Patents

Literature

87results about How to "Cleaning effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

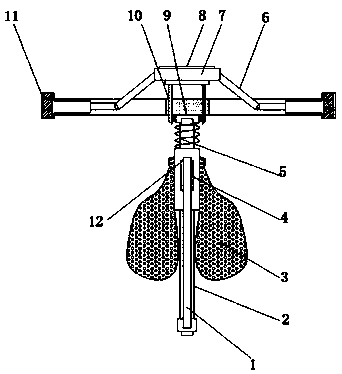

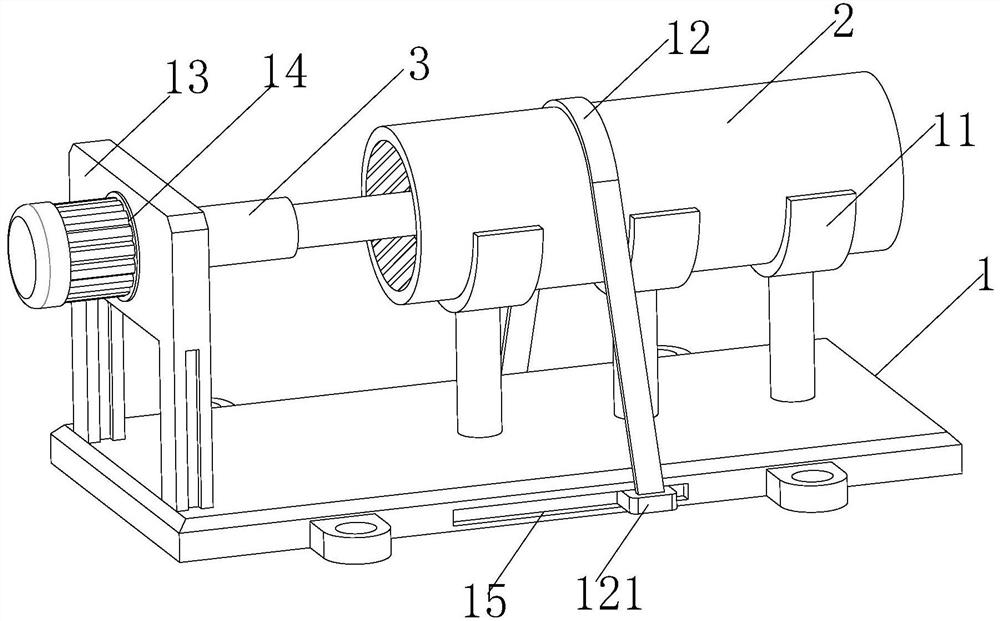

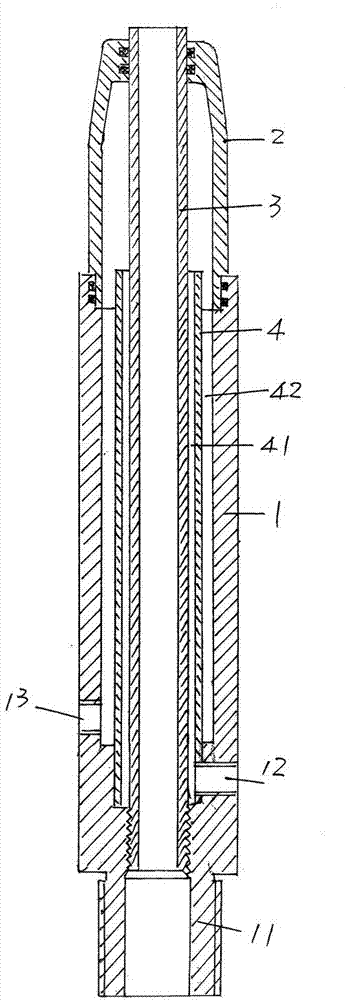

Multifunctional bionic tube cleaner and cleaning method thereof

ActiveCN106975641AWide range of applicationsIncrease flexibilityHollow article cleaningRubber ringStructural engineering

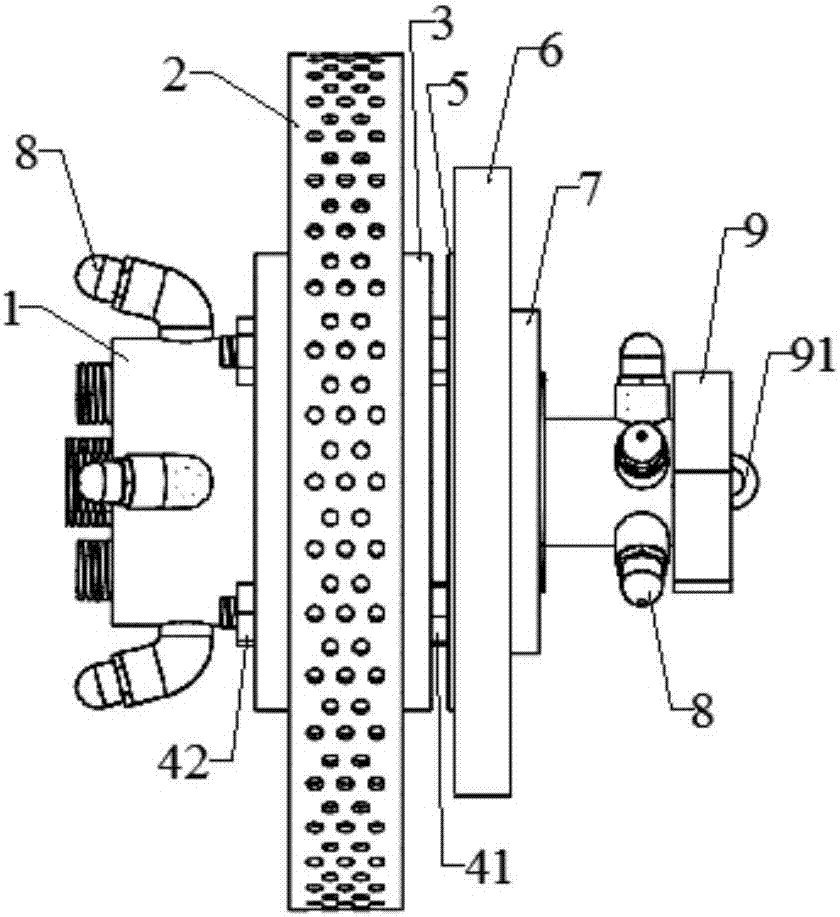

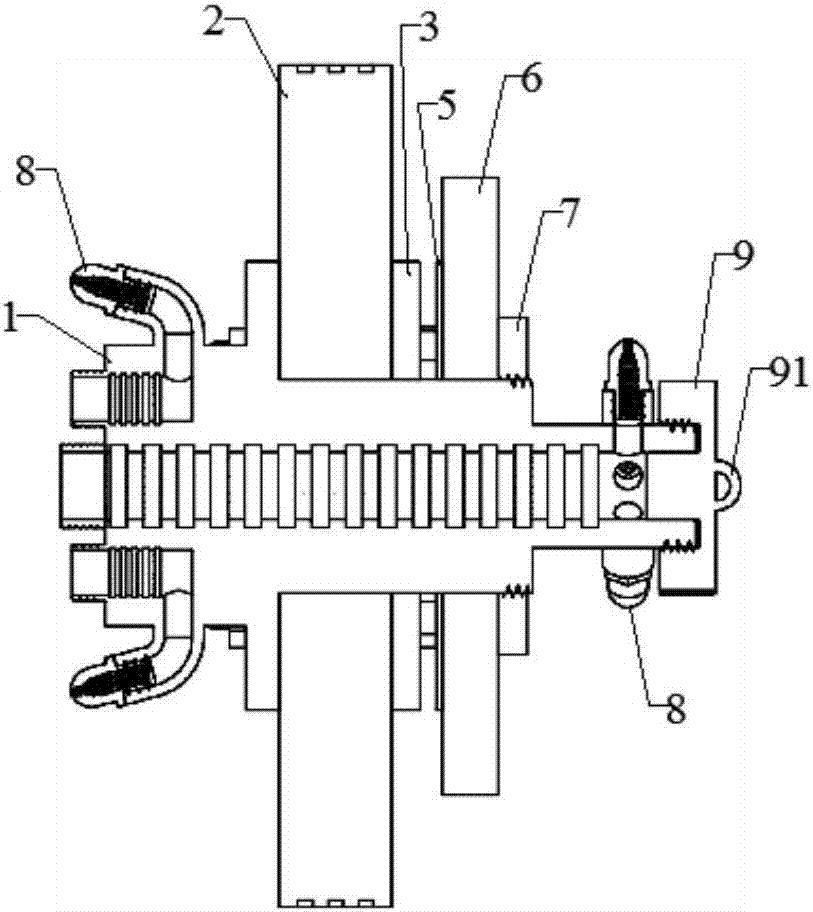

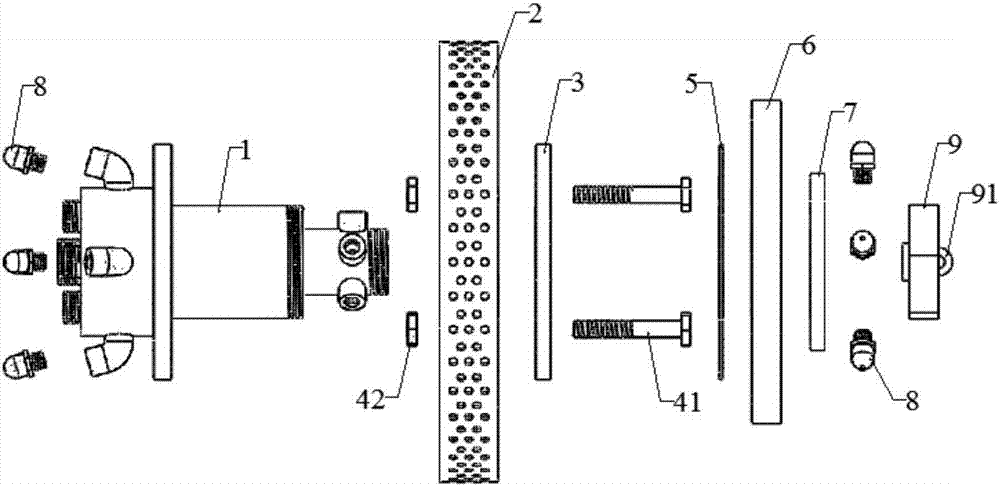

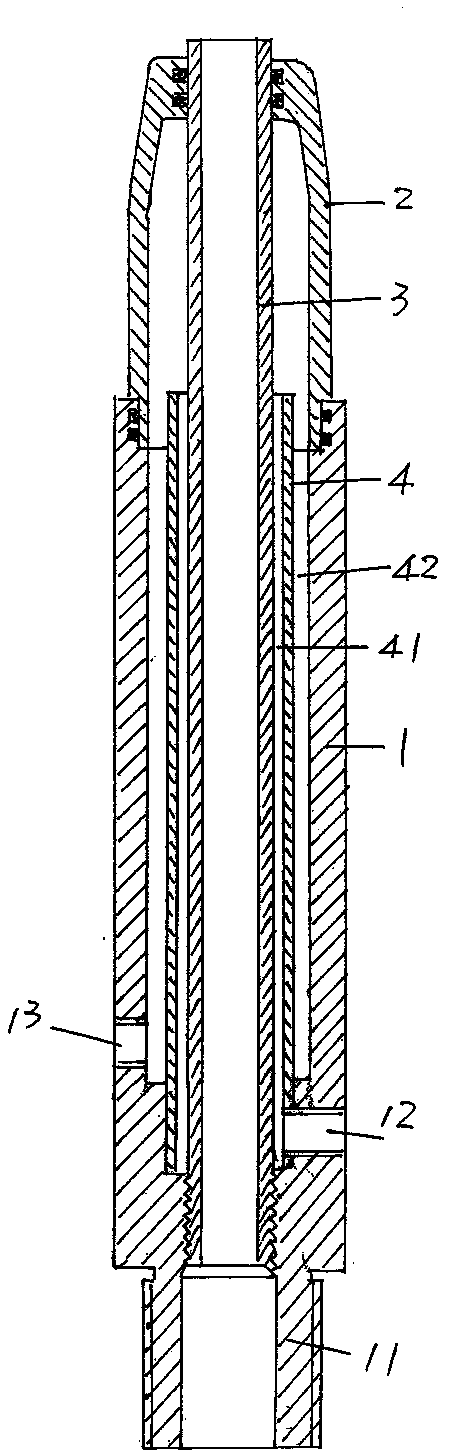

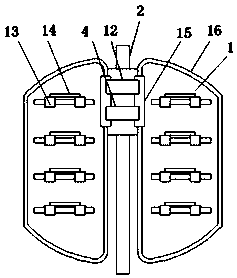

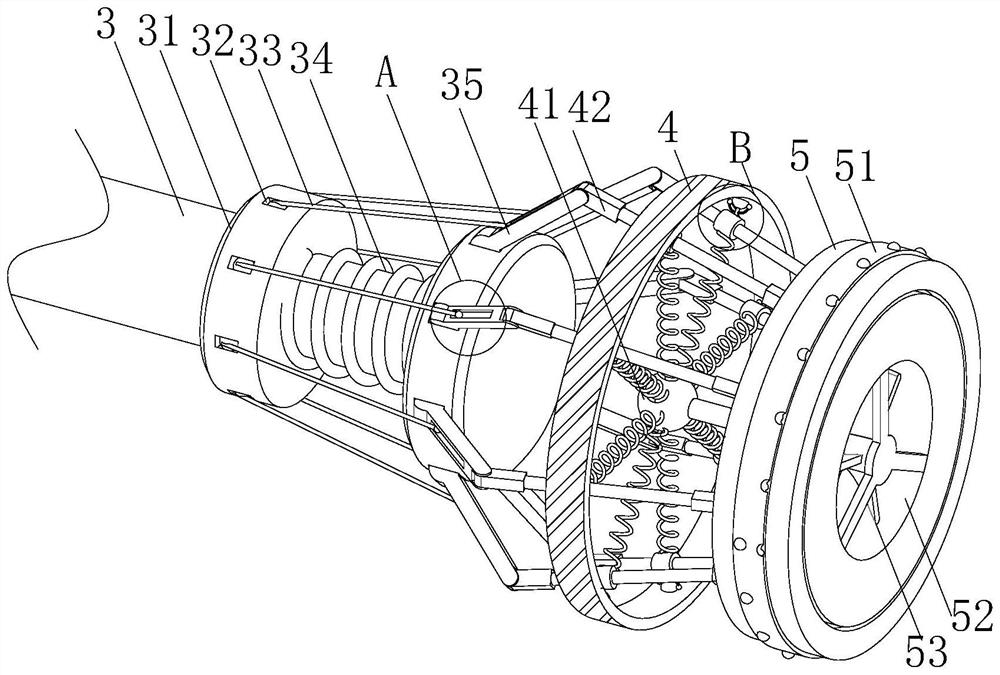

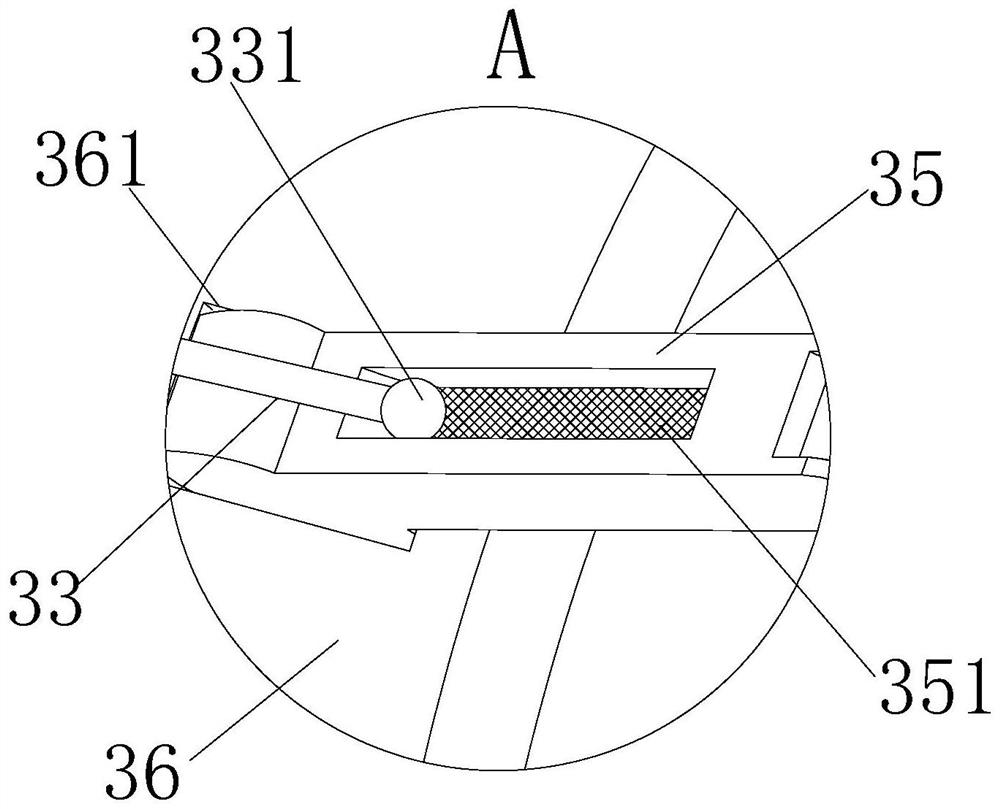

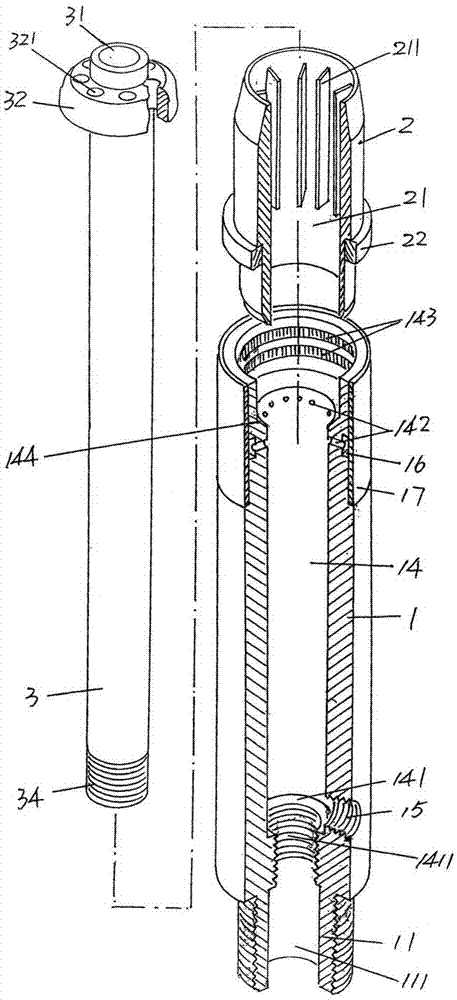

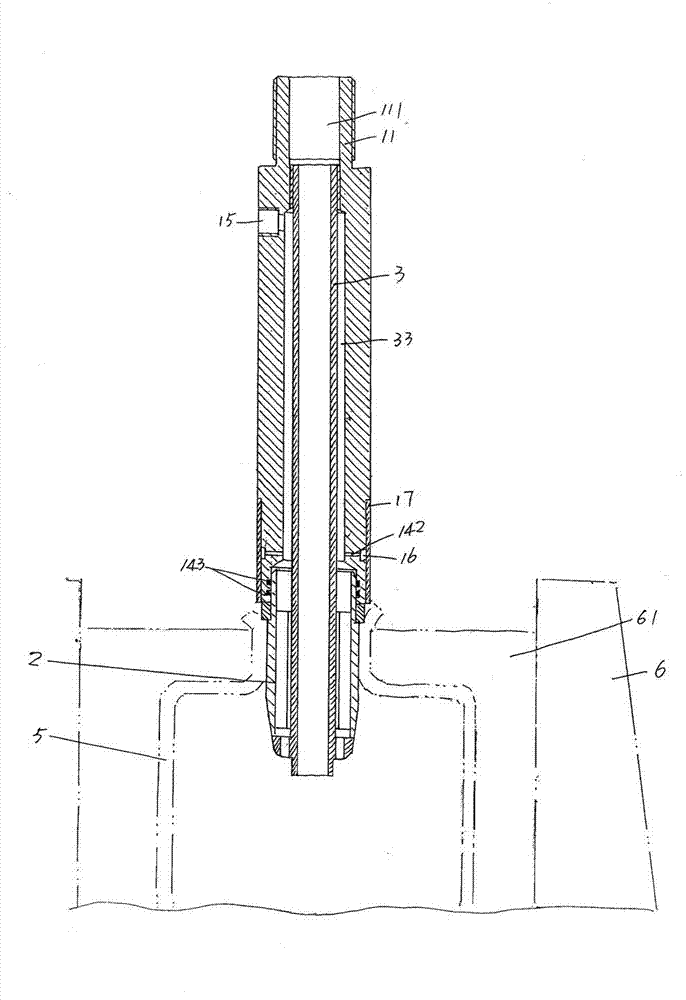

The invention relates to a multifunctional bionic tube cleaner and a cleaning method thereof. The bionic tube cleaner comprises a center shaft, a rubber ring, a rubber ring pressing plate, an annular magnet and a baffle plate, wherein the center shaft is sleeved with the rubber ring, the rubber ring pressing plate, the annular magnet and the baffle plate in order; the inner part of the center shaft is hollow, and a liquid flow channel is formed in the center shaft; a liquid inlet connecting port and a plurality of air inlet connecting ports are formed in the left end face of the center shaft, the liquid inlet connecting port is communicated with the liquid flow channel, and the air inlet connecting ports are communicated with nozzles through airflow channels in a mode of one to one correspondence; all nozzles positioned at the left end of the center shaft incline to the left; the right end of the center shaft is detachably provided with a plugging end cover in a sealing mode, and the right end of the center shaft is annularly provided with a plurality of nozzles communicated with the liquid flow channel. The inner wall of a tube is cleaned in a scraping mode through high-pressure liquid flow and the rubber ring, metal debris in the tube can be attracted through the annular magnet, and the whole device can move in the tube through high pressure air flow. The multifunctional bionic tube cleaner has the advantages of high efficiency, environmental protection, low consumption and strong flexibility and adaptability.

Owner:CHENGDU UNIVERSITY OF TECHNOLOGY

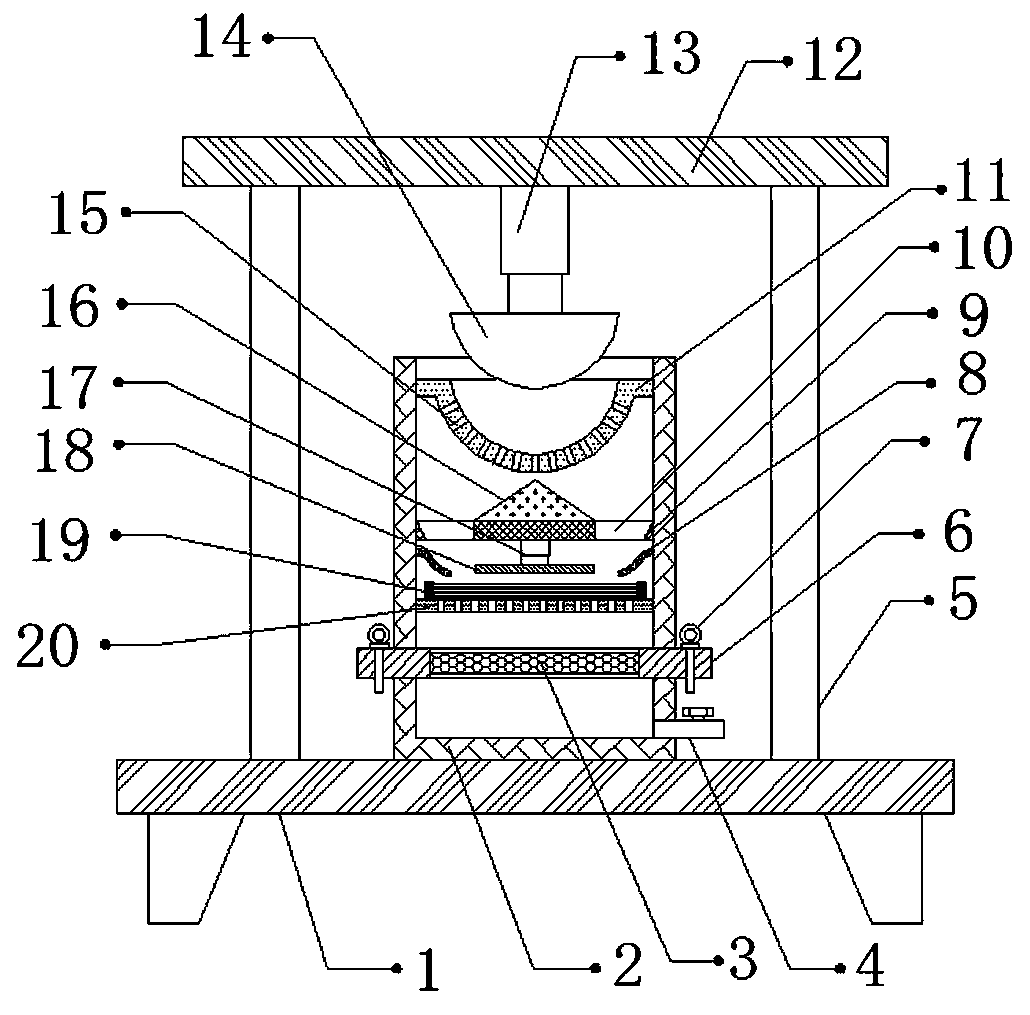

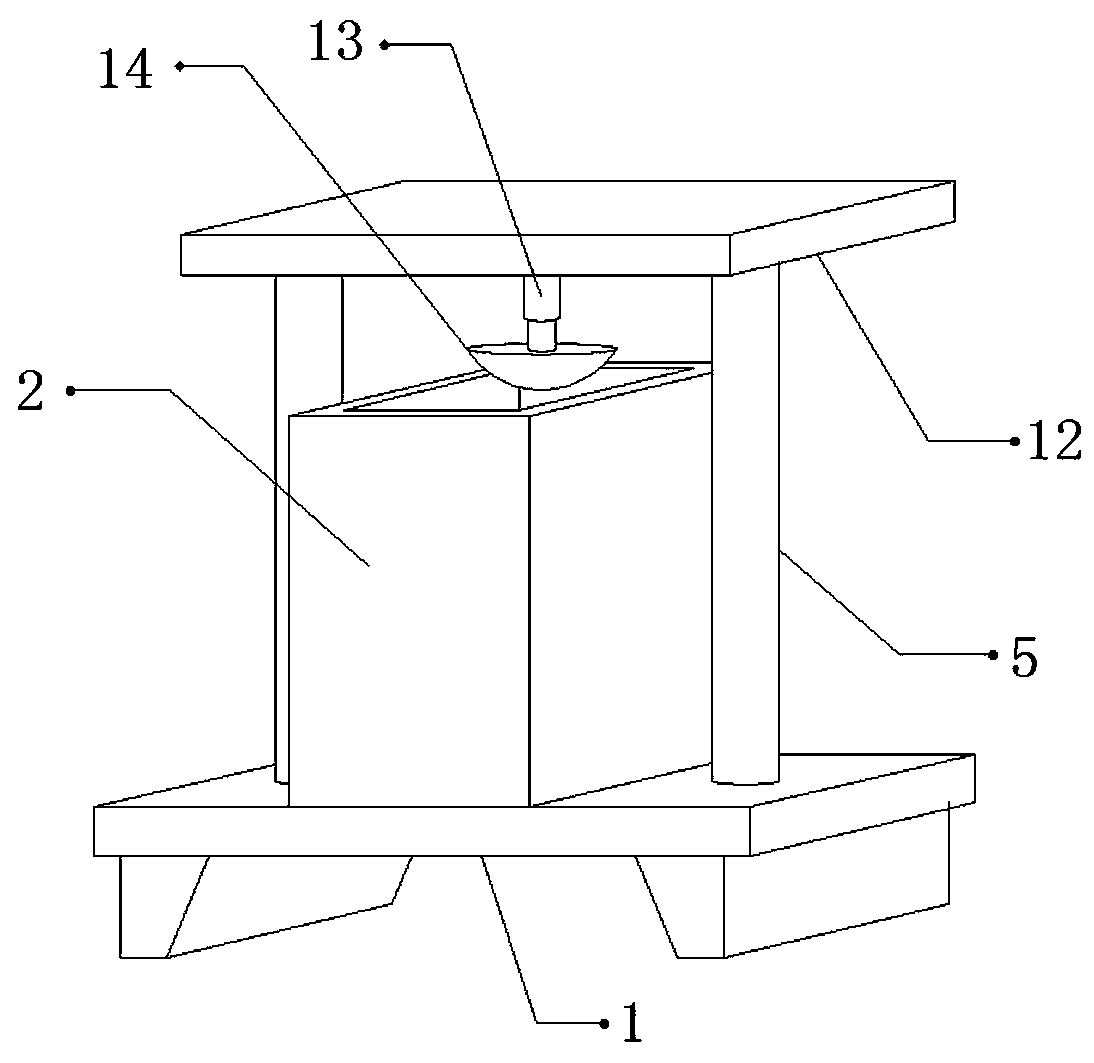

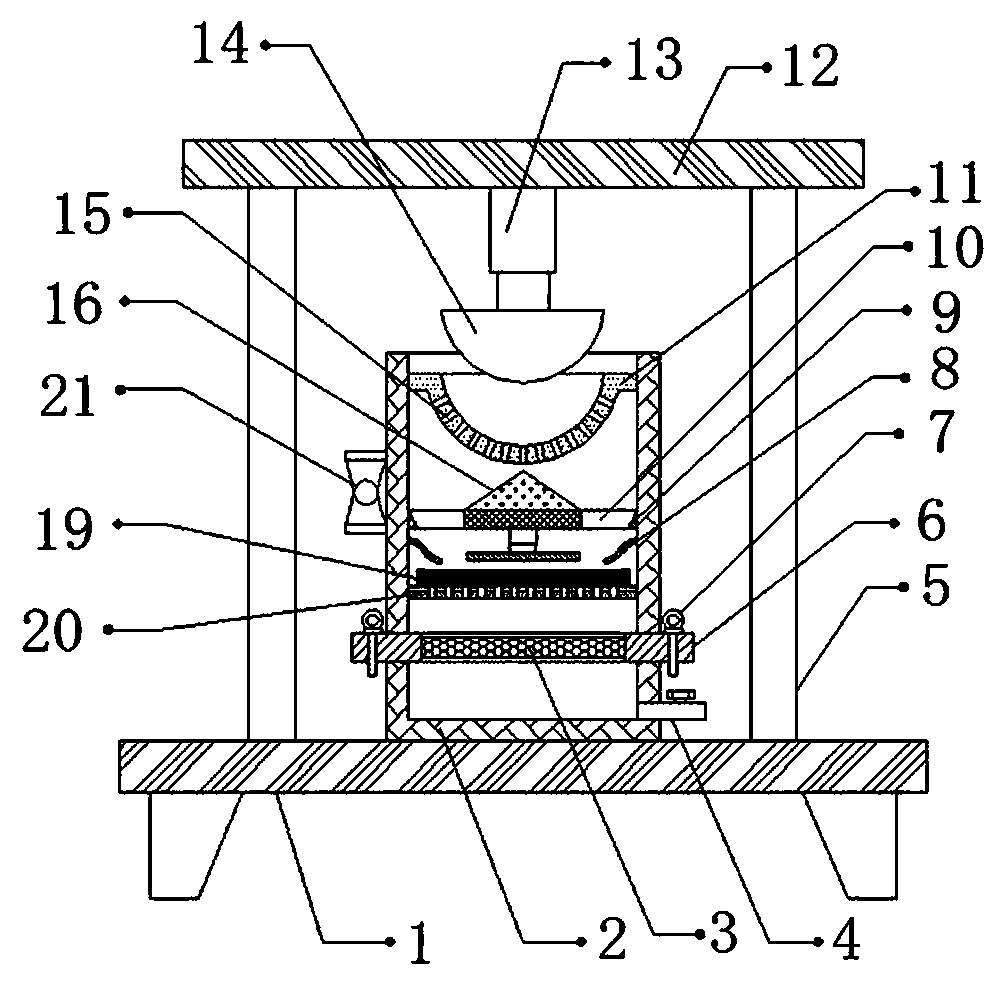

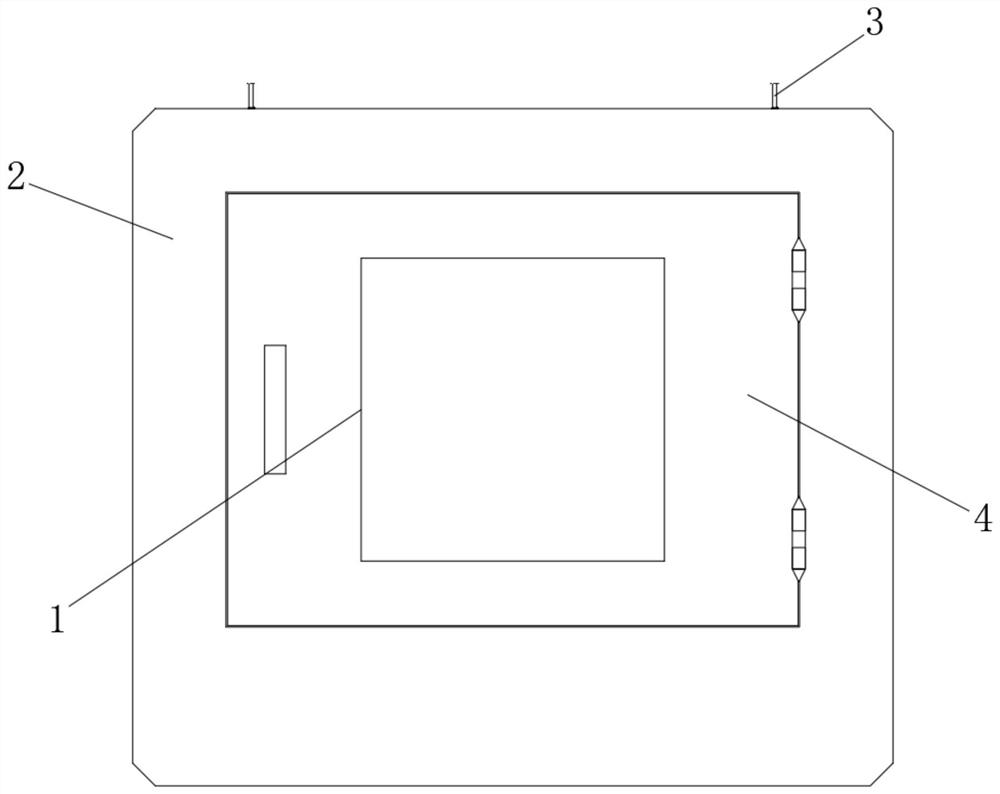

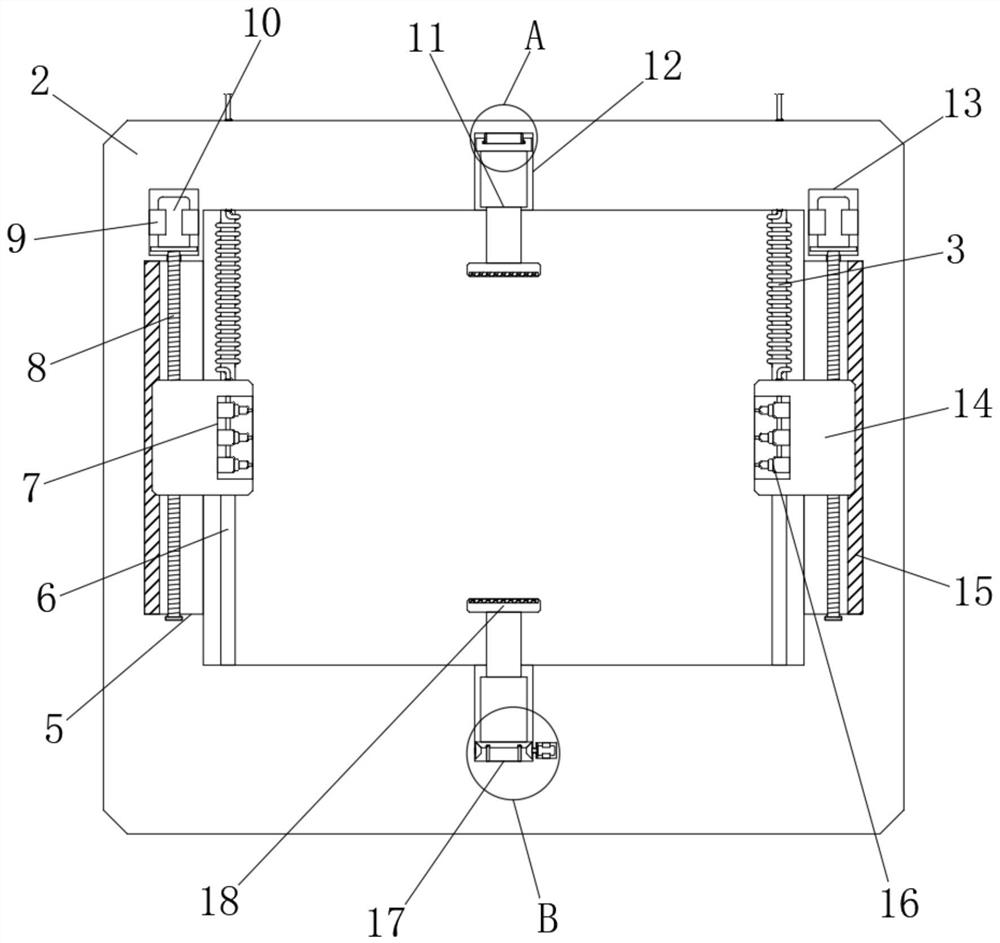

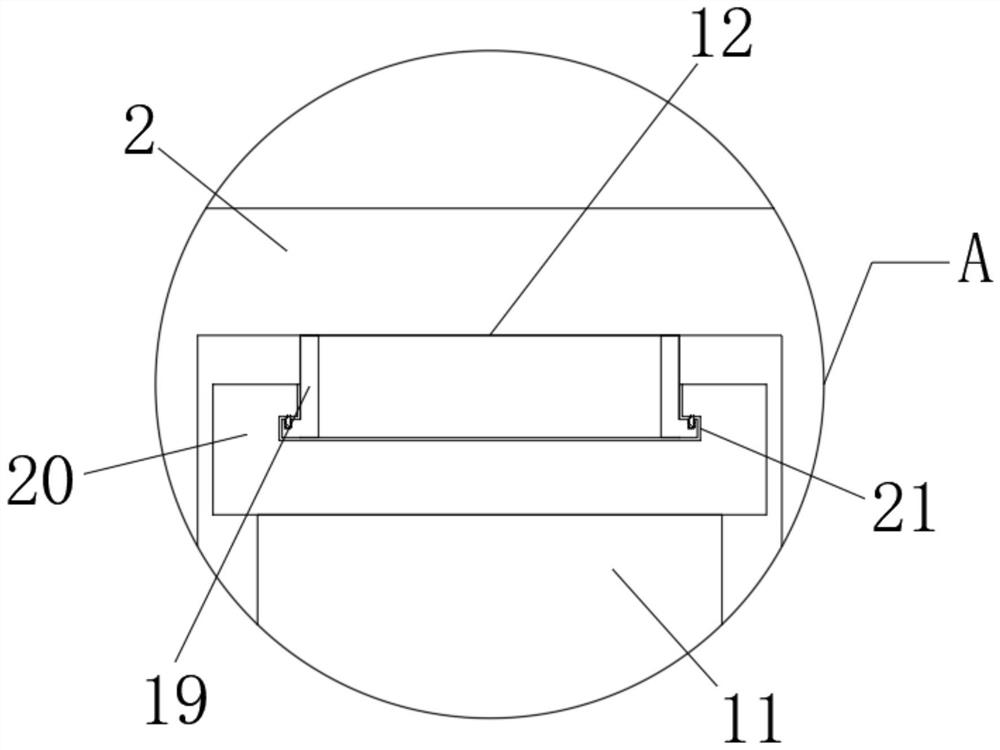

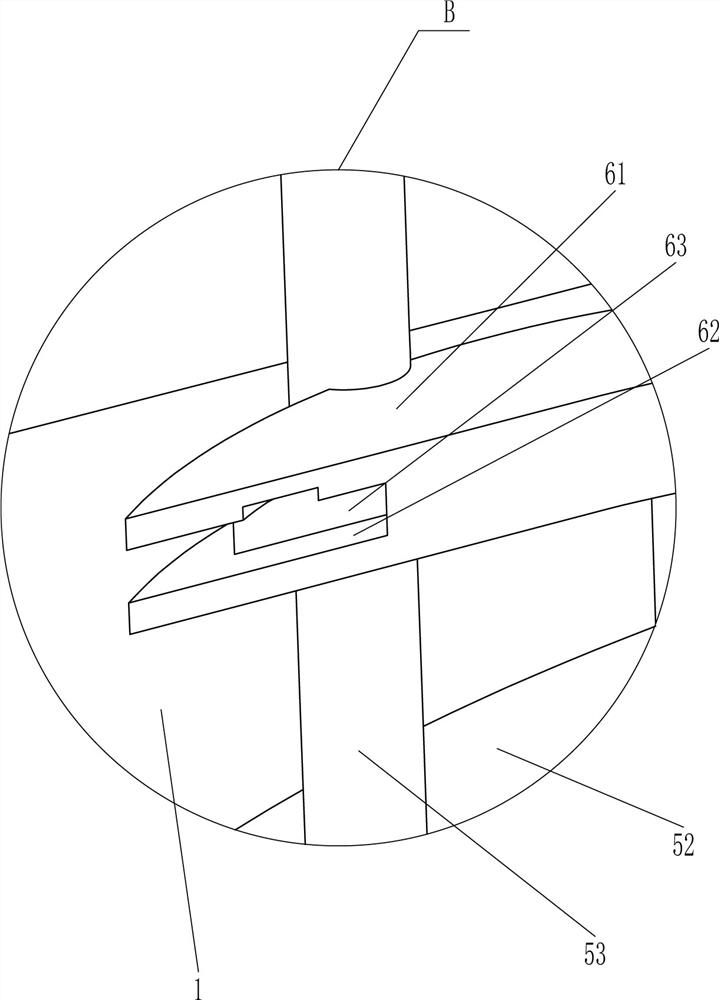

Cleaning device of floor-sweeping robot

ActiveCN108685528AEasy to cleanEasy to collectCarpet cleanersFloor cleanersUniversal jointEngineering

The invention discloses a cleaning device of a floor-sweeping robot. The cleaning device comprises a base, placement shelves, connecting rods, universal joints, a top cover, a fixed ring, a miniatureelectric motor, a placement groove, a brush roller, a hinge, electric push rods, a filtering net, a hot air pipe, an electric air heater, a ventilation opening, a bearing shelf, a transmission shaft,a material collection hopper, a collection box, a through groove, a pull rod, slide grooves, a miniature motor, lead screws, lead screw nuts and an inclined board. The cleaning device is reasonable instructure, novel in design, easy to operate and convenient to install; through the miniature motor, the placement groove, the brush roller, the electric push rods, the bearing shelf, the transmissionshaft, the material collection hopper, the collection box, the through groove, the pull rod, the slide grooves, the miniature motors, the lead screws and the lead screw nuts, the bottom of the floor-sweeping robot is conveniently cleaned through a brush, impurities such as hair are conveniently removed, the dust and impurities fall into the collection box, and the dust is conveniently collected and discharged, so that the bottom of the floor-sweeping robot is kept clean, and the hair and the dust are prevented from influencing the cleanliness of the floor-sweeping robot.

Owner:江苏昊科汽车空调有限公司

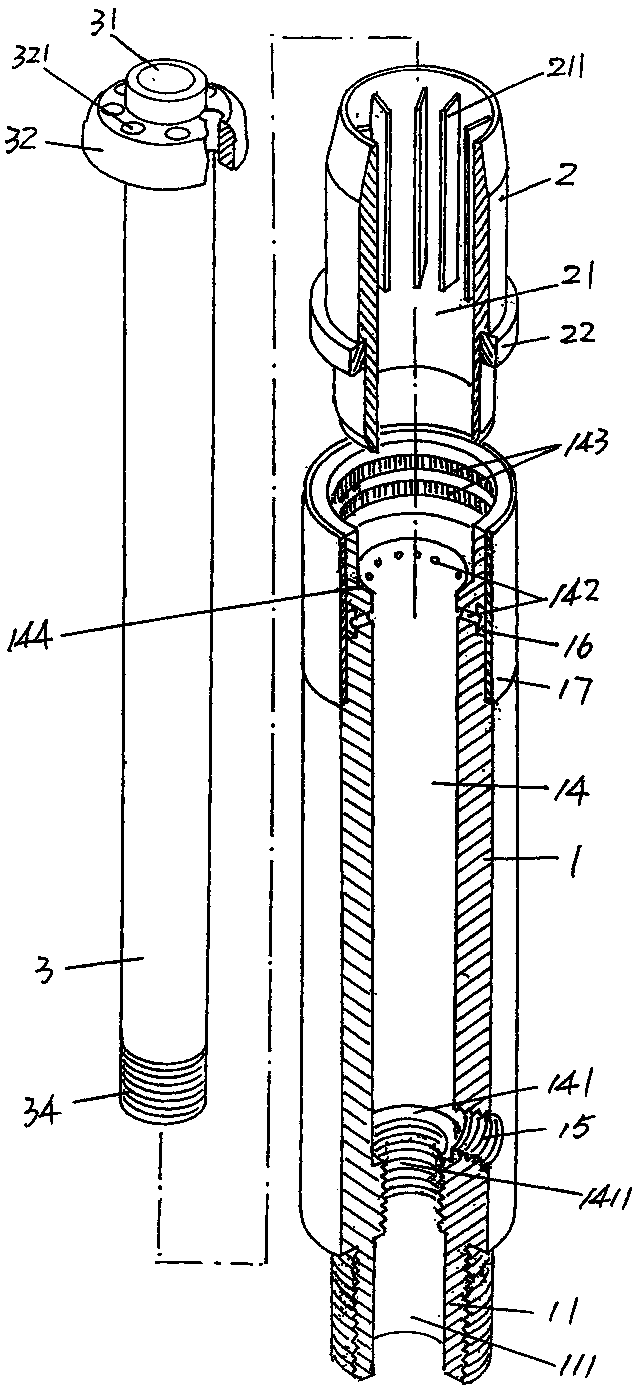

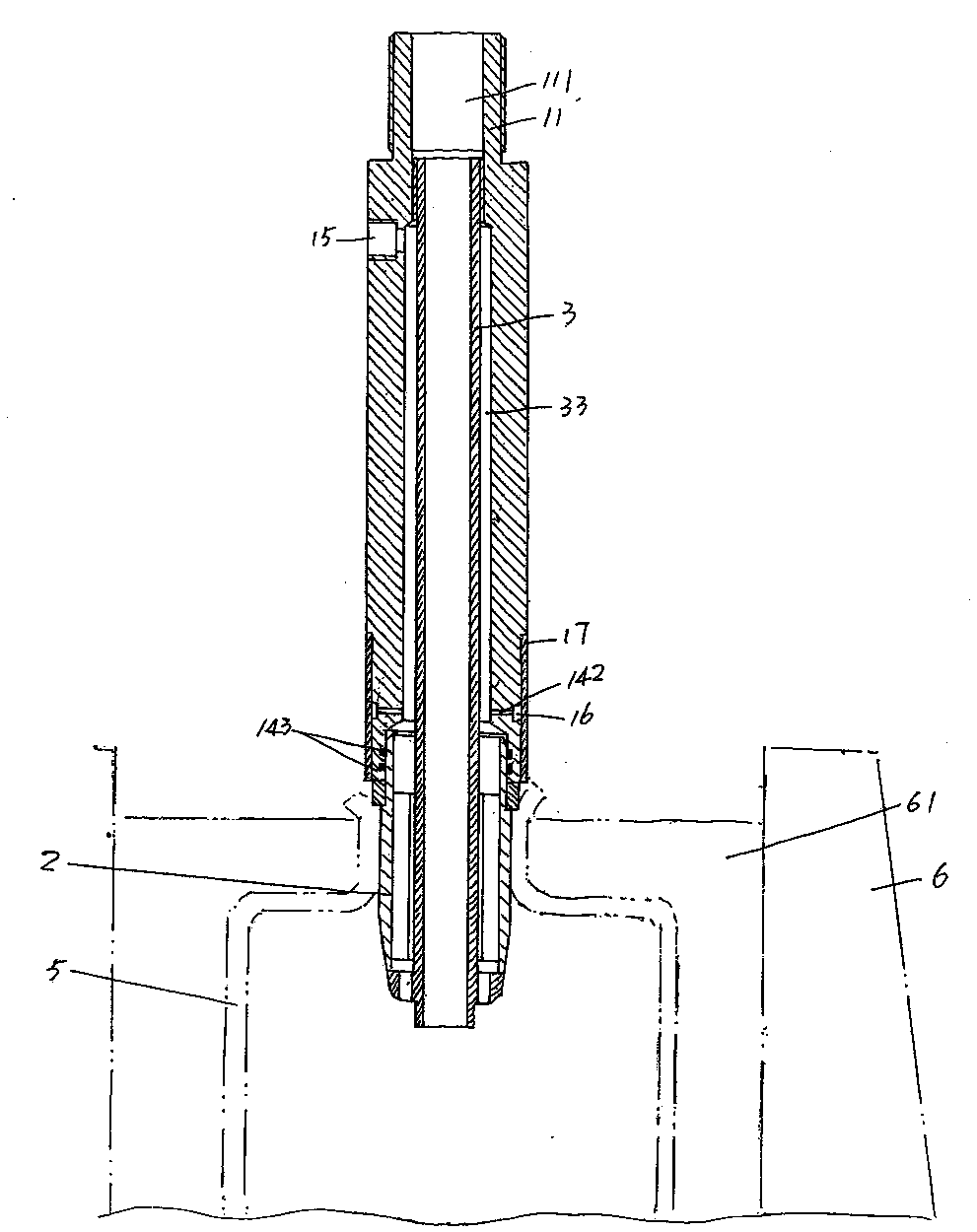

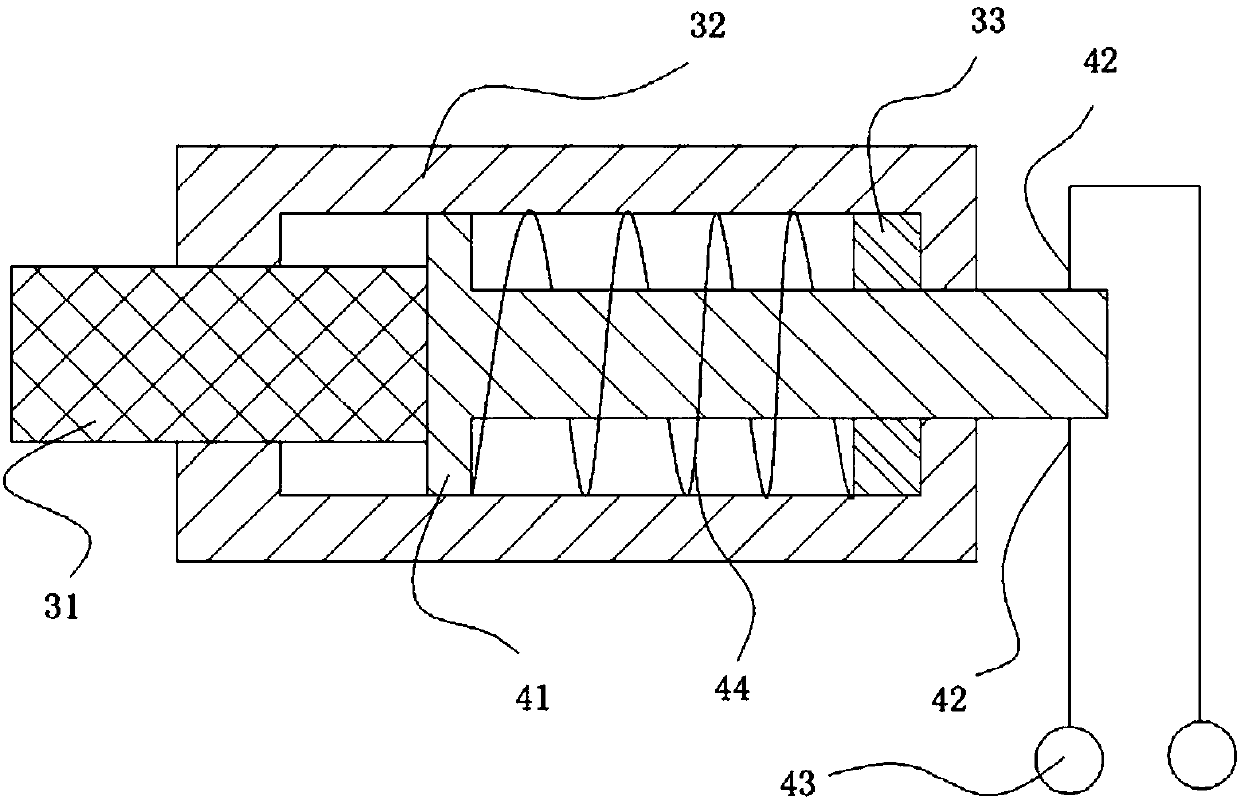

Air-cooled blow needle mechanism

ActiveCN102848559BCleaning effectReduce the temperatureHollow articlesEngineeringMechanical engineering

The invention relates to an air-cooled blow needle mechanism, and belongs to the technical field of an air blowing mechanism of a blowing machine. The mechanism comprises a blow needle body with a hollow chamber. An air inlet pipe joint extends at one end of the blow needle body. A cooling air inlet is provided on a side of the blow needle body. A blowing pipe joint seat is formed on a wall of the hollow chamber. An annular air groove is provided on the other end of the blow needle body, and a cooling sleeve is fixed. A set of cooling sleeve cooling air ports is provided on the inner wall of the hollow chamber. A blow needle head with a blow needle head cavity is formed. A set of heat sinks is formed on the inner wall of the blow needle head cavity. The blowing pipe is positioned in the hollow chamber. One end of the blowing pipe extends out of the blow needle head, and a blow needle cap is formed. A set of secondary air jet holes is provided on the blow needle cap. The space between the outer wall of the lowing pipe and the inner wall of the hollow chamber forms a cooling air entraining cavity. The cooling air inlet communicates with the cooling air entraining cavity. The cooling sleeve cooling air ports communicate with the cooling air entraining cavity. The mechanism has the advantages that: with the mechanism, product is prevented from being polluted; blank blowing time is shortened; production efficiency is improved; and heat dissipation effect is improved.

Owner:SUZHOU TONGDA MACHINERY

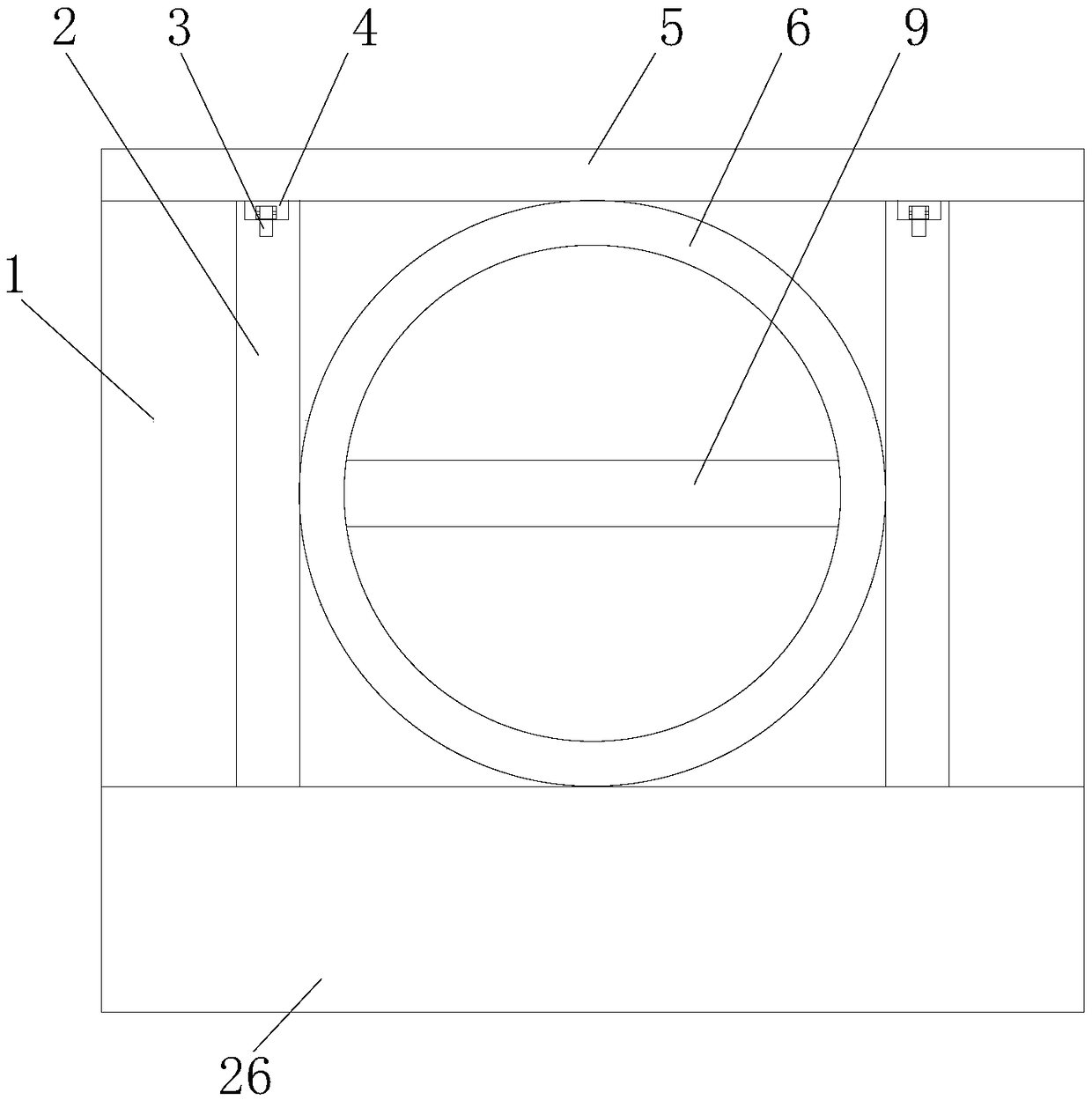

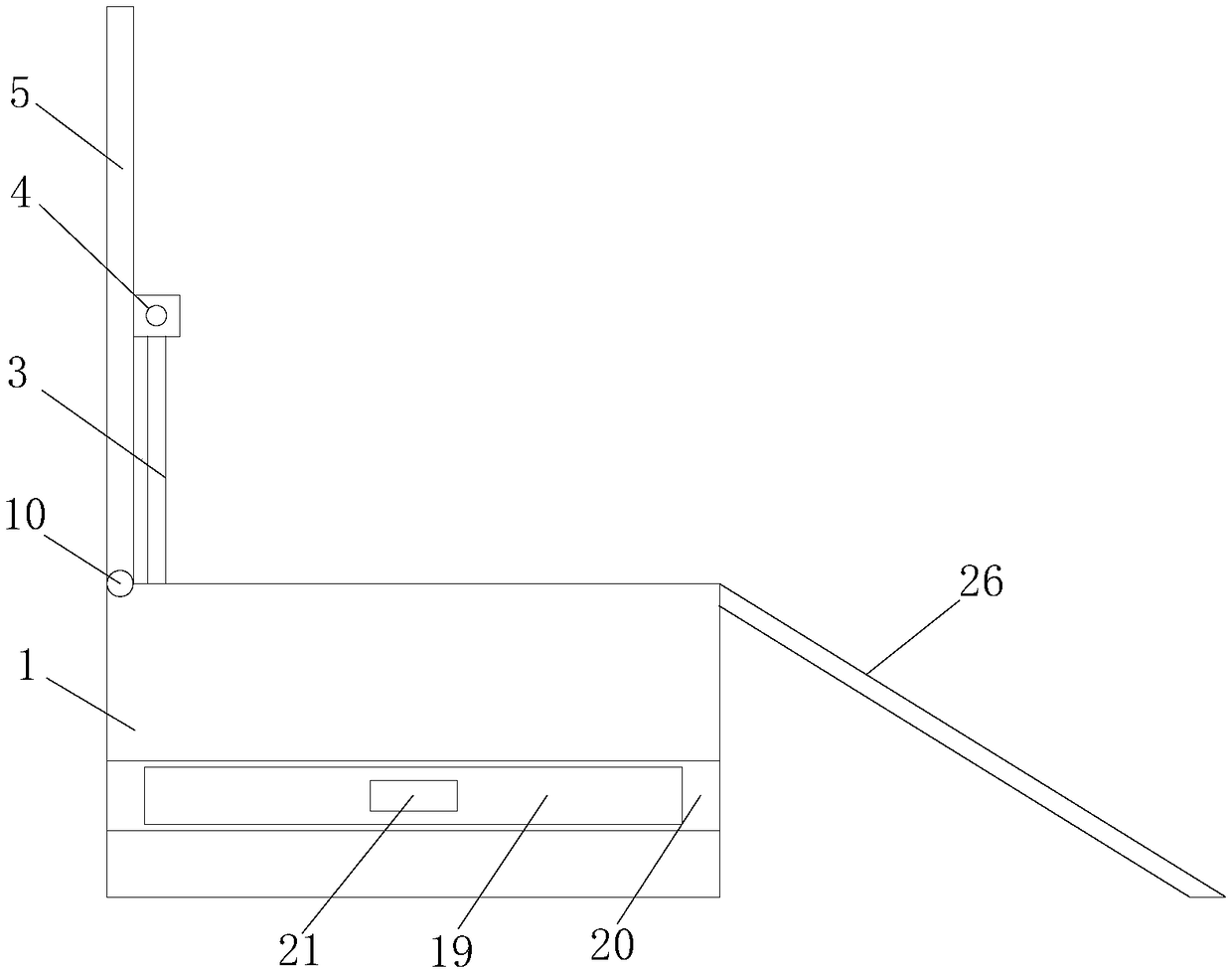

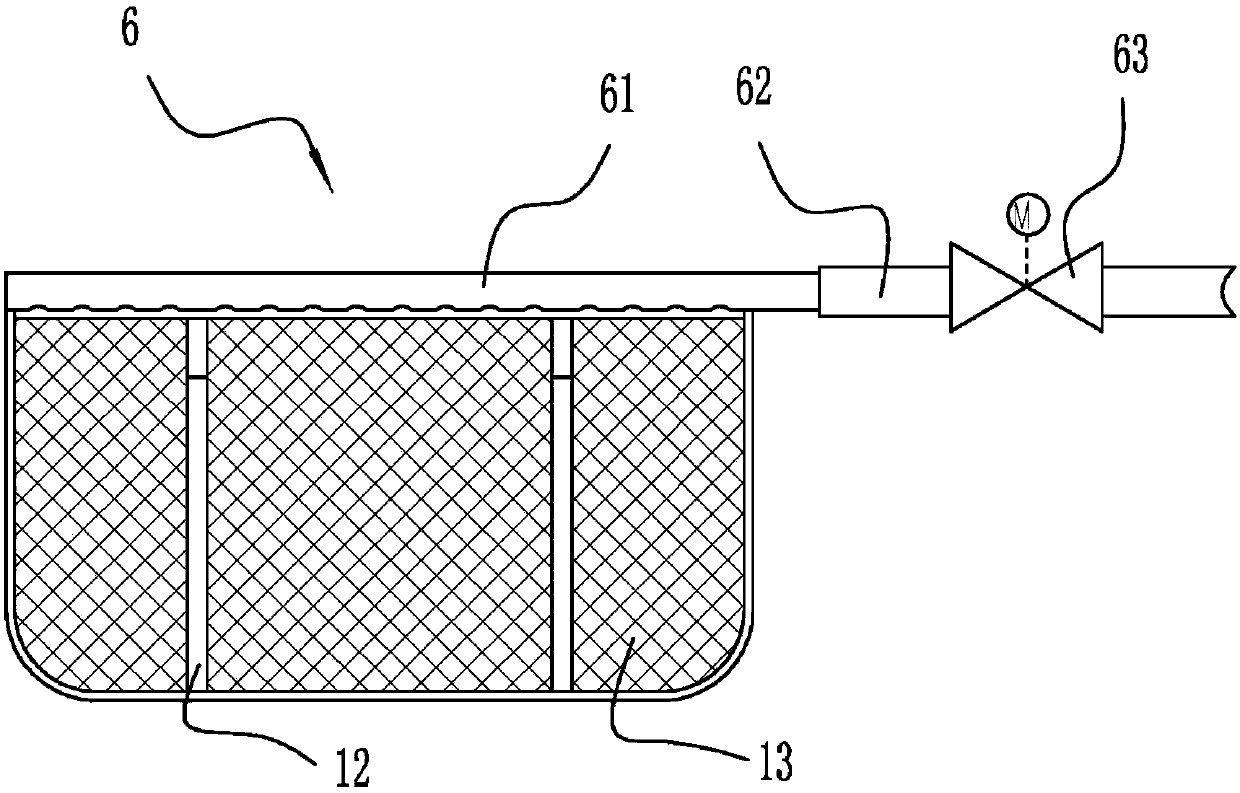

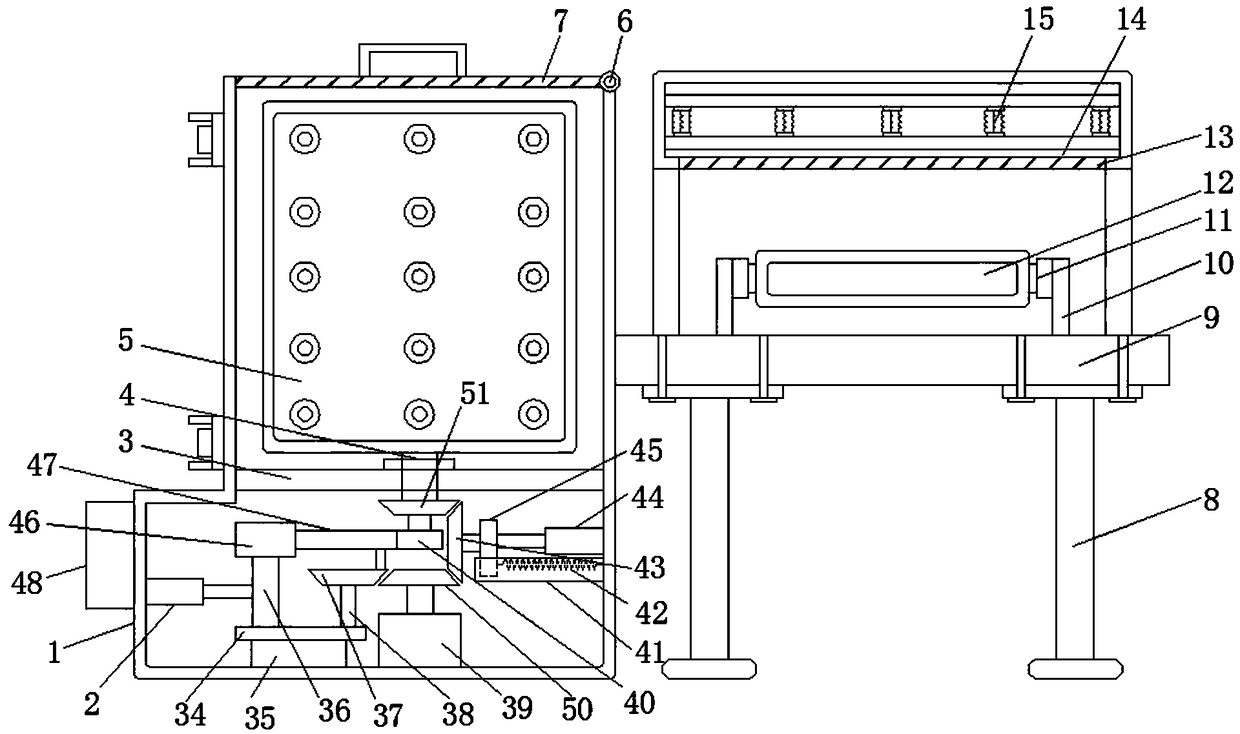

Sprinkler water outlet hole cleaning device

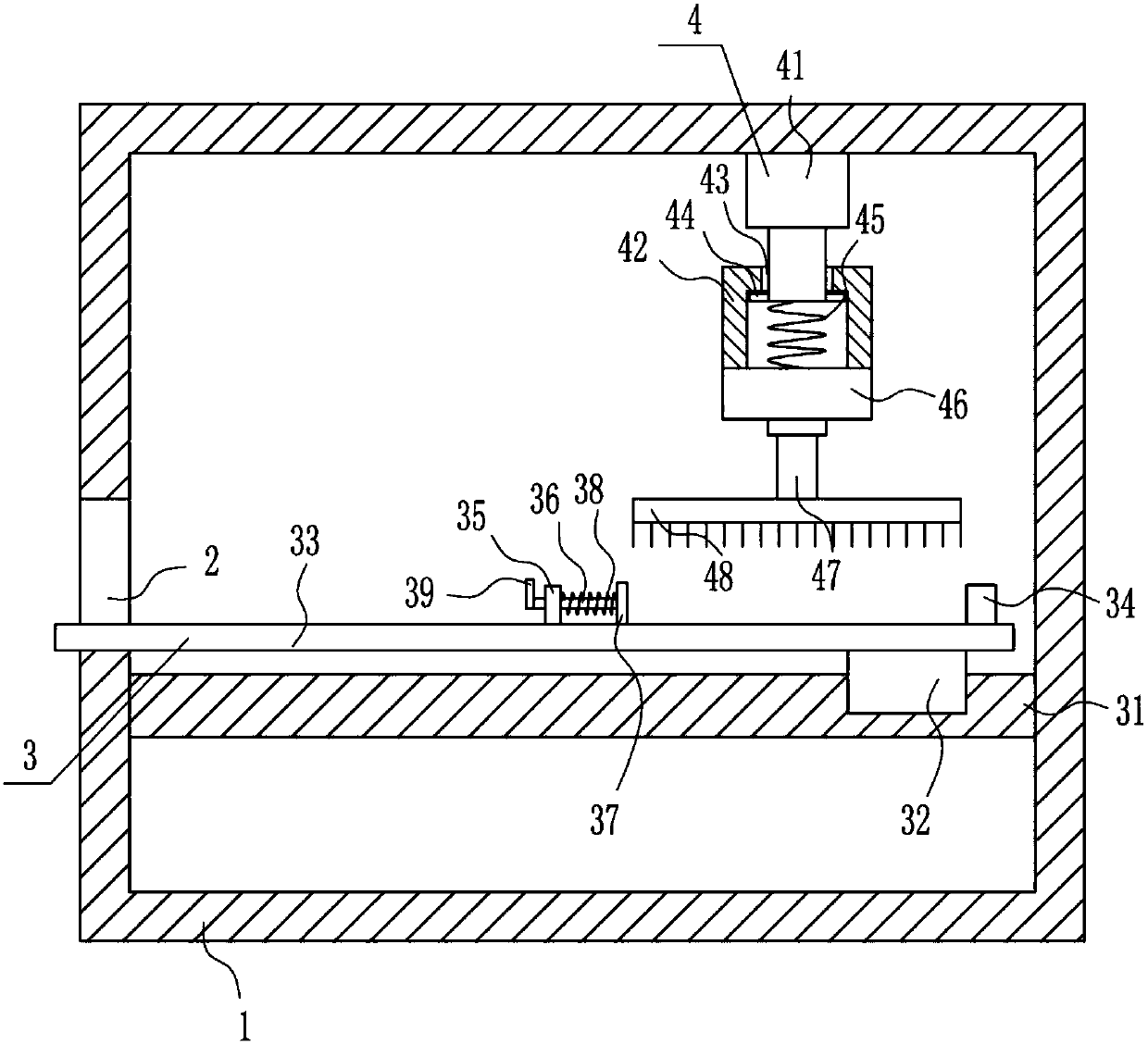

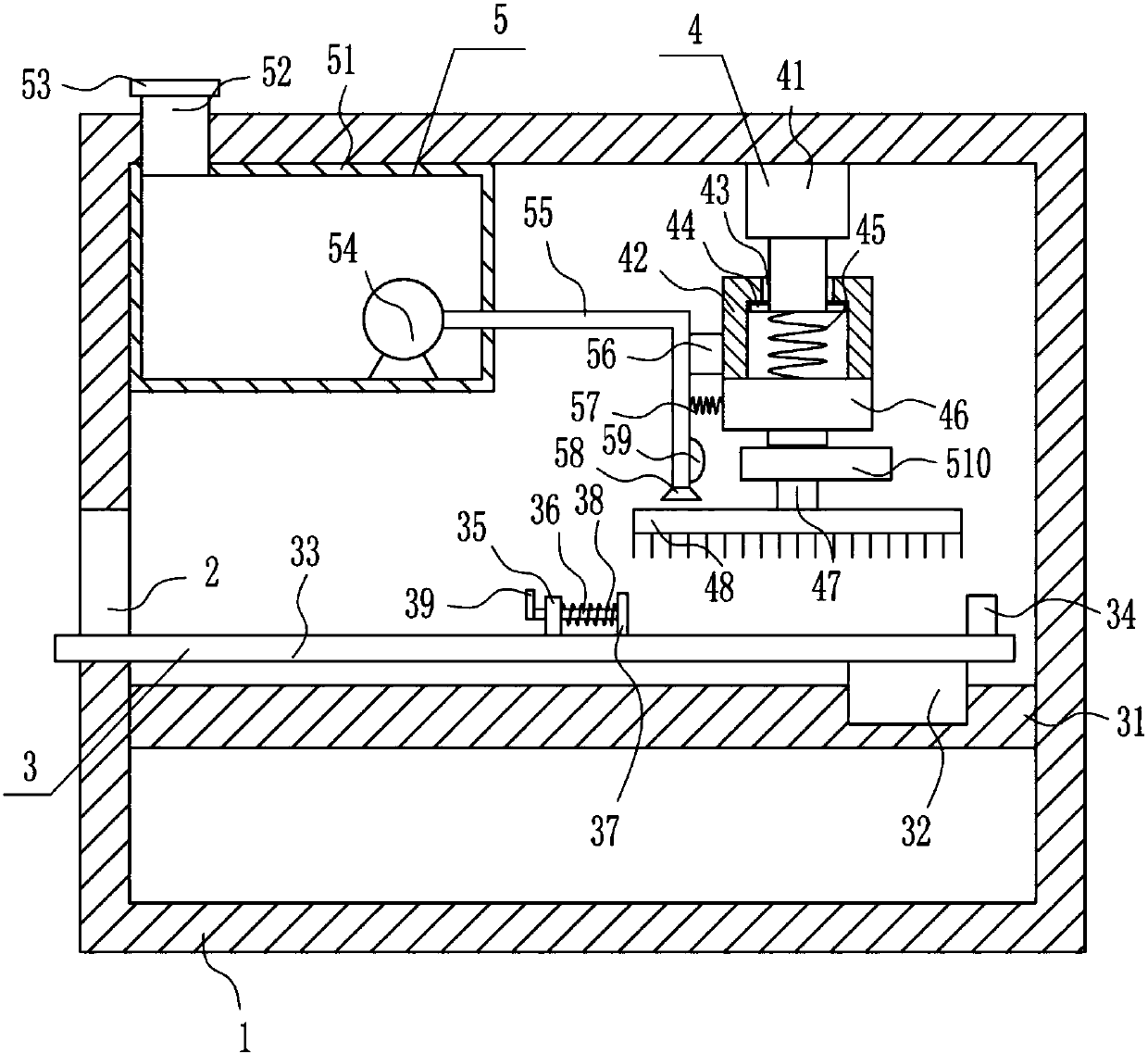

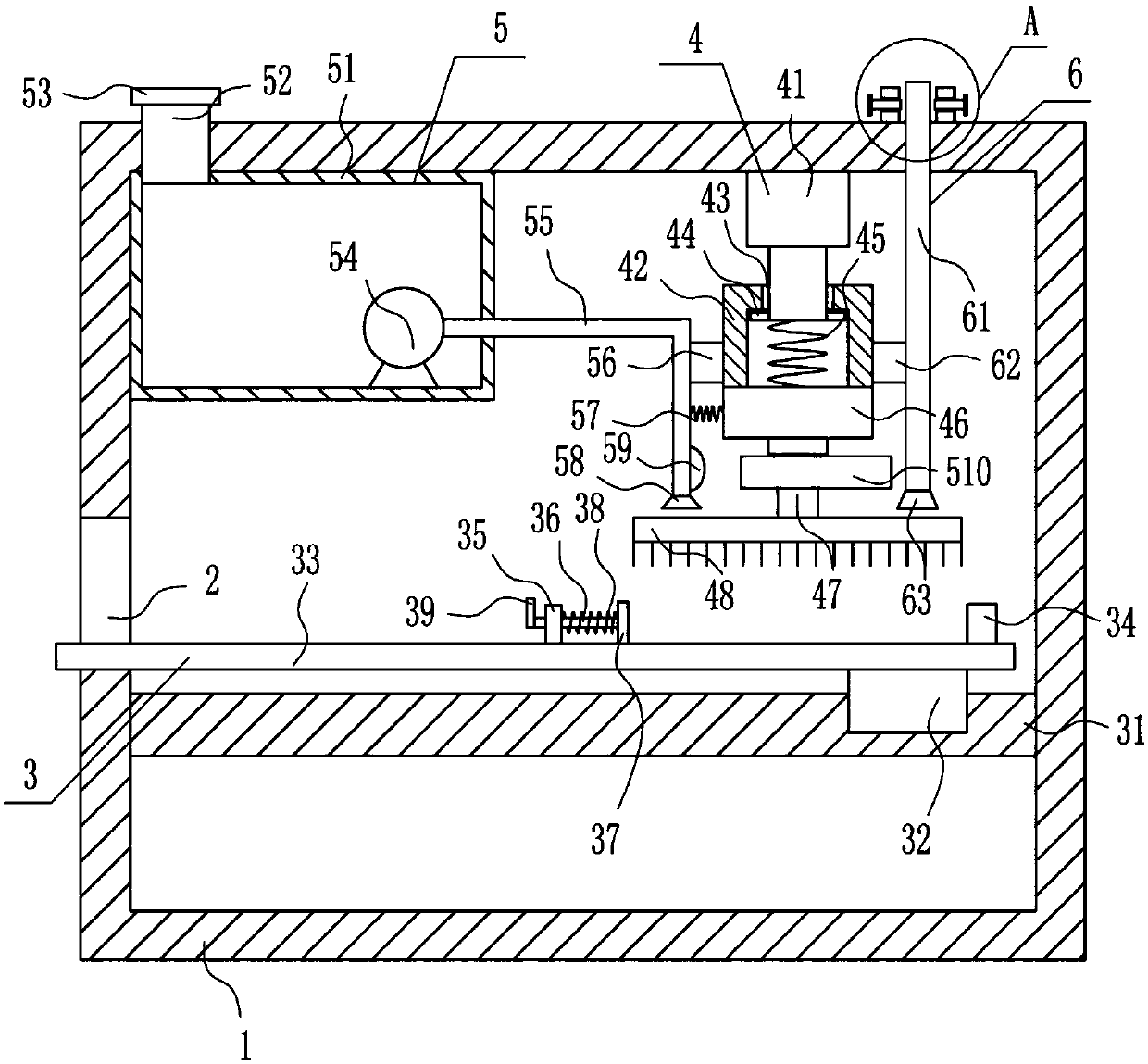

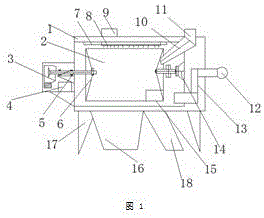

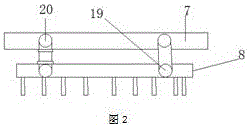

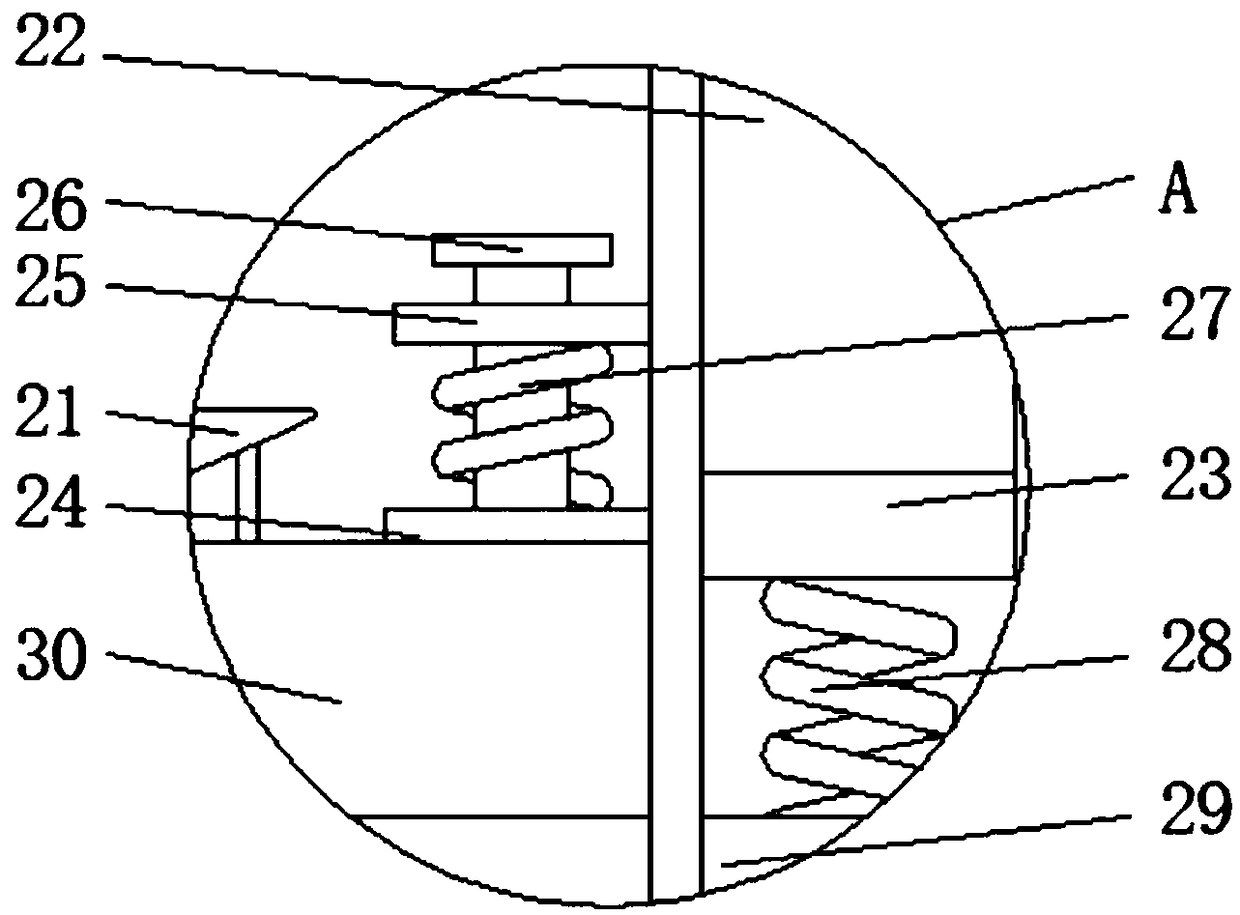

The invention relates to a cleaning device, in particular to a sprinkler water outlet hole cleaning device and aims at solving the technical problem of providing the sprinkler water outlet hole cleaning device which saves time and labor, is good in cleaning effect and cannot block water outlet holes of a sprinkler nozzle in the cleaning process. In order to solve the technical problem, the invention provides the sprinkler water outlet hole cleaning device which comprises a box body and the like; a through hole is formed in the lower part of the left side of the box body; a placing device is arranged at the lower part in the box body; a placing component of the placing device is arranged in the through hole; and a cleaning device is arranged on the right side of the top in the box body. Forthe sprinkler water outlet hole cleaning device, through a liquid spraying device, the effect of cleaning the water outlet holes of the sprinkler nozzle can be better, and a water spraying device canspray water to eliminate a cleaning solution on the sprinkler nozzle without eliminating the cleaning solution by a person, so that the effects of saving the time and the labor, good cleaning effectand not being capable of blocking the water outlet holes of the sprinkler nozzle in the cleaning process are reached.

Owner:浙江五峰汽车轴承制造有限公司

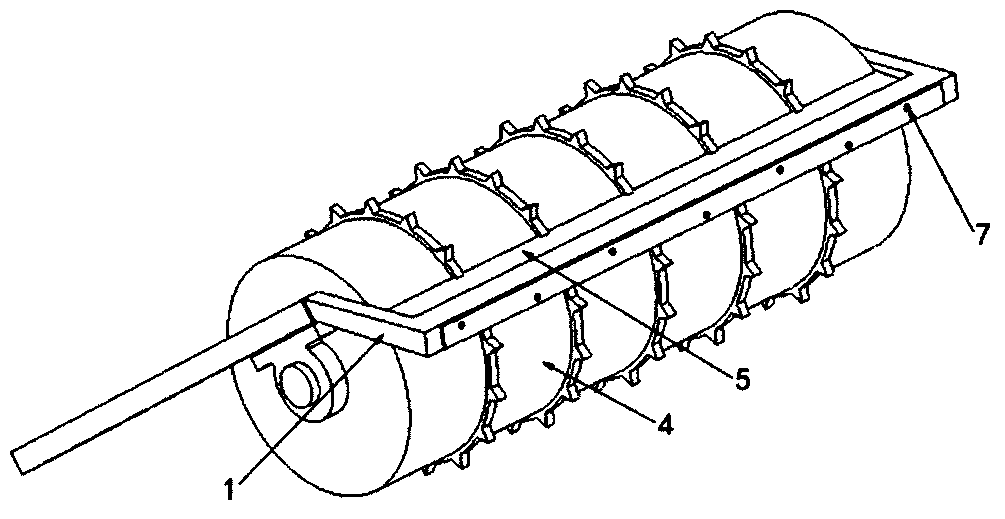

Cylinder cleaning screen for vacuum low-temperature grain drying tower

The invention discloses a cylinder cleaning screen for a vacuum low-temperature grain drying tower. The cylinder cleaning screen comprises a cleaning screen shell and a screen drum. A feeding port and an air suction port are formed in the top of the cleaning screen shell. The bottom of the feeding port is connected with a feeding shedding plate which can be connected with the screen drum. A variable-frequency motor is arranged on one side of the cleaning screen shell. Rotation rods are arranged on the two sides of the screen drum and are connected with the cleaning screen shell through bearing blocks. An output shaft of the variable-frequency motor is connected with the rotation rods. A brush is arranged at the top end of the screen drum, and the brush is connected with the cleaning screen shell through a fixing rod. An induced draft fan is arranged at the bottom end of the cleaning screen shell. The induced draught fan is located on one side of the screen drum. The cylinder screening screen is simple in overall structure and novel in design and has very good popularization value.

Owner:安徽富通环保节能科技股份有限公司

Spray nozzle cleaning device and manner

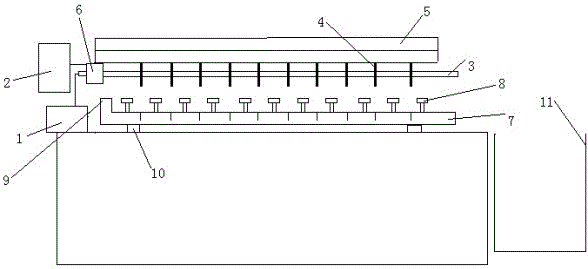

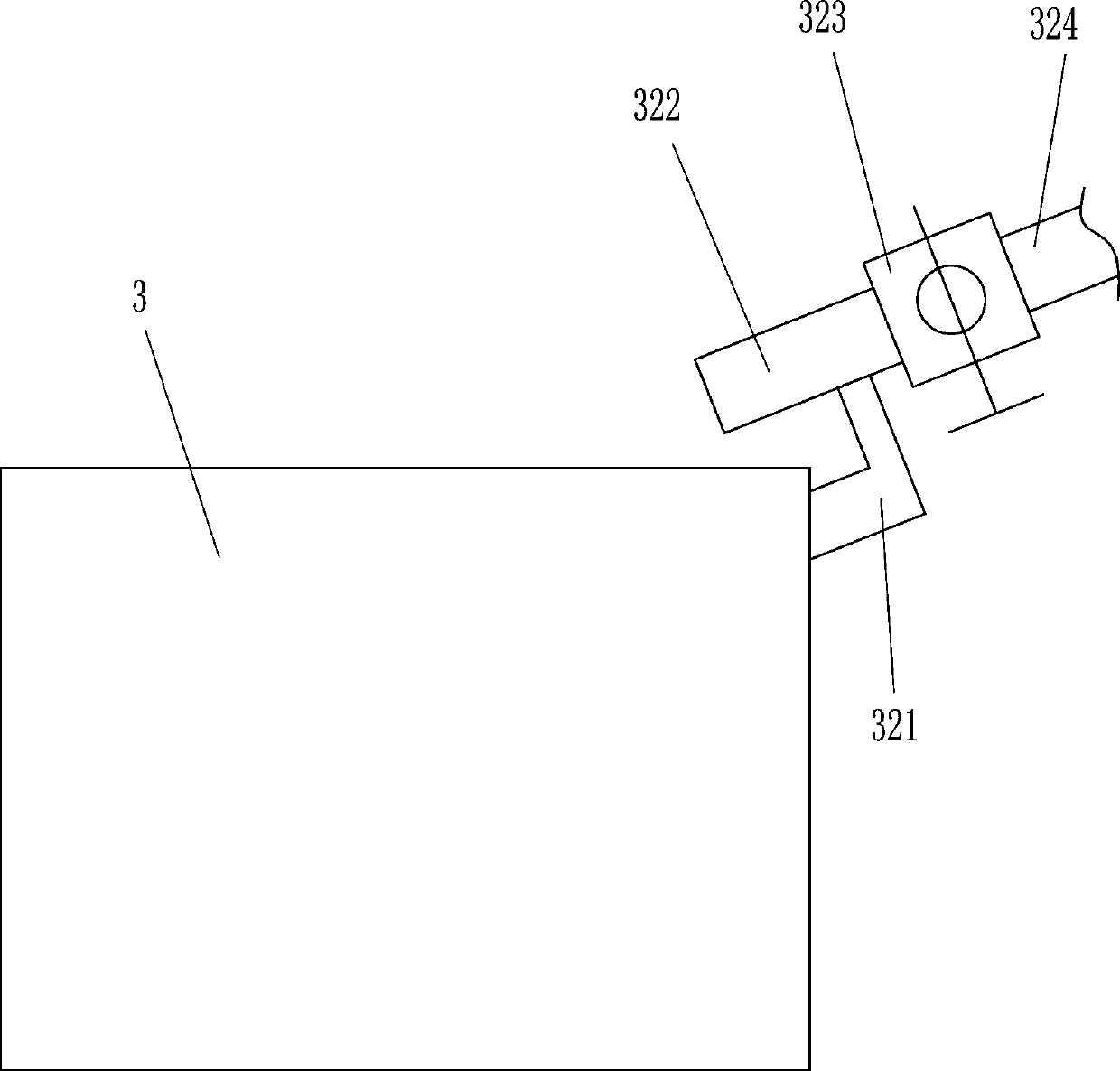

InactiveCN107812748AAvoid destructionReduce the process of disassembling and assembling the droplet nozzleDrying gas arrangementsCleaning using liquidsSpray nozzleMegasonic cleaning

The invention discloses a spray nozzle cleaning device and manner. According to the spray nozzle cleaning device, the cleaning device is horizontally moved to the position below a micro drop spray nozzle through a mechanical conveying device, ultrasonic cleaning is performed on the micro drop spray nozzle, and the micro drop spray nozzle is fast dried by adopting a convection drying row grate. Bymeans of the spray nozzle cleaning device and manner, the cleaning efficiency of the micro drop spray nozzle can be improved, the immersion depth of the micro drop spray nozzle is accurately controlled, and it is effectively prevented that damage is caused to the micro drop spray nozzle in the cleaning process.

Owner:XIAMEN UNIV OF TECH

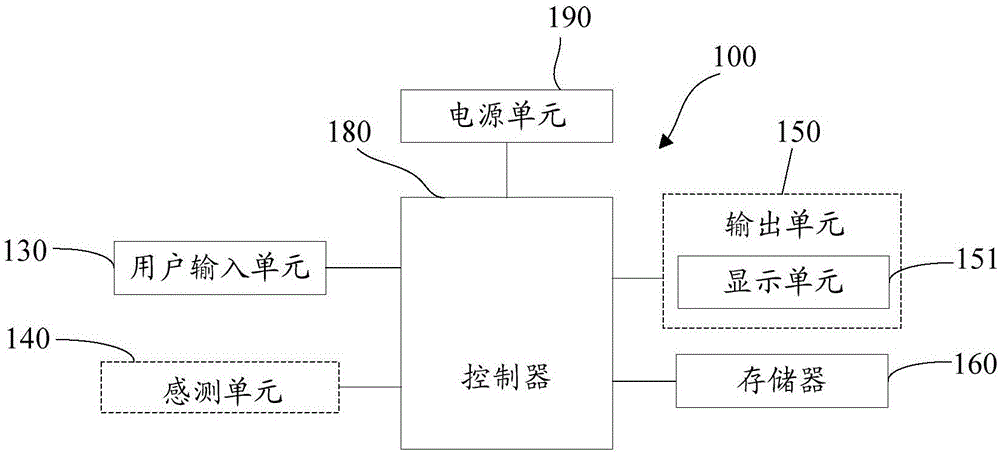

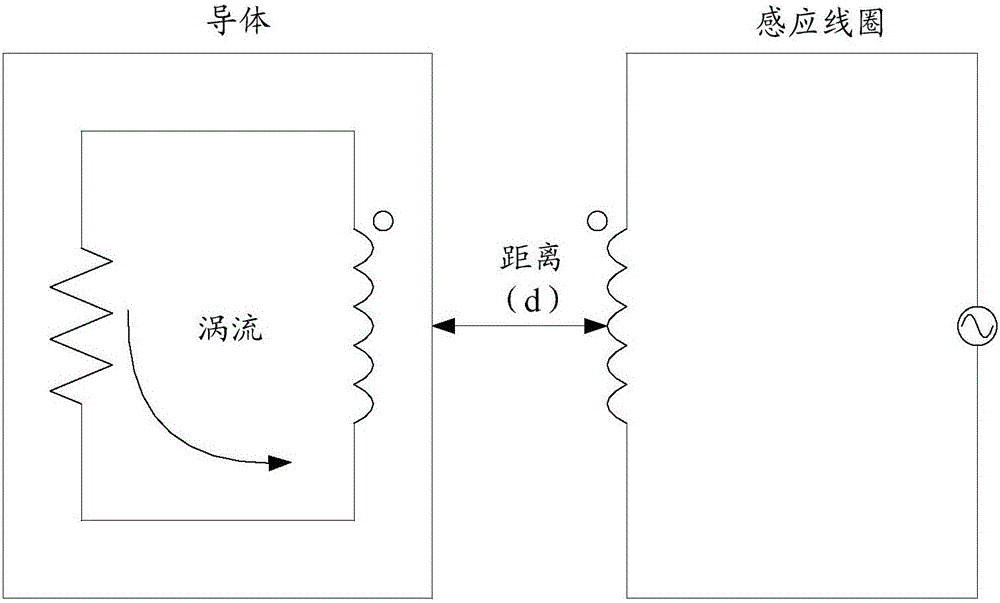

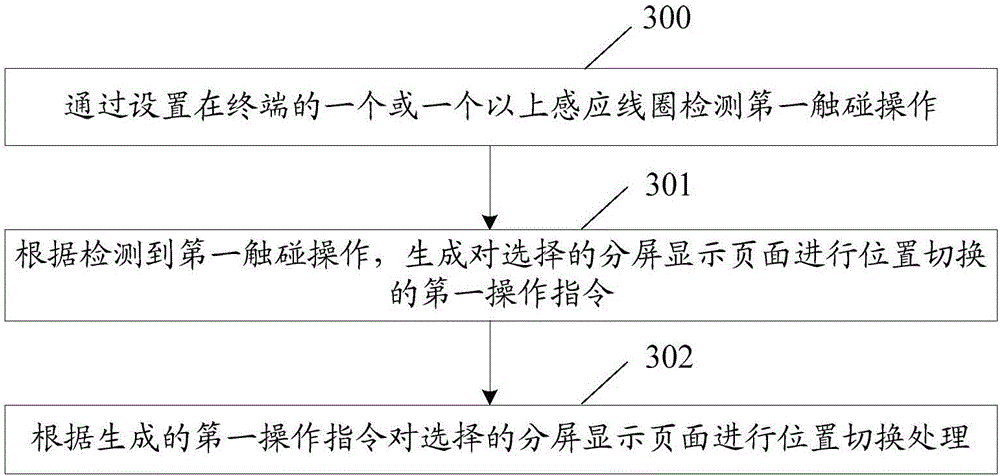

Split screen switching method and terminal

InactiveCN106843679ASimplify location switching operationsCleaning effectInput/output processes for data processingComputer engineeringInduction coil

The invention discloses a split screen switching method and a terminal. The method includes the steps that first touch operation is detected through one or more induction coils arranged in the terminal; a first operation instruction of conducting position switching on a selected split screen display page is generated according to the detected first touch operation; position switching processing is conducted on the selected split screen display page according to the generated first operation instruction. According to the split screen switching method and the terminal, position switching of the split screen display page is conducted through the induction coils, the operation of position switching of the split screen display page is simplified, it is avoided that the cleanness of a display screen of the terminal is influenced, and the use experience of a user is improved.

Owner:NUBIA TECHNOLOGY CO LTD

Squeezing liquid taking device for producing wine

InactiveCN110789167AEasy to disassembleEasy to cleanAlcoholic beverage preparationPressesFiltrationEngineering

The invention discloses a squeezing liquid taking device for producing wine. The squeezing liquid taking device for producing wine comprises a fixing seat, wherein a squeezing box is fixed onto the outer wall of the top of the fixing seat; a squeezing groove is fixed in a position, near the top, of the inner wall of the squeezing box; filter holes distributed at equal intervals are formed in the inner wall of the squeezing groove; insertion grooves are respectively formed in the outer walls of the two sides of the squeezing box; a pulling plate is connected with the inner walls of the two insertion grooves in an inserting way; a fixing opening is formed in the outer wall of the top of the pulling plate; a filter screen is fixed to the inner wall of the fixing opening; insertion holes are formed in two sides of the outer wall of the top of the pulling plate; a plug pin is connected with the inner wall of each of the two insertion holes in an inserting way; fixing rods are fixedly arranged at the two sides of the outer wall of the top of the fixing seat. The squeezing liquid taking device for producing wine has the advantages that the filter screen can be conveniently dismounted, sothat the influence caused by cleaning inconvenience of the filter screen on the liquid filtration is prevented; the squeezing effect of the device on raw materials can be conveniently improved; and the blockage of the inside of the device because raw material fragments are adhered onto the inside of the device during the squeezing can be prevented.

Owner:HUNAN YUHAITANG BIOTECH

Clothes twining prevention device for pulsator semi-automatic washing machine

The invention discloses a clothes twining prevention device for a pulsator semi-automatic washing machine. The device comprises a sliding rod, a sliding sleeve is slidingly connected to the outer wallof the sliding rod, clothes bags are fixed to the outer walls of the two sides of the sliding sleeve through bolts, angle adjusting bases are fixed to the outer wall of the other two sides of the sliding sleeve through hinges, and clothes spreading plates are fixed to the inner walls of the bottoms of the angle adjusting bases through bolts; a vibration spring is welded to the outer wall of the top of the sliding sleeve, a hinge base is fixed to the outer wall of the top of the sliding rod through bolts, the outer wall of the top of the hinge base is fixedly provided with a sleeve rod throughbolts, and bending crank arms are slidingly connected to the inner walls of the two sides of the sleeve rod. According to the clothes twining prevention device, clothes with easily-twined sleeves ortrouser legs are fixed by magnetic clamping pieces on clothes spreading frames and fully spread to be washed and cannot be twined together, and it can also be ensured that the clothes are washed thoroughly; through the cooperation of the clothes bags and the clothes spreading frames, the clothes different in size are classified and washed, and the situation is avoided that small clothes are stuffed in large clothes, washing of the clothes is influenced, and the clothes are insufficiently washed.

Owner:ANHUI JINSHUAI WASHING MACHINE

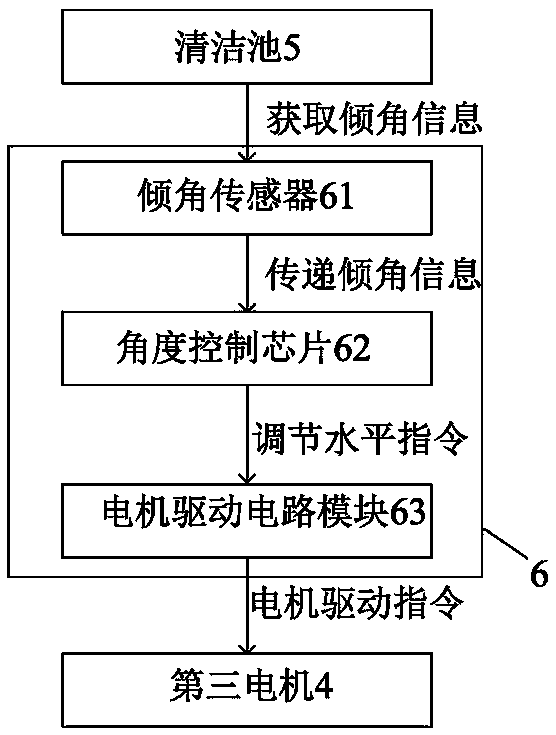

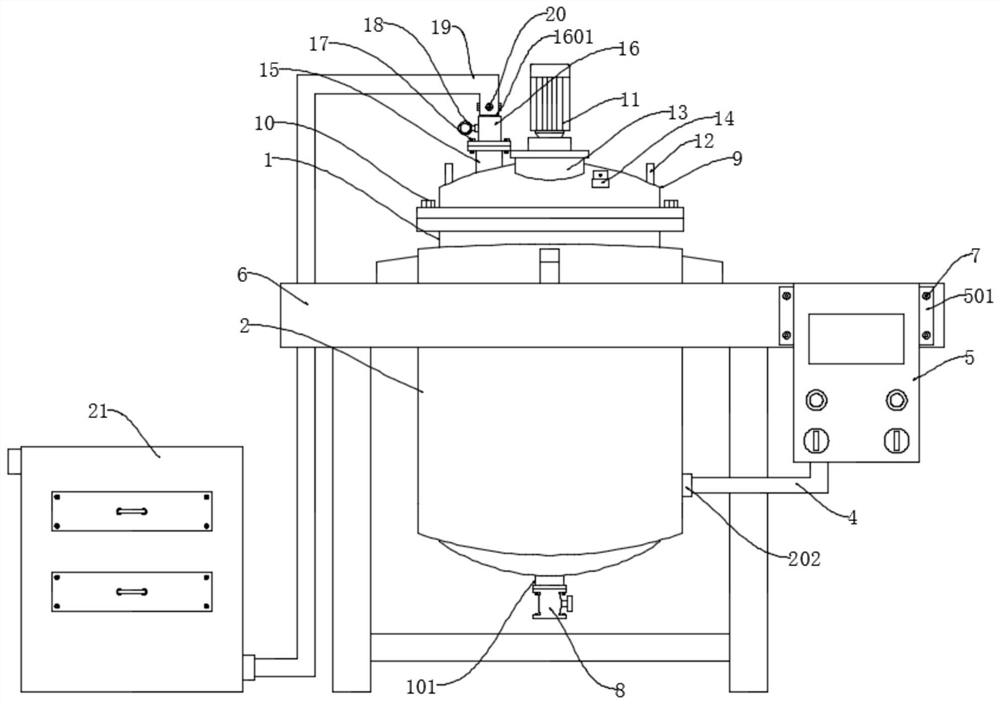

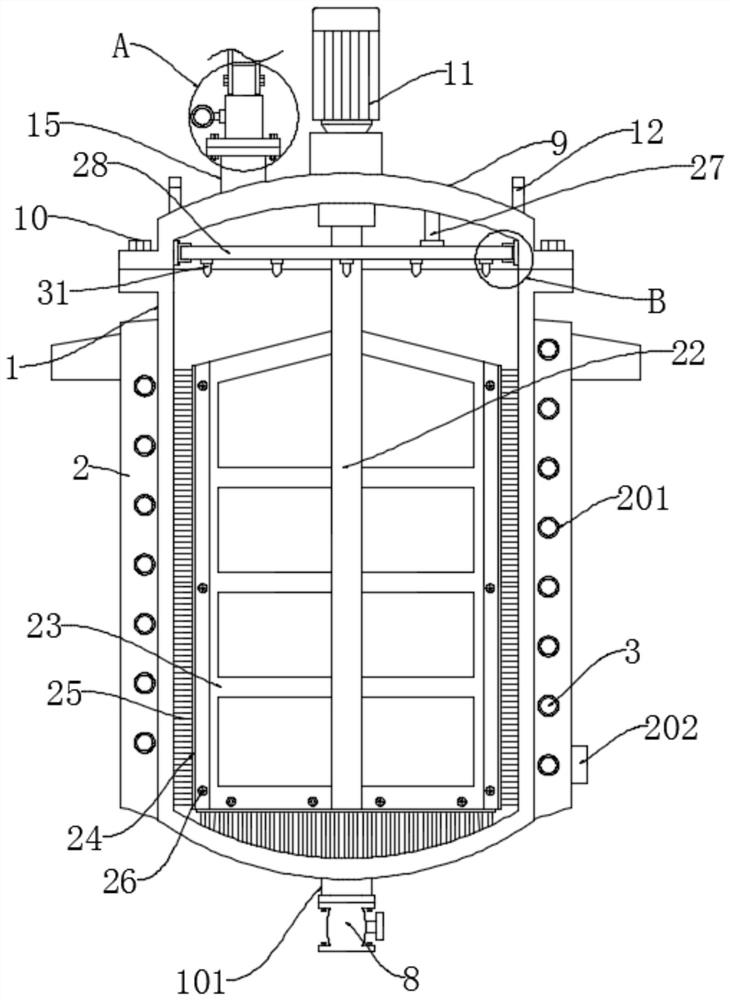

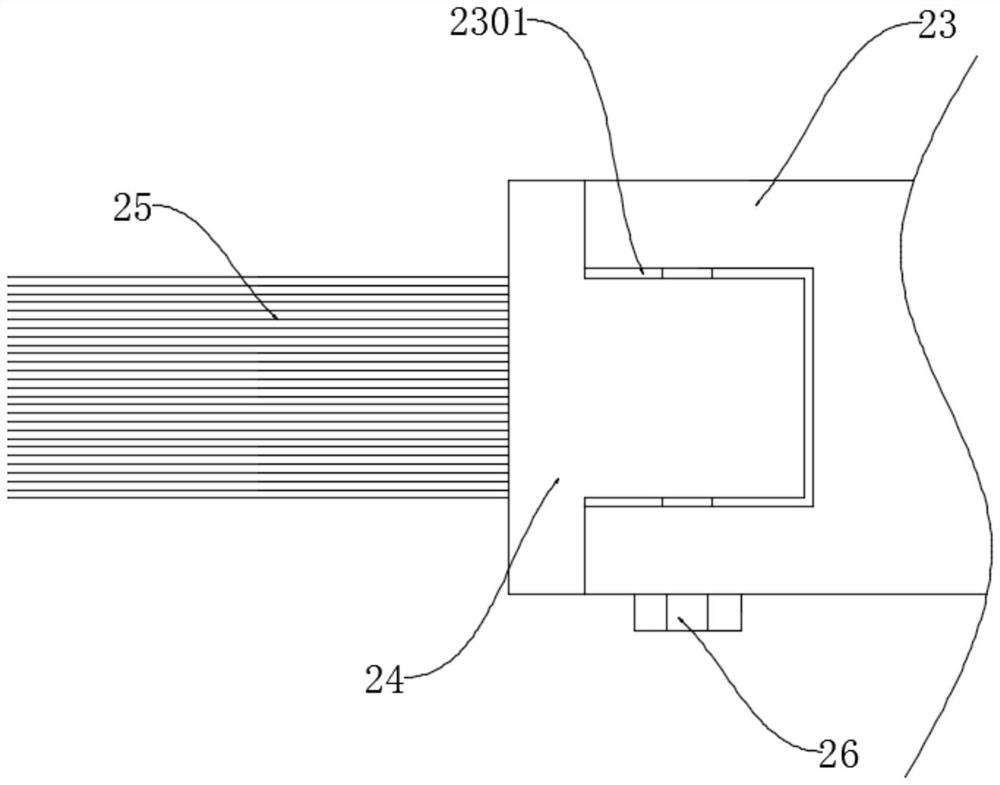

Coal pitch melting equipment in prebaked anode production

InactiveCN112143516AUse impactEasy to cleanRotary stirring mixersTransportation and packagingElectric machineWater flow

The invention discloses coal pitch melting equipment in prebaked anode production, relates to the technical field of coal pitch melting equipment structures, and aims to solve the problem that meltingequipment cannot be effectively cleaned after existing coal pitch melting equipment is used. The coal pitch melting equipment is characterized in that a heating jacket is installed on the periphery of the outer wall of a melting equipment tank, an installation supporting frame is installed on one side of the outer wall of the heating jacket, an electric heating control box is installed at the front end of the installation supporting frame, a tank cover is installed above the melting equipment tank, a stirring motor is installed above the tank cover, a feeding port is formed in the front end of the stirring motor, a water inlet is formed in one side of the feeding port, an exhaust port is formed in one side of the stirring motor, a rotating shaft is installed at the lower end of the stirring motor, stirring rods are installed at the two ends of the rotating shaft, a water inlet pipe is arranged at the lower end of the water inlet, a water flow pipeline is installed at the lower end ofthe water inlet pipe, and a cleaning nozzle is installed below the water flow pipeline.

Owner:赤壁长城炭素制品有限公司

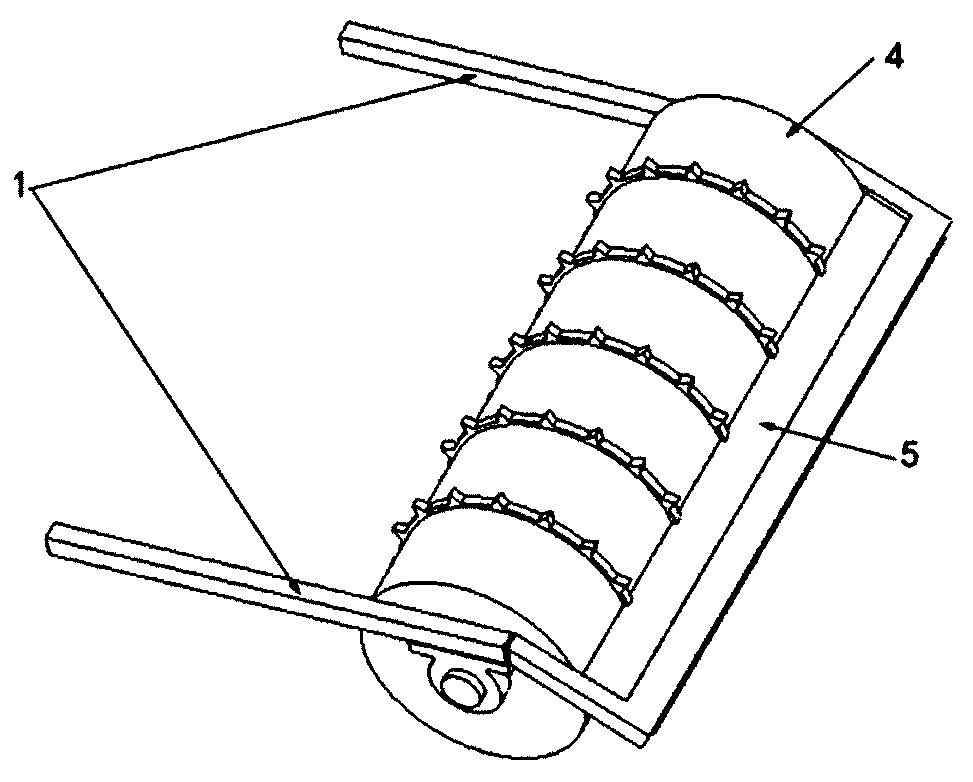

Bathroom quick defogging mirror

The present invention provides a bathroom quick defogging mirror, and belongs to the field of daily necessities manufacturing. The bathroom quick defogging mirror comprises a mirror body and two rollers arranged in parallel; the outer sides of the two rollers are sleeved with an annular structure scrubbing belt which can synchronously rotate with the two rollers; the scrubbing strip is an annularstructure and is arranged around the mirror body; the scrubbing belt is provided with a viewing window; the viewing window can correspond to a mirror surface of the mirror body; and the mirror body isfixed between the two rollers, and the mirror surface of the mirror body is in contact with the scrubbing belt. According to the bathroom quick defogging mirror provided by the present invention, themirror surface is continuously cleaned by the reciprocating rotating rollers to drive the annular structure scrubbing belt, so that the influence on use by the water mist condensate on the mirror surface can be avoided; and when the bathroom quick defogging mirror is not in use, the scrubbing belt can be used to directly cover the mirror surface to avoid dust falling on the mirror surface, and the purpose of automatically drying the scrubbing belt can be also achieved.

Owner:NANNING UNIV

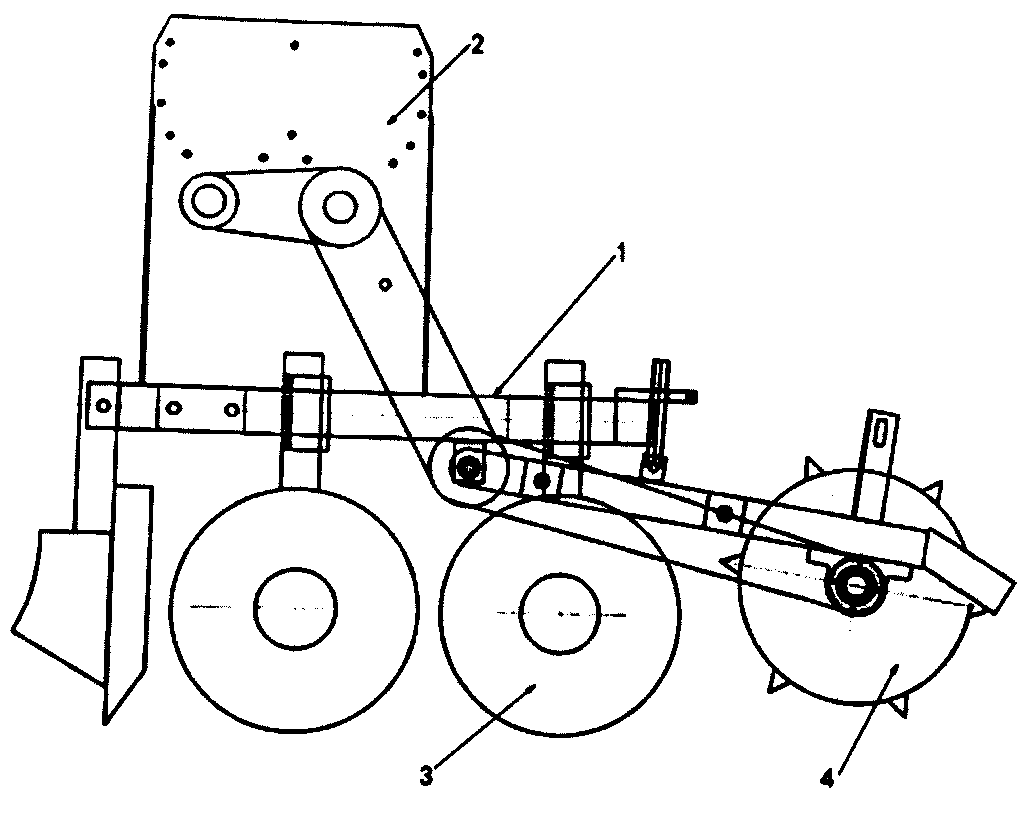

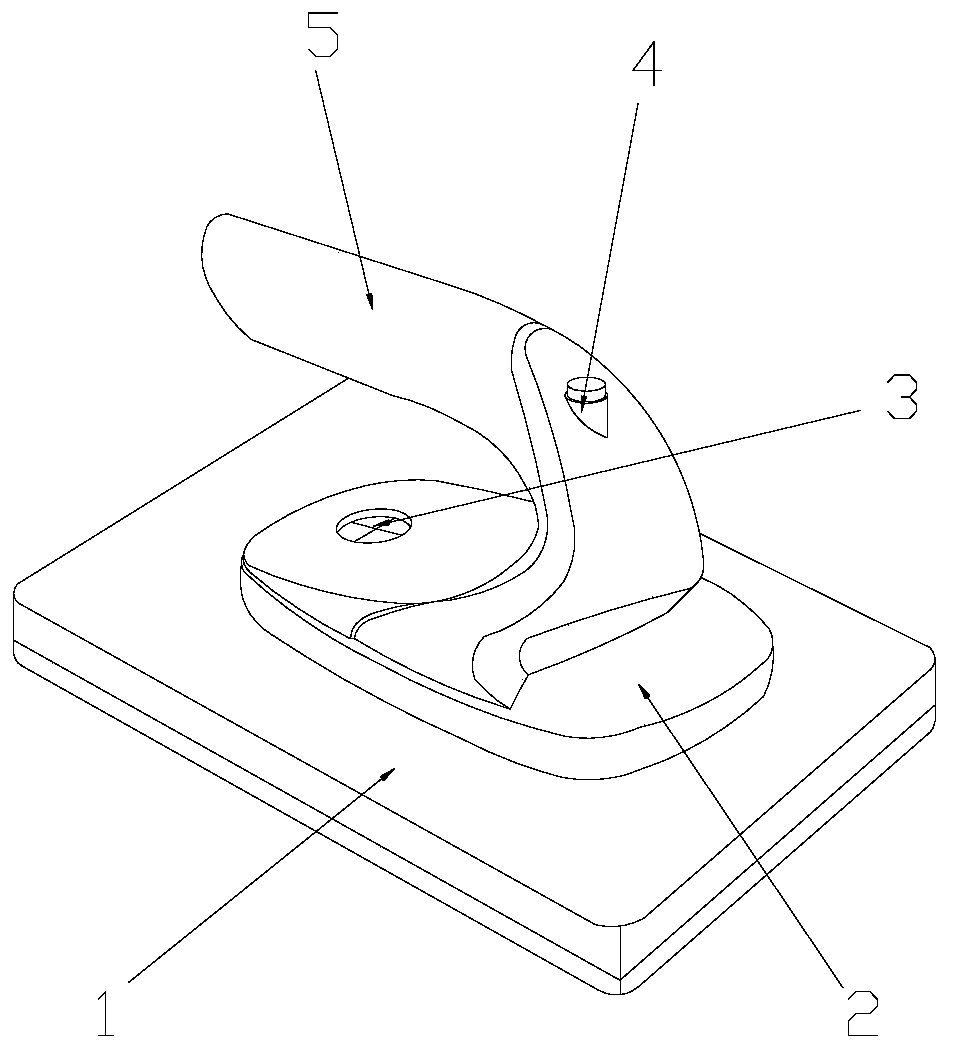

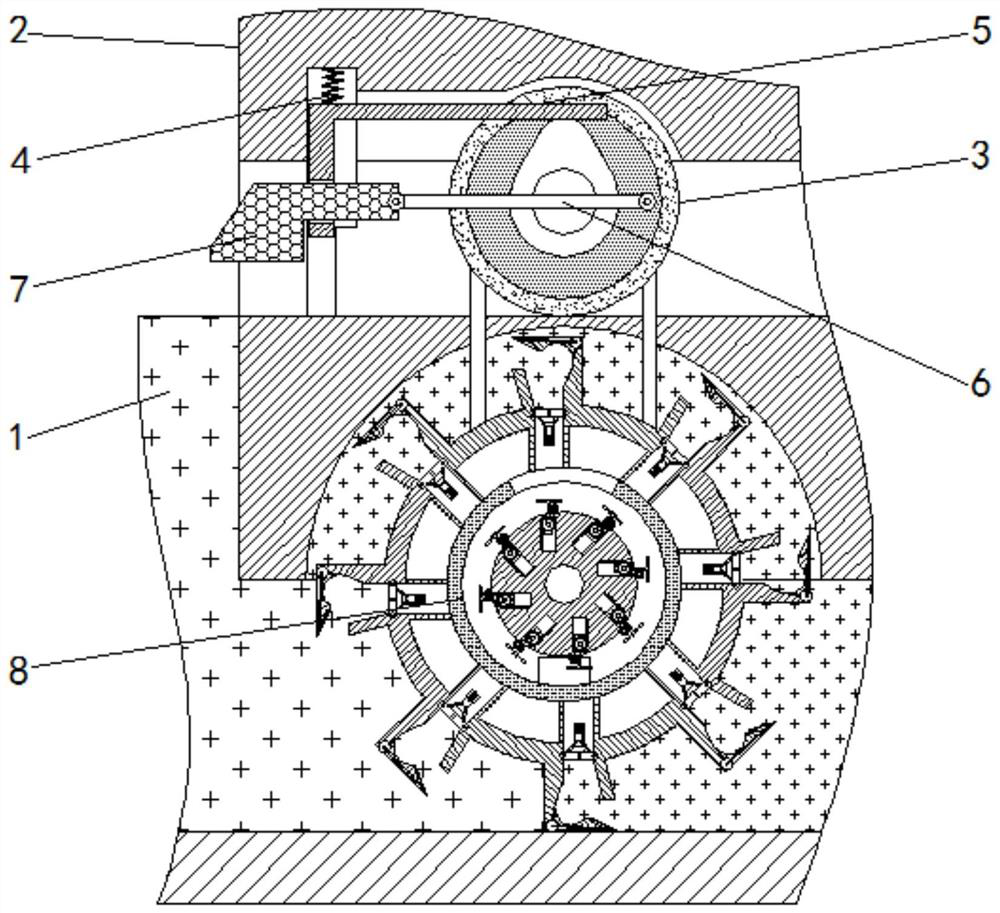

Deep ploughing sower

InactiveCN109104950APrevent disengagementCleaning effectAgricultural machinesFertiliser and seeding apparatusSeederForeign matter

The invention belongs to the technical field of sowing equipment, and particularly relates to a deep ploughing sower, which comprises a rack, and a seed manure tank, a furrow opener and a compacting roller which are arranged on the rack; a scraper connected with the compacting roller is arranged on the rack, is used for clearing up soil on the outer surface of the compacting roller, and is connected with the rack in an inserting manner; a corresponding inserting groove is formed in the rack; one end of the scraper can extend out of the inserting groove and is in contact with the compacting roller; and the scraper and the rack are fixed by means of a bolt. Foreign matters adhered to the scraper can be conveniently cleared up through simple pulling and inserting operations, so that the clearing effect of the scraper on the compacting roller is not influenced.

Owner:XINJIANG COUNTY YINONG SOWING MACHINERY CO LTD

Household kitchen oil stain cleaner

ActiveCN110918513ACleaning effectSave cleaning timeCleaning using toolsEnvironmental engineeringMechanical engineering

The invention discloses a household kitchen oil stain cleaner. The household kitchen oil stain cleaner structurally comprises a cleaning structure, a connecting seat, a filling port, a button, a handle, wherein the connecting seat is horizontally mounted at the upper end of the cleaning structure, the filling port penetrates through the connecting seat and is connected with the upper end of the cleaning structure, the button is mounted at the front end of the handle, and the handle is horizontally mounted at the rear end of the upper portion of the connecting seat, the cleaning structure comprises a water tank, a supporting plate, a brushing structure and a stain absorbing structure, the water tank is horizontally mounted at the upper end of the supporting plate, the brushing structure ishorizontally embedded at the lower end of the inner side of the supporting plate, the stain absorbing structure penetrates through the water tank and is connected with the inner side of the supportingplate, the brushing structure surrounds the outer side of the stain absorbing structure. According to the household kitchen oil stain cleaner, the brushing structure is arranged at the lower end of the supporting plate, the cleaning solution is prevented from slipping too quickly to affect the cleaning of oil stains, the cleaning time of oil stains is reduced, the stain absorbing structure is arranged on the inner side of the brushing structure, the stains from being brushed are prevented from slipping off and polluting other positions, and the cleaning is more convenient and rapid.

Owner:诸暨市青辰科技服务有限公司

Paint spraying device with anti-splashing structure for metal product machining

The invention relates to the technical field of metal product machining and in particular discloses a paint spraying device with an anti-splashing structure for metal product machining. The paint spraying device comprises a paint spraying box. A box door is rotatably connected to the upper end of the front surface of the paint spraying box close to the center position, an observation hole penetrating the box door longitudinally is formed in the center of the front surface of the box door, a top surface groove is formed in the center of the top surface of the inner wall of the paint spraying box, and a T-shaped fixed block is fixedly connected to the top surface of the inner wall of the top surface groove. As two electric telescopic rods are rotatably connected to the top surface groove andthe bottom surface groove separately, a metal between two clamping plates can be driven to rotate, so that it is convenient to paint spray to different surfaces of the metal, and therefore, the paintspraying efficiency is improved. By arranging the box door and the paint spraying box, the probability that the paint is splashed to staff in the paint spraying process can be reduced, so that influence on cleaning clothes of the staff is reduced.

Owner:苏州市华艺金属制品有限公司

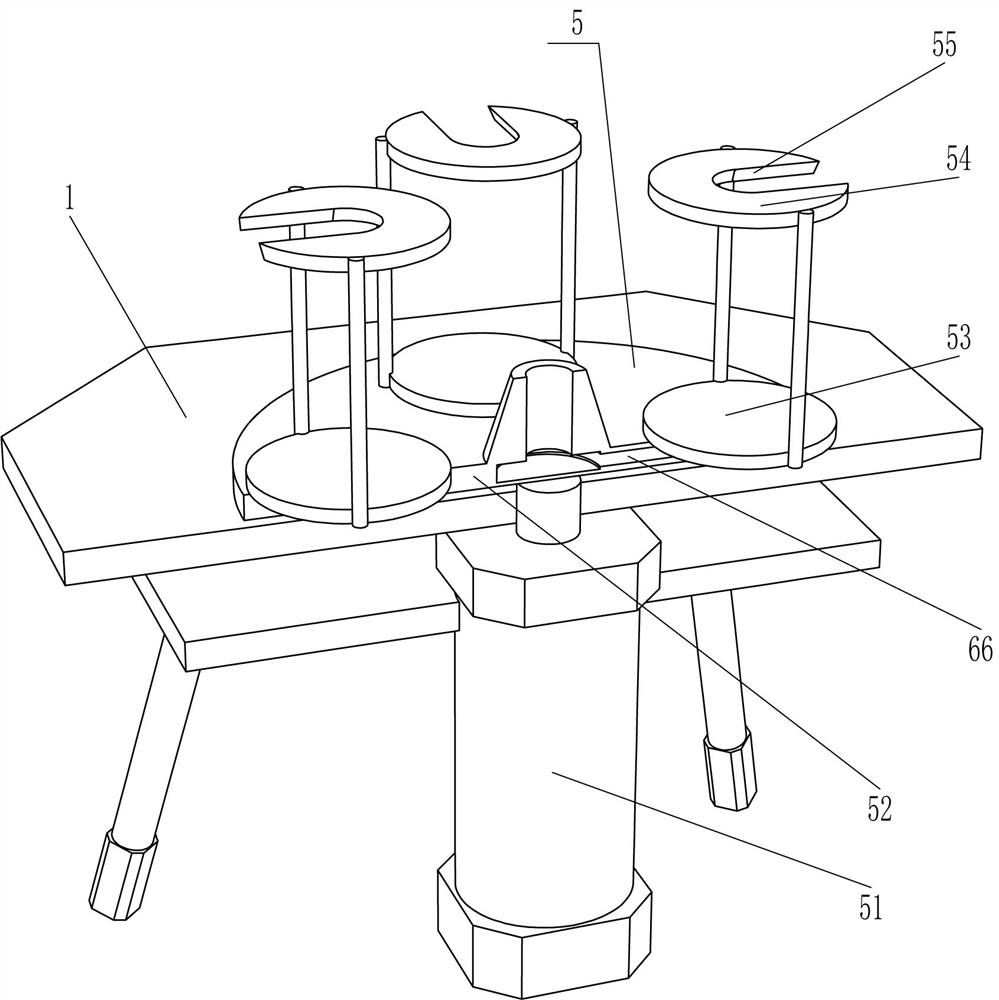

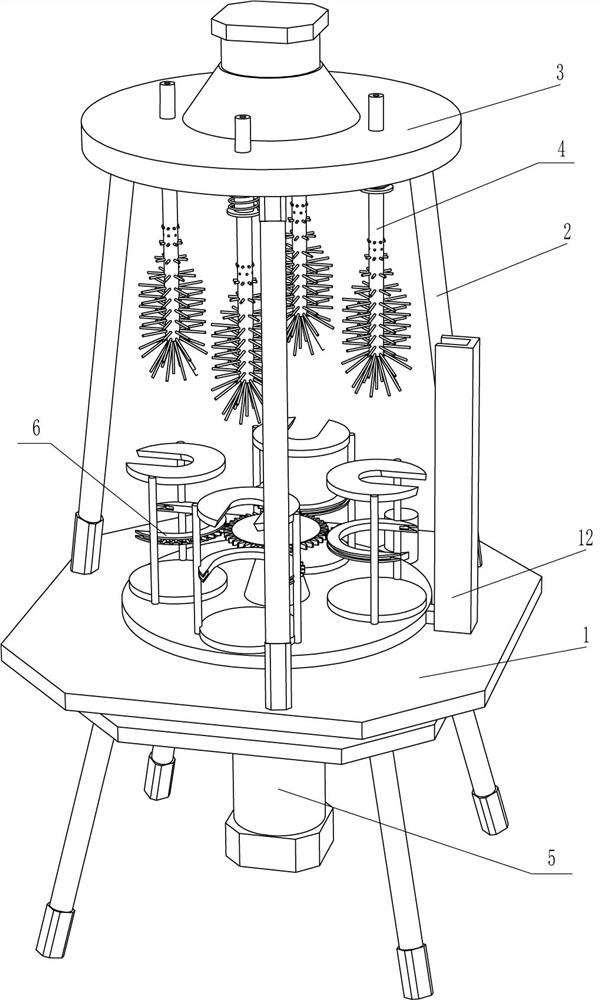

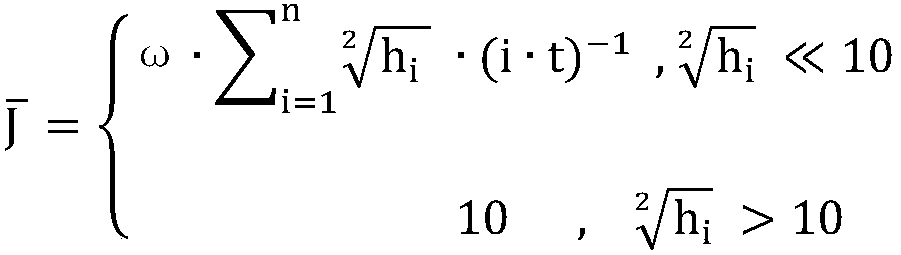

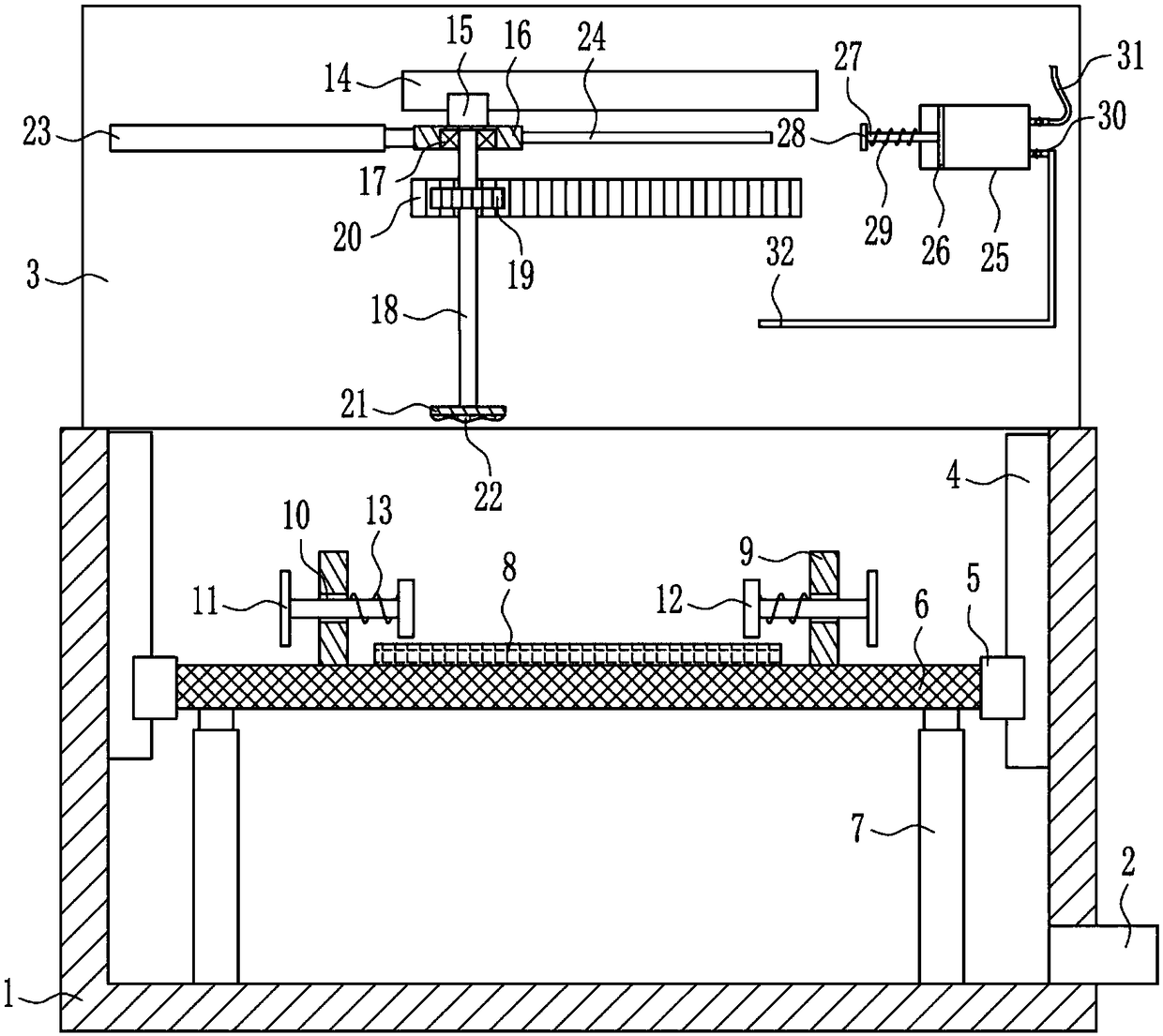

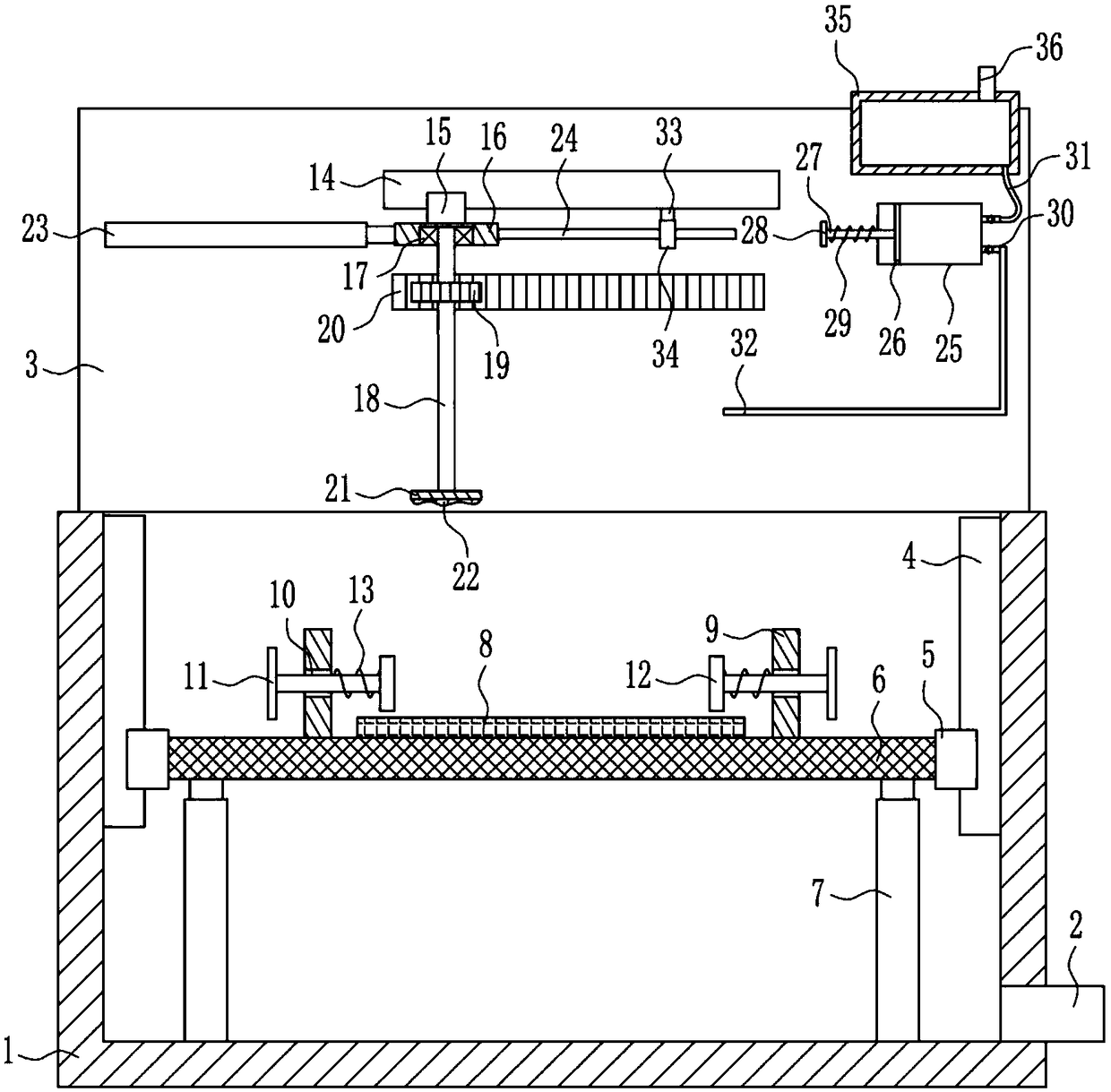

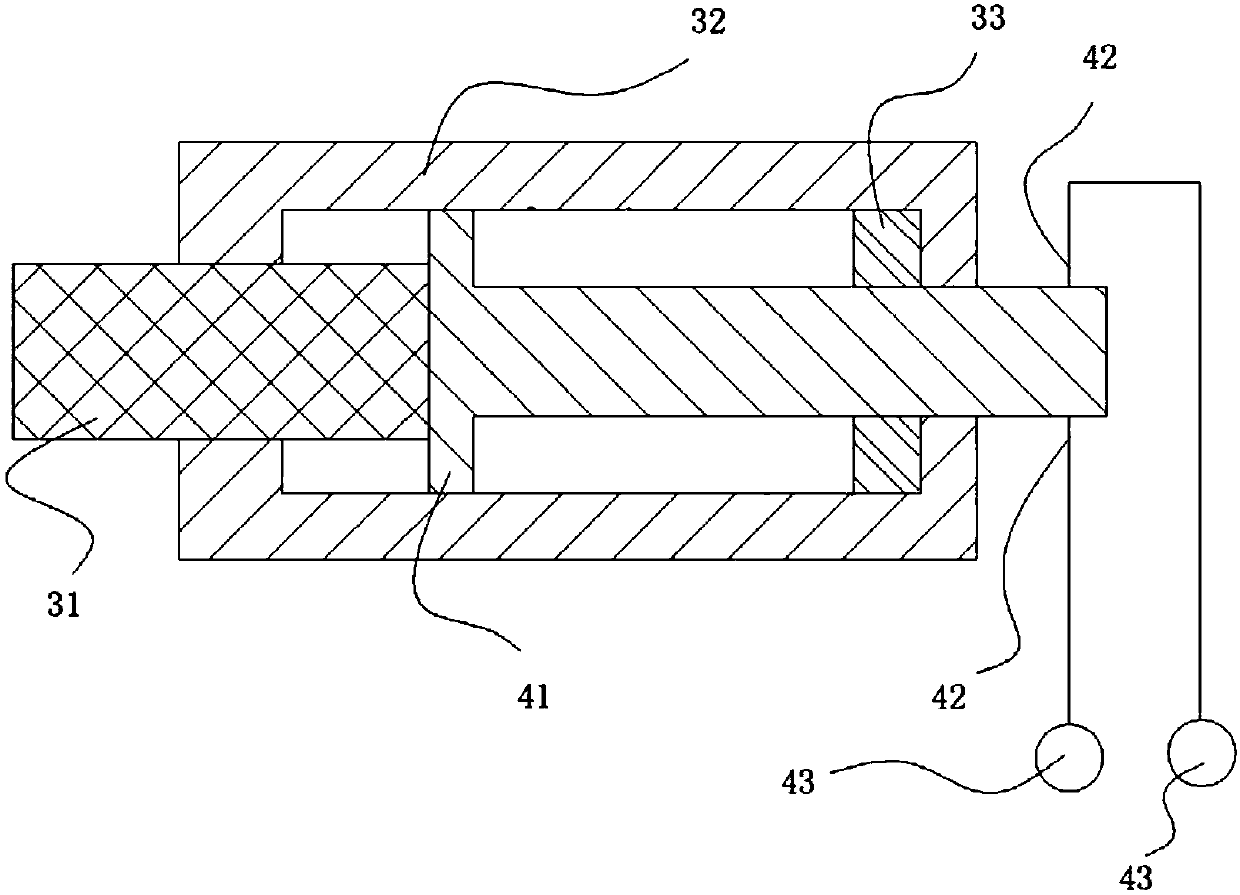

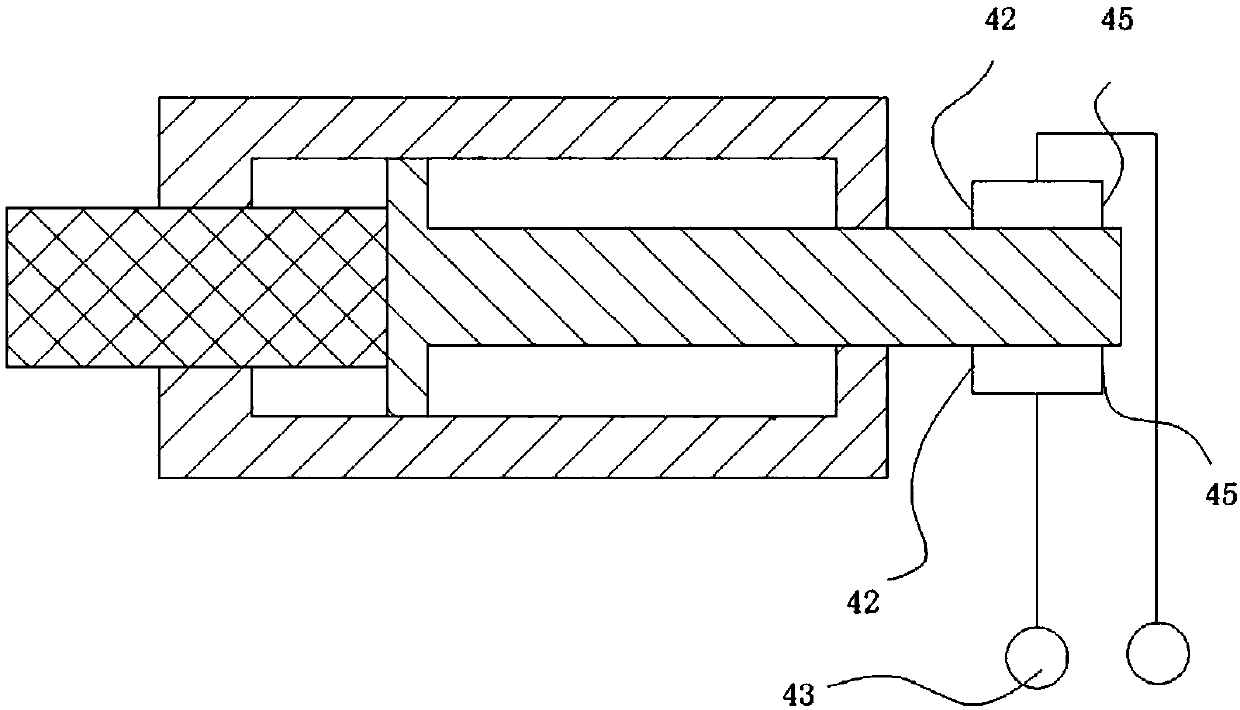

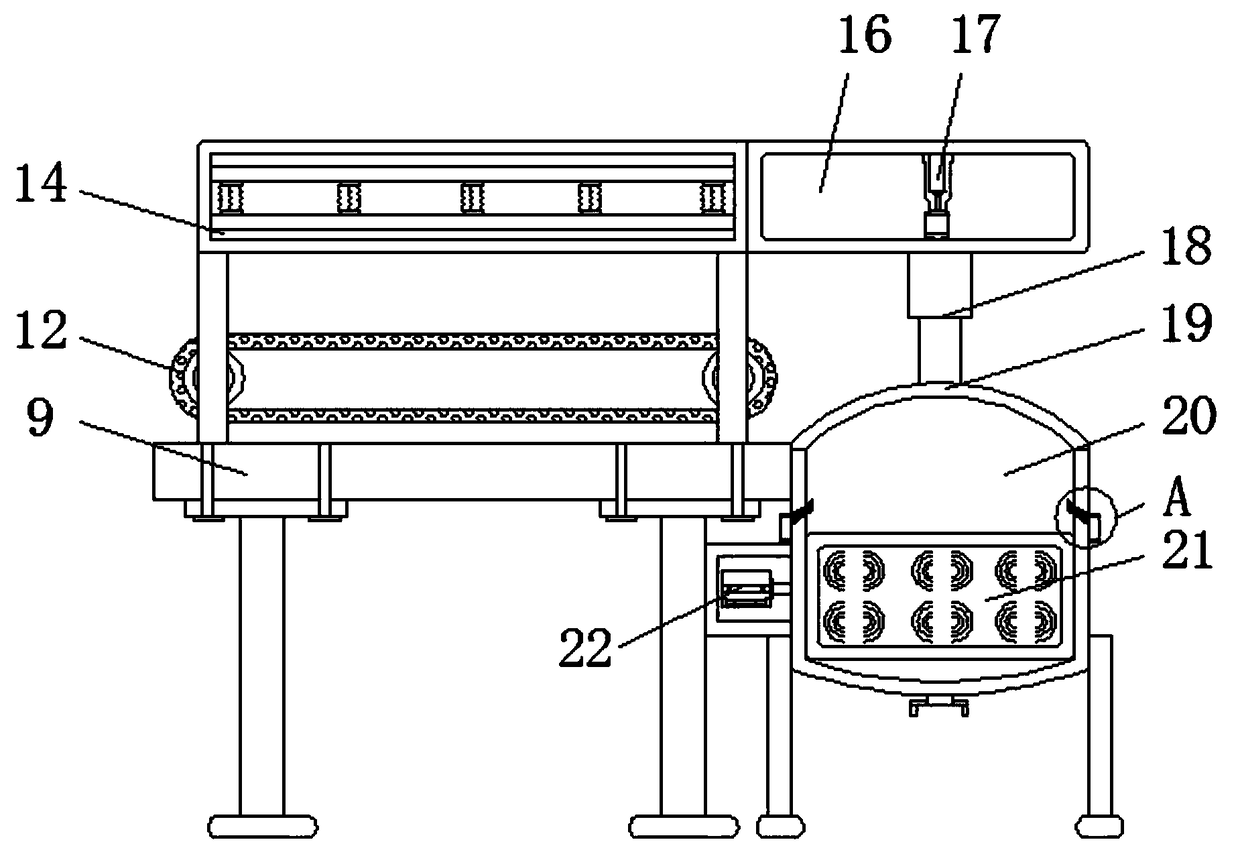

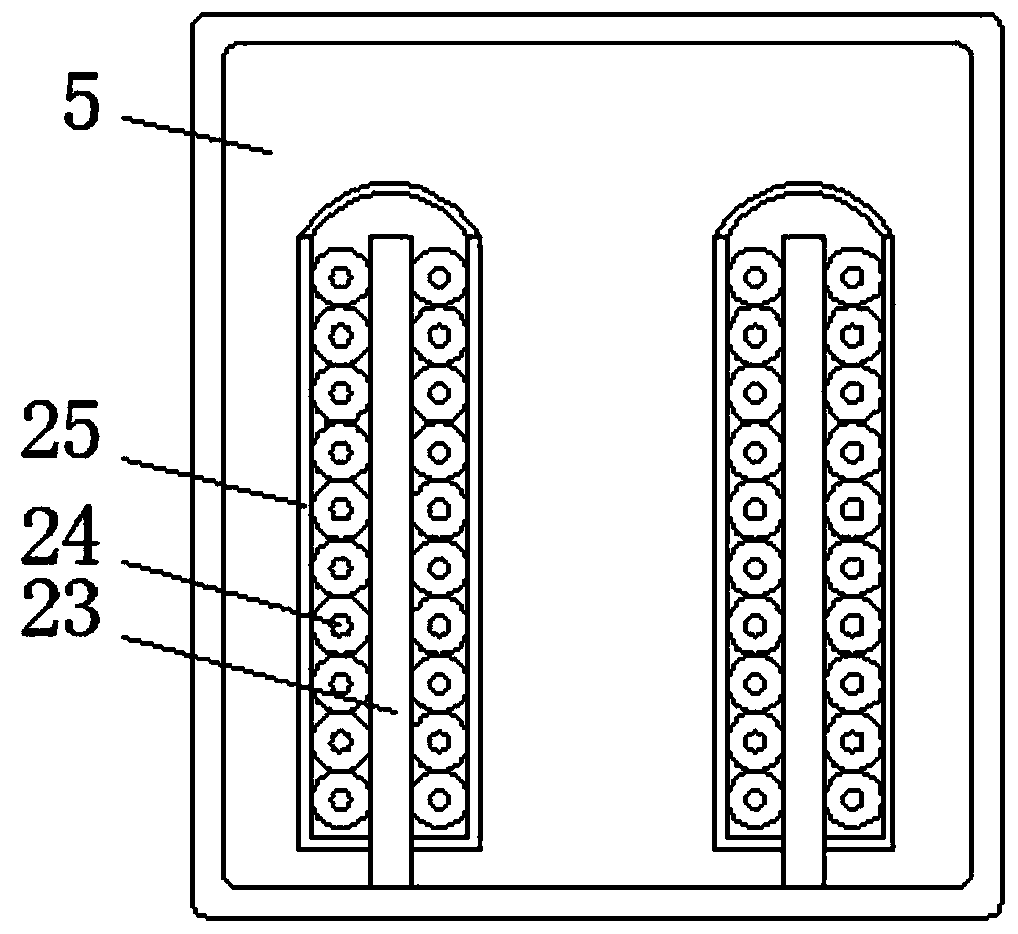

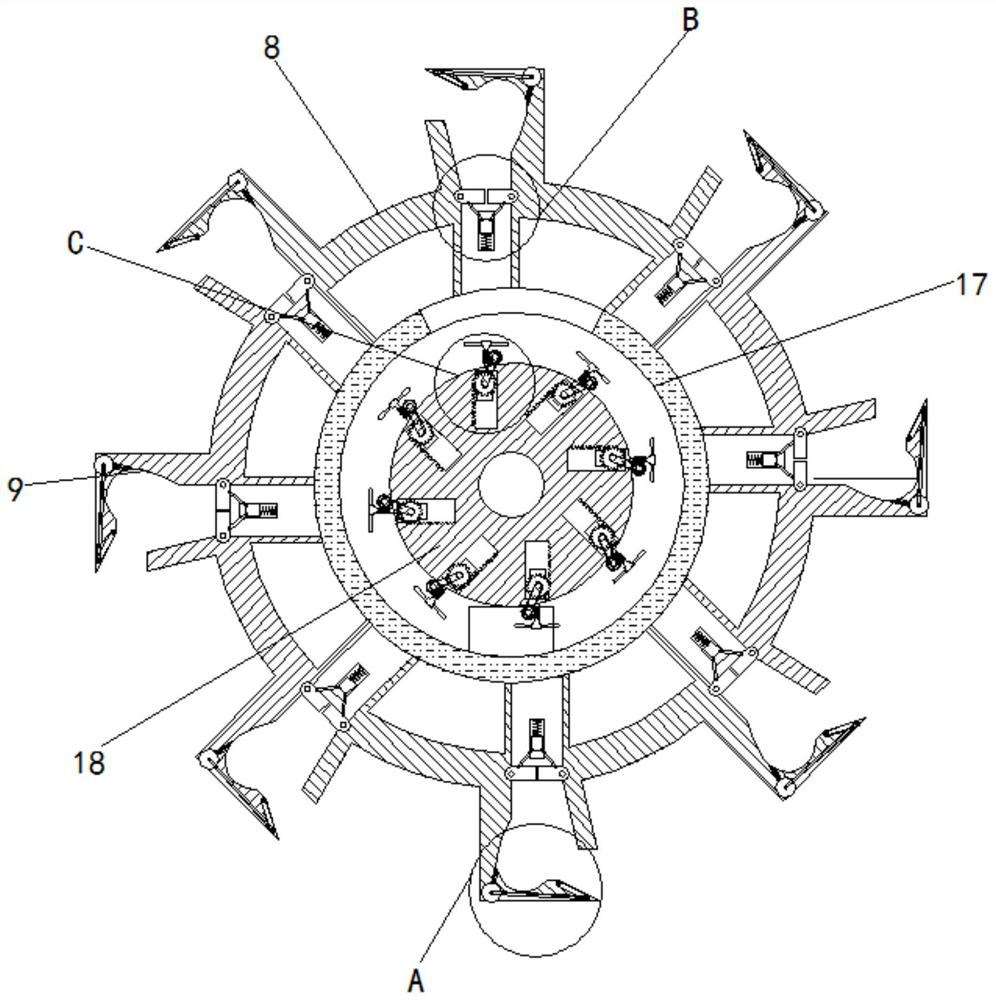

Beverage bottle inner wall rapid cleaning equipment

PendingCN112427430AEasy to operateImprove work efficiencyHollow article cleaningElectric machineryEngineering

The invention relates to cleaning equipment, in particular to beverage bottle inner wall rapid cleaning equipment. The technical aim to be achieved is how to design the beverage bottle inner wall rapid cleaning equipment. The equipment can replace manual work to clean the inner walls of beverage bottles, is convenient to operate and labor-saving, can clean the inner walls of the four beverage bottles at a time and is high in working efficiency. The beverage bottle inner wall rapid cleaning equipment comprises a double-layer fixing frame, and four supporting rods are fixedly connected to one side of the double-layer fixing frame at intervals. The four beverage bottles are placed on putting frames, an air cylinder is started, a mounting disc can drive the beverage bottles to move upwards through the putting frames to sleeve brush hollow rods, the air cylinder is stopped, a motor is started, the brush hollow rods can rotate to clean the inner walls of the beverage bottles through water, therefore people do not need to clean the inner walls of the beverage bottles manually, labor is saved, operation is convenient, and working efficiency is high.

Owner:林超辉

Traditional Chinese medicine composition for treating urticaria

InactiveCN103656413ASymptoms improvedClean skinAnthropod material medical ingredientsHydroxy compound active ingredientsSide effectCeltis sinensis

The invention discloses traditional Chinese medicine composition for treating urticaria. The composition comprises raw materials in parts by weight as follows: 10-15 parts of golden cypress, 10-15 parts of divaricate saposhnikovia roots, 15-20 parts of broom cypress fruits, 5-10 parts of cortex dictamni, 12-16 parts of longan leaves, 10-15 parts of radix sophorae flavescentis, 14-18 parts of artemisia apiacea, 15-20 parts of folium artemisiae argyi, 10-15 parts of tribulus terrestris, 5-10 parts of celtis sinensis leaves, 10-15 parts of radix angelicae, 5-10 parts of cherry stones, 10-15 parts of schizonepeta spikes, 6-12 parts of pepper roots, 10-15 parts of radix stemonae, 5-10 parts of fructus cnidii, 10-15 parts of chlamydoboea sinensis, 8-14 parts of rhizoma atractylodis, 5-10 parts of jasmine, 4-8 parts of liquidambar formoana hance fruits, 10-15 parts of magnolia officinalis, 15-20 parts of silkworm excrement, 6-12 parts of calamine, 8-14 parts of alumen and 10-15 parts of borneol. The traditional Chinese medicine composition has functions of clearing heat, cooling blood, expelling wind, relieving exterior syndromes, moistening skin, eliminating dampness, killing parasite, relieving itching, promoting eruption and eliminating rash and is significant in effect of treatment of the urticaria, quick in action, instant in effect, short in treatment cycle, capable of avoiding recurrence after recovery, free from side effects and adverse reactions, low in price, safe and reliable.

Owner:青岛米品品服装有限公司

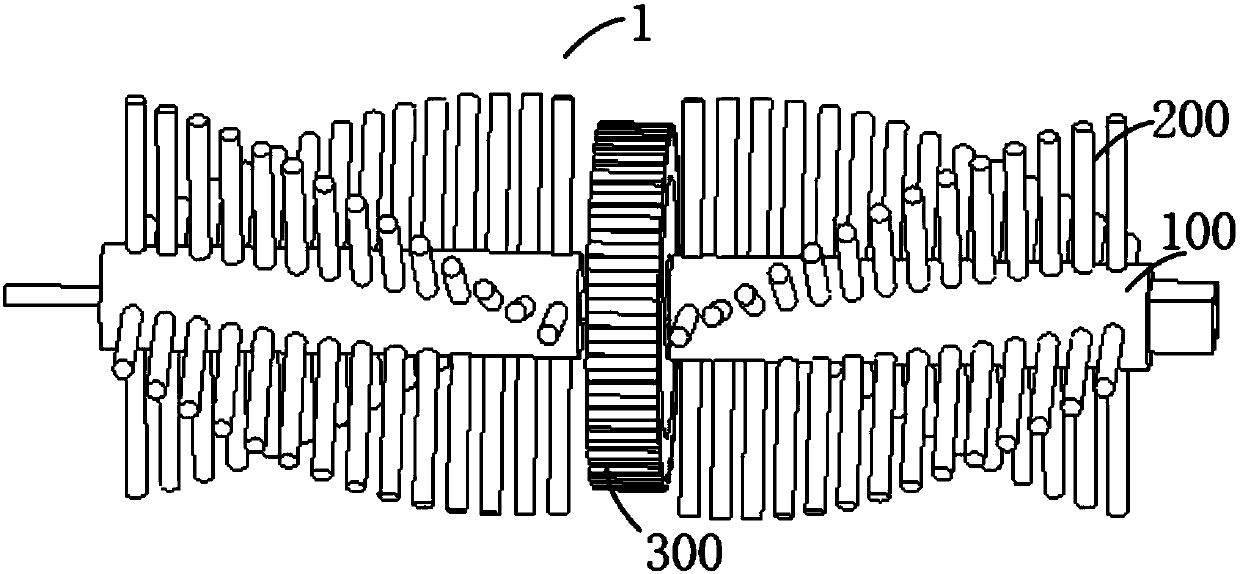

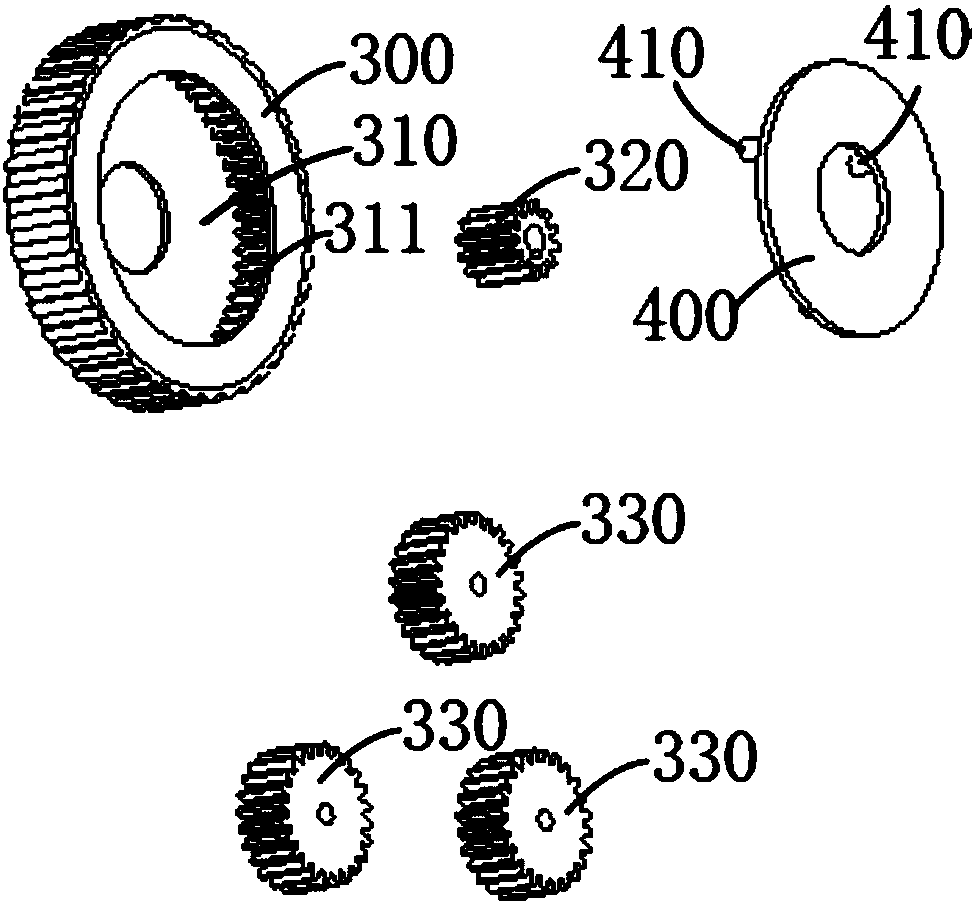

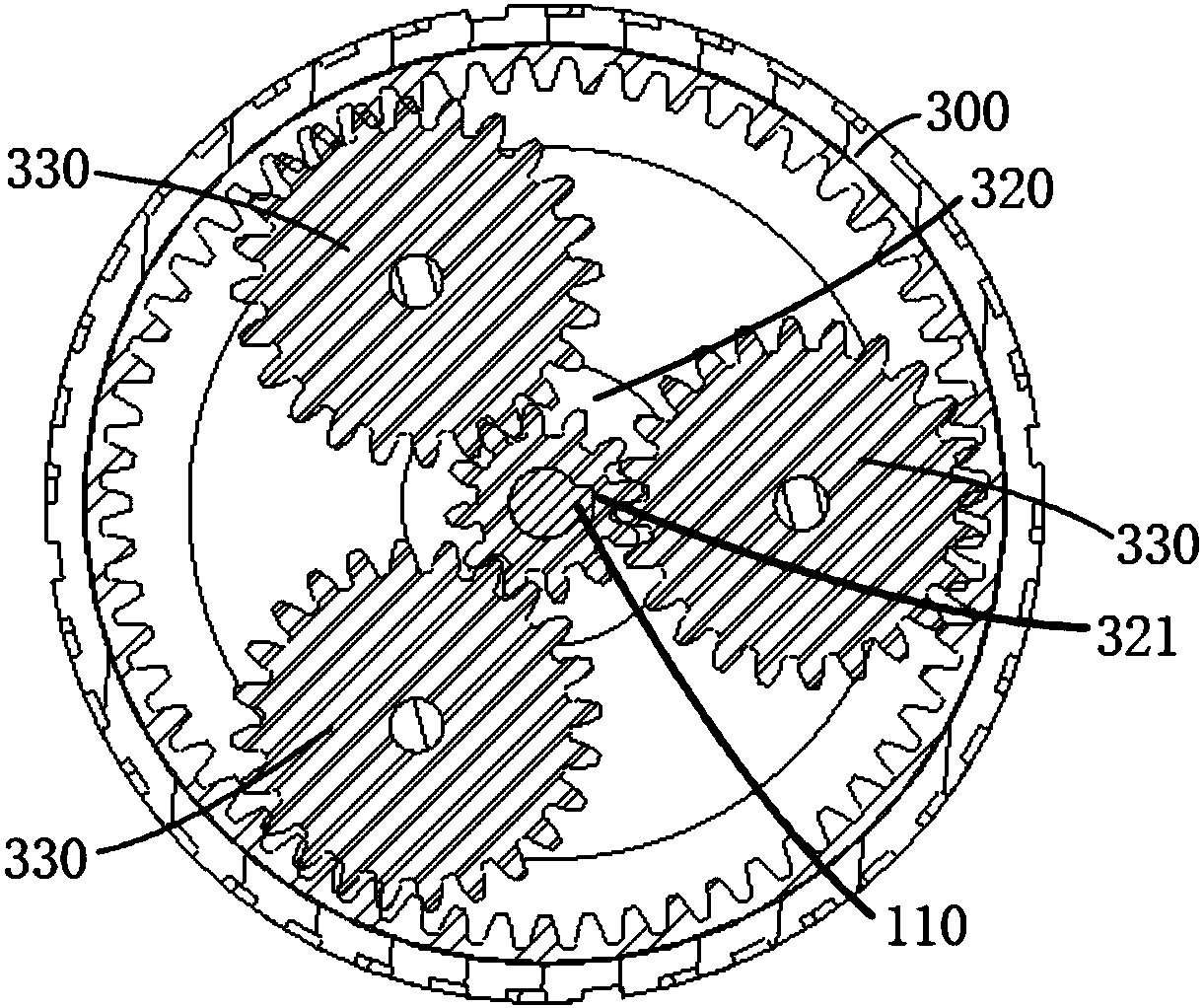

Roller brush assembly of dust collector and dust collector with roller brush assembly

The invention discloses a roller brush assembly of a dust collector and the dust collector with the roller brush assembly. The roller brush assembly of the dust collector comprises a roller brush shaft, brush bristles, a power assisting wheel, a roller brush driving device and a power assisting wheel driving device, wherein the brush bristles are arranged on the roller brush shaft and rotate together with the roller brush shaft; the power assisting wheel sleeves the roller brush shaft in a manner of being capable of rotating relatively; the roller brush driving device is in transmission connection with the roller brush shaft for driving the roller brush shaft to rotate; the power assisting wheel driving device is in transmission connection with the power assisting wheel for driving the power assisting wheel to rotate. The roller brush assembly of the dust collector provided by the embodiment of the invention has the advantages that the cleaning effect is good, the use is convenient, etc.

Owner:MIDEA ROBOZONE TECH CO LTD

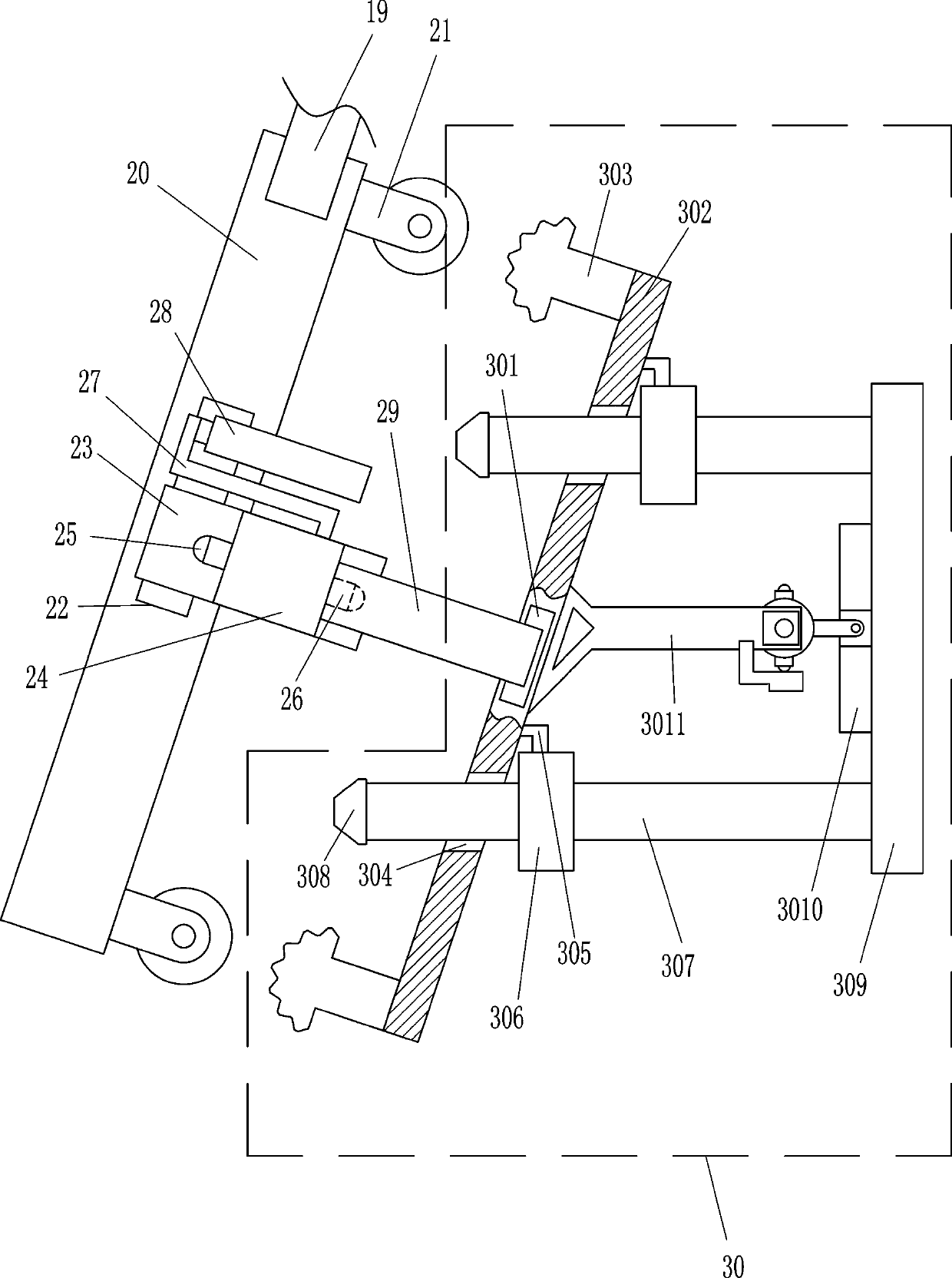

metal pipe cutting machine

ActiveCN104014865BImprove cleanlinessCleaning effectTube shearing machinesShearing machine accessoriesMotor driveMachining process

A metal tube cutting machine comprises a driving unit and a cutting unit, wherein the driving unit specifically comprises a motor and an air cylinder, the cutting unit specifically comprises round cutters and an outer shell above the cutters, a cutting shaft is sleeved with the round cutters, one side of the cutting shaft is provided with a bearing connected with the air cylinder, the cutting shaft is connected with the motor driving the cutting shaft to rotate, a metal tube containing platform is arranged below the cutters, and the upper surface of the metal tube containing platform is provided with a plurality of pneumatic clamps. In a machining process, the cutting shaft presses downwards, each cutter is arranged between every two pneumatic clamps, the left end of the metal tube containing platform protrudes upwards to form a limiting platform, the height of the limiting platform is consistent with that of each pneumatic clamp, a lifting column is arranged below the left portion of the metal tube containing platform and connected with the air cylinder, and the right side of the metal tube containing platform is provided with a blanking basket. The metal tube cutting machine can be used for machining a plurality of sets of metal tubes at a time and is higher in efficiency, lower in cost and more convenient to maintain, and only the distance between every two round cutters needs to be changed when the machining lengths of the metal tubes change.

Owner:DONGQING TECH

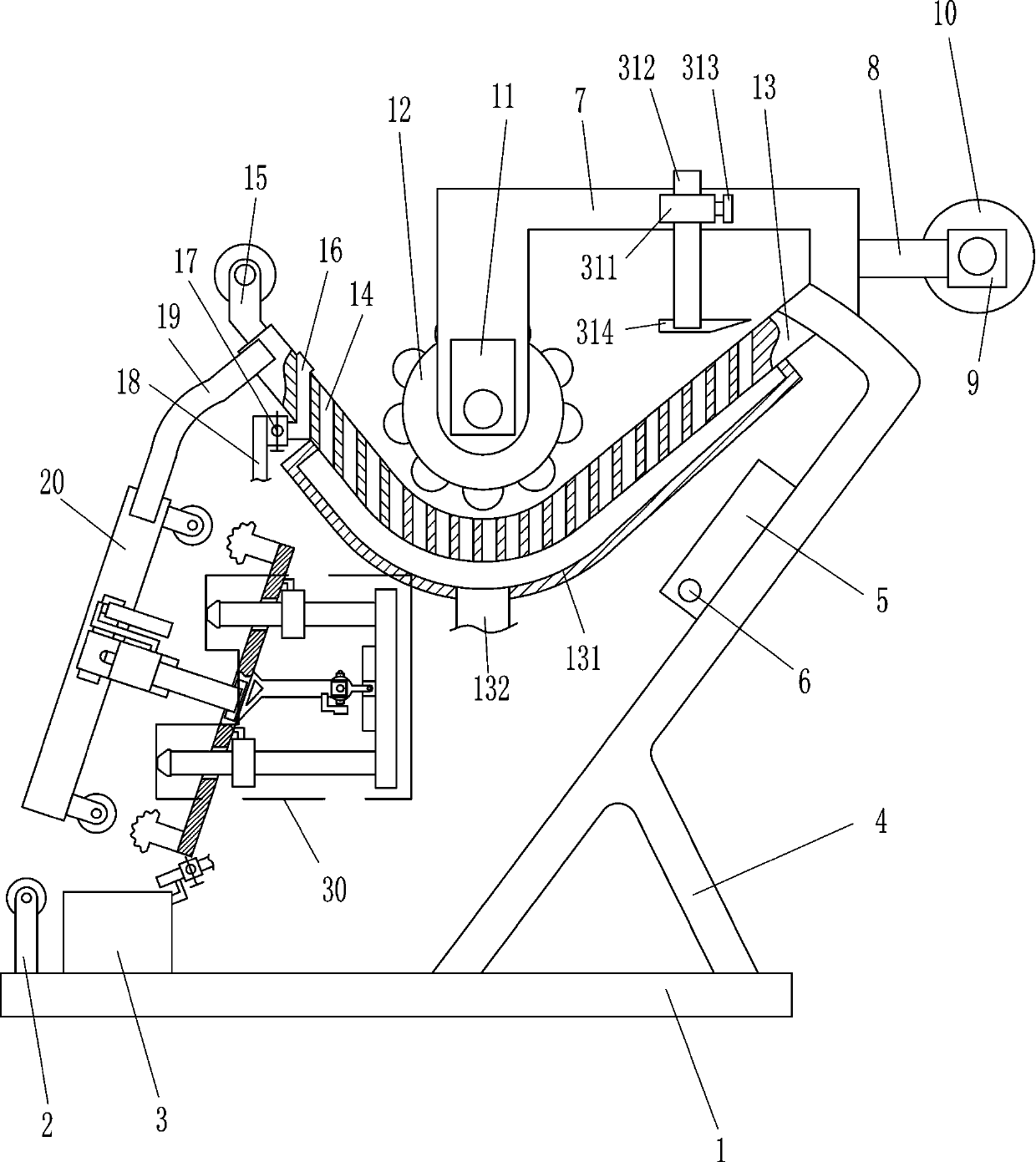

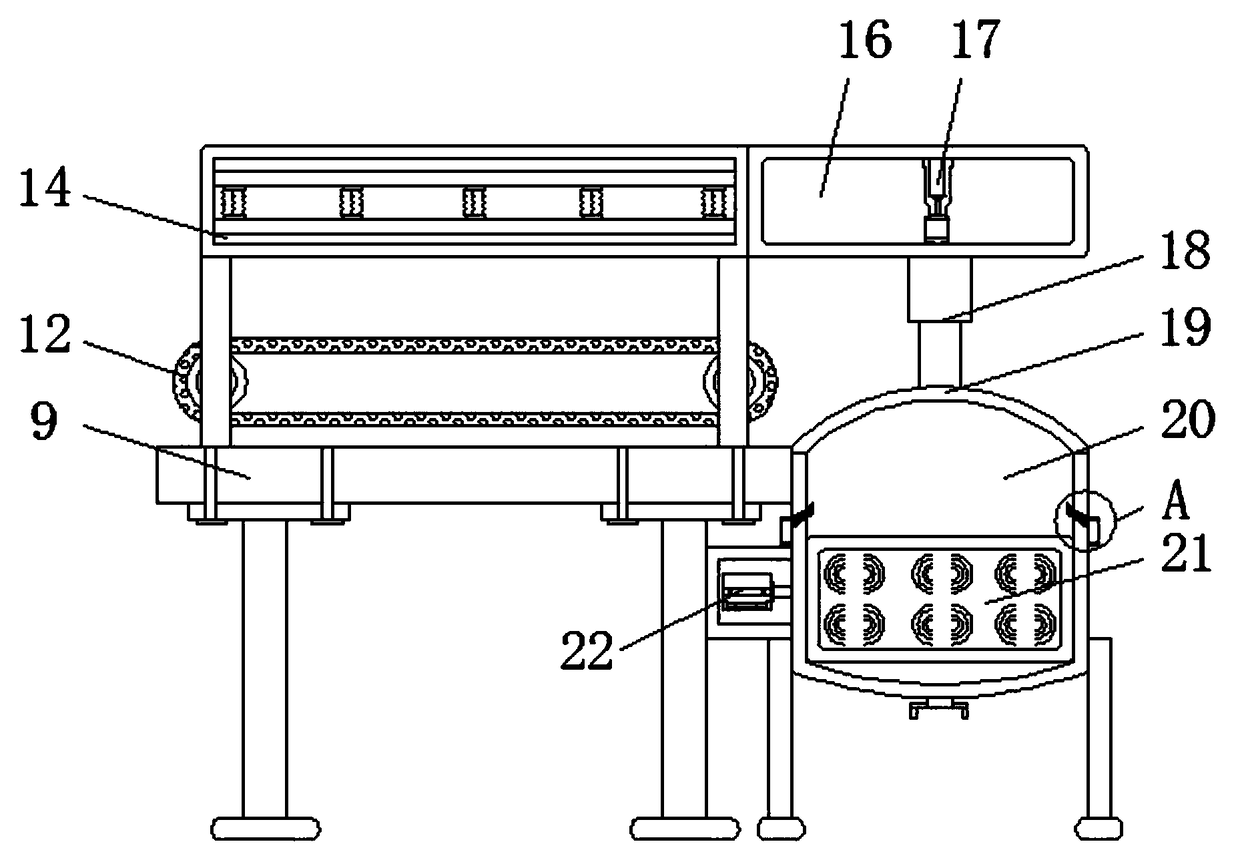

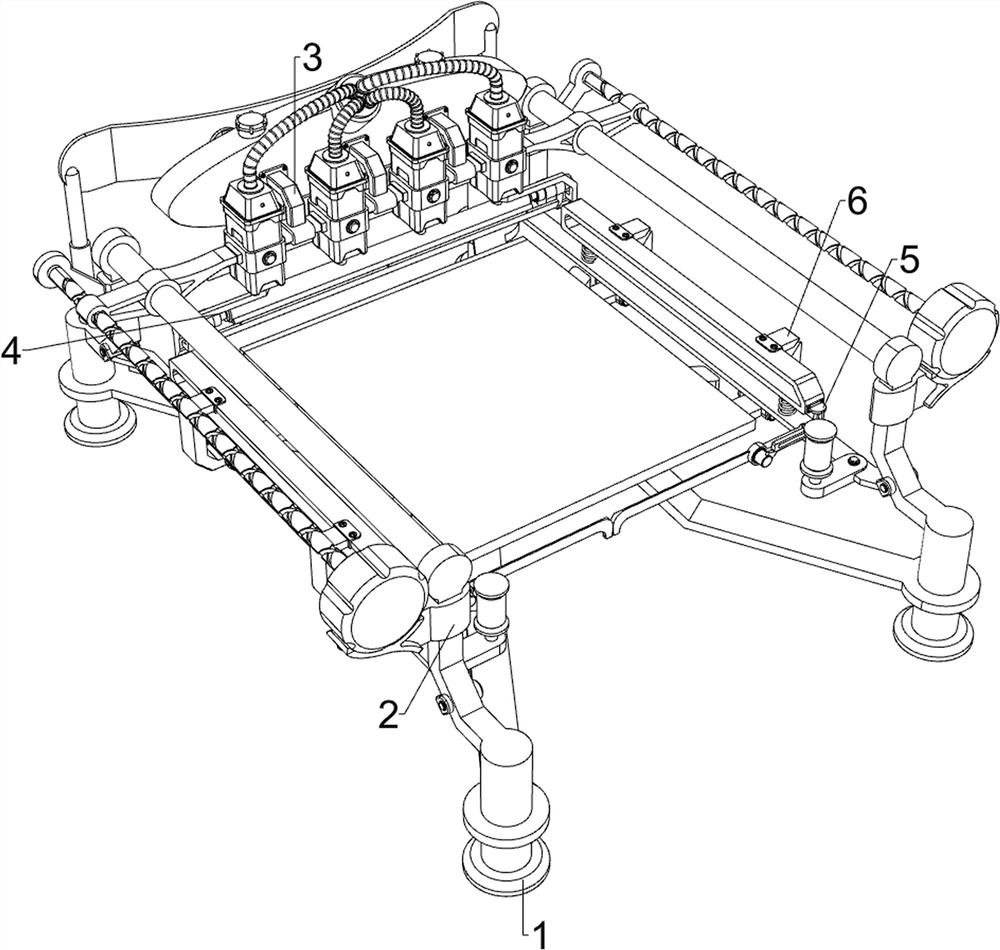

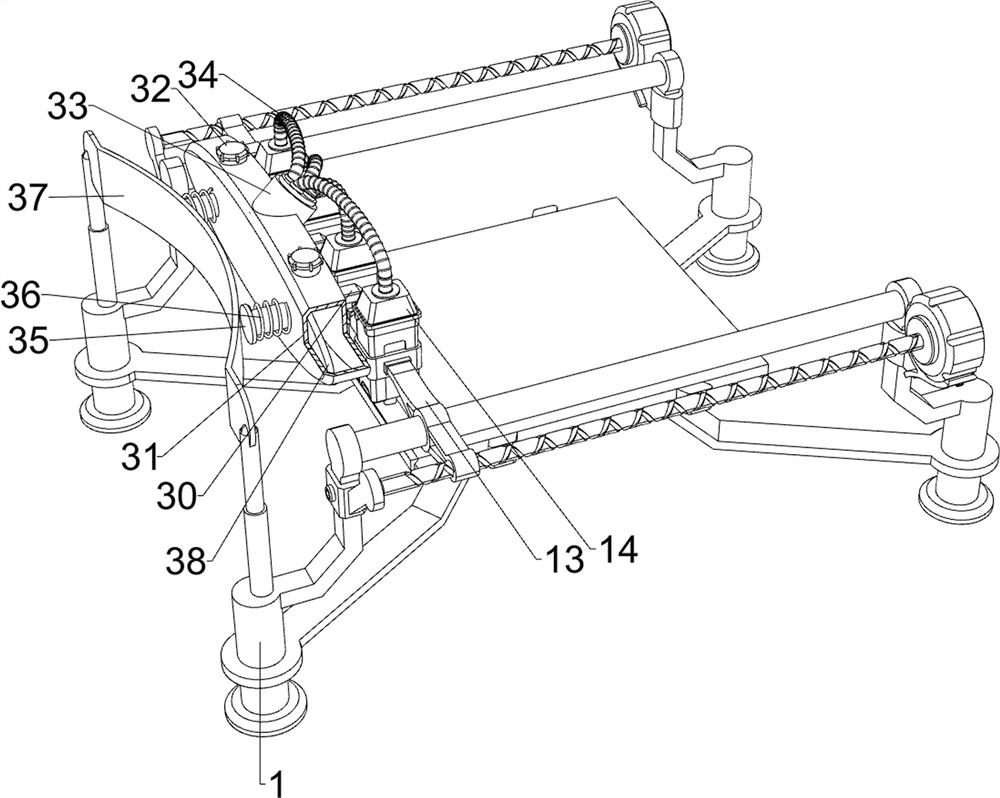

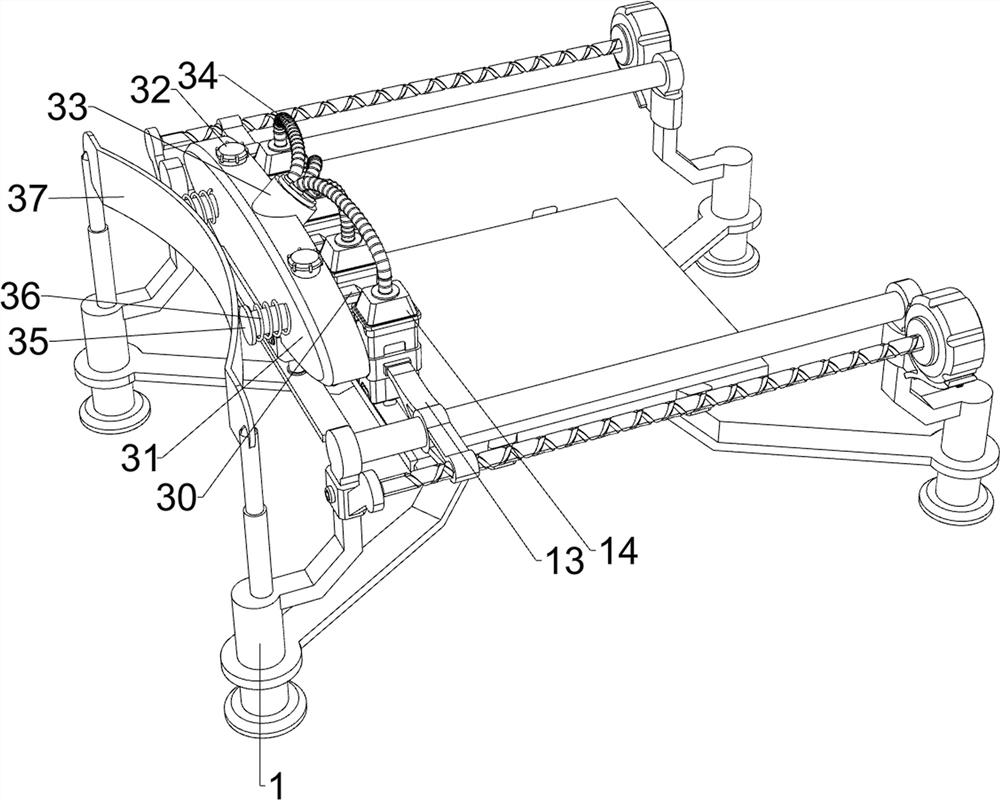

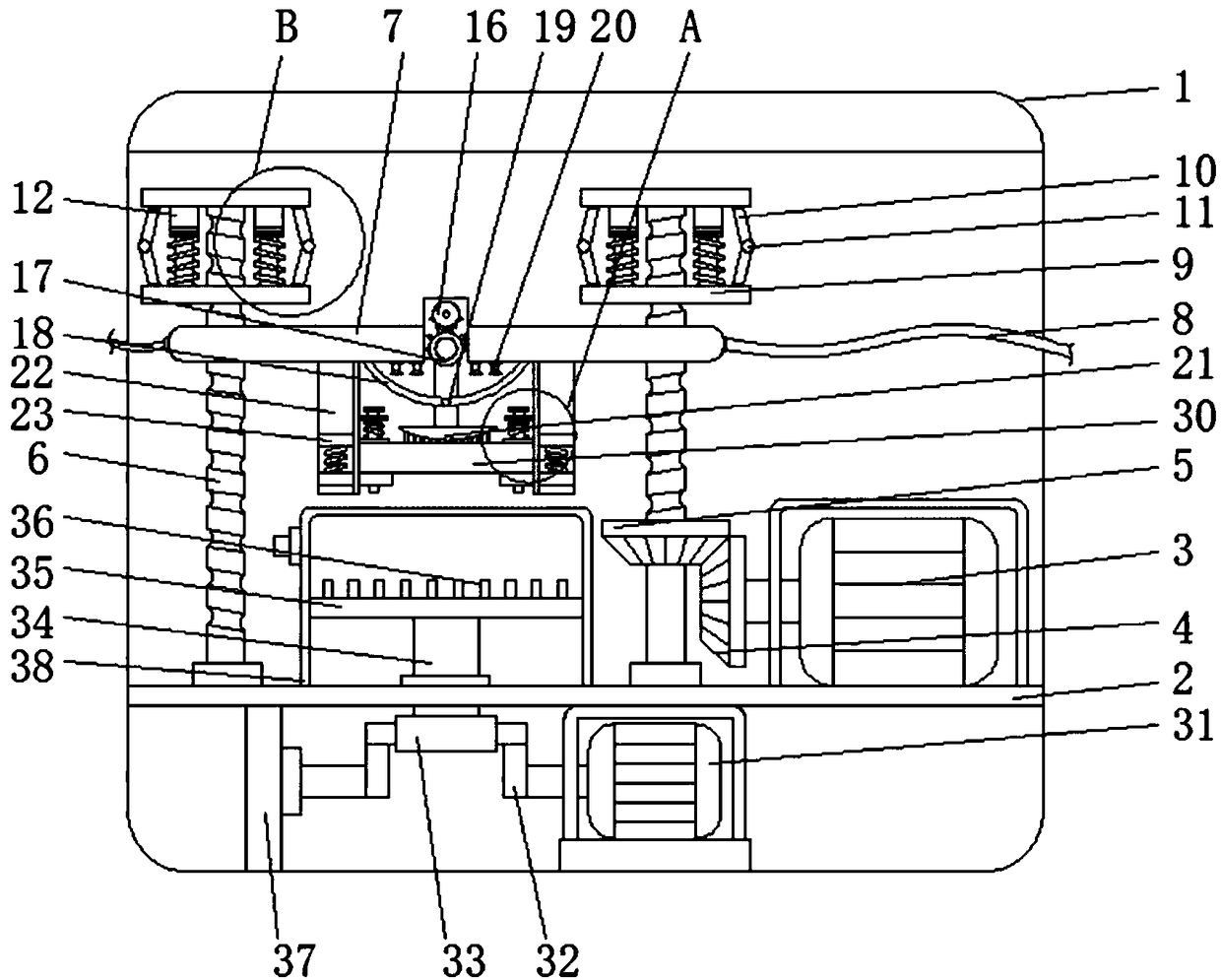

Long blanket intelligent cleaning equipment

InactiveCN110403559AImprove cleaning efficiencyClean upHousehold cleanersCleaning using liquidsConductor CoilBlanket

The invention relates to cleaning equipment, and especially relates to long blanket intelligent cleaning equipment. The technical problem of the invention is to provide the long blanket intelligent cleaning equipment which is capable of saving manpower, high in cleaning efficiency, capable of shaking off the dust on the long blanket and capable of falling dust. The long blanket intelligent cleaning equipment comprises a baseplate, a first roller and a collecting box; the top left side of the baseplate is connected with the first roller, and the collecting box is arranged at the left side of the top of the baseplate. The long blanket is intermittently wound through a cloth-winding roller, thereby continuously cleaning the long blanket; the dust on the long blanket can be shaken off througha dust shaking device, thereby preventing the dust from influencing the cleaning of the long blanket, the cleaning efficiency is higher, and the long blanket can be washed cleaner; a first electric-control valve is opened so that the water can flow out from a spray pipe, the long blanket is wetted by the water, and the water on the long blanket is extruded through a pinch roller, thereby reachinga cleaning effect; and the long blanket is further extruded through a compressing plate, so that the water on the long blanket can be further extruded.

Owner:李岗

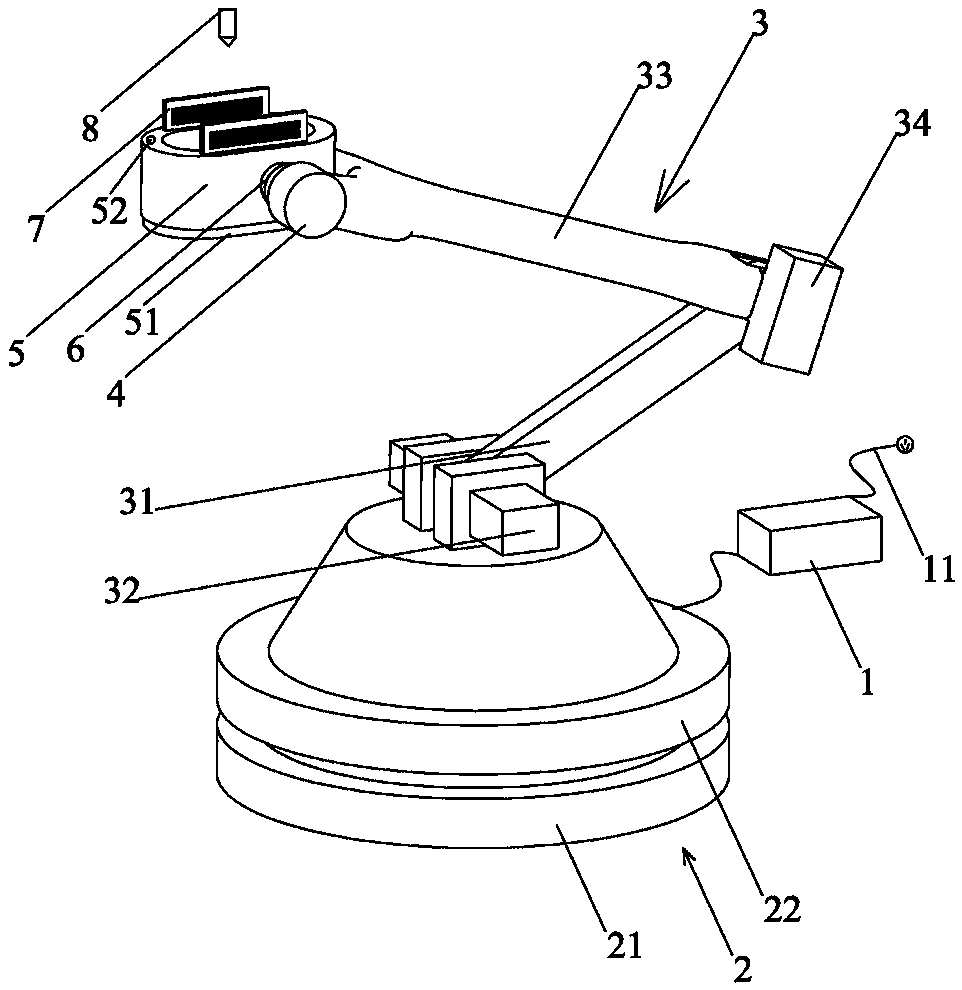

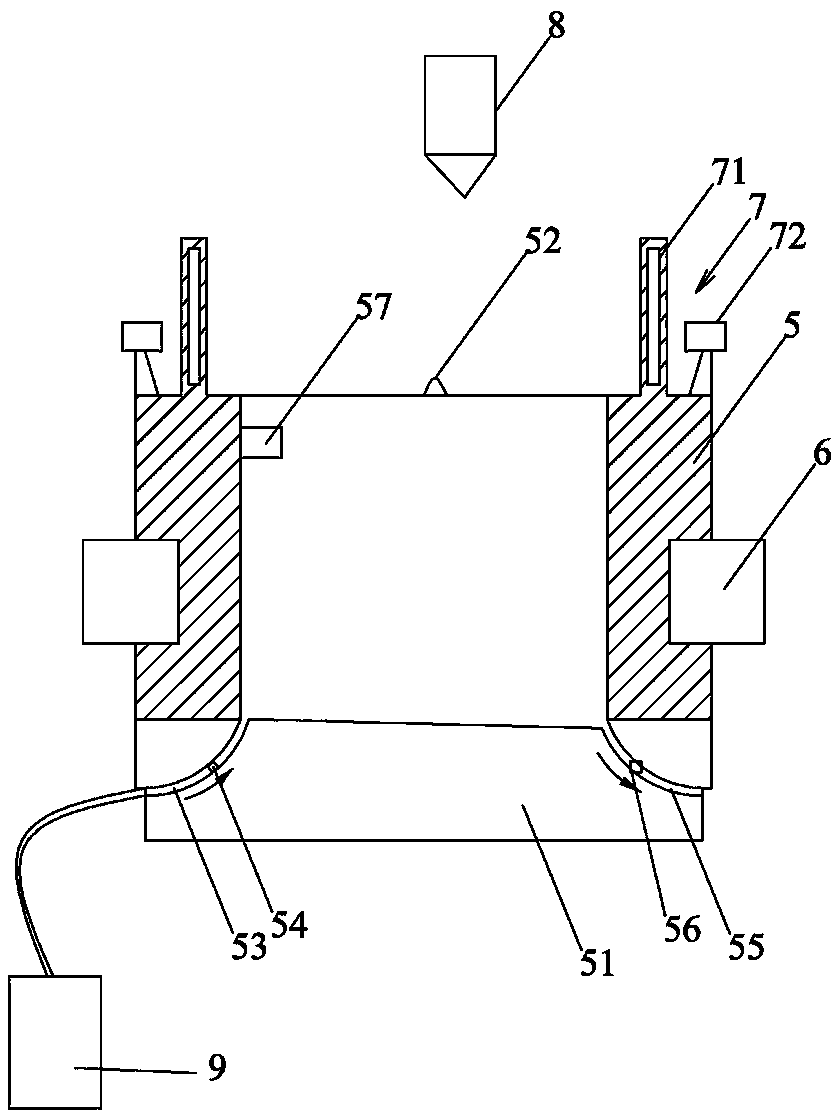

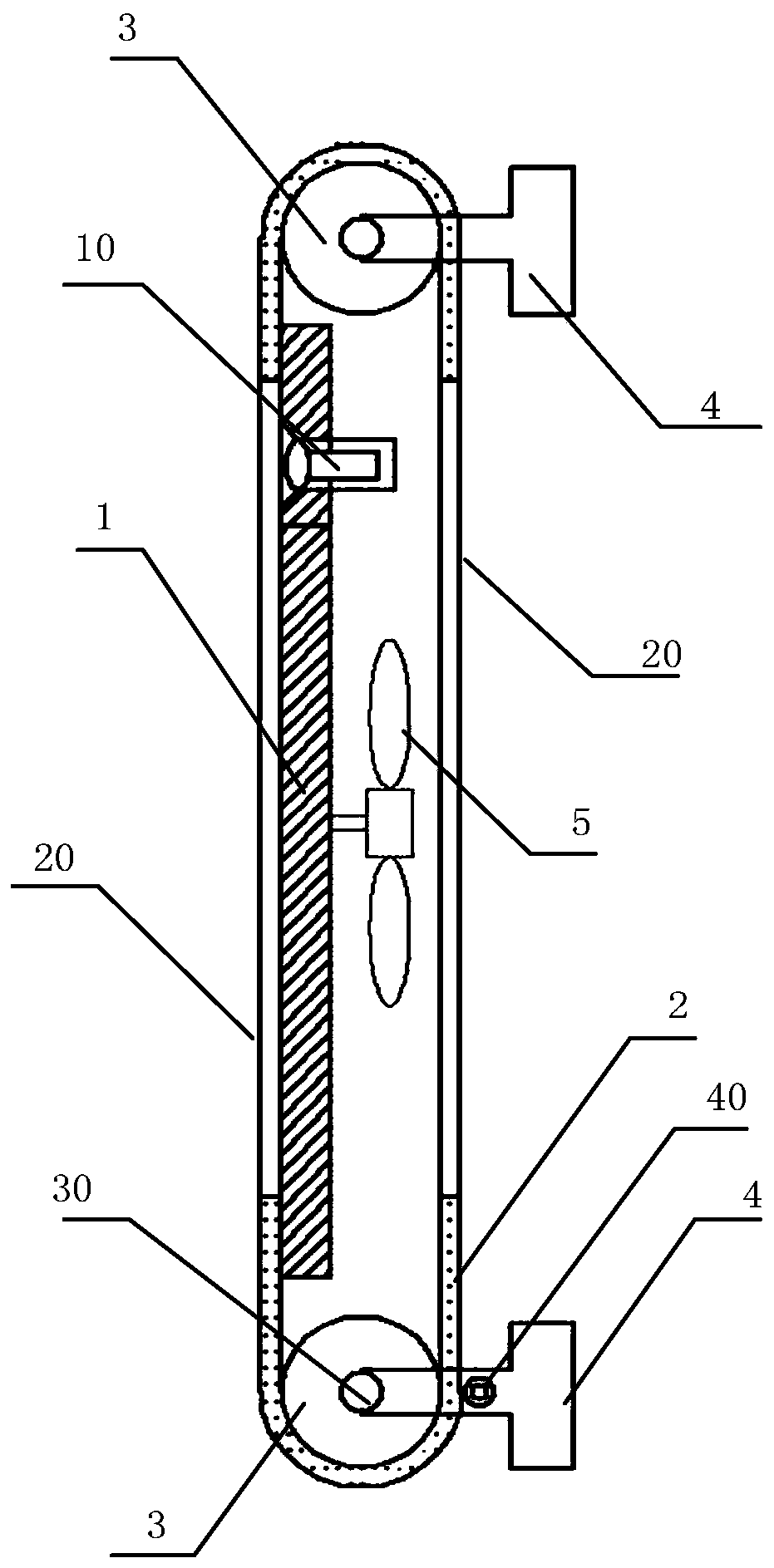

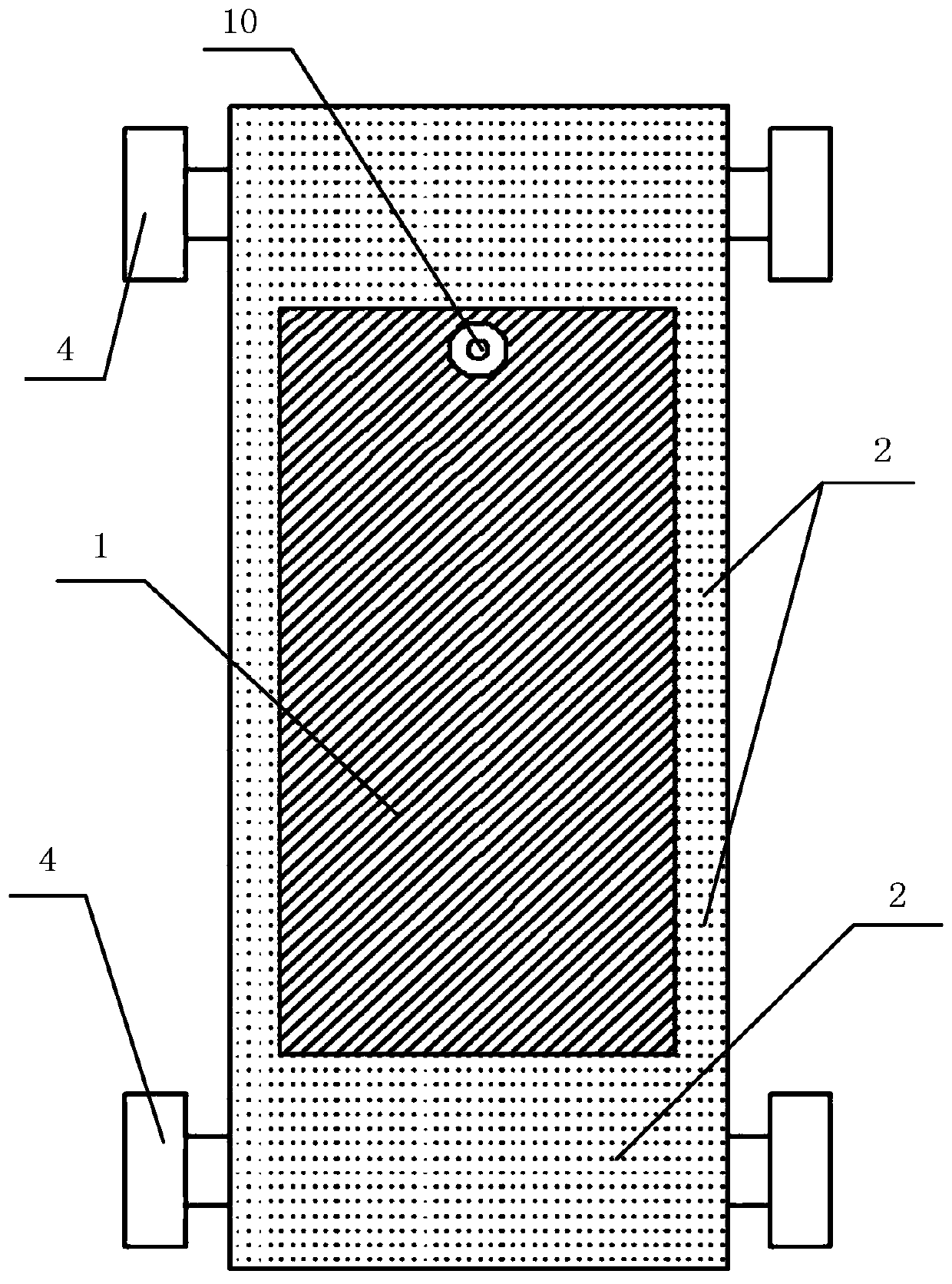

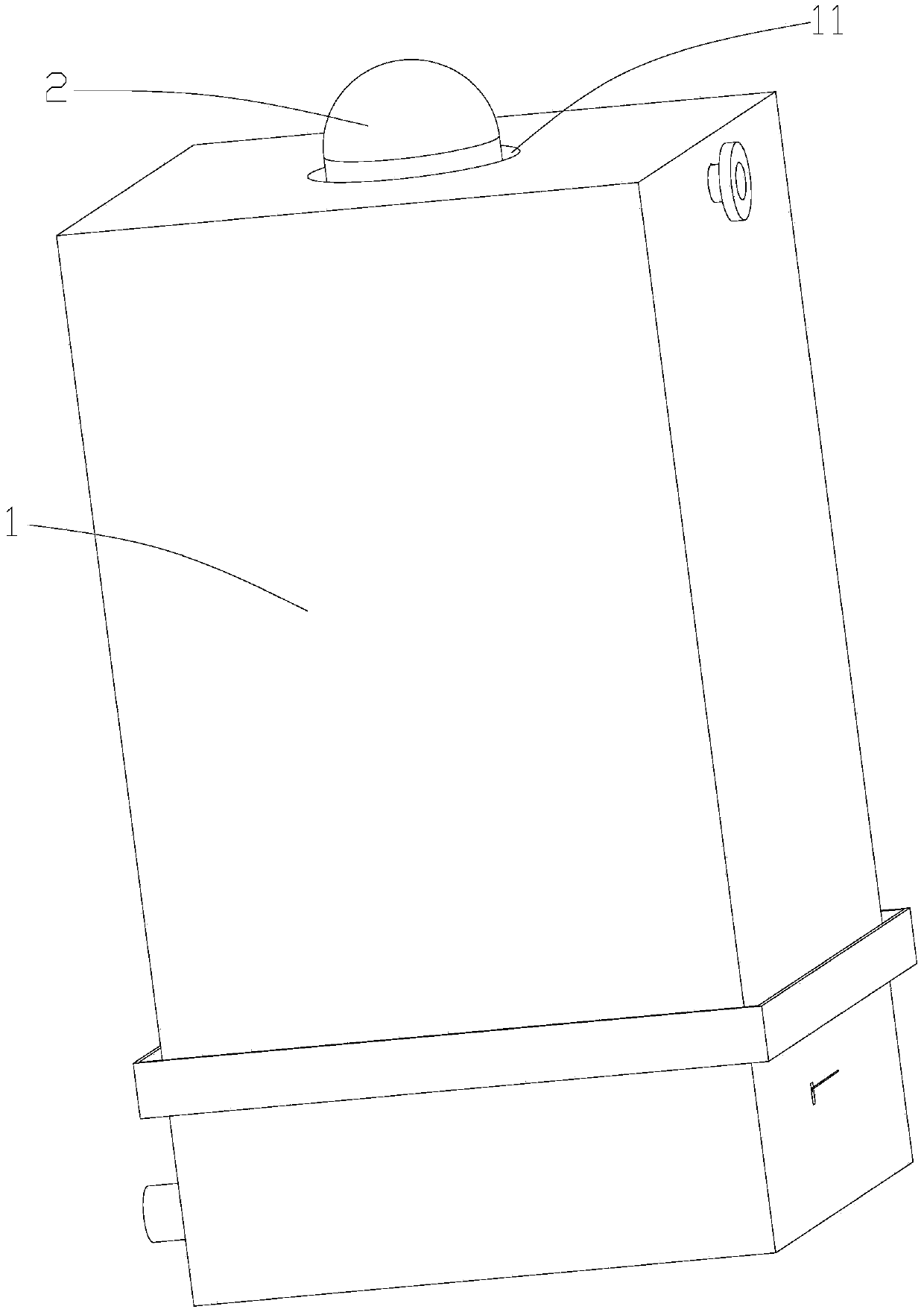

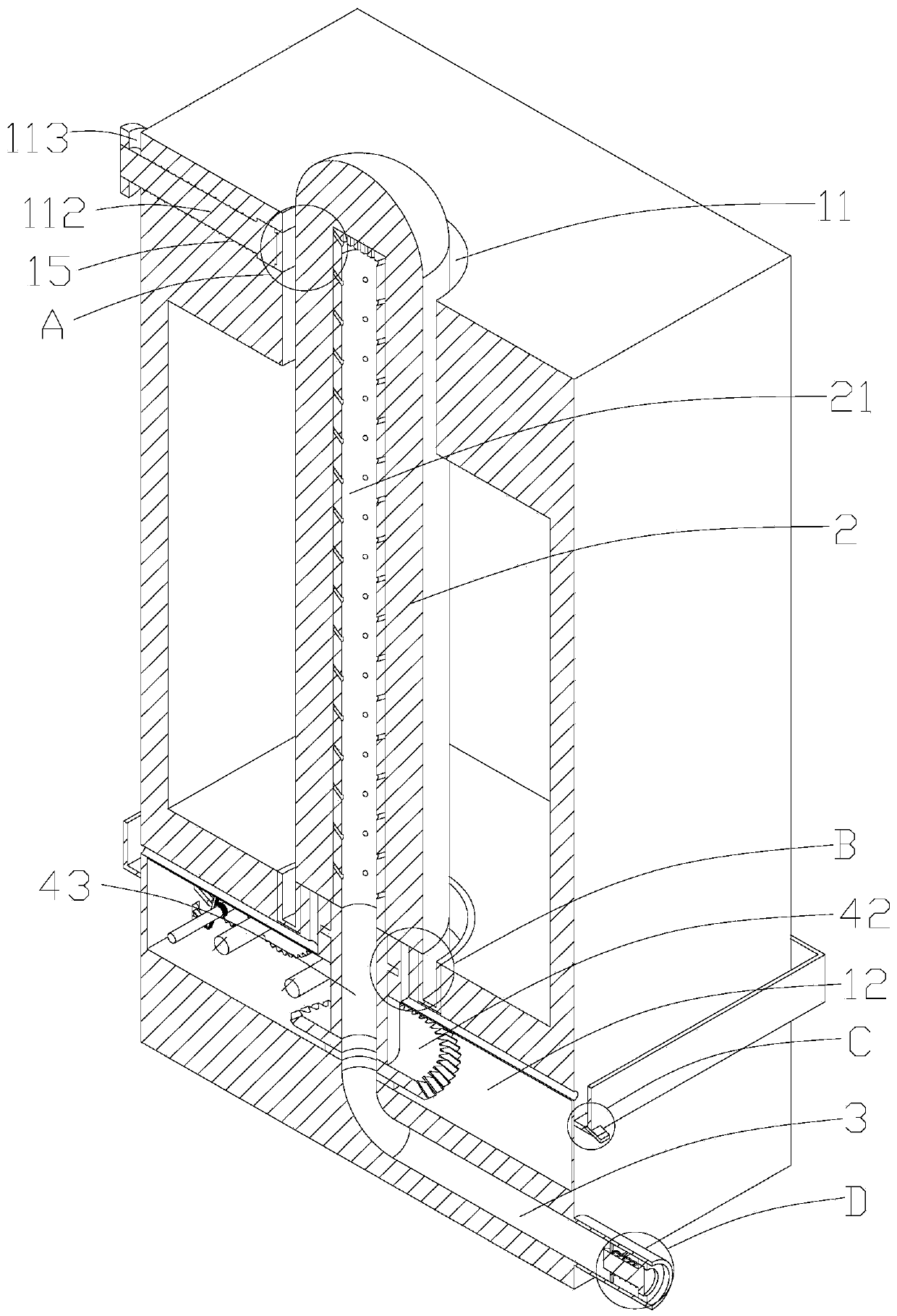

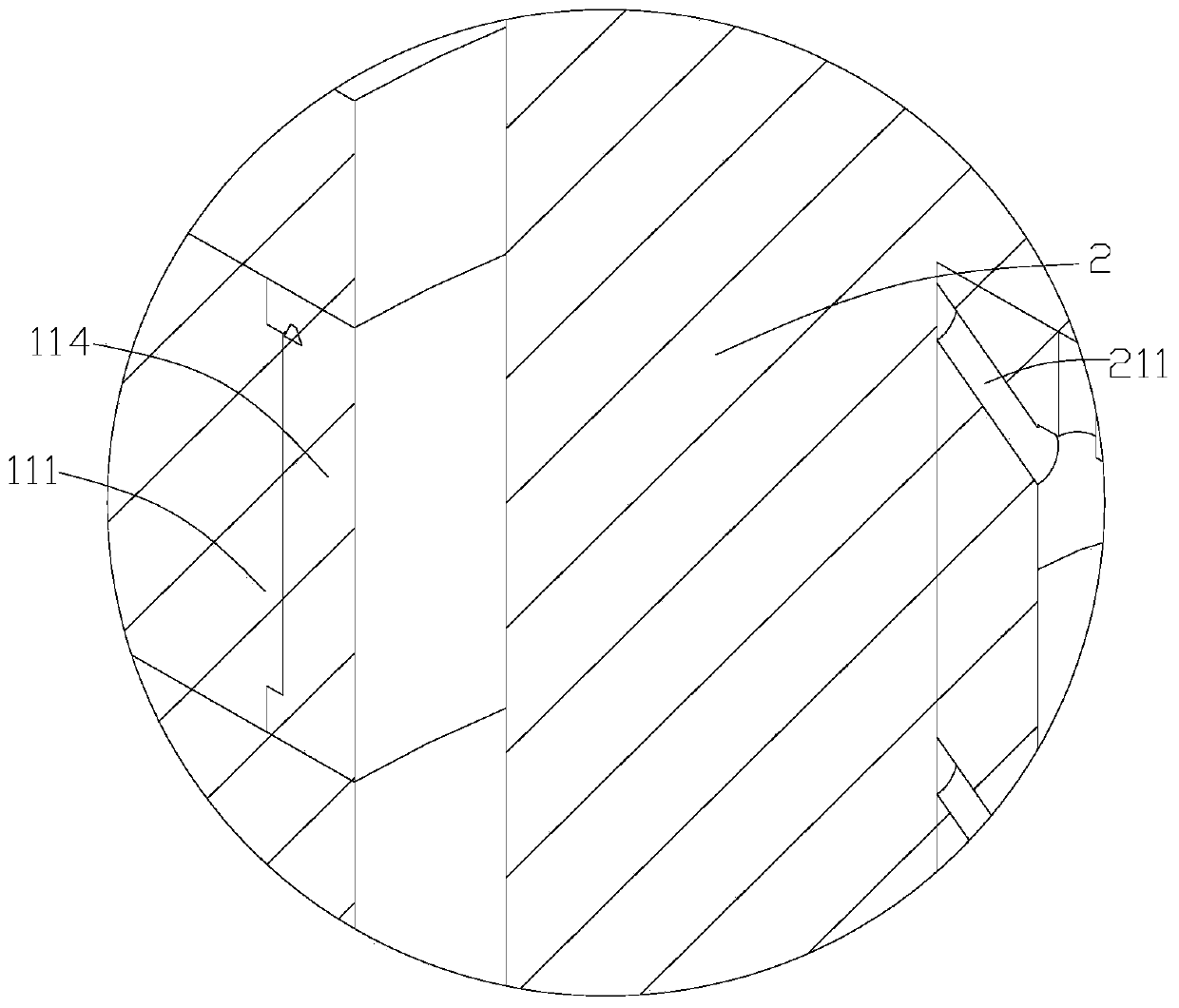

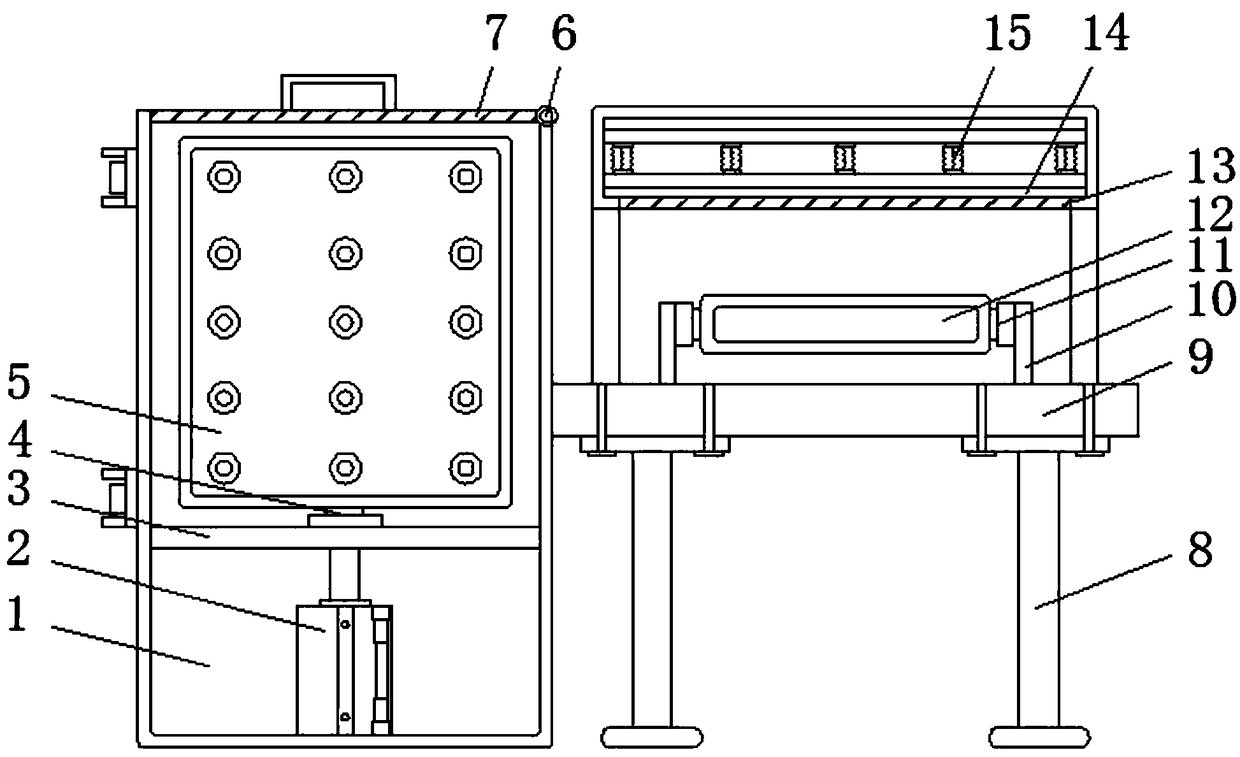

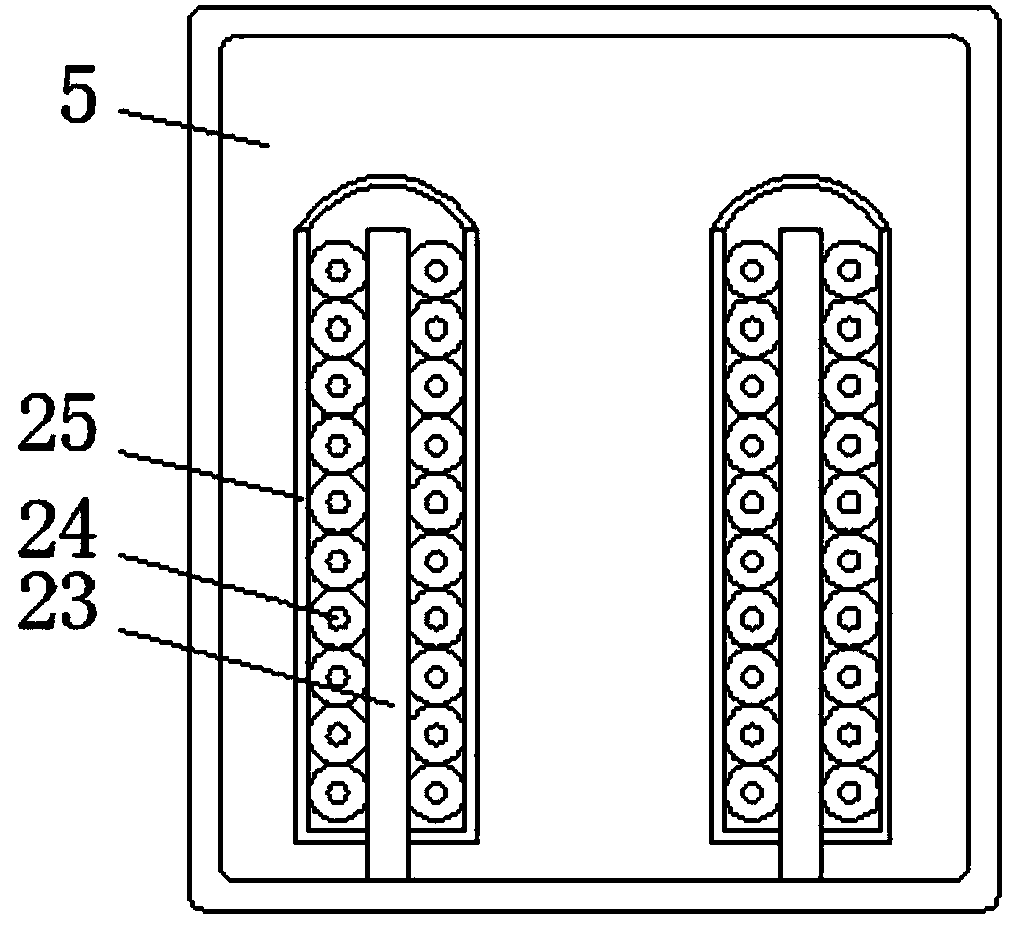

Device for cleaning vertical vacuum tube of solar water heater

ActiveCN109945526ALight in massEasy to moveSolar heating energySolar heat collectors safetySolar waterWater heater

The invention discloses a device for cleaning a vertical vacuum tube of a solar water heater. The device comprises a working box for cleaning a solar vacuum tube and a feeding port for placing the solar vacuum tube into the working box, wherein a cleaning brush for brushing the inner wall of the solar vacuum tube, a driving mechanism for driving the cleaning brush to rotate and a conveying pipe for conveying cleaning liquid and clear water for cleaning the solar vacuum tube are arranged in the working box. Through the arrangement of the structure, the solar vacuum tube can be effectively cleaned through the cleaning brush, so that dirt on the inner wall of the solar vacuum tube is effectively removed; at the same time, the arrangement of a driving part is omitted, so that the maintenance cost of the device is reduced, the size of the device is smaller, and the occupied space is effectively reduced; and the device is simple in structure, easy to operate and quite practical.

Owner:HANGZHOU LESHOU TECH CO LTD

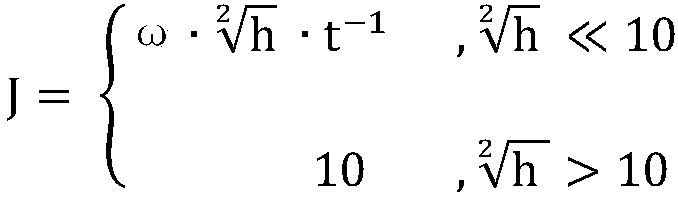

Control method of clothes treating apparatus and clothes treating apparatus

ActiveCN110241592AObtain vibration information at all timesCleaning effectTextiles and paperLaundry driersControl systemEngineering

The invention discloses a control method of a clothes treating apparatus. The control method includes the steps of judging the cleaning operation executing moment of a broken thread filtering device of the apparatus in the apparatus operation process, establishing a cleaning moment judgment evaluating system through a control system of the apparatus when the apparatus is started, determining an evaluating object of the evaluating system, determining an evaluating index of the evaluating system, obtaining the state score of the evaluating system according to the evaluating object and the evaluating index, and judging whether the cleaning operation is conducted on the broken thread filtering device through the control system according to the state score. The invention further discloses the clothes treating apparatus controlled according to the method.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

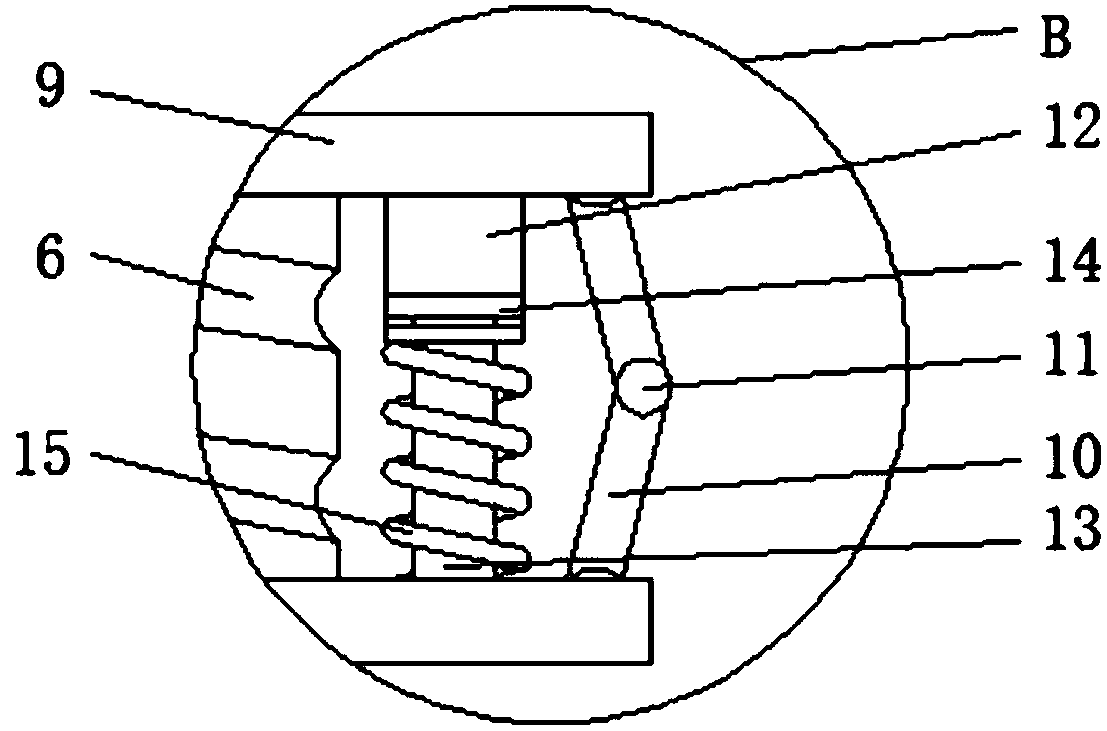

Cleaning device for circuit board used for production of instrument

InactiveCN108770224AEasy to useCleaning effectConductive pattern polishing/cleaningEngineeringInstrumentation

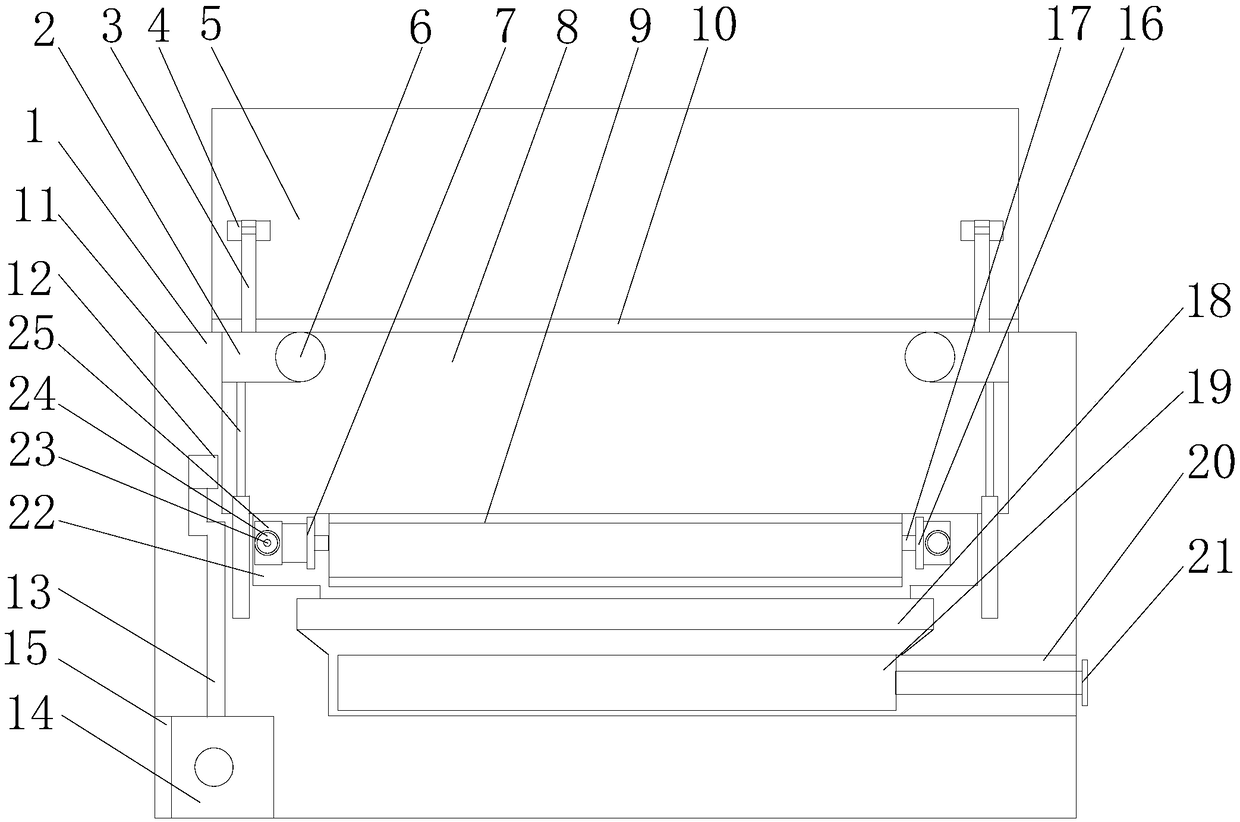

The invention relates to a cleaning device, and especially relates to a cleaning device for a circuit board used for production of an instrument. Therefore, the technical problem of the invention is to provide the cleaning device for the circuit board used for production of the instrument, which is capable of thoroughly cleaning the circuit board, avoiding damage and dropping of parts during cleaning, and reducing a use cost. The cleaning device comprises a box, a drain pipe, a rear side plate, a first sliding rail, a first sliding block, a screen board, a first cylinder, a sponge cushion, a vertical plate, a guide rod, a clamping plate, a first spring and so on; wherein the top of the box is opened, the drain pipe is mounted at the lower part of the right side of the box, and the drain pipe communicates with the box. The cleaning device of the invention has the beneficial effects that: the circuit board is fixed through the clamping plate, so as to prevent the circuit board from moving to affect cleaning during the process of cleaning, in addition, the height of the circuit board is adjusted through the first cylinder, and a cleaning fabric is driven by a second cylinder to cleanthe circuit board, thereby achieving the effects of thoroughly cleaning the circuit board, avoiding damage and dropping of the parts during cleaning, and reducing the use cost.

Owner:谢曼娟

Clothes treatment device

PendingCN110241588AGet location information at all timesCleaning effectCleaning using gasesTextiles and paperEngineeringBiomedical engineering

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Recycling fusion device for non-woven fabric production

InactiveCN108588855AImprove cleaning efficiencyAffect qualityFilament forming substance formingEngineeringNonwoven fabric

The invention relates to a recycling fusion device for non-woven fabric production. The device comprises a cleaning box and a second motor, a first motor is installed at the bottom side inside the cleaning box, a partition is fixed to the upper end of the first motor, a rotary shaft is inlaid at the right side of the upper end of the cleaning box, a box cover is connected to the left side of the rotary shaft, a top plate is arranged in the middle of the right side of the cleaning box, and supporting columns are arranged at the two sides of the lower end of the top plate. The recycling fusion device has the advantages that non-woven fabrics inside the cleaning box can be driven by a cleaning cylinder for rotating cleaning, it is due to the fact that mesh holes are formed in the cleaning cylinder, cleaning liquid can circularly flow in and flow out of the cleaning cylinder, cleaning efficiency of the non-woven fabrics is improved, impurities contained in the non-woven fabrics are removed, it is avoided that impurities exist in the melted liquid of the non-woven fabrics so as to cause impurity of the melted liquid and affect quality of subsequent remolding non-woven fabrics, and rotation of the cleaning cylinder can quickly dewater the non-woven fabrics after cleaning, so that it is avoid that non-woven fabrics containing excessive water affects subsequent fusion.

Owner:汤佳

Non-woven fabric fusion device with cleaning function

InactiveCN108866642ADehydration fastAffect meltingFilament forming substance formingEngineeringNonwoven fabric

The invention relates to a non-woven fabric fusion device with a cleaning function. The device comprises a cleaning box and a second motor, a driving device is installed on the bottom side of the inner portion of the cleaning box, and a partition plate is fixed to the upper end of the driving device; a rotary shaft is inlaid in the right side of the upper end of the cleaning box, a box cover is connected to the left side of the rotary shaft, a top plate is arranged in the middle of the right side of the cleaning box, and supporting columns are arranged on the two sides of the lower end of thetop plate. The device has the advantages that non-woven fabrics in the cleaning box can be driven to be cleaned rotatably through a cleaning cylinder, due to mesh openings formed in the cleaning cylinder, cleaning fluid can circularly flow in and out of the cleaning cylinder to increase the cleaning efficiency of the non-woven fabrics, and impurities contained in the non-woven fabrics can be removed, it is avoided that the liquid melted by the non-woven fabrics contains impurities, so the liquid is not pure, and the quality of the non-woven fabrics after later secondary moulding is influenced,the cleaning cylinder can rotate after cleaning to quickly dehydrate the non-woven fabrics, and it is avoided that the non-woven fabrics contain too much water, so the later fusion is influenced.

Owner:汤佳

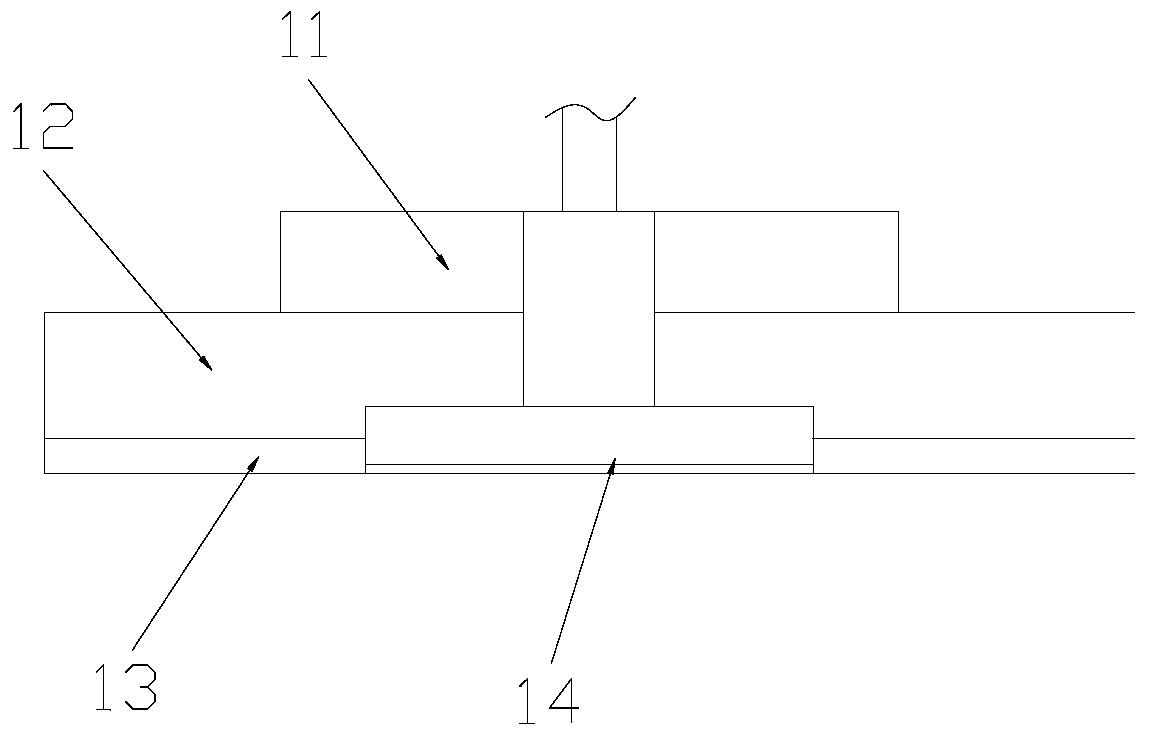

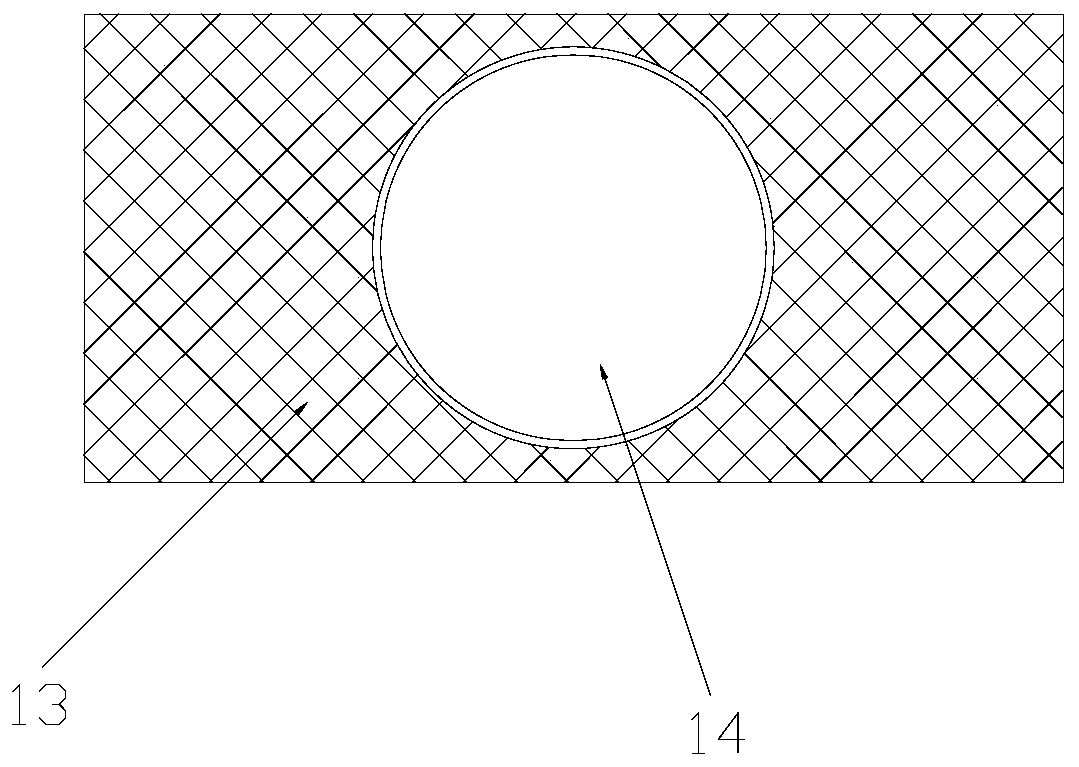

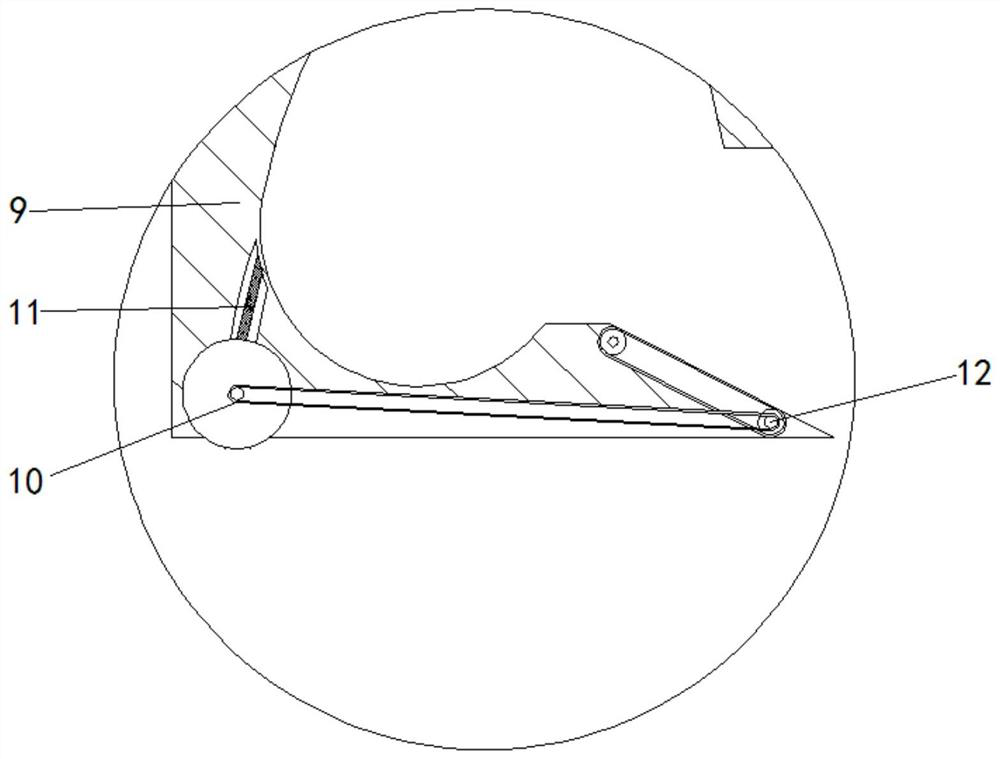

Threaded pipeline inner wall cleaning device

InactiveCN114042708AImprove cleaning efficiencyEasy to cleanGrinding drivesHollow article cleaningThreaded pipeClassical mechanics

The invention discloses a threaded pipeline inner wall cleaning device, which comprises a limiting base, wherein a plurality of straight rods are fixedly connected to the surface of the limiting base, a supporting ring is fixedly connected to the straight rods, a threaded pipe is arranged on the supporting ring, a plurality of mounting blocks are fixedly connected to the side wall of the limiting base, a plurality of mounting holes are formed in the mounting blocks, a pair of sliding grooves are formed in the side wall of the limiting base, sliding blocks are arranged in the sliding grooves in a sliding mode, limiting ropes are fixedly connected to the surfaces of the sliding blocks and have elasticity, and a pair of supporting vertical rods are fixedly connected to the surface of the limiting base. Compared with the prior art, after a driving ring enters a pipeline, a driving block on the surface of a movable ring can abut against the gap of an internal thread, the movable ring can be driven to rotate, rust in the thread can be cleaned in cooperation with a cleaning agent, and the cleaning efficiency of the internal thread can be improved; and fine vibration can occur in the rotating process of the movable ring, and the cleaning effect on the internal threads can be enhanced.

Owner:绍兴市江览机械科技有限公司

Air-cooled blow needle mechanism

ActiveCN102848559ACleaning effectReduce the temperatureHollow articlesEngineeringMechanical engineering

The invention relates to an air-cooled blow needle mechanism, and belongs to the technical field of an air blowing mechanism of a blowing machine. The mechanism comprises a blow needle body with a hollow chamber. An air inlet pipe joint extends at one end of the blow needle body. A cooling air inlet is provided on a side of the blow needle body. A blowing pipe joint seat is formed on a wall of the hollow chamber. An annular air groove is provided on the other end of the blow needle body, and a cooling sleeve is fixed. A set of cooling sleeve cooling air ports is provided on the inner wall of the hollow chamber. A blow needle head with a blow needle head cavity is formed. A set of heat sinks is formed on the inner wall of the blow needle head cavity. The blowing pipe is positioned in the hollow chamber. One end of the blowing pipe extends out of the blow needle head, and a blow needle cap is formed. A set of secondary air jet holes is provided on the blow needle cap. The space between the outer wall of the lowing pipe and the inner wall of the hollow chamber forms a cooling air entraining cavity. The cooling air inlet communicates with the cooling air entraining cavity. The cooling sleeve cooling air ports communicate with the cooling air entraining cavity. The mechanism has the advantages that: with the mechanism, product is prevented from being polluted; blank blowing time is shortened; production efficiency is improved; and heat dissipation effect is improved.

Owner:SUZHOU TONGDA MACHINERY

Antiskid glazed tile surface spraying device

PendingCN114558736ARealize the effect of automatic feedingReduce the frequency of manual feedingPretreated surfacesCleaning using toolsSprayerStructural engineering

The invention relates to a spraying device, in particular to an anti-skid glazed tile surface spraying device. The technical problem to be solved is to provide the anti-slip glazed tile surface spraying device which can realize automatic material supplementing, reduce the manual material supplementing frequency and further improve the spraying efficiency. According to the technical scheme, the anti-skid glazed tile surface spraying device comprises mounting frames, a material bracket, guide rods, a movable frame, a sprayer and the like, the material bracket is arranged among the four mounting frames, the guide rods are arranged between the two mounting frames on the left side and between the two mounting frames on the right side, the movable frame is arranged between the rear portions of the two guide rods in a sliding mode, and the sprayer is arranged on the movable frame. And four sprayers are arranged on the movable frame at equal intervals. The anti-slip agent in the material supplementing box can be extruded into the material spraying device through the extrusion plate, the automatic material supplementing effect on the material spraying device is achieved, and therefore the frequency of manual material supplementing is reduced, time can be saved, and the spraying efficiency is improved.

Owner:江苏金鼎建设集团有限公司

Anti-locking aluminum alloy door and window with automatic cleaning function

InactiveCN112482938AWith automatic cleaning functionAvoid stickingWindow cleanersWing arrangementsGear wheelCam

The invention relates to the technical field of aluminum alloy doors and windows, and discloses an anti-locking aluminum alloy door and window with an automatic cleaning function. The door and windowcomprise a guide rail, a frame is slidably connected to the top of the guide rail, a slider is movably connected to one side, away from a swing door, of a connecting rod, and a support spring is fixedly connected to one side, away from the connecting rod, of the slider. A collecting wheel is arranged in the cleaning wheel, an inner wheel is fixedly connected into the collecting wheel, a gear is slidably connected into the inner wheel, a worm wheel is fixedly connected to the outer side of the inner wheel, and an air suction rod is engaged with the left side of the worm wheel. According to theanti-locking aluminum alloy door and window with the automatic cleaning function, the frame moves to drive the roller to rotate, the roller rotates to drive the pull rod to swing, the pull rod drivesthe scraping block to slide, meanwhile, the roller drives the cam to rotate, the cam drives the supporting rod to move, and then the supporting rod and the pressure spring are matched for use, so thatthe effect of preventing the pulley from being locked is achieved.

Owner:广州富科机械贸易有限公司

Plate washing machine used for washing elisa plate and operation method thereof

ActiveCN108620346AEasy to cleanPrevent slipping outCleaning using toolsCleaning using liquidsMedical equipmentDrive wheel

The invention relates to the technical field of medical equipment, and discloses a plate washing machine used for washing an elisa plate and an operation method thereof. The plate washing machine comprises plate washing equipment, a supporting plate is fixedly arranged in the plate washing equipment, a servo motor is fixedly arranged on the top of the supporting plate, an output shaft of the servomotor is fixedly sleeved with a driving wheel, outer teeth of the driving wheel are in engaged connection with a driven wheel, and the middle of the driven wheel is fixedly provided with a screw. According to the plate washing machine used for washing the elisa plate and the operation method thereof, through the effect of a cleaning cylinder, the elisa plate is soaked in the cleaning cylinder, residue on the elisa plate becomes soft, the phenomenon that in the cleaning process of the elisa plate, the residue cannot be washed down is avoided, through cooperation of the driving wheel, the driven wheel and the screw, a supporting table can move to different positions up and down, cleaning of the elisa plate is facilitated, and through cooperation of a buffer plate, a compression spring and atelescopic rod, the phenomenon that in the moving process of the supporting table, the supporting table slides out of the screw is avoided.

Owner:浙江众申生物科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com