Beverage bottle inner wall rapid cleaning equipment

A technology for cleaning equipment and beverage bottles, which is applied to the field of rapid cleaning equipment for the inner wall of beverage bottles, can solve the problems of low work efficiency, cumbersome operation, laborious and other problems, and achieves the effect of convenient operation and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

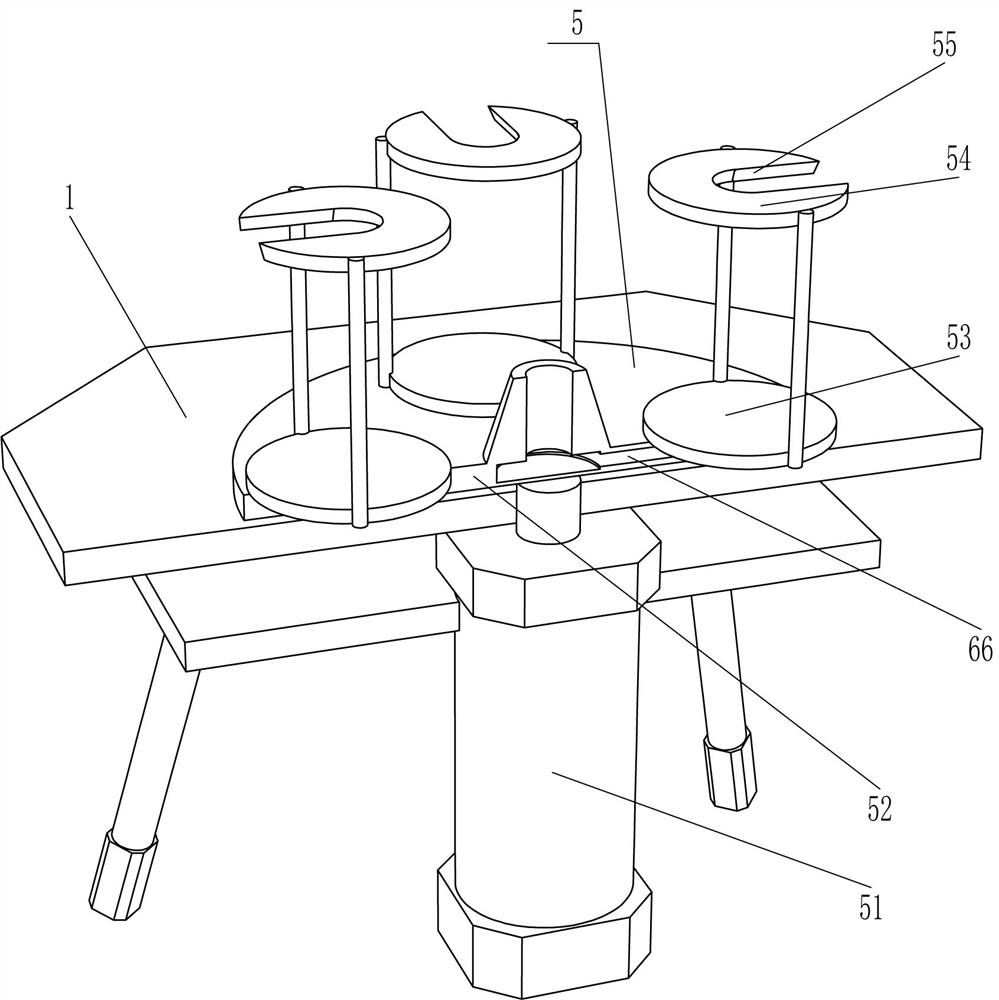

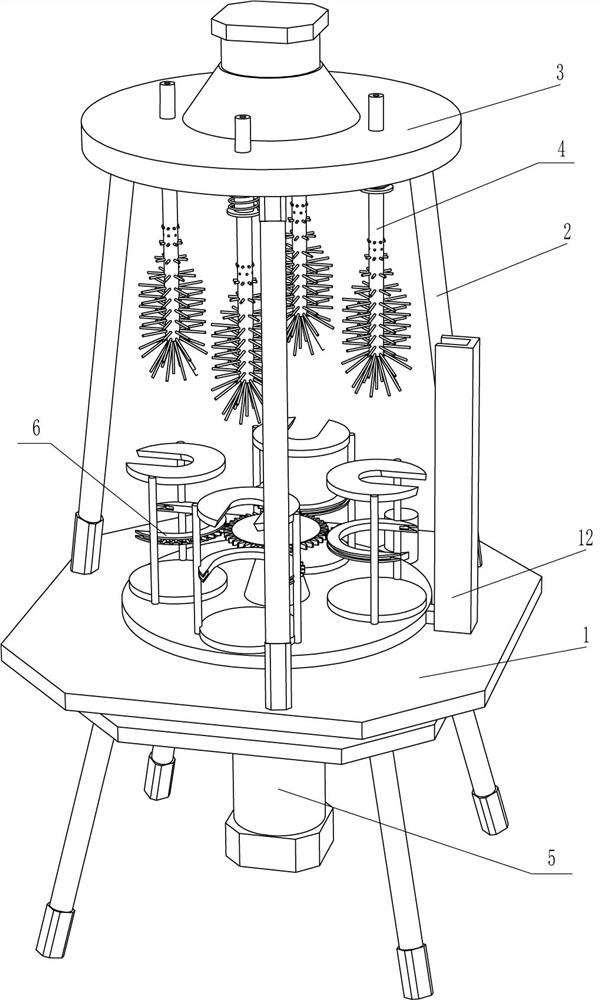

[0026] A quick cleaning device for the inner wall of a beverage bottle, such as figure 1 , figure 2 , image 3 and Figure 6 As shown, it includes a double-layer fixed frame 1, a support rod 2, an installation frame 3, a cleaning mechanism 4, and a pushing mechanism 5. The top of the double-layer fixed frame 1 is fixedly connected with three support rods 2 evenly spaced around the circumference, and the three support rods 2 An installation frame 3 is fixedly connected between the top ends, a cleaning mechanism 4 is provided in the installation frame 3, and a pushing mechanism 5 is provided on the double-layer fixed frame 1.

[0027] The cleaning mechanism 4 includes a motor 41, a first gear 42, a brush hollow rod 43 and a second gear 44, and the evenly spaced rotating type between the upper and lower sides of the installation frame 3 is connected with a brush hollow rod 43, and the brush hollow rod 43 has water outlet holes 45 evenly spaced in the middle circumferential di...

Embodiment 2

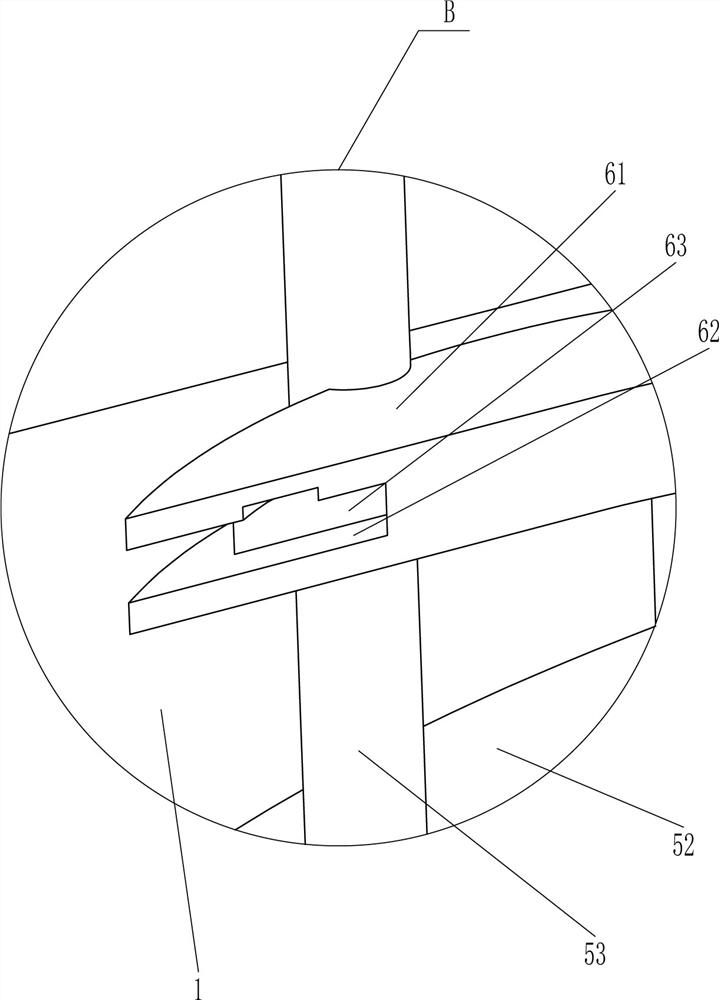

[0033] On the basis of Example 1, such as figure 1 , Figure 4 and Figure 7As shown, a locking mechanism 6 is also included. The locking mechanism 6 includes a c-shaped locking ring 61, an arc-shaped rack 63, a rotating shaft 64, a third gear 65 and a toggle lever 67. Connected with a rotating shaft 64, the top of the rotating shaft 64 is fixedly connected with a third gear 65, the outer surface of the mounting plate 52 is provided with a chute 66 toward the rear side, the bottom end of the rotating shaft 64 is fixedly connected with a toggle lever 67, and the tail end of the toggle lever 67 is located at Outside the chute 66, the toggle lever 67 is slidably matched with the chute 66, and a c-type lock ring 61 is fixedly connected between the middle part of the both sides of the discharge rack 53, and the outer surface of the c-type lock ring 61 is circumferentially provided with a guide groove 62, and the guide groove 62 The inner sliding type is provided with an arc-shape...

Embodiment 3

[0036] On the basis of embodiment 1 and embodiment 2, such as Figure 4 and Figure 5 As shown, it also includes a valve core 8, a compression spring 9 and a transmission ring sleeve 10. There is a special-shaped cavity 7 on the upper circumference of the brush hollow rod 43, and a sliding valve core 8 is provided in the special-shaped cavity 7. The two ends of the valve core 8 are located at Outside the special-shaped cavity 7, the valve core 8 cooperates with the inner side of the brush hollow rod 43, and the outer upper part of the brush hollow rod 43 is circumferentially slidingly provided with a transmission ring sleeve 10, and the top of the transmission ring sleeve 10 is fixedly connected with the outer two ends of the valve core 8 A compression spring 9 is fixedly connected to the inner bottom of the transmission ring sleeve 10, and the tail end of the compression spring 9 contacts and cooperates with the outer bottom of the installation frame 3.

[0037] Also include...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com