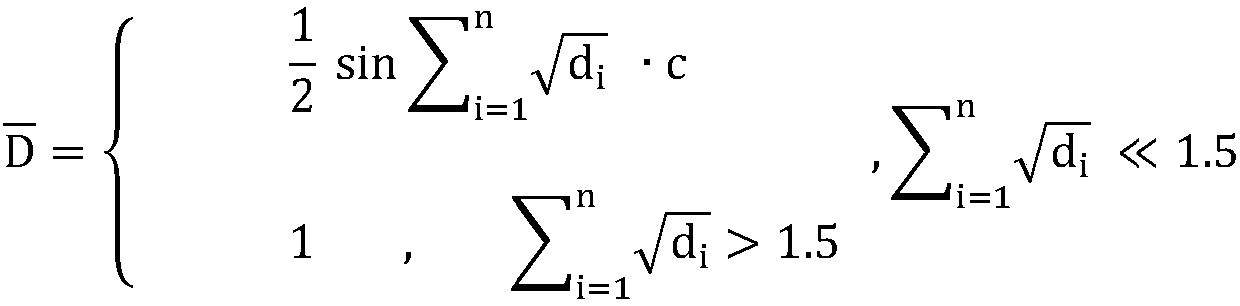

[0088] Further preferably, when the evaluation object is a certain area of the lint filtering device and the evaluation index is the distance of the lint filtering device from its ideal installation position, the control system will deviate the area from its ideal installation position. The distance of the ideal installation position is converted into the characteristic value of the deviation distance; two significant figures are taken for the characteristic value of the deviation distance to obtain the corresponding state score;

[0089] Further preferably, the conversion formula of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com