Spray nozzle cleaning device and manner

A cleaning device and technology for cleaning devices, which are applied to cleaning methods and utensils, cleaning methods using liquids, and arrangement of drying gas, etc., can solve the problems of easy water seepage of the nozzle, long drying process, and time-consuming, etc. The effect of dripping nozzle process, avoiding adverse effects and improving drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

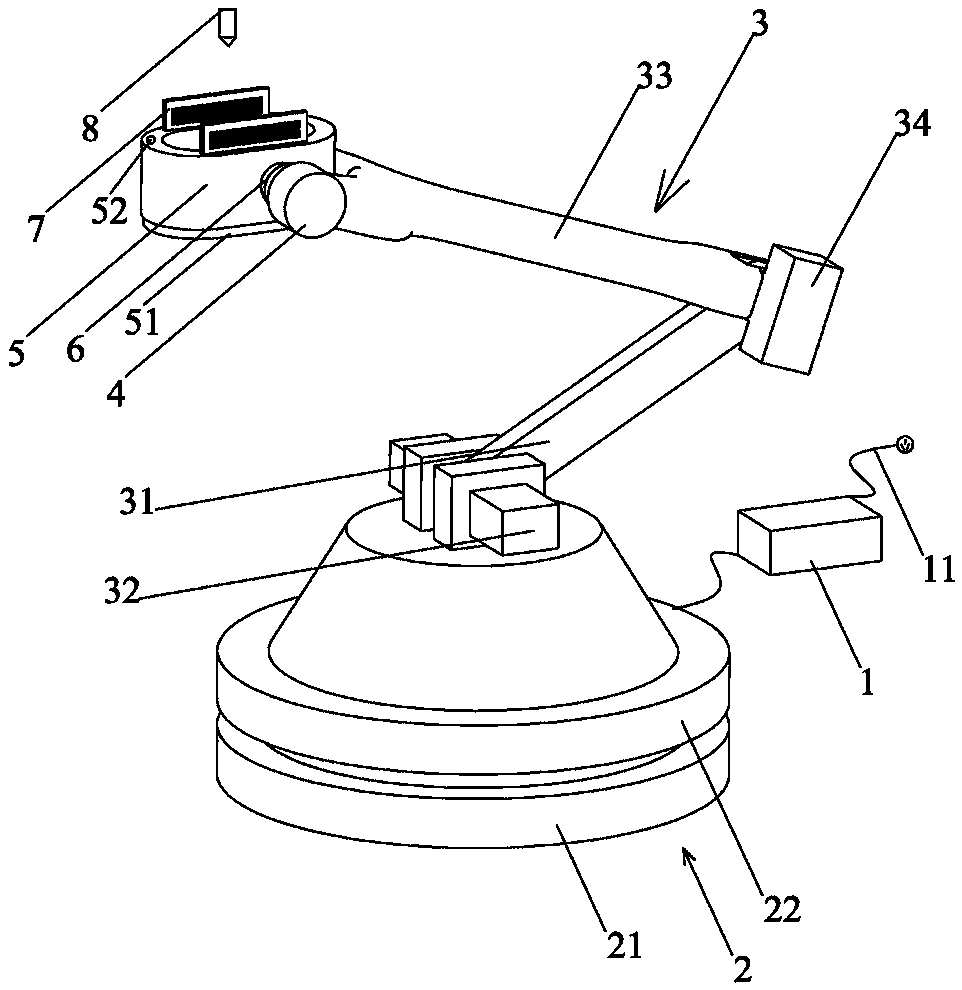

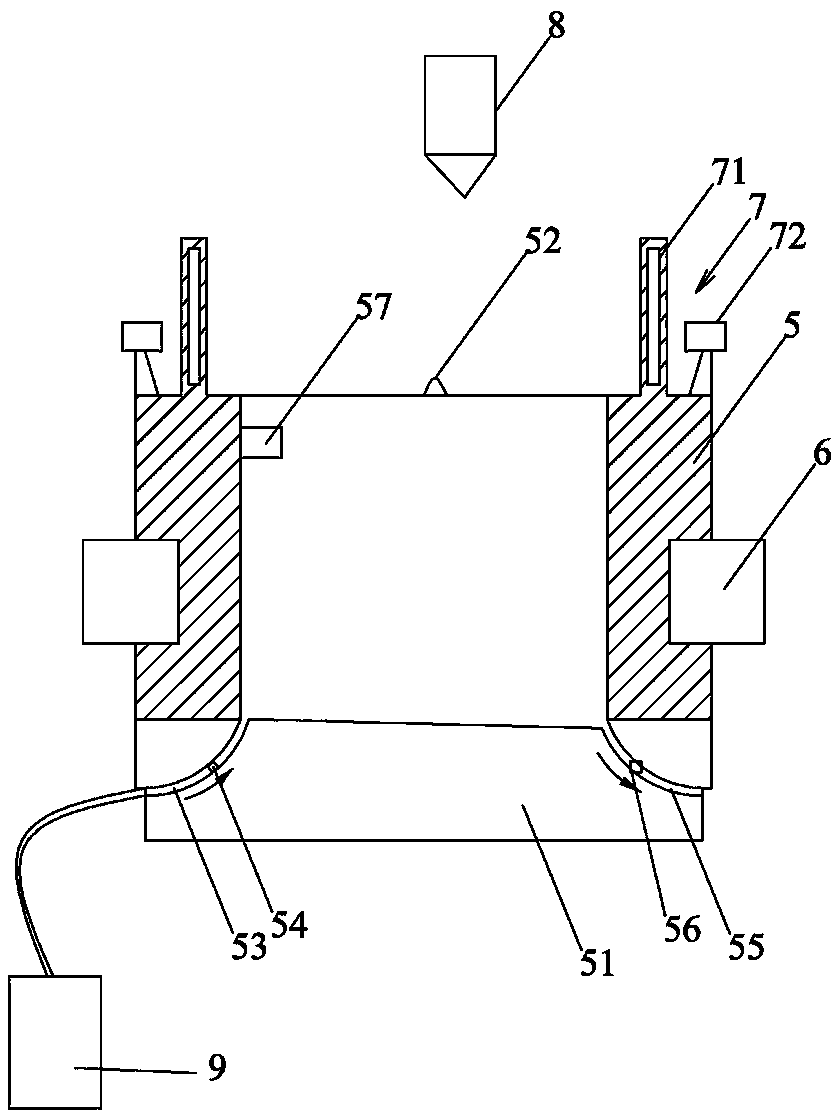

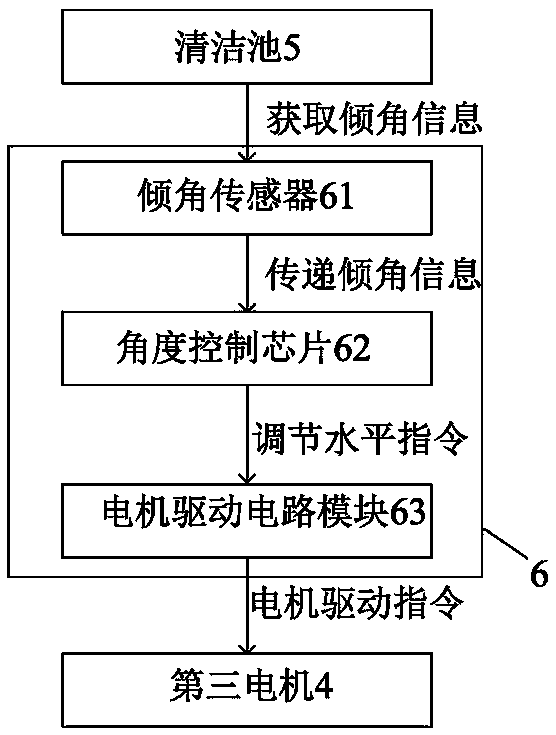

[0034] Disclosed in the present invention is a nozzle cleaning device, such as Figure 1-8 As shown, it is a preferred embodiment of the present invention, the cleaning device includes a mechanical transfer device, a cleaning device and a central control unit 1, such as figure 1 As shown, the mechanical transfer device controls the cleaning device at different positions under the drive of the central control unit 1 according to the position of the droplet nozzle to complete each process link of cleaning the droplet nozzle. The mechanical transmission device includes a worktable 2 and a mechanical arm 3 installed on the worktable. The mechanical arm 3 is controllably hinged on the worktable 2. The cleaning device can be flipped and installed at the end of the mechanical arm 3. The cleaning device can be installed on the mechanical arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com