Patents

Literature

33results about How to "Automatic drying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

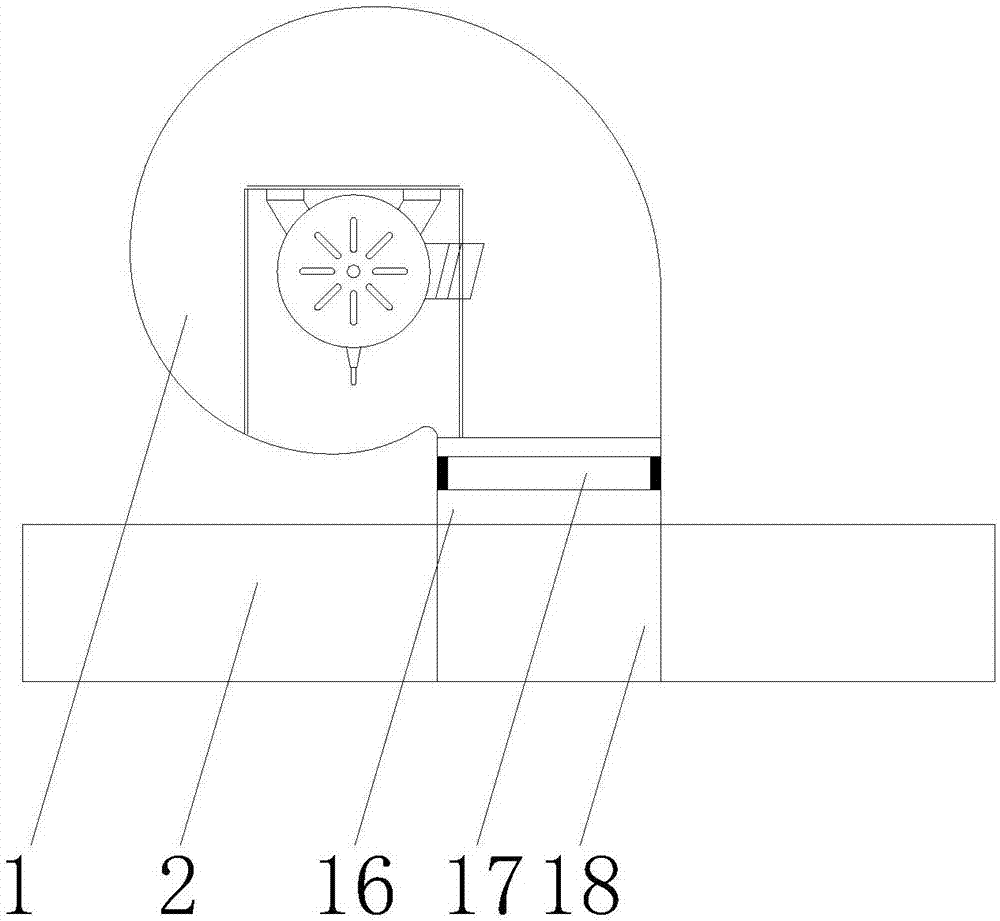

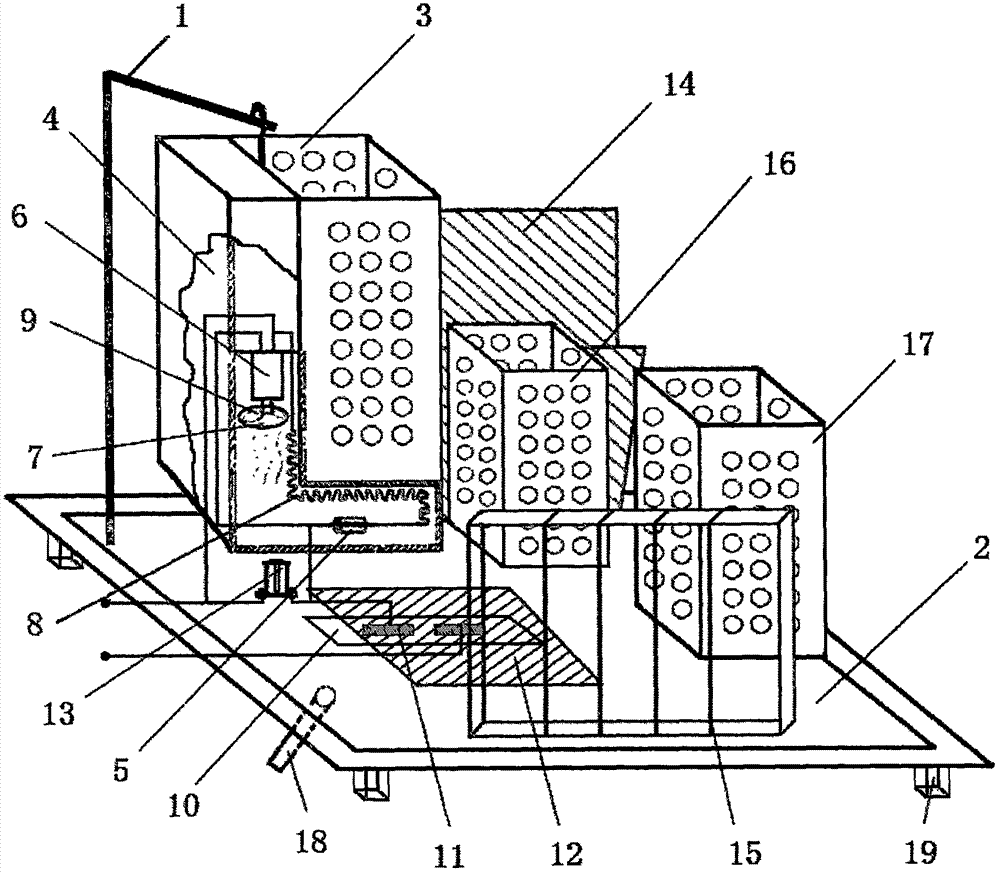

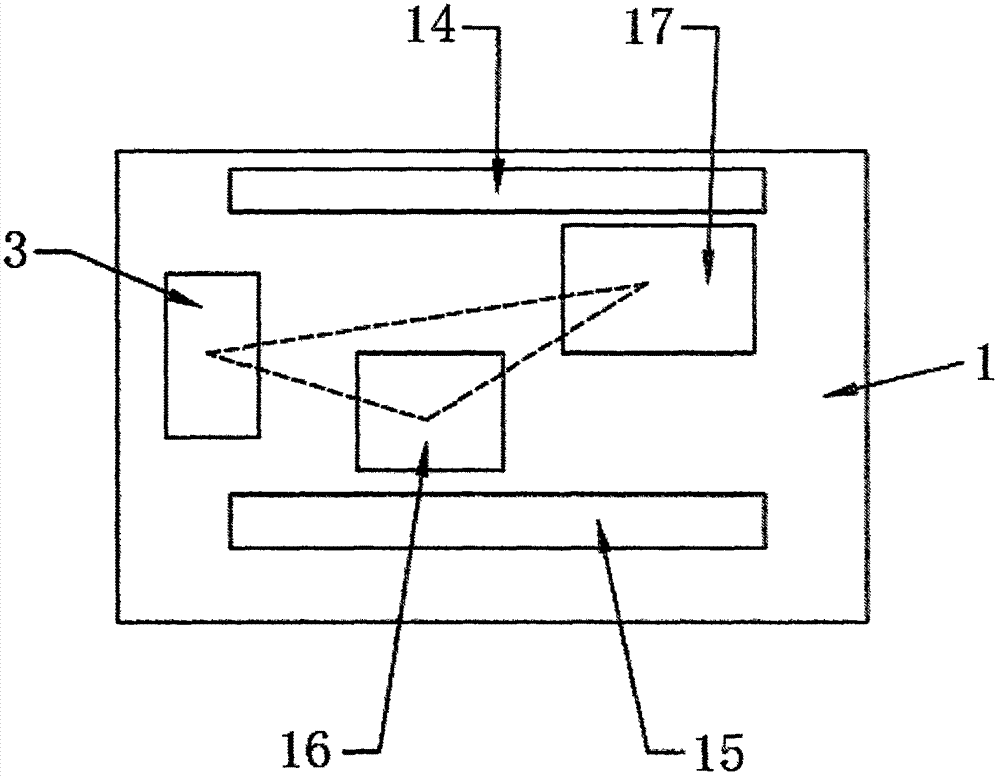

Heat dissipation integrated cabinet for communication equipment

InactiveCN107241892AReal-time monitoring of temperature and humidityAvoid it happening againCooling/ventilation/heating modificationsAutomatic controlEngineering

The invention discloses a heat dissipation integrated cabinet for communication equipment. The heat dissipation integrated cabinet comprises a draught fan, a cabinet body, a controller, ventilation covers and an electric push rod, wherein an air inlet passage is formed in an upper end of the cabinet body and is connected with an air outlet, the other end of the air outlet is connected with the draught fan, a heater is arranged in the air outlet, an air inlet is formed in one side of the draught fan, the controller is arranged on an inner wall of a cabinet door and is electrically connected with a control panel through a wire, a temperature sensor and a humidity sensor are arranged at a lower end of the controller, ventilation holes are formed in a side wall of the cabinet body, the ventilation covers are arranged at upper ends of the ventilation holes and are rotatably connected with the cabinet body by a rotation shaft, gears are fixedly arranged at two ends of the rotation shaft and are connected with a rack in the cabinet body, and the electric push rod is fixedly arranged at a lower end of the rack. The communication equipment can be cooled by the draught fan, heat dissipation is automatically controlled by the controller, and timely heat dissipation is achieved.

Owner:合肥念萍电子商务有限公司

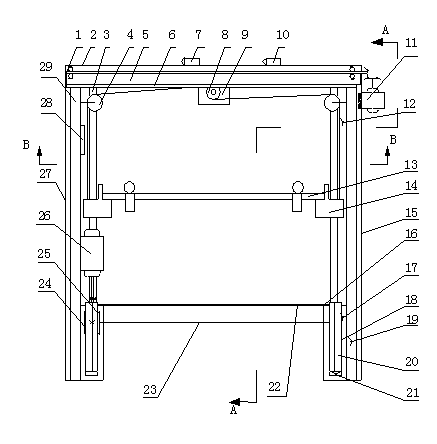

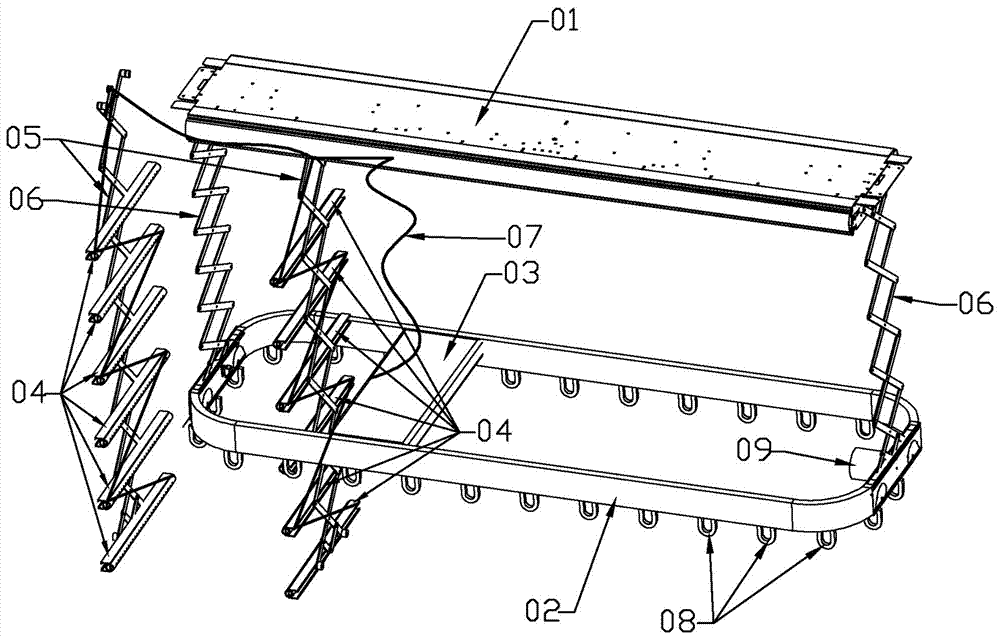

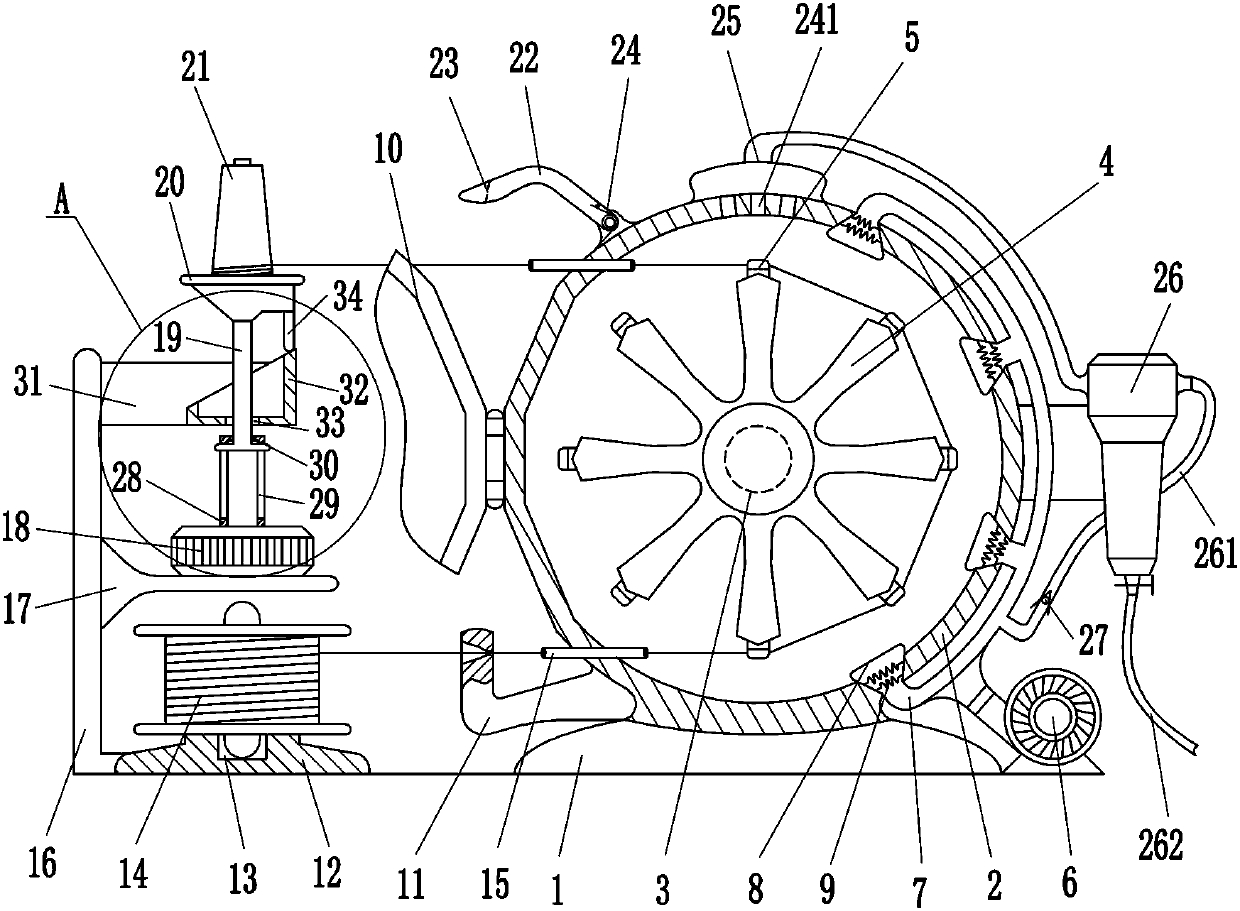

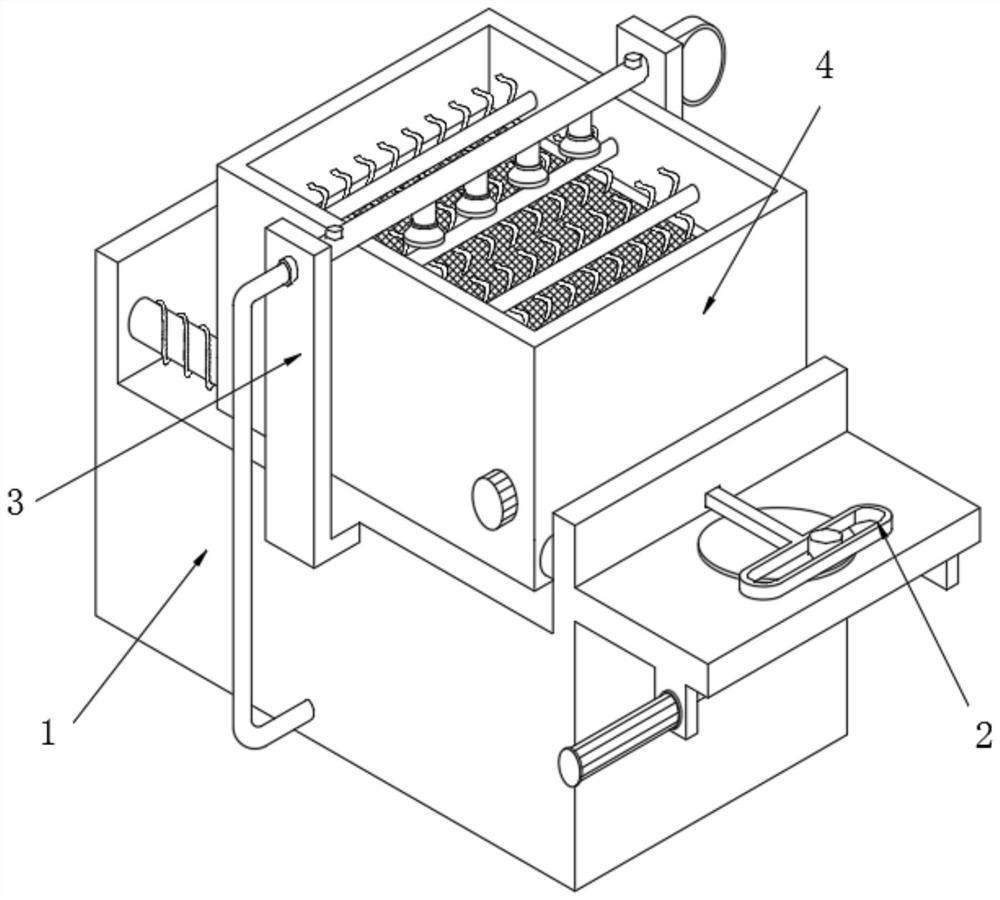

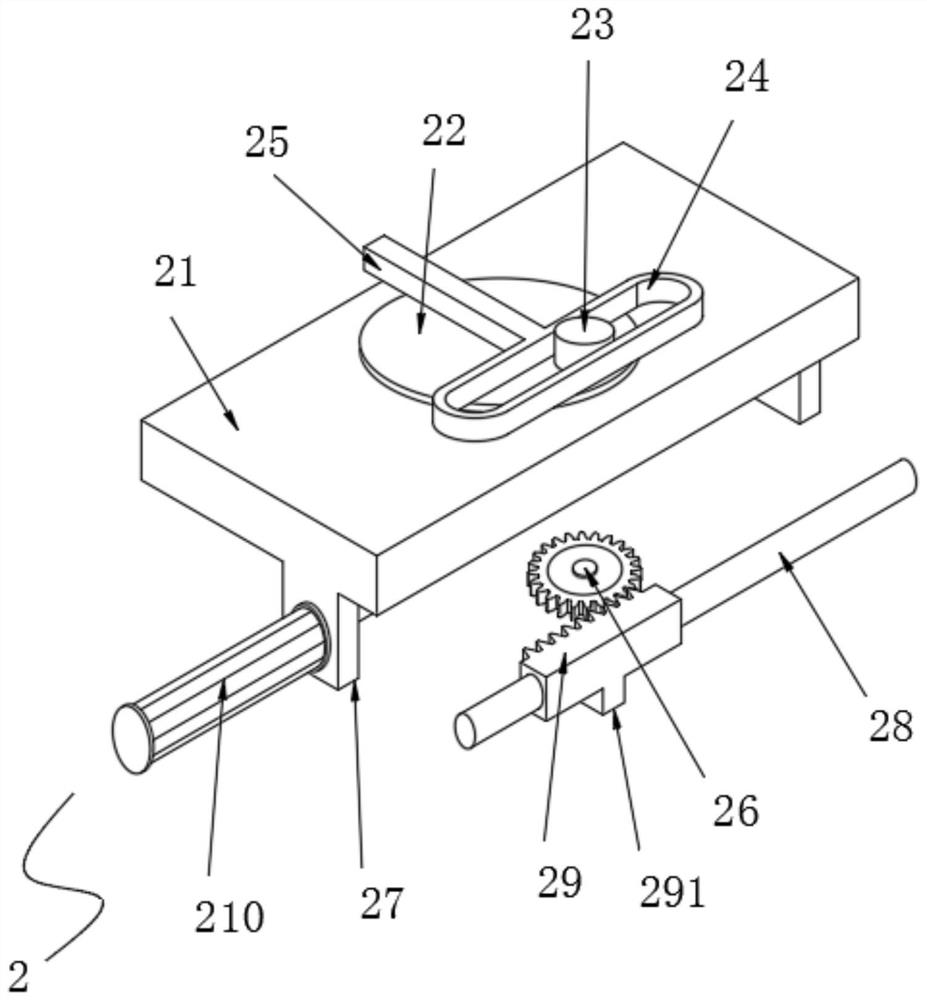

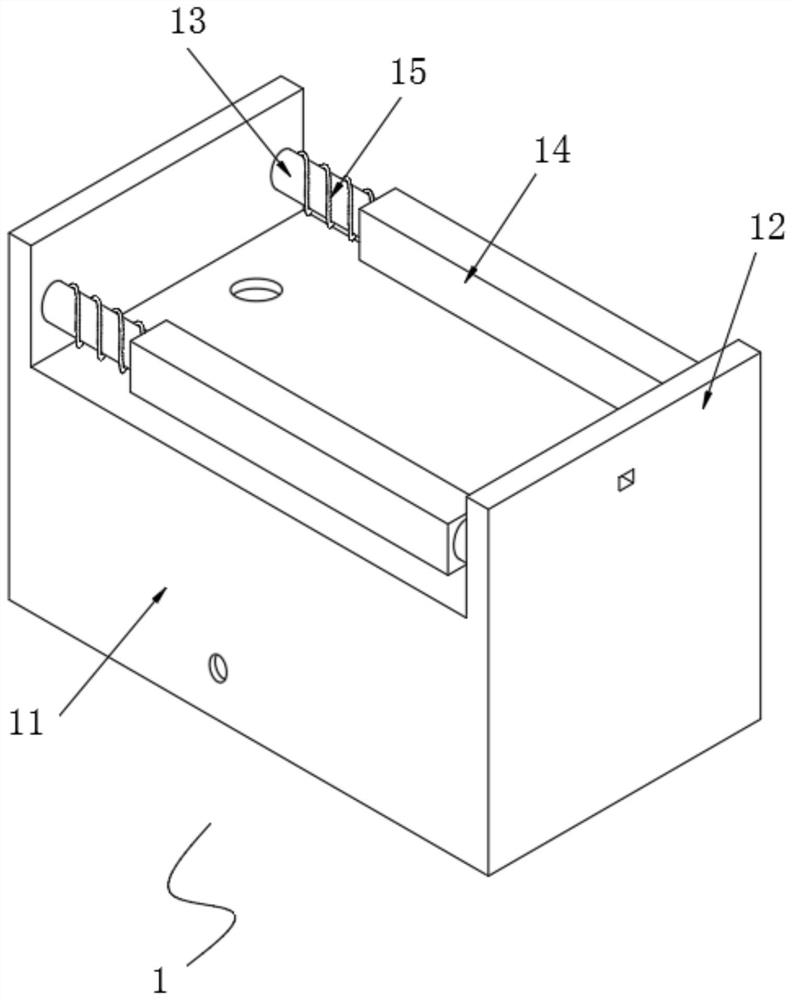

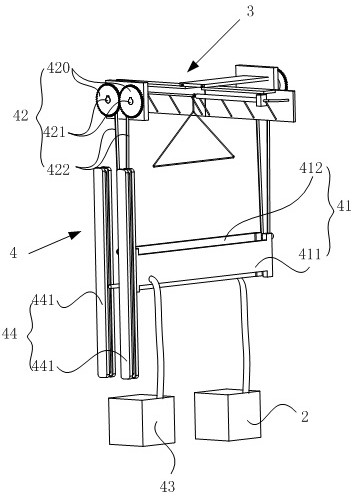

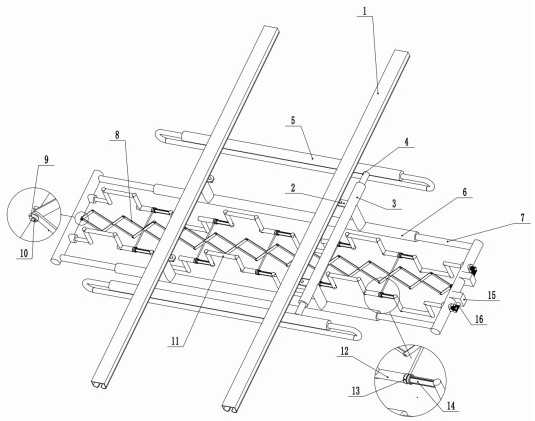

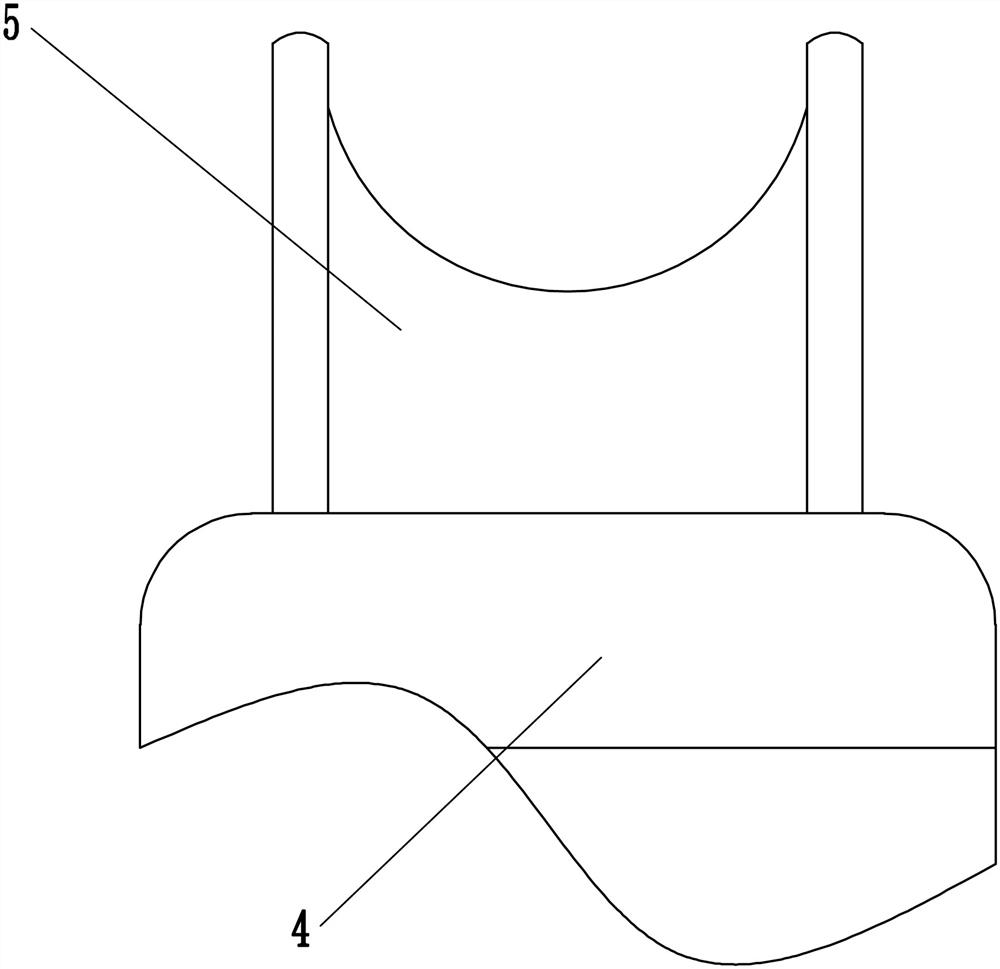

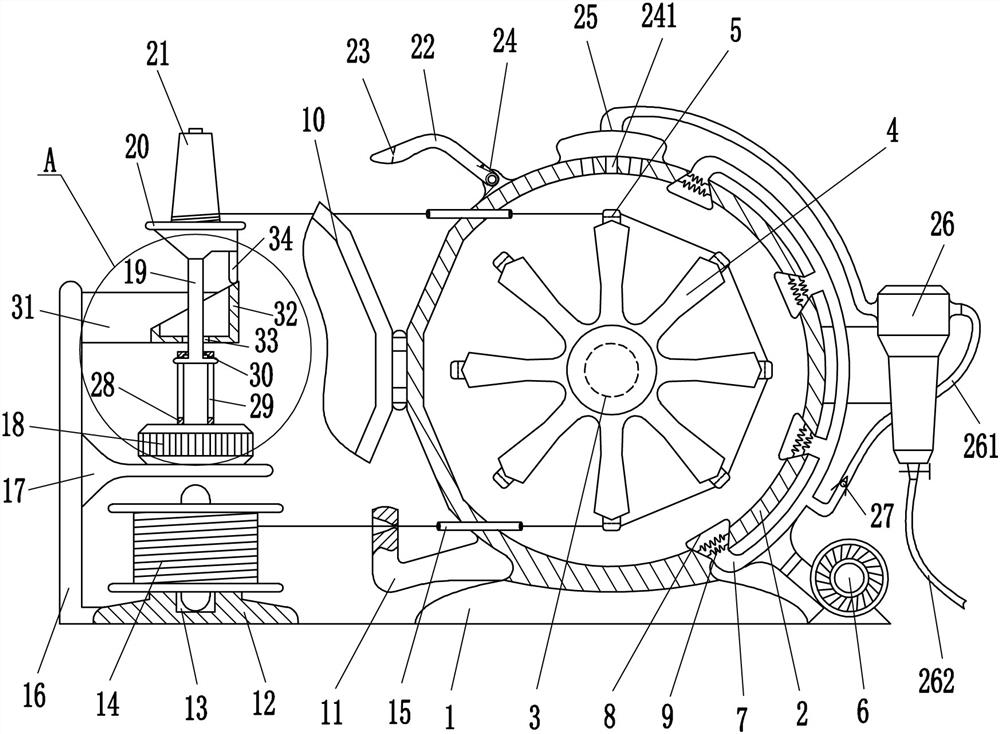

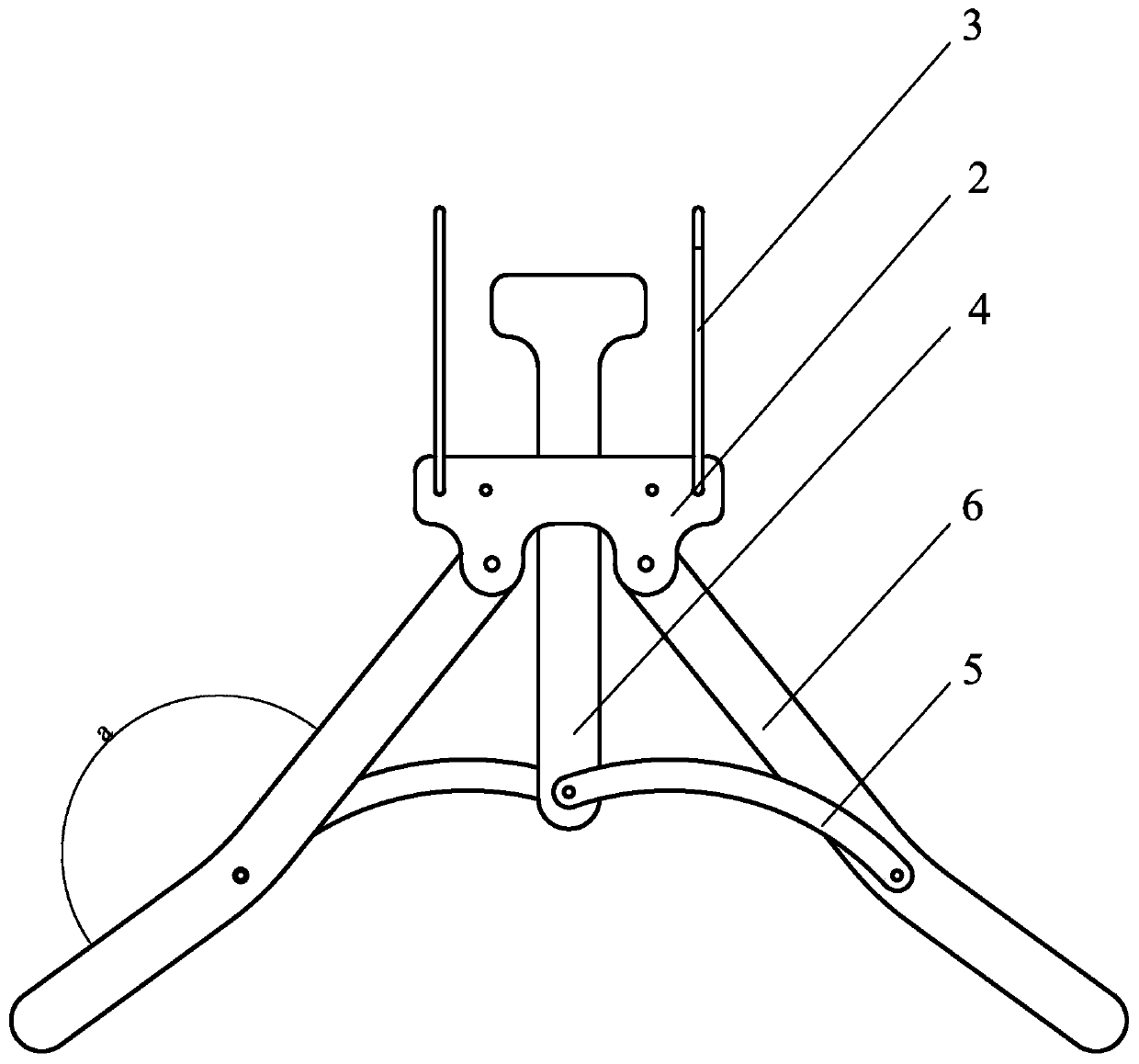

Fully-automatic clothes airing and collecting device

InactiveCN103266457AAutomatic retractionRegular dryingOther drying apparatusTextiles and paperElectric machineryEngineering

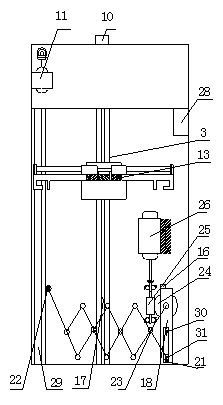

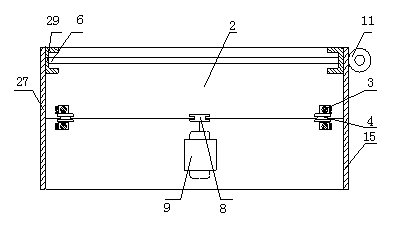

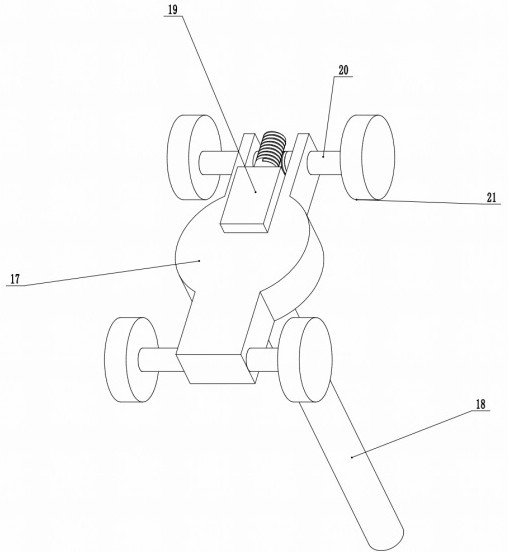

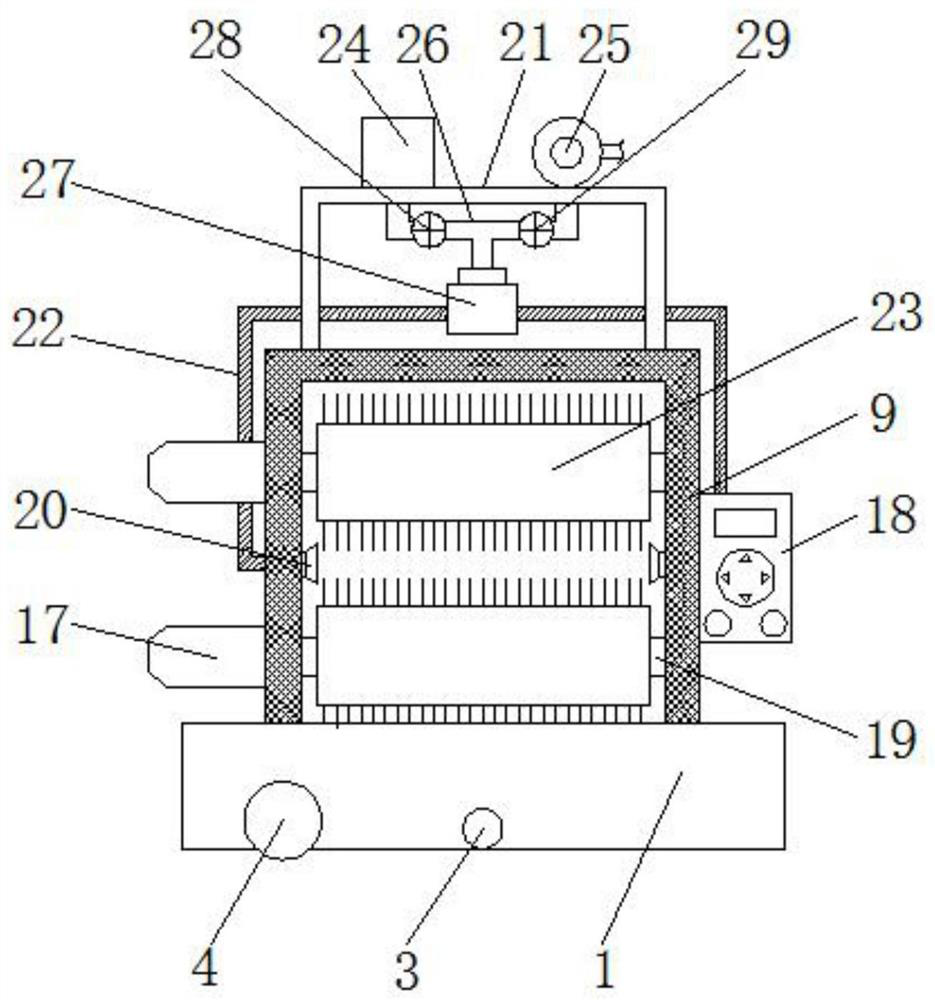

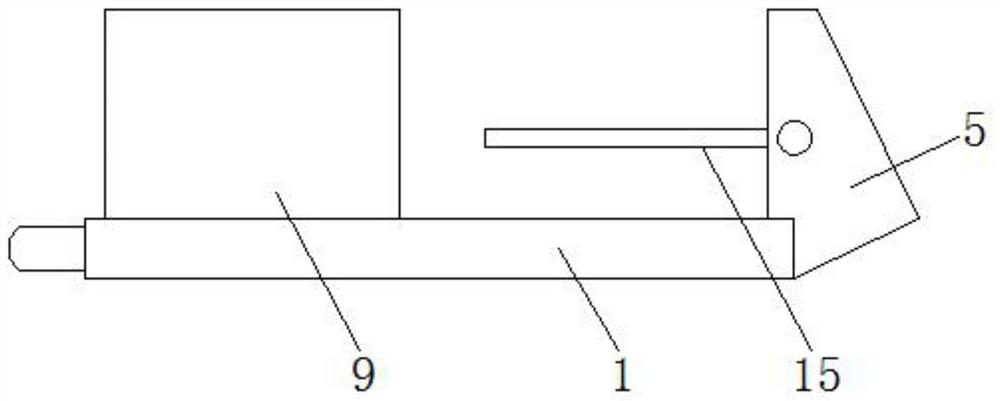

The invention belongs to the technical field of a fully-automatic clothes airing and collecting device. According to the technical scheme, a second motor (26) fixed on a left side plate (27) is in shaft connection with a worm (25) which is meshed with a worm gear (24), outer telescopic rods (20) on an outer telescopic rod shaft (23) are hinged to second sliding blocks (31) in guide grooves, and a third travel switch (30) and a fourth travel switch (21) are correspondingly installed on the upper portion and the lower portion of the right guide groove. A steel wire rope is wound on a wining drum (8) on a shaft of a first motor (9) and is connected with corresponding first sliding blocks (14) through two fixed pulleys (4), and an inner telescopic rod (13) are movably installed on the upper portions of the first sliding blocks (14). A shaft of a third motor (11) is connected with a roller shutter shaft (1) by means of bevel gear transmission, the upper end and the lower end of a roller shutter (5) are respectively connected with the roller shutter shaft (1) and a sliding rod (6) installed in sliding grooves (29), and fully-automatic clothes airing and collecting software is installed in a single chip microcomputer (28). The fully-automatic clothes airing and collecting device has the advantages of being high in safety, convenient to use, and capable of airing and collecting clothes in a timed mode.

Owner:WUHAN UNIV OF SCI & TECH

Working method of sludge cleaning device for municipal engineering river treatment

InactiveCN109056878AAvoid the hassle of follow-up processingAutomatically realize the lifting operationSludge treatment by de-watering/drying/thickeningWater cleaningSludgeEnvironmental engineering

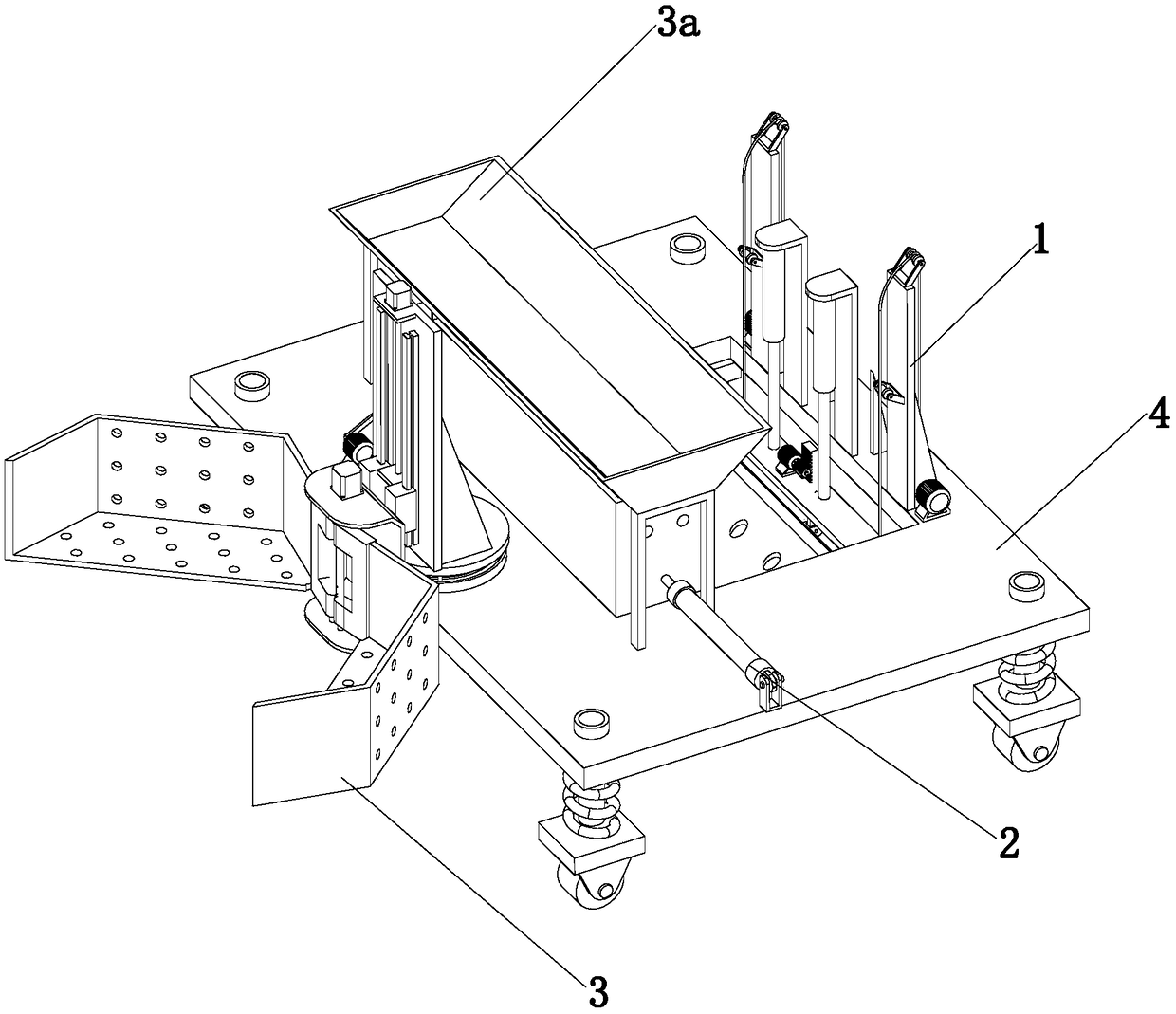

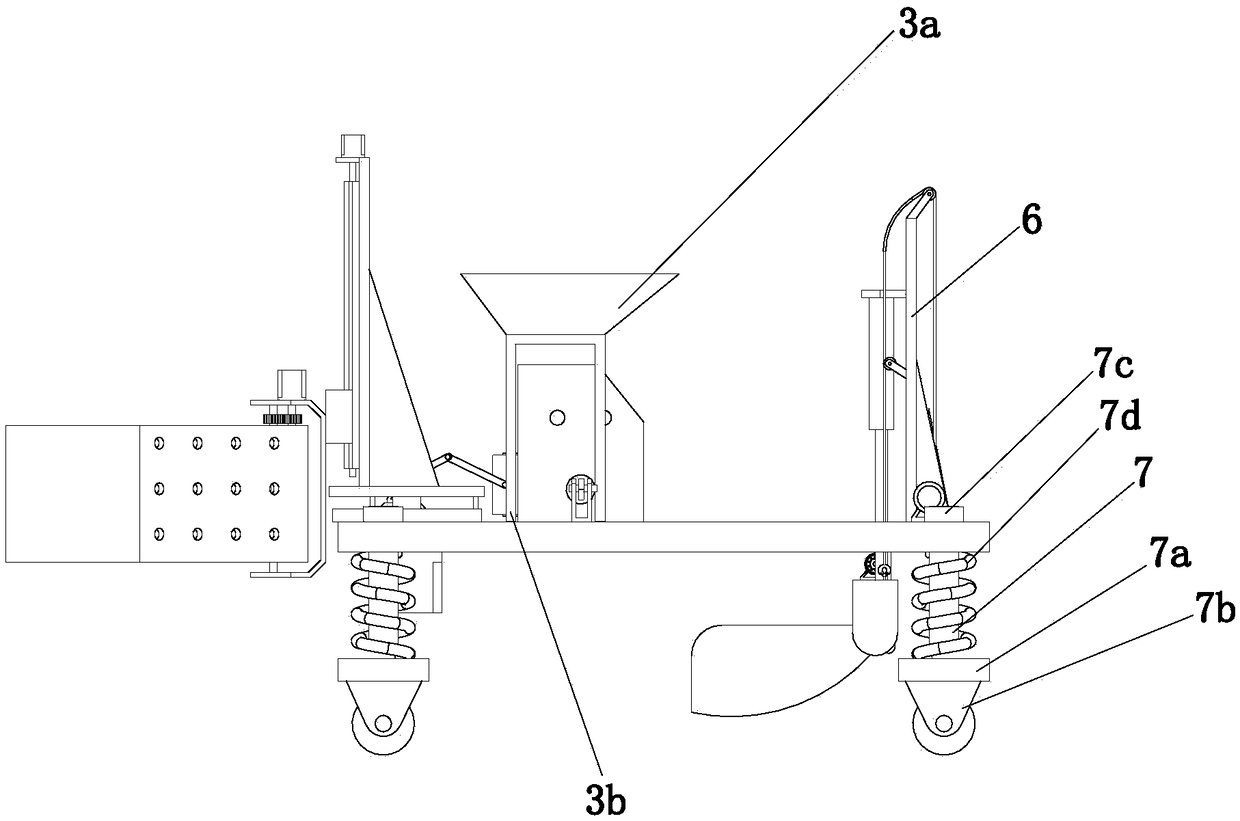

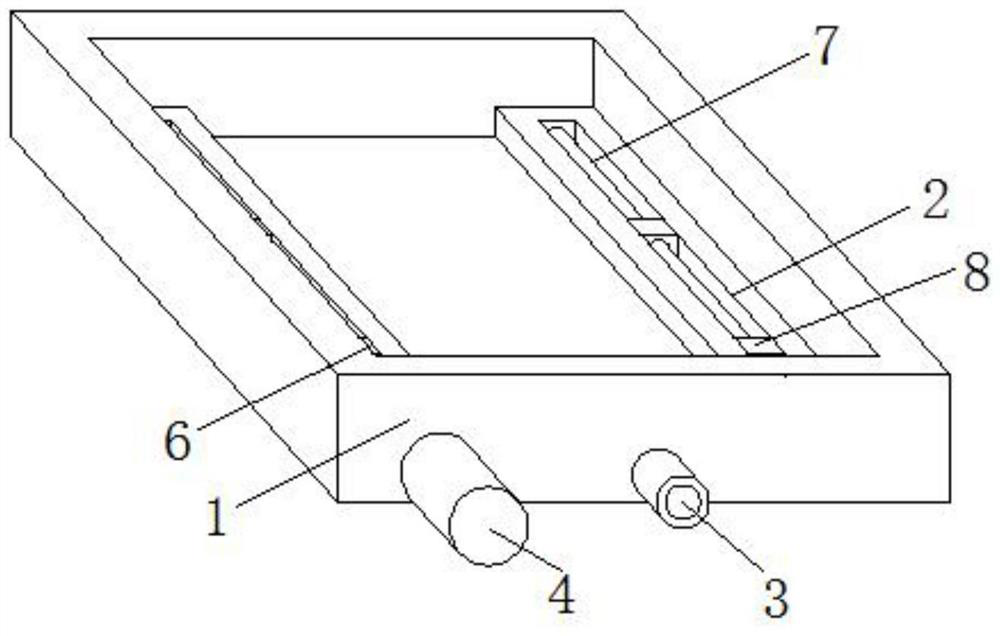

The invention relates to the technical field of municipal machinery, in particular to a sludge cleaning device for municipal engineering river treatment. The sludge cleaning device comprises a sludgefishing mechanism, a sludge treating mechanism, a floating object collecting mechanism and a bottom plate which is horizontally arranged, wherein the bottom plate is of a cuboid structure; and the sludge fishing mechanism comprises a sludge collecting assembly and a lifting assembly which is used for driving the sludge collecting assembly to ascend and descend, the sludge collecting assembly comprises a U-shaped connecting plate and a rotating shaft, and the rotating shaft is provided with a fishing box with an upward opening in a sleeve mode. The sludge cleaning device has the beneficial effects that the fishing operation of river sludge can be automatically realized through the sludge fishing mechanism, the drying and crushing operation of the sludge can be automatically realized throughthe sludge treating mechanism, and floating objects can be automatically collected through the floating object collecting mechanism, so that workers do not need to manually carry out fishing, and therefore the working efficiency of municipal administration is improved.

Owner:无锡盛佳亿建设工程有限公司

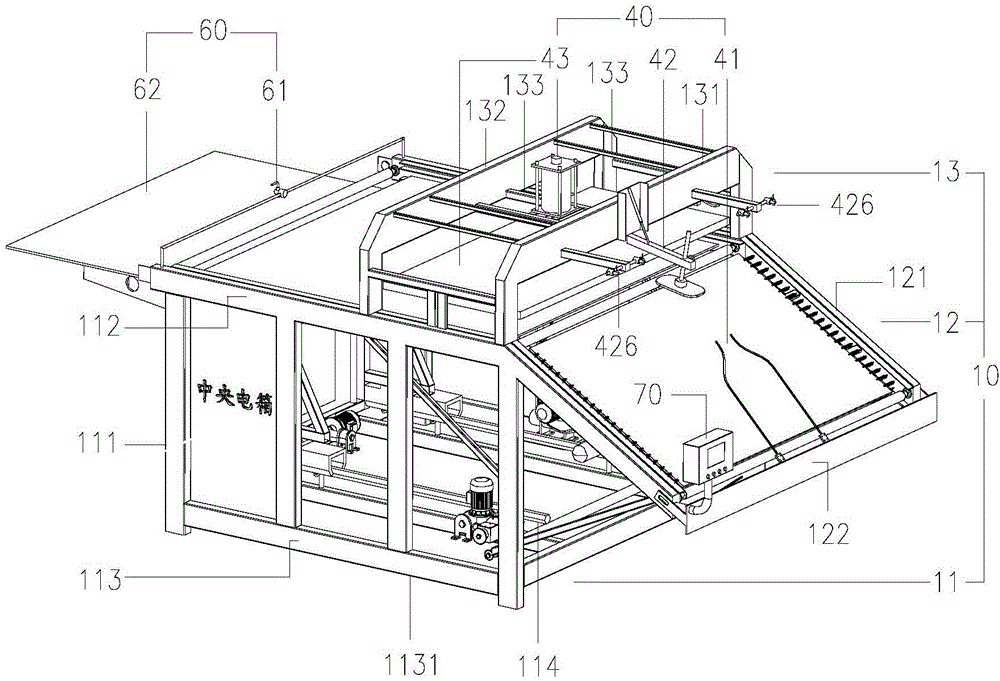

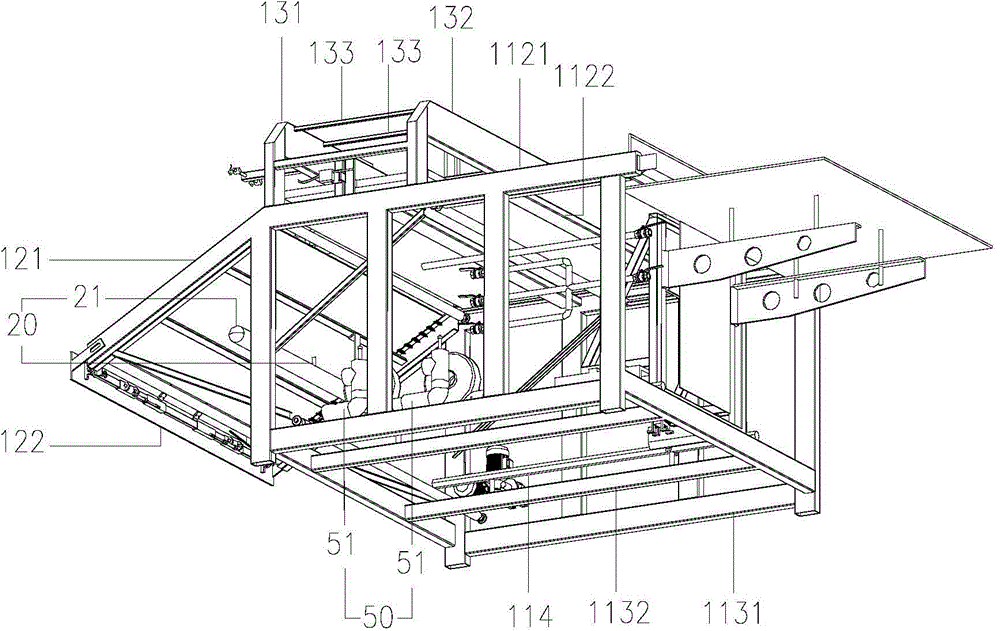

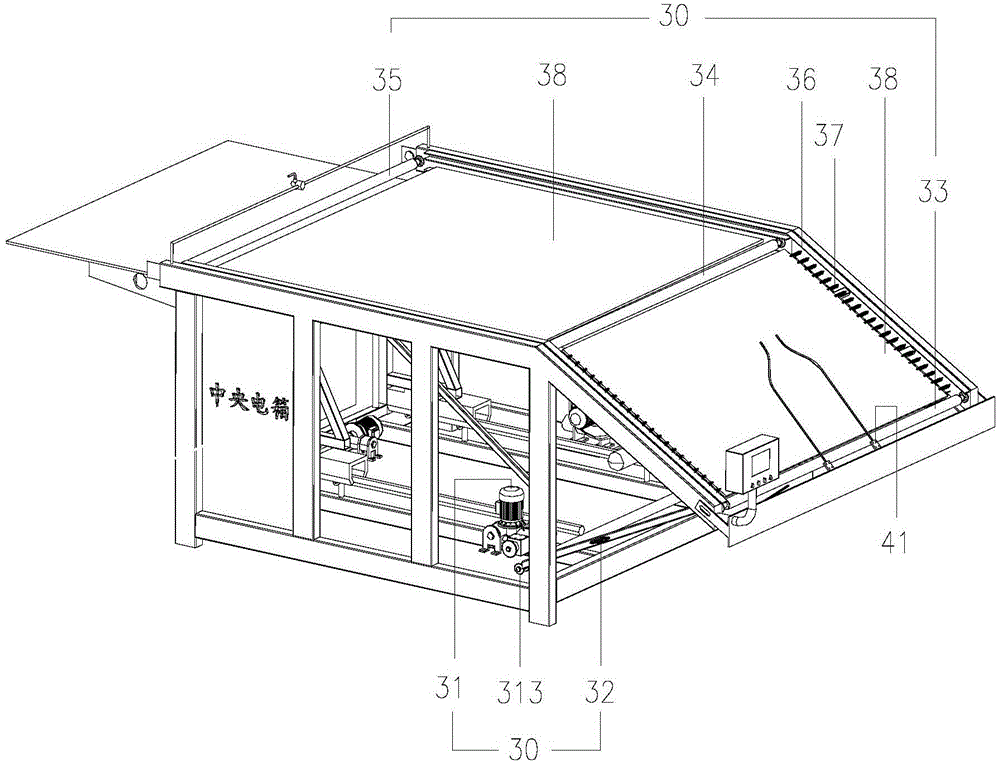

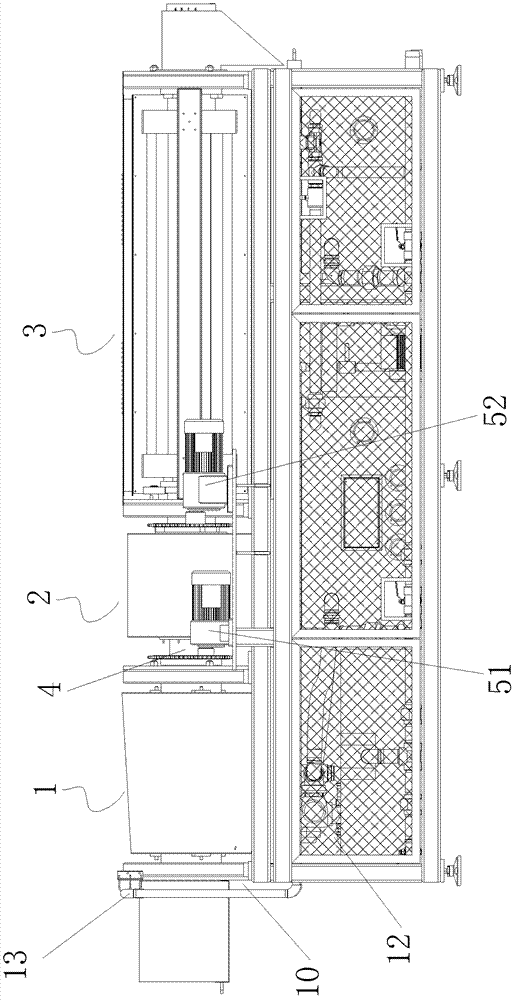

Woolen knitwear steaming setting machine

InactiveCN104805666AAchieve ironing and settingAvoid out of shapeHeating/cooling textile fabricsIroning apparatusSupport groupPulp and paper industry

The invention provides a woolen knitwear steaming setting machine. The woolen knitwear steaming setting machine comprises a machine frame, a steam evaporating group, a transmission group, an ironing positioning group, a ventilating dehumidifying group, a counting clothes supporting group and an electric control group, wherein the machine frame comprises a main frame part, an inclined frame part and a top frame part; the main frame part is provided with a main rod, an upper frame and a lower frame; the inclined frame part is combined with the front side of the upper frame body and is provided with a surface beam; the top frame part is arranged on the upper frame body; the steam evaporating group comprises a steam temporary storage device; the steam temporary storage device is communicated with the ventilating dehumidifying group through a pipeline; the transmission group drives a first roller, a second roller, a third roller and a conveying cloth belt of the transmission group by adopting chain transmission; a transmission chain used for the chain transmission is provided with ear holes; the first roller is overlapped to the second roller and the third roller through the conveying cloth belt; metal rings are arranged on the two side peripheries of the conveying cloth belt corresponding to the ear holes; the ear holes are connected with the metal rings through springs. Through the structure, the technical problems about woolen knitwear steaming and setting are solved; good effects that the operation is facilitated, and the steaming efficiency is improved are achieved.

Owner:郑野

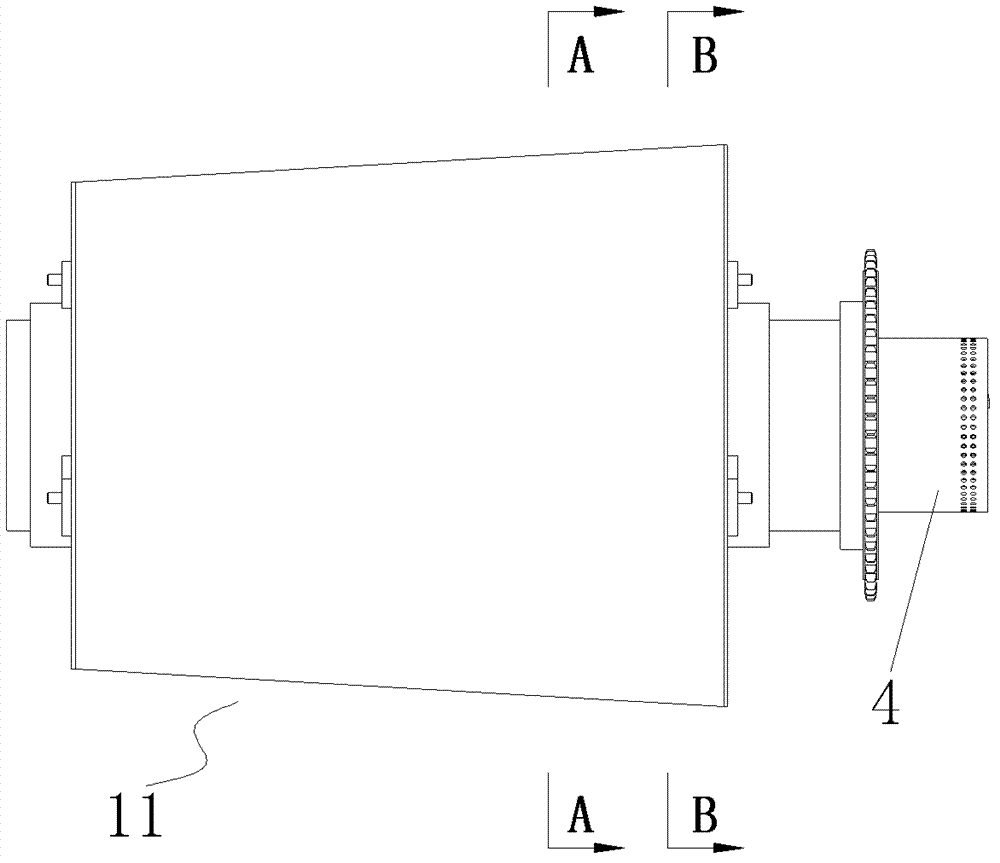

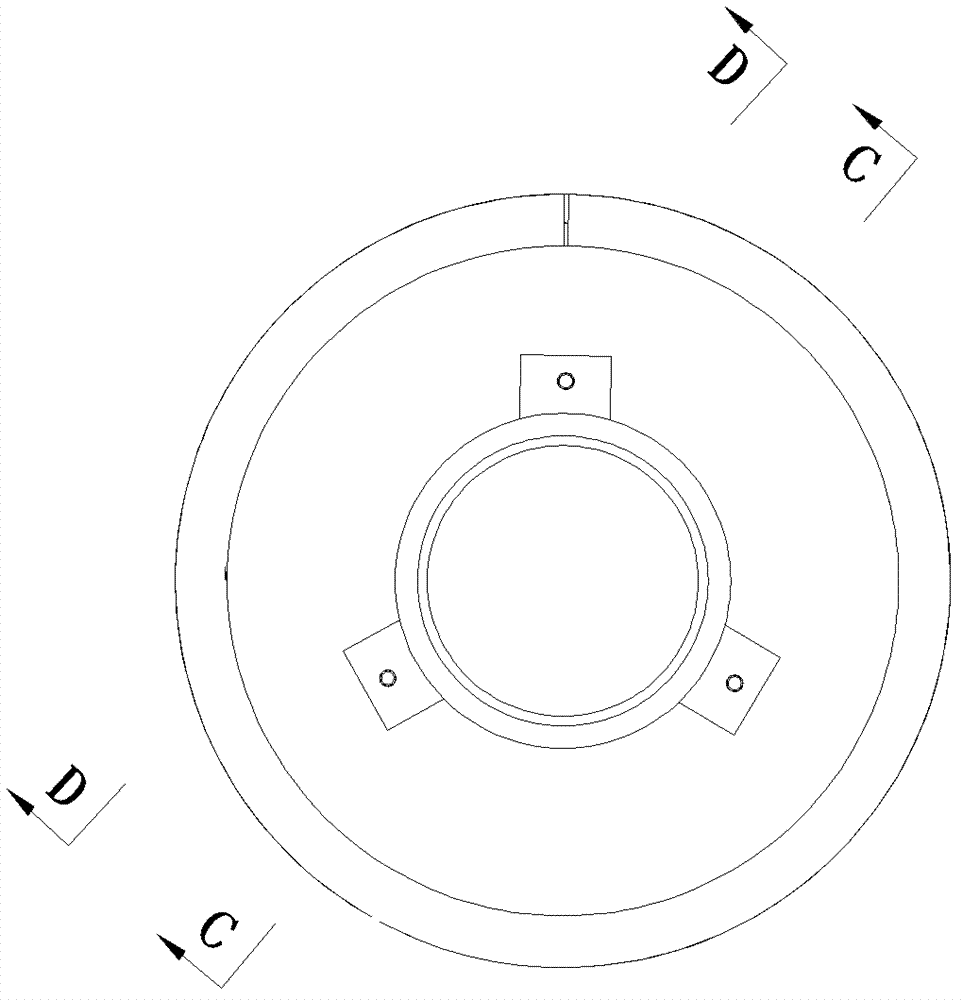

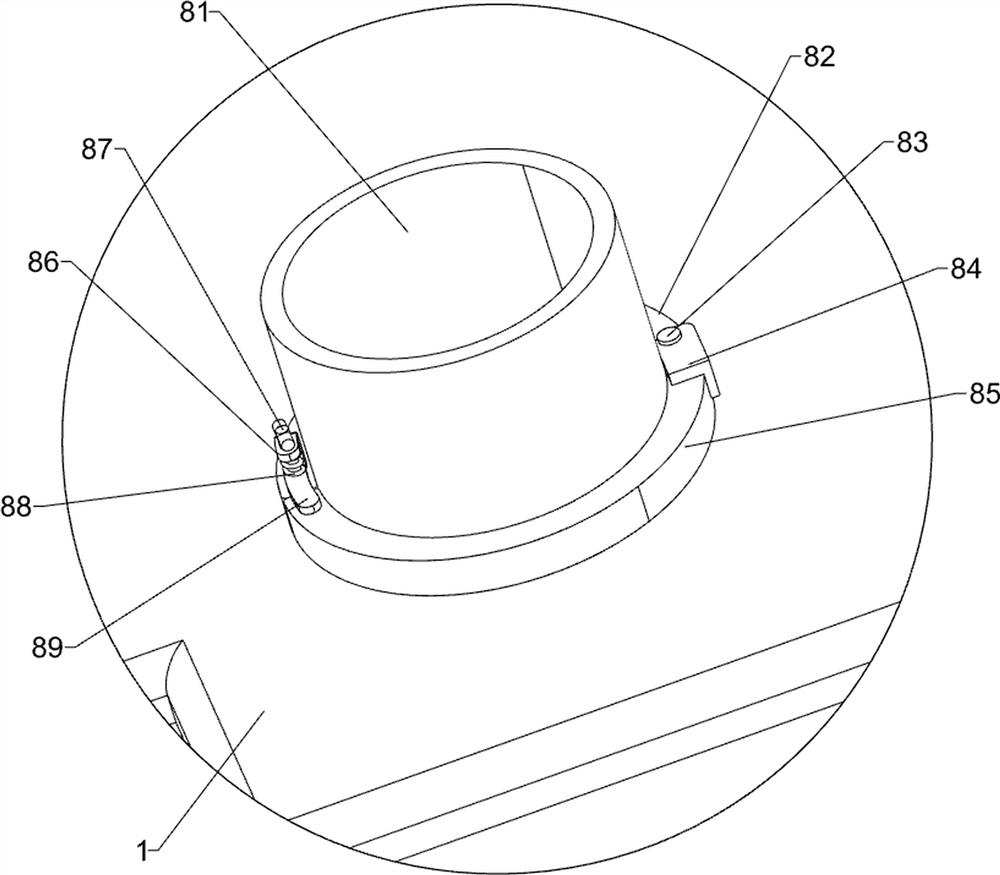

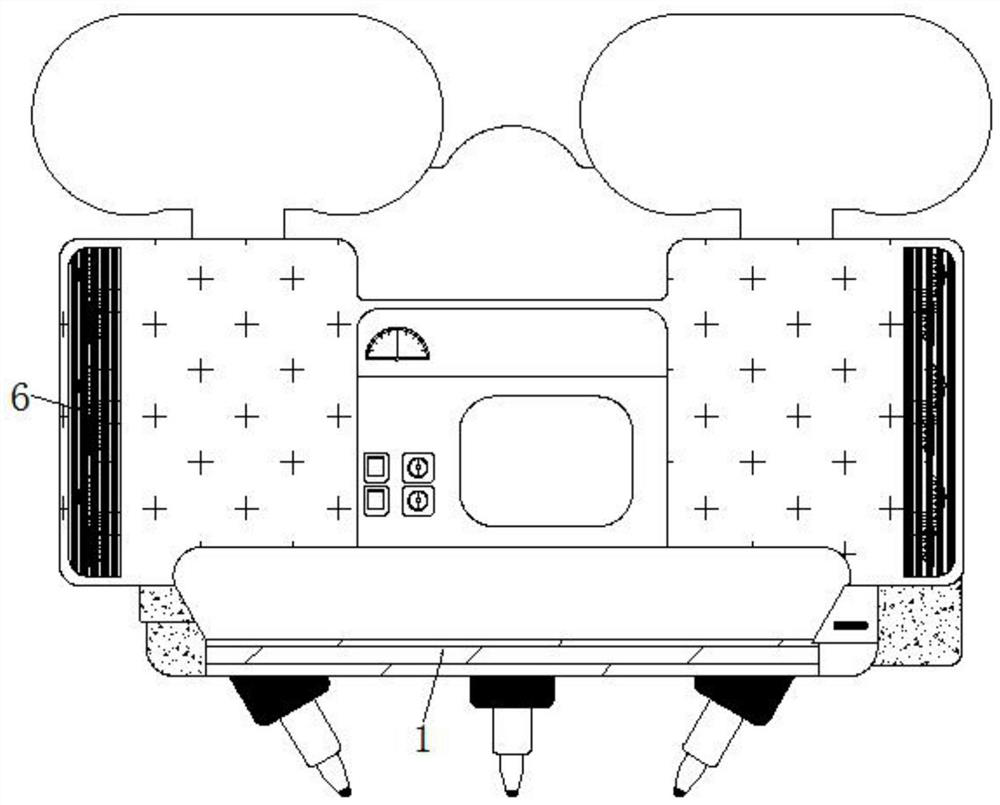

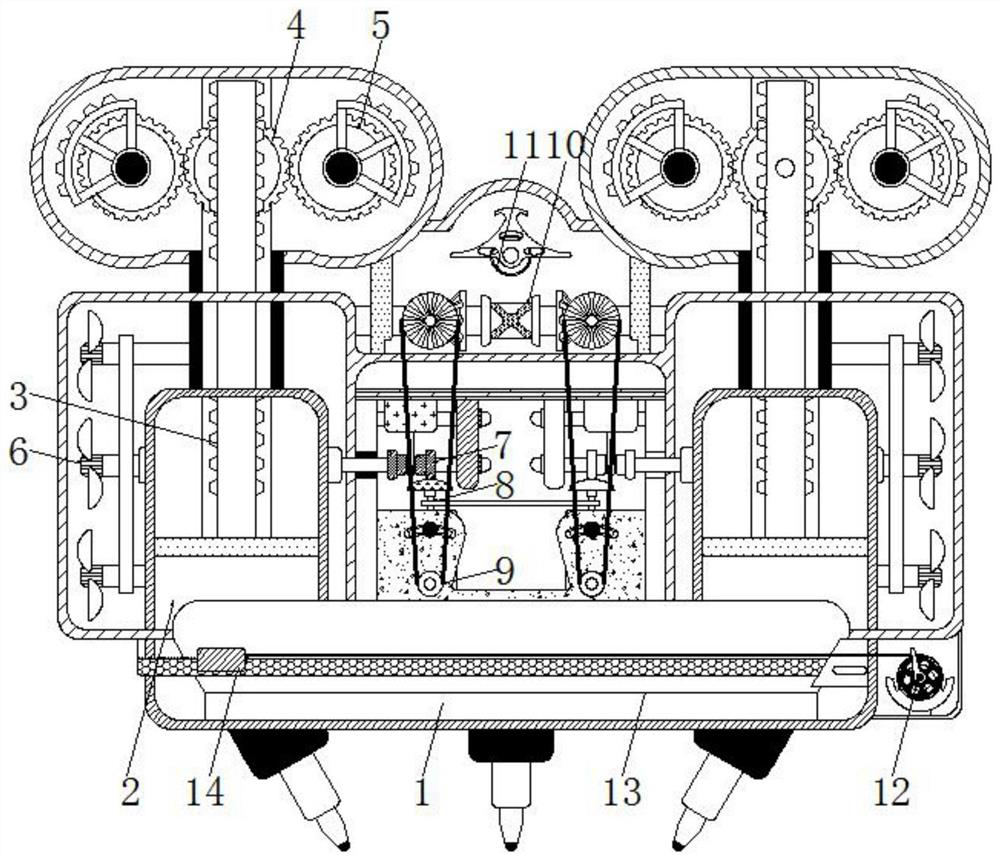

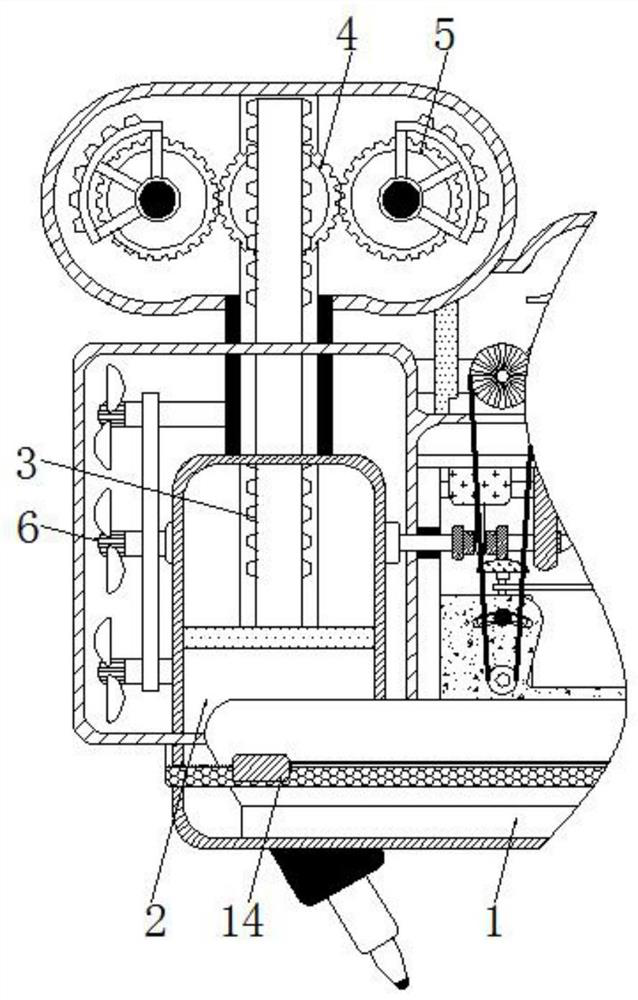

Clothes airing machine with automatic hanging ironing function

PendingCN107964773ANo manual operationAchieve dryingIroning apparatusOther drying apparatusMechanical engineeringIndustrial engineering

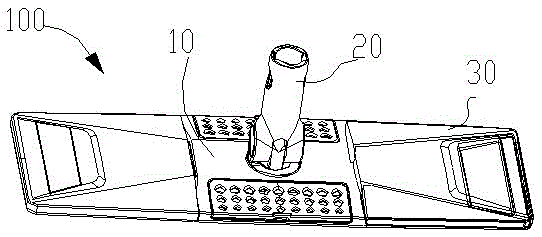

The invention discloses a clothes airing machine with an automatic hanging ironing function, and belongs to clothes airing machines. An existing drying rack with the hanging ironing function cannot hang multiple clothes and iron the clothes automatically. According to the clothes airing machine, the drying rack is designed to be shaped like a ring and provided with a hanging structure which can bedriven to move along the ring-shaped drying rack, steam nozzles are arranged on the inner side and the outer side of the ring-shaped drying rack, when clothes move along the ring-shaped drying rack along with the hanging structure, the steam nozzles spray steam to the clothes from the inner side and the outer side to iron the clothes, manual operation is not needed, and full-automatic airing andhanging ironing are achieved.

Owner:AUPU HOME STYLE CORP LTD

Drying device

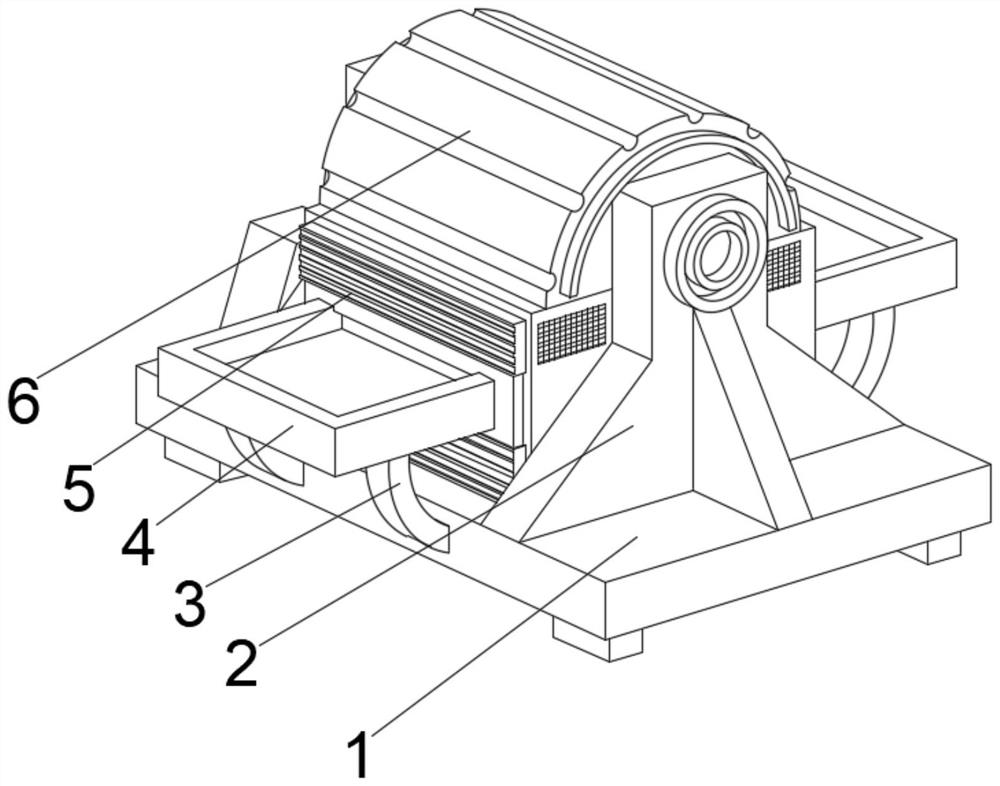

InactiveCN102901337AAutomatic dryingEasy to operateDrying solid materials with heatHearth type furnacesHorizontal axisEngineering

The invention relates to a drying device, in particular to a drying device for drying a U-shaped tube. The drying device comprises a material conveying device and a heating device. The material conveying device comprises a drying cylinder which can rotate around a horizontal axis and a spiral flange plate which is mounted in the drying cylinder and is used for material guiding, and the heating device is mounted outside the drying cylinder. The drying device has the advantages that water on the U-shaped tube can be dried automatically, and the drying device is convenient to operate, safe and reliable.

Owner:ZHONGSHAN OMS AUTOMATION EQUIP

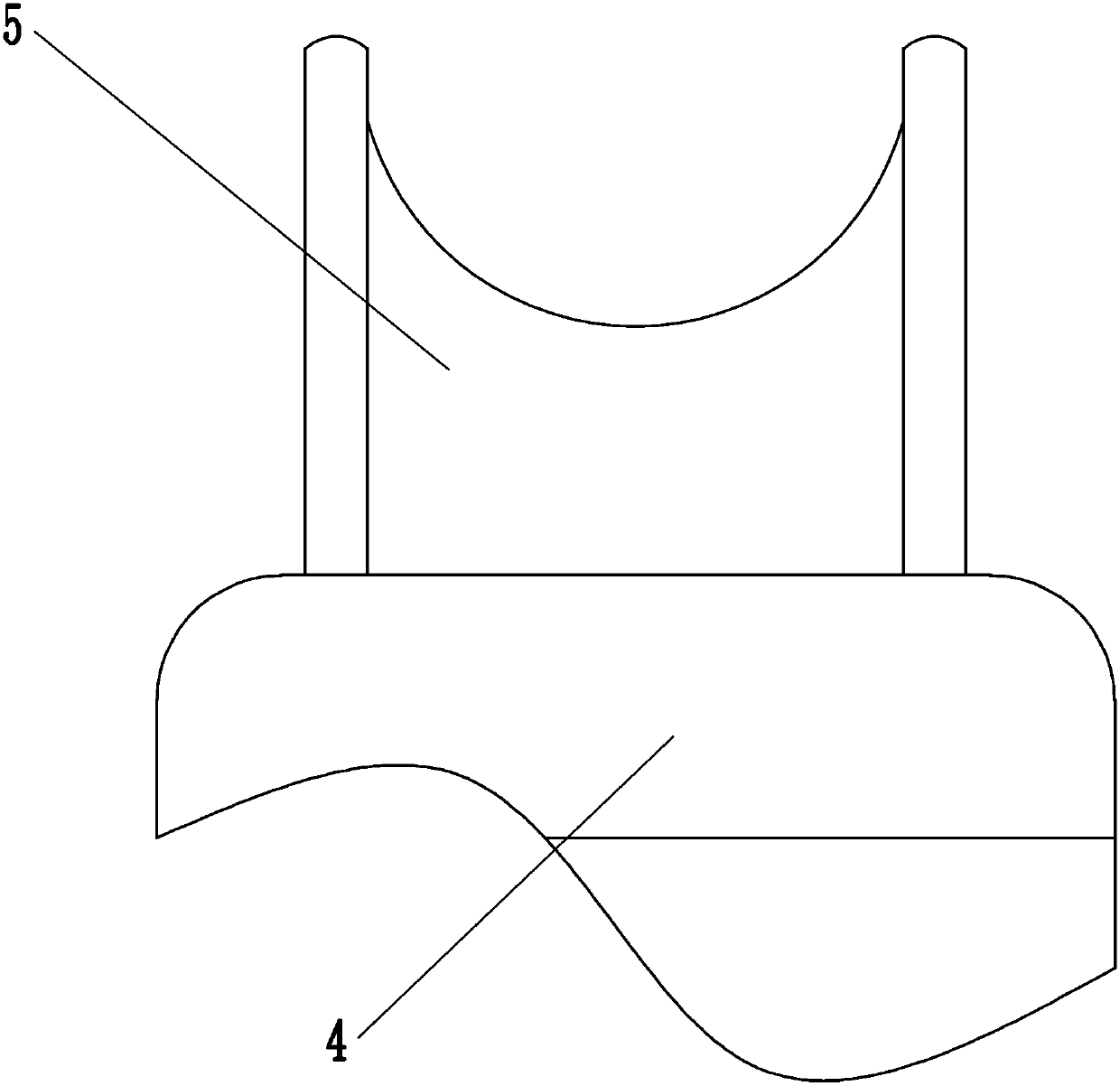

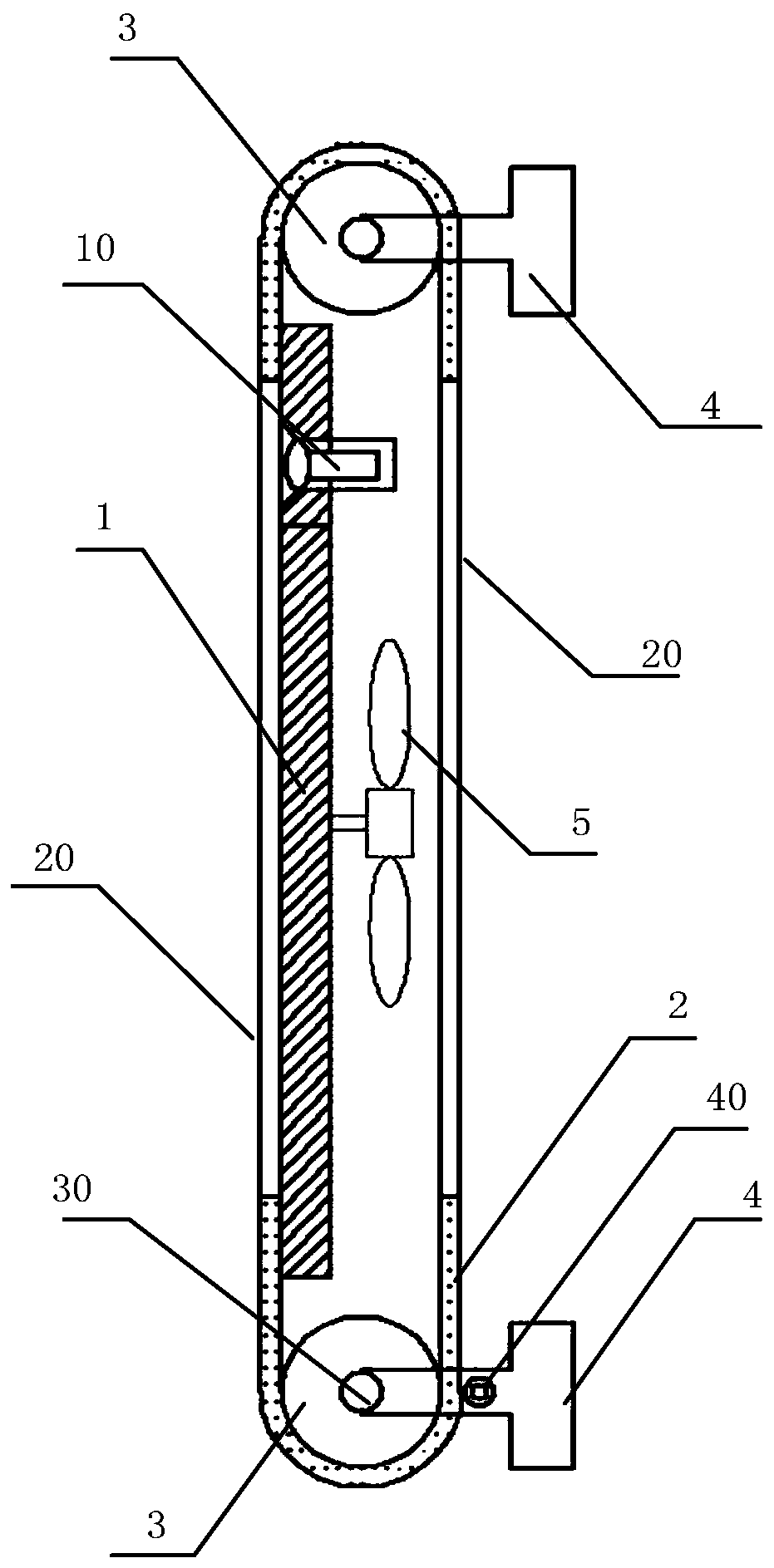

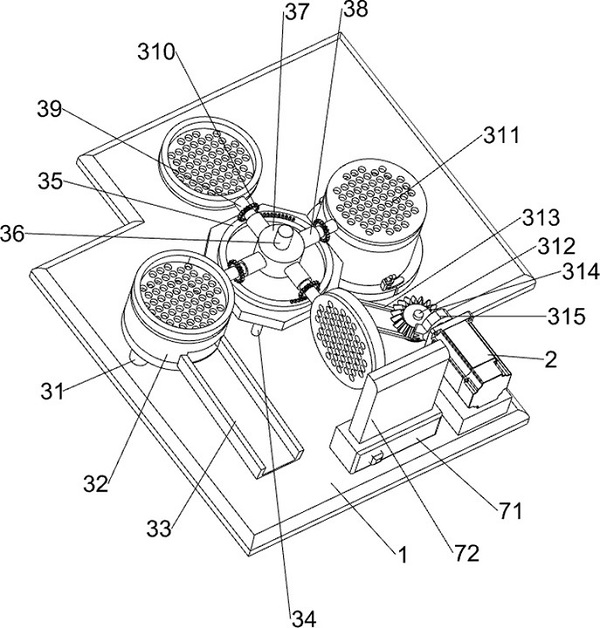

Yarn drying equipment for textile

ActiveCN110230921AAutomatic dryingAutomatic windingFilament handlingDrying gas arrangementsElectric heatingYarn

The invention relates to drying equipment, in particular to a yarn drying equipment for textile. The invention aims to provide the yarn drying equipment for the textile which can automatically wind updried yarn and completely dry the yarn. According to the technical scheme, the yarn drying equipment for the textile comprises a first base, a box body, a first motor, a polygonal support, arc-shapedsupporting blocks, an air blower, a multi-way pipe, a trumpet-shaped air inlet pipe, an electric heating wire, a box door and the like; the top of the first base is provided with the box body, the first motor is connected to the middle of the inner rear side of the box body through a bolt, an output shaft of the first motor is provided with the polygonal support, and the eight arc-shaped supporting blocks which are uniformly spaced are fixedly connected to the outer side of the polygonal support. According to the yarn drying equipment for the textile, air can be heated into hot air through the electric heating wire, so that the yarn can be dried; and due to the fact that the yarn is wound around the arc-shaped supporting blocks, the hot air can be uniformly sprayed on the yarn, and then the yarn can be completely dried.

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

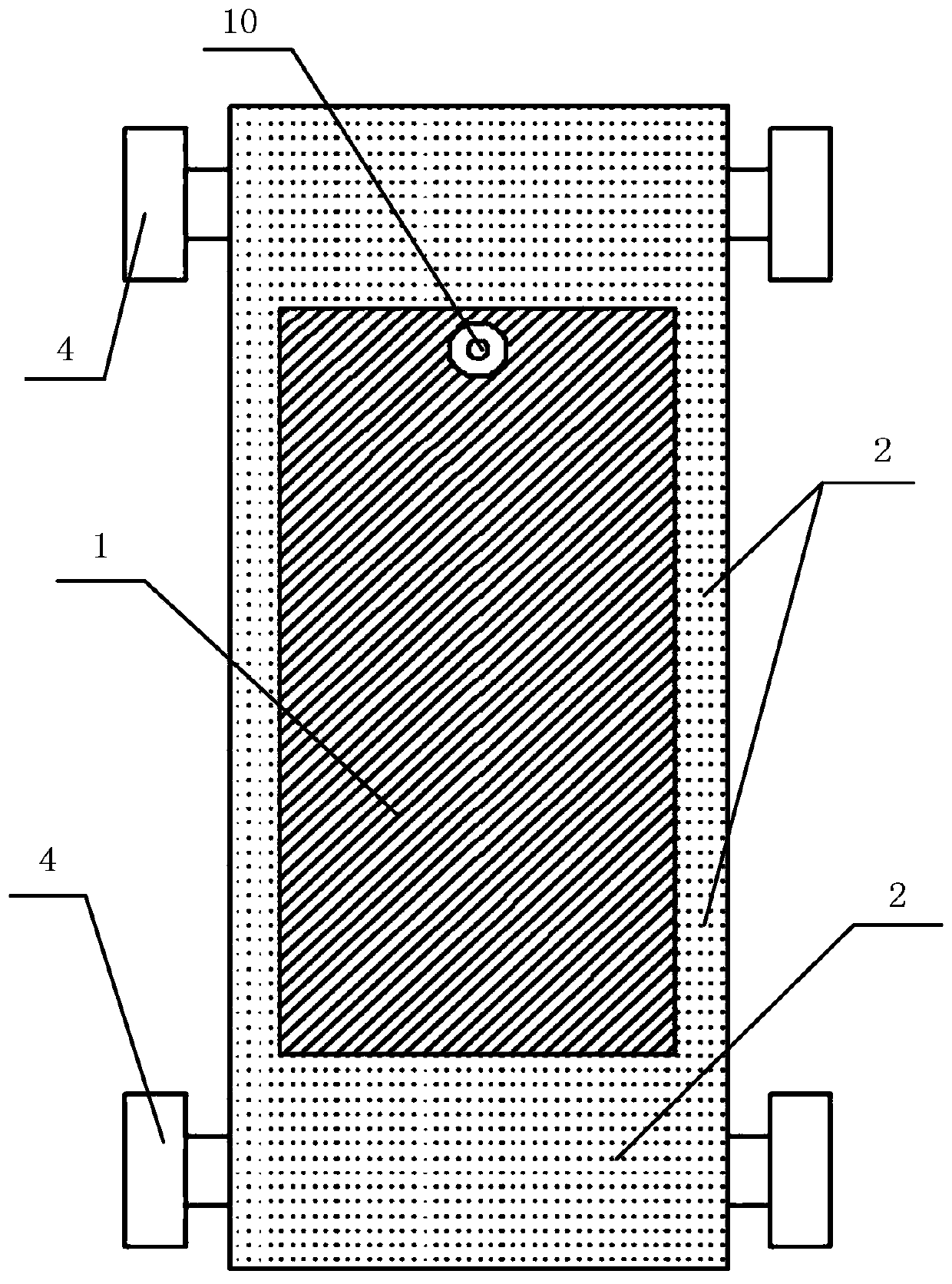

Bathroom quick defogging mirror

The present invention provides a bathroom quick defogging mirror, and belongs to the field of daily necessities manufacturing. The bathroom quick defogging mirror comprises a mirror body and two rollers arranged in parallel; the outer sides of the two rollers are sleeved with an annular structure scrubbing belt which can synchronously rotate with the two rollers; the scrubbing strip is an annularstructure and is arranged around the mirror body; the scrubbing belt is provided with a viewing window; the viewing window can correspond to a mirror surface of the mirror body; and the mirror body isfixed between the two rollers, and the mirror surface of the mirror body is in contact with the scrubbing belt. According to the bathroom quick defogging mirror provided by the present invention, themirror surface is continuously cleaned by the reciprocating rotating rollers to drive the annular structure scrubbing belt, so that the influence on use by the water mist condensate on the mirror surface can be avoided; and when the bathroom quick defogging mirror is not in use, the scrubbing belt can be used to directly cover the mirror surface to avoid dust falling on the mirror surface, and the purpose of automatically drying the scrubbing belt can be also achieved.

Owner:NANNING UNIV

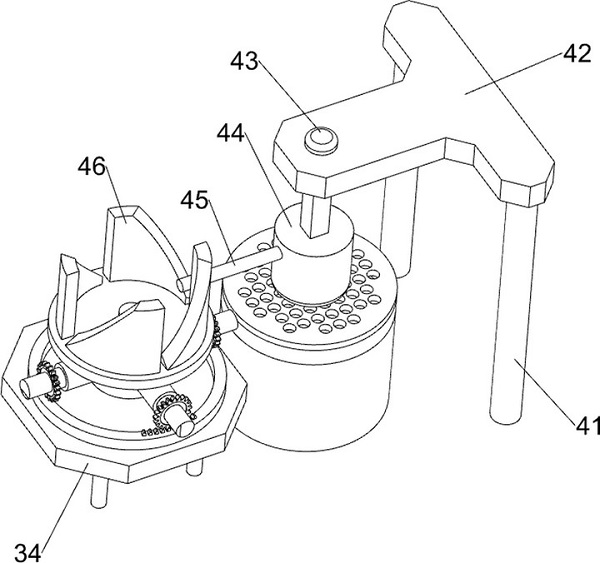

Full-intelligent pneumatic operation process for precision accessories of medical devices

InactiveCN112808643AImprove cleaning qualityReduce labor intensityDrying gas arrangementsCleaning using toolsControl engineeringProcess engineering

Owner:武汉嘉安特精密机械有限公司

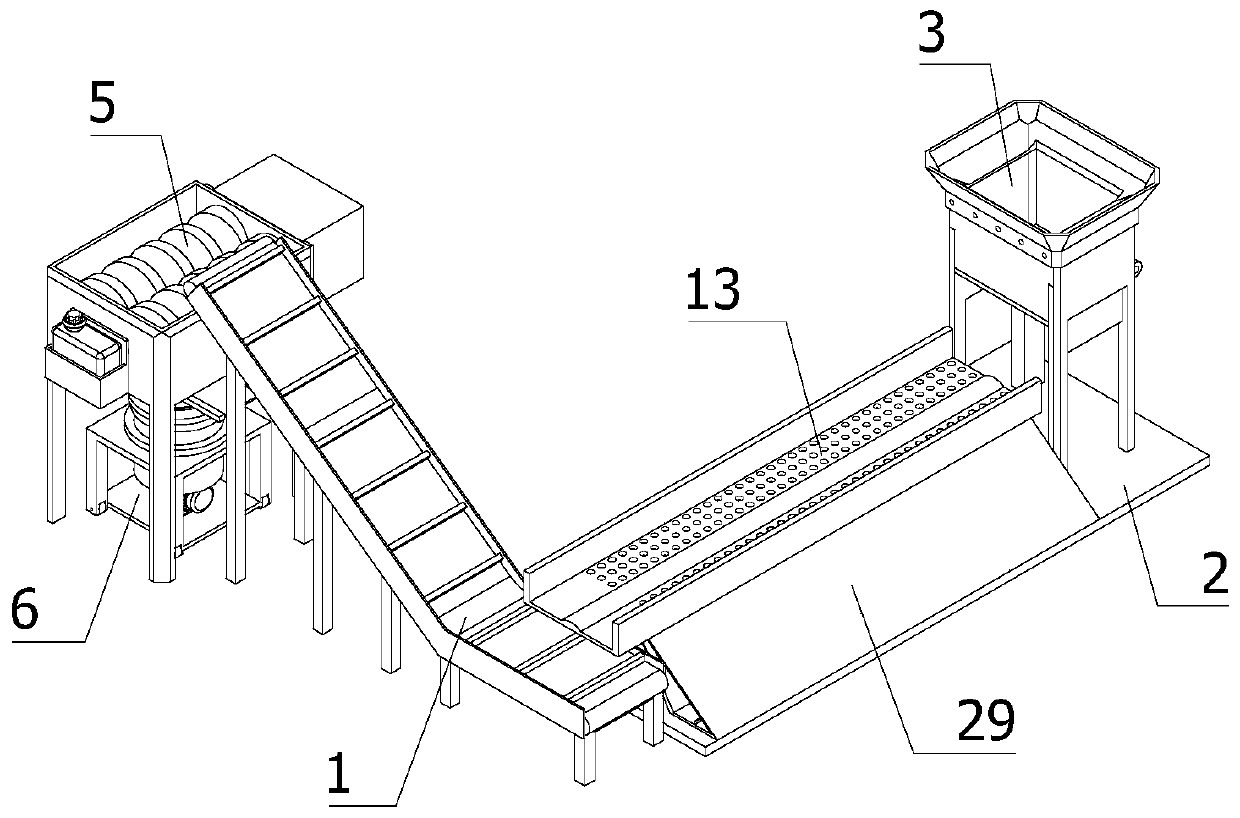

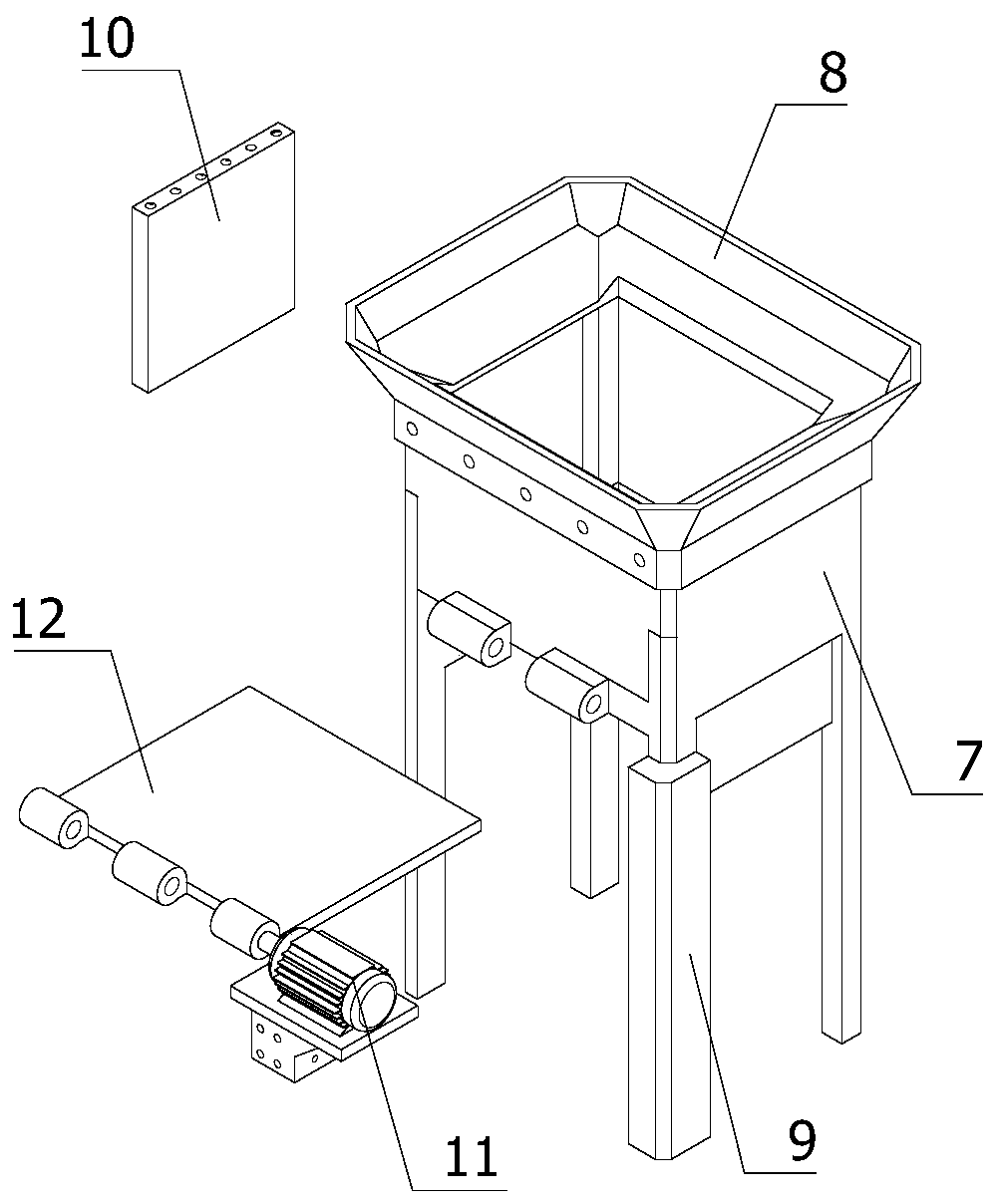

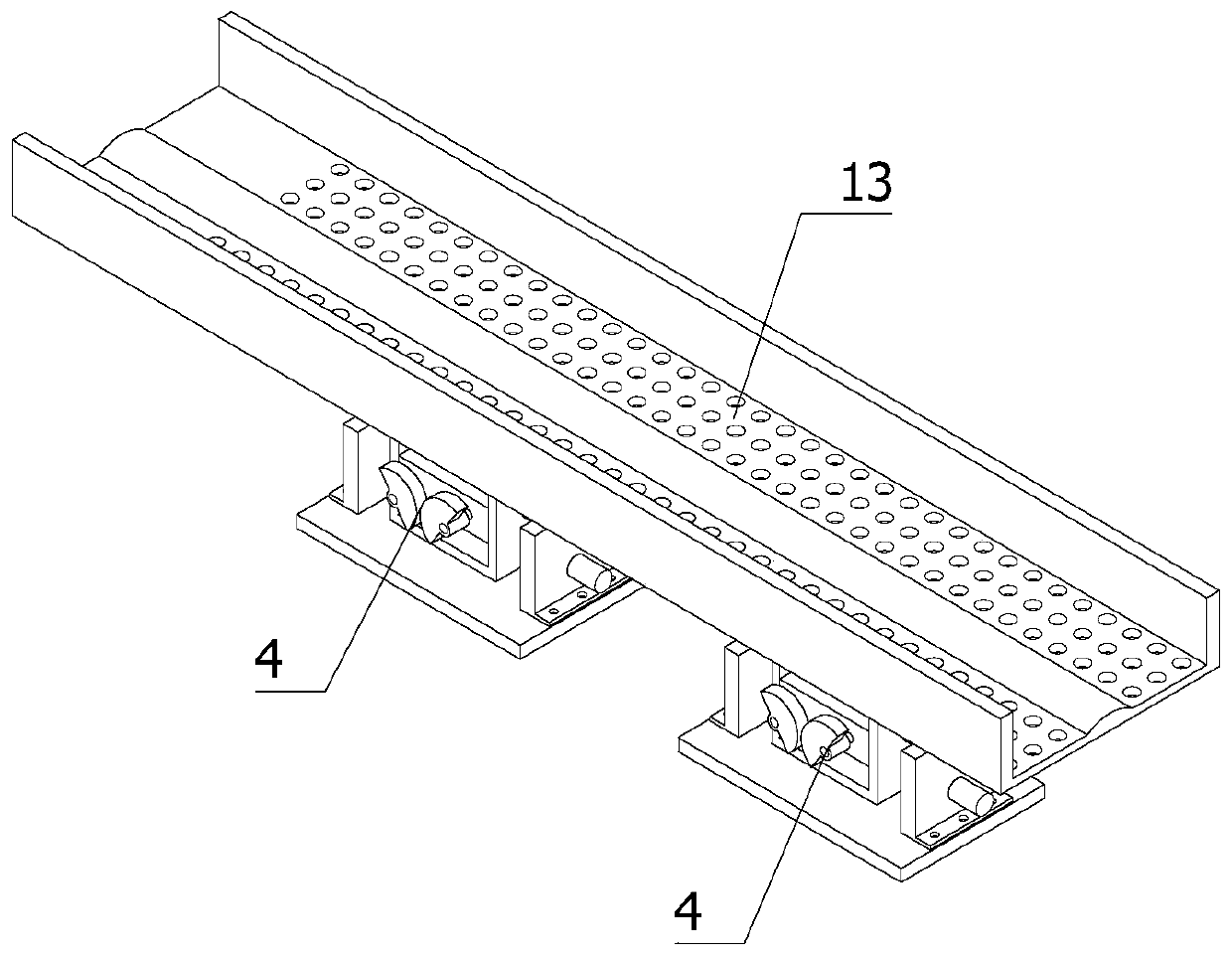

Automatic cleaning device for livestock breeding

InactiveCN111480584AEasy to collectEasy to replaceAnimal housingGrain treatmentsAnimal scienceCrop livestock

The invention relates to the field of livestock breeding equipment, in particular to an automatic livestock breeding cleaning device which comprises a conveying belt device and further comprises a base, a drying storage device, a vibration feeding device, a smashing device and a movable collecting device. The drying storage device is arranged at one end of base, the vibration feeding device is horizontally arranged on base, the conveying belt device is vertically arranged on the side, away from the drying and storing device, of the vibration feeding device, the smashing device is arranged at the end, away from the vibration feeding device, of the conveying belt, and the movable collecting device is arranged under the smashing device and can automatically dry, screen and smash mixtures suchas padding in the breeding shed. Meanwhile, the packing grass is more convenient to collect and replace, the device is particularly suitable for being used in a large livestock farm, a large amount of labor force of workers is reduced, and secondary utilization of the collected packing grass is facilitated.

Owner:郝芮一

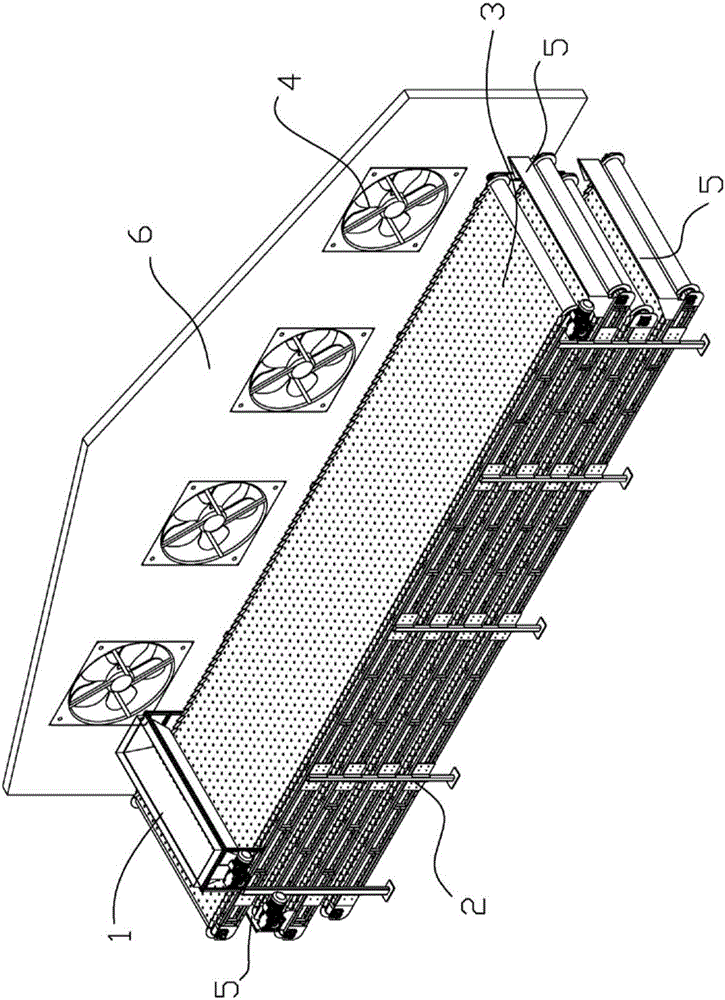

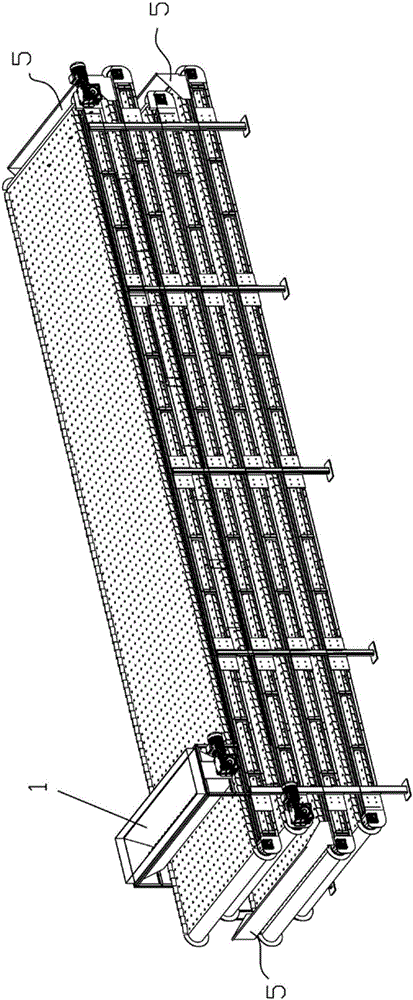

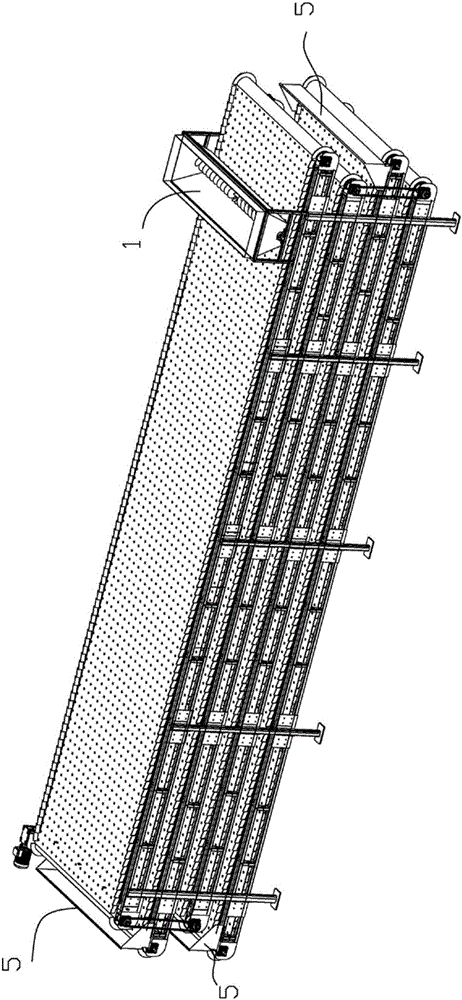

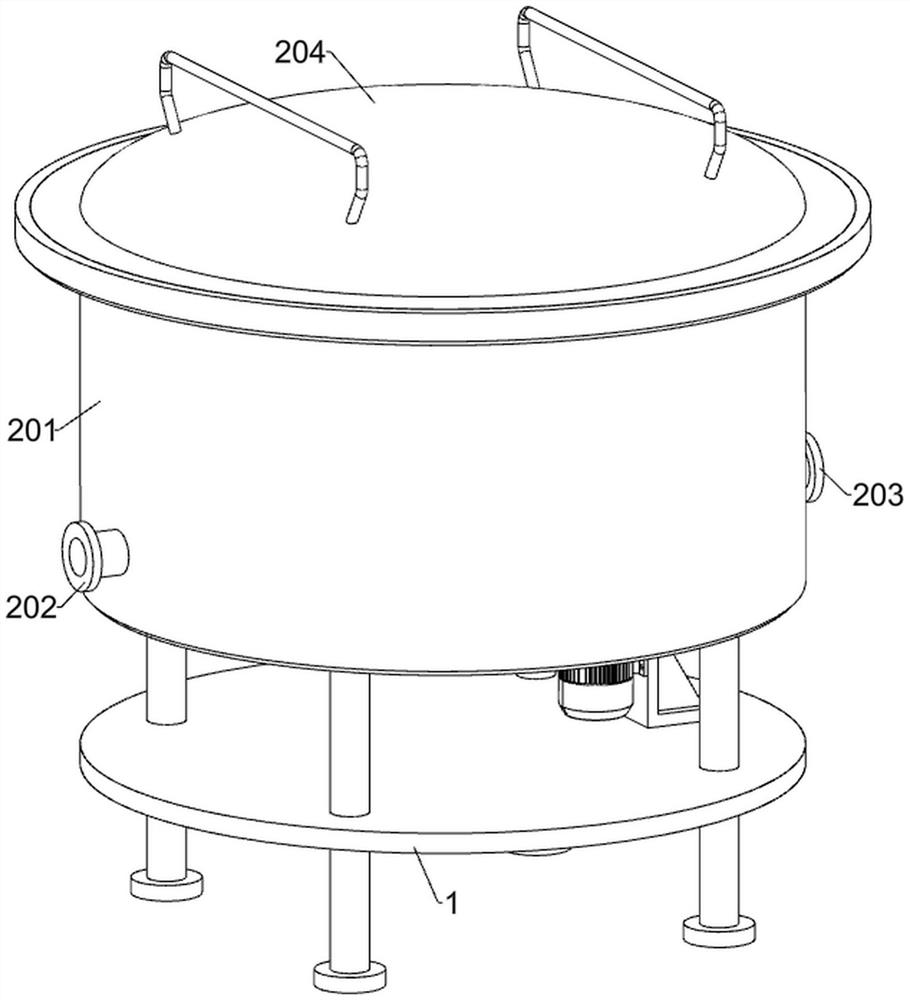

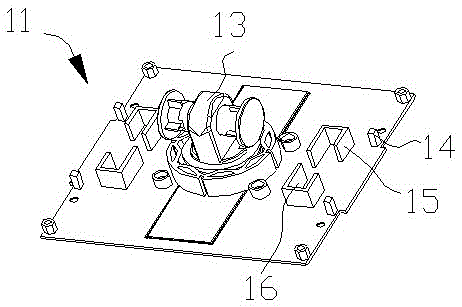

Animal manure automatic drying equipment

InactiveCN106186637AReduce secondary fermentationSimple and fast operationSludge treatment by de-watering/drying/thickeningSmall animalFeces

The invention discloses animal manure automatic drying equipment. The animal manure automatic drying equipment comprises a framework, a conveying belt array, a fan array and a material distributor, wherein the conveying belt array consists of conveying belts, and the conveying belts are staggered on the framework to form a conveying path which circulates from top to bottom; the fan array consists of fans, and is used for drying animal manure on the conveying belts; the material distributor is arranged at the top part of the framework, and is used for uniformly spreading the animal manure onto the conveying belts. The animal manure automatic drying equipment has the advantages that the operation is simple and convenient, the use effect is good, the durability is good, the anti-corrosive property is strong, the emission of pollution gas from a culture farm is reduced, the secondary fermentation of animal manure is reduced, the animal manure in the culture farm is automatically dried, the environment of the culture farm is improved, the emission of harmful gas is reduced, and the labor intensity is decreased; the animal manure is dried by the original fans on the wall of the culture farm, so that a large amount of energy source is reduced, and the culture cost is reduced.

Owner:北京国农中科科技有限公司

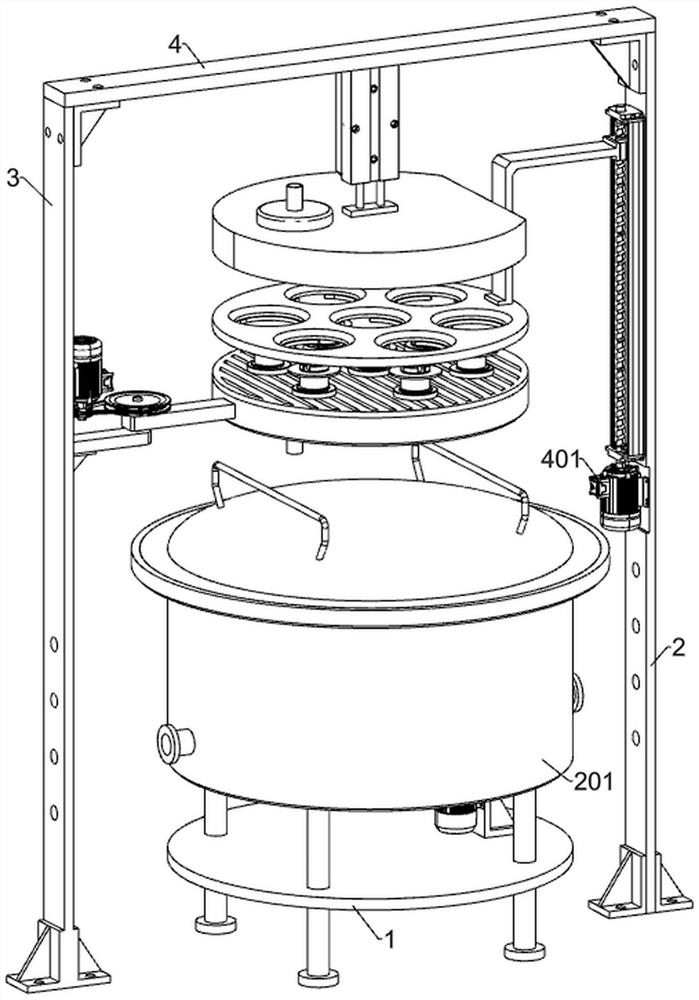

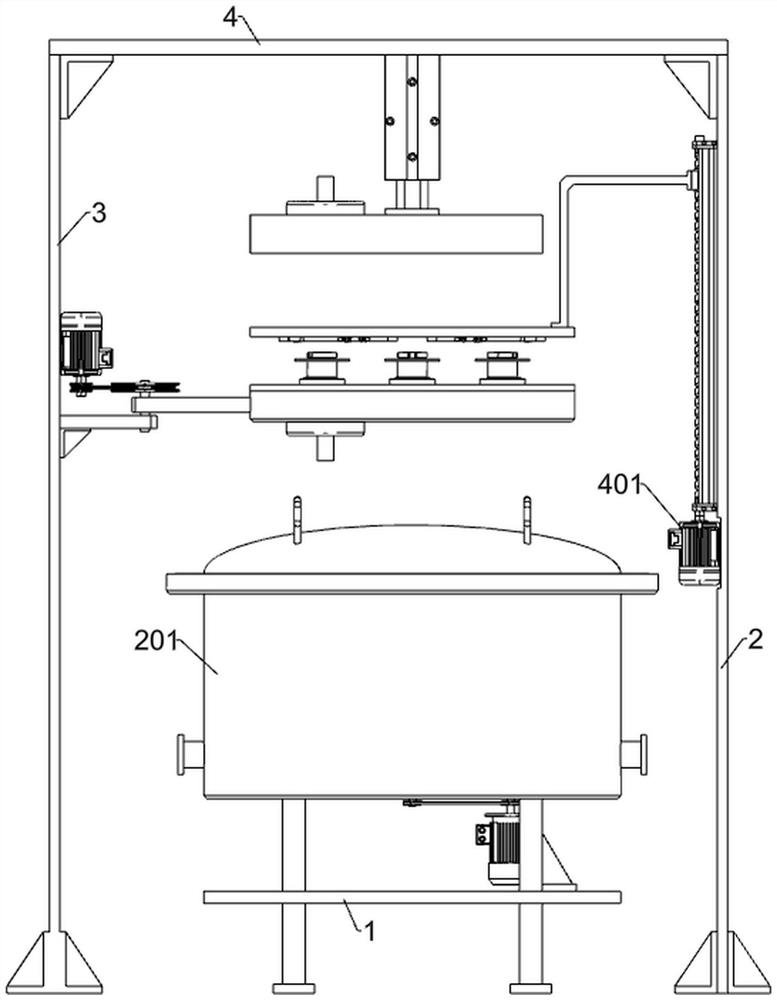

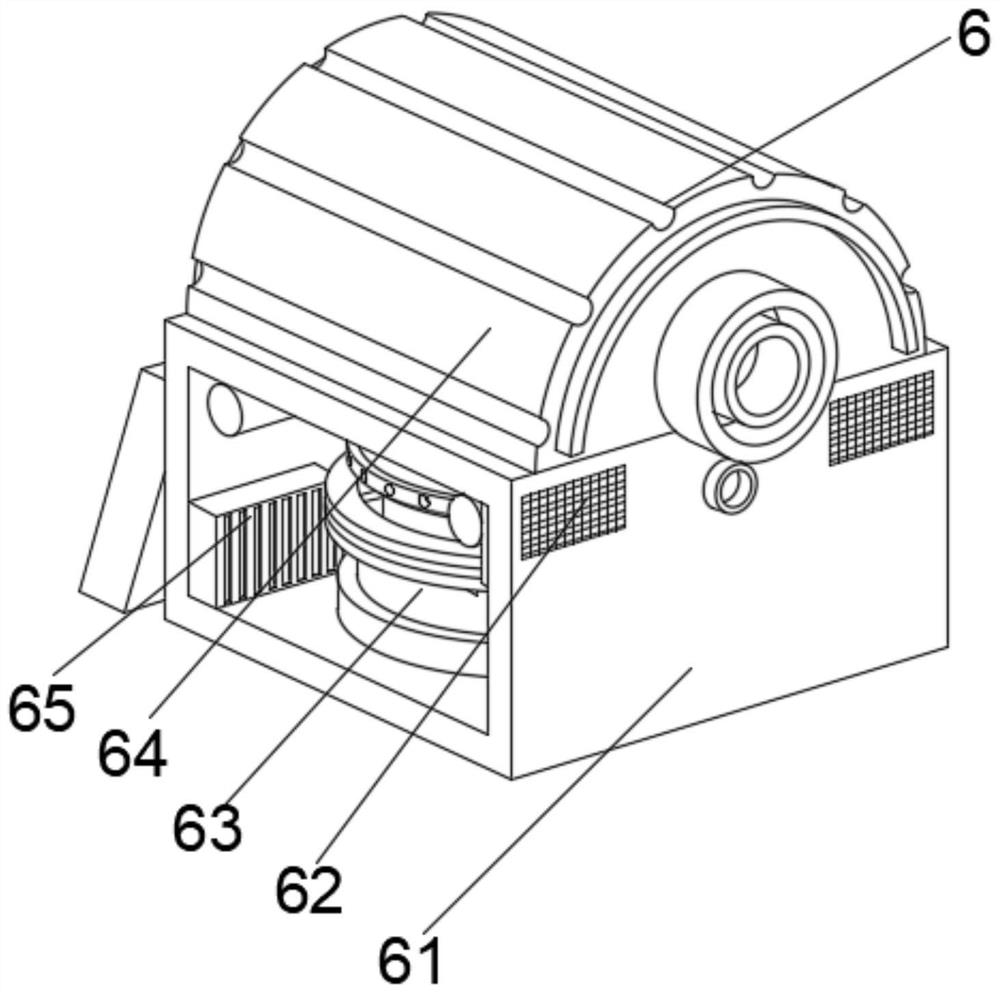

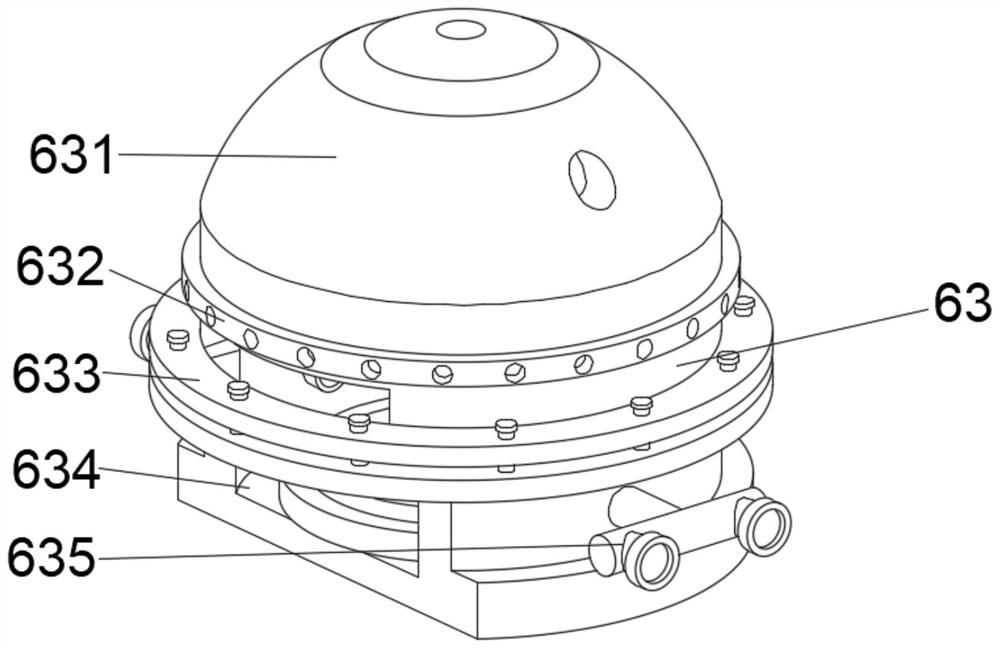

Metal heat treatment softening annealing treatment device

InactiveCN113862438AAvoid the disadvantage of uneven hardnessAvoid driftingFurnace typesDrying chambers/containersContact positionWasher

The invention relates to the field of metal heat treatment, in particular to a metal heat treatment softening annealing treatment device. The technical problem to be solved is that the heating degree of the contact position of a copper sealing washer and a tray is insufficient. According to the technical scheme, the metal heat treatment softening annealing treatment device comprises a supporting table, an annealing assembly, first adjusting assemblies and the like, wherein the annealing assembly is installed on the upper part of the supporting table; and the seven sets of first adjusting assemblies are installed on the inner side of the annealing assembly. During use, the copper sealing washer is heated uniformly by adjusting the bearing position of the copper sealing washer, the defect that the hardness of the sealing washer is not uniform after annealing is overcome, meanwhile, the copper sealing washer is prevented from deviating, the copper sealing washer is automatically dried, and meanwhile, cleaning liquid remaining on the bottom face of the outer ring face of the copper sealing washer is automatically removed; and the dried copper sealing washer is synchronously put into a designated position in an annealing furnace, so that the copper sealing washer does not need to be manually taken out and then put into the annealing furnace, and the efficiency is greatly improved.

Owner:惠州市先力得金属科技有限公司

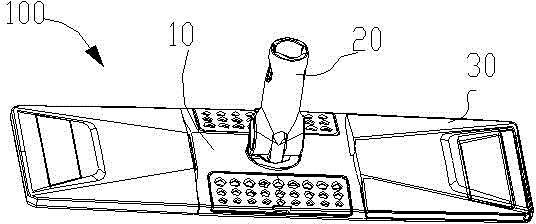

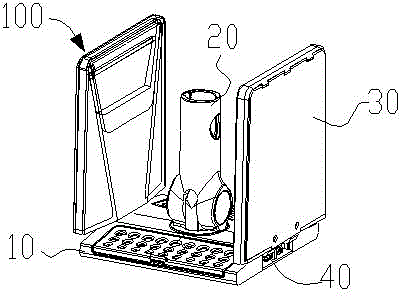

Collapsible wall painting device

The invention discloses a collapsible wall painting device. The Collapsible wall painting device comprises a support plate, at least one wall painting plate in movable connection with the support plate and assembly components mounted in both the support plate and the wall painting plates; the assembly components comprise a plurality of moving parts and springs of which the number is the same as that of the wall painting plates; one end of each moving part is fixedly connected with a mounting board, and the other end of each moving part is fixedly connected with the wall painting plates; each spring comprises a first spring section, a spiral spring section and a second spring section, the first spring section is connected with the wall painting plates, and the spiral spring section and the second spring section are both mounted in the support plate; the wall painting plates and the support plate are in movable connection through the moving parts and the springs. The wall painting plates which can rotate along the support plate can be retracted for storage, so that the occupied space is reduced. Meanwhile, wall painting can be realized within a relatively small space, and automatic cleaning and drying can be realized.

Owner:会同会泓新材料科技有限公司

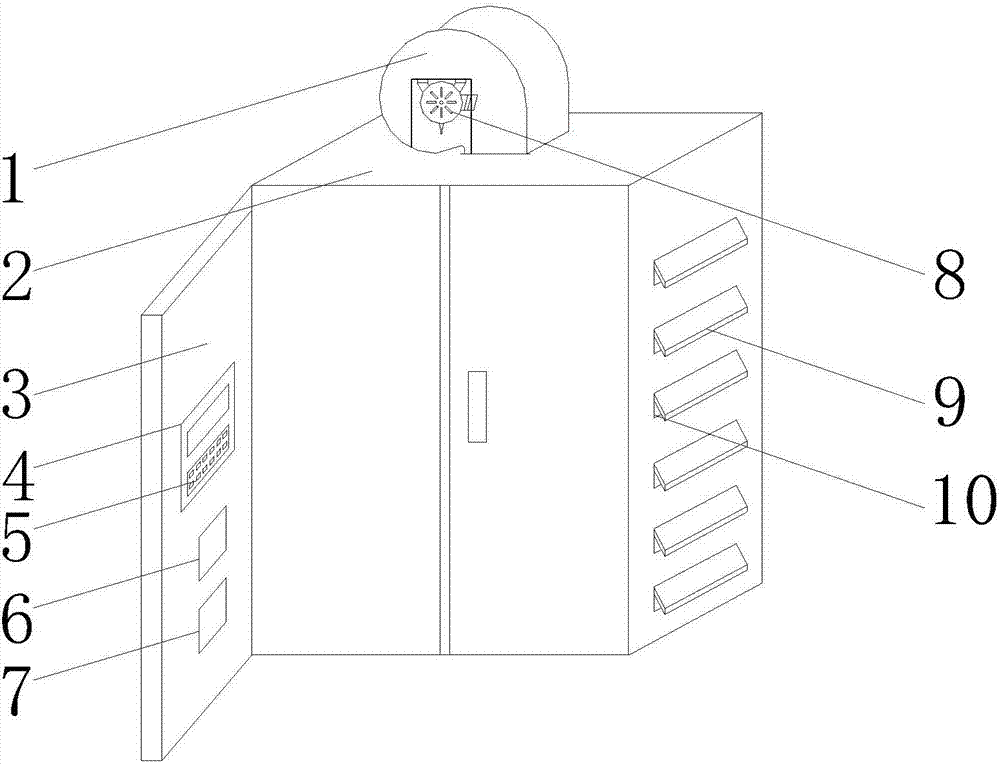

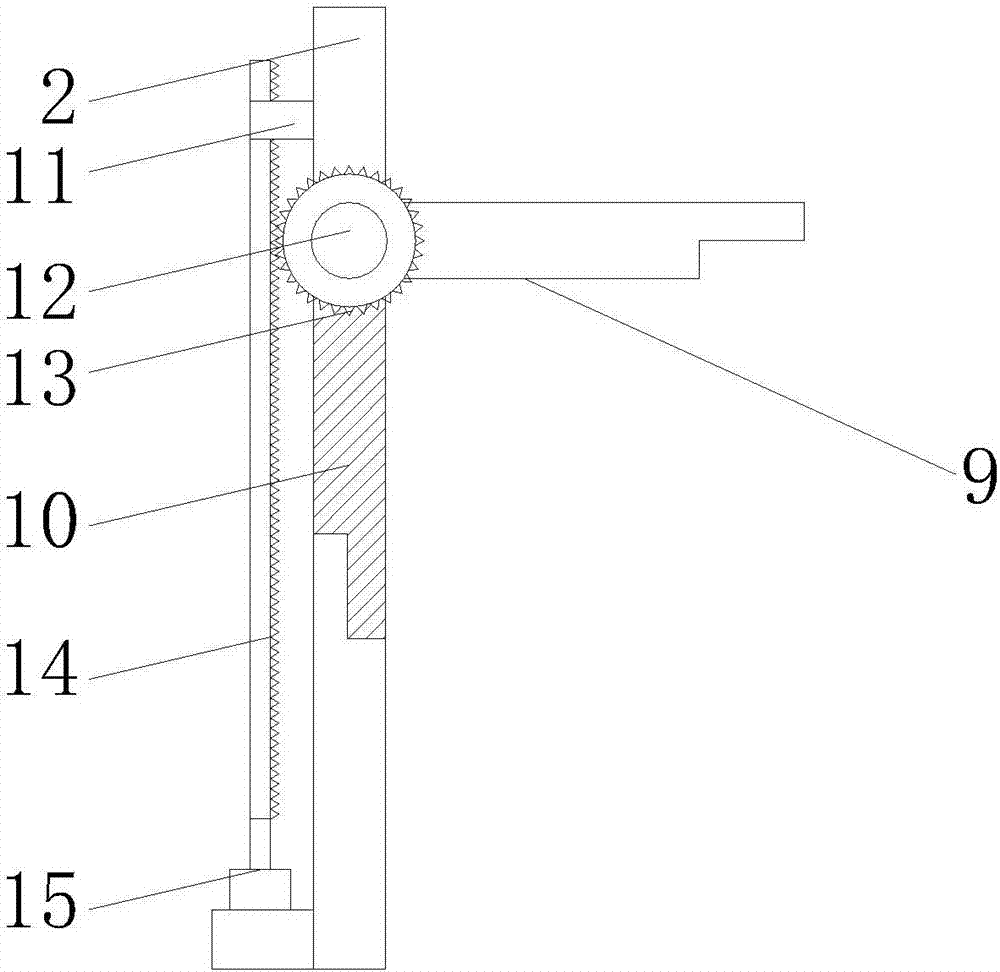

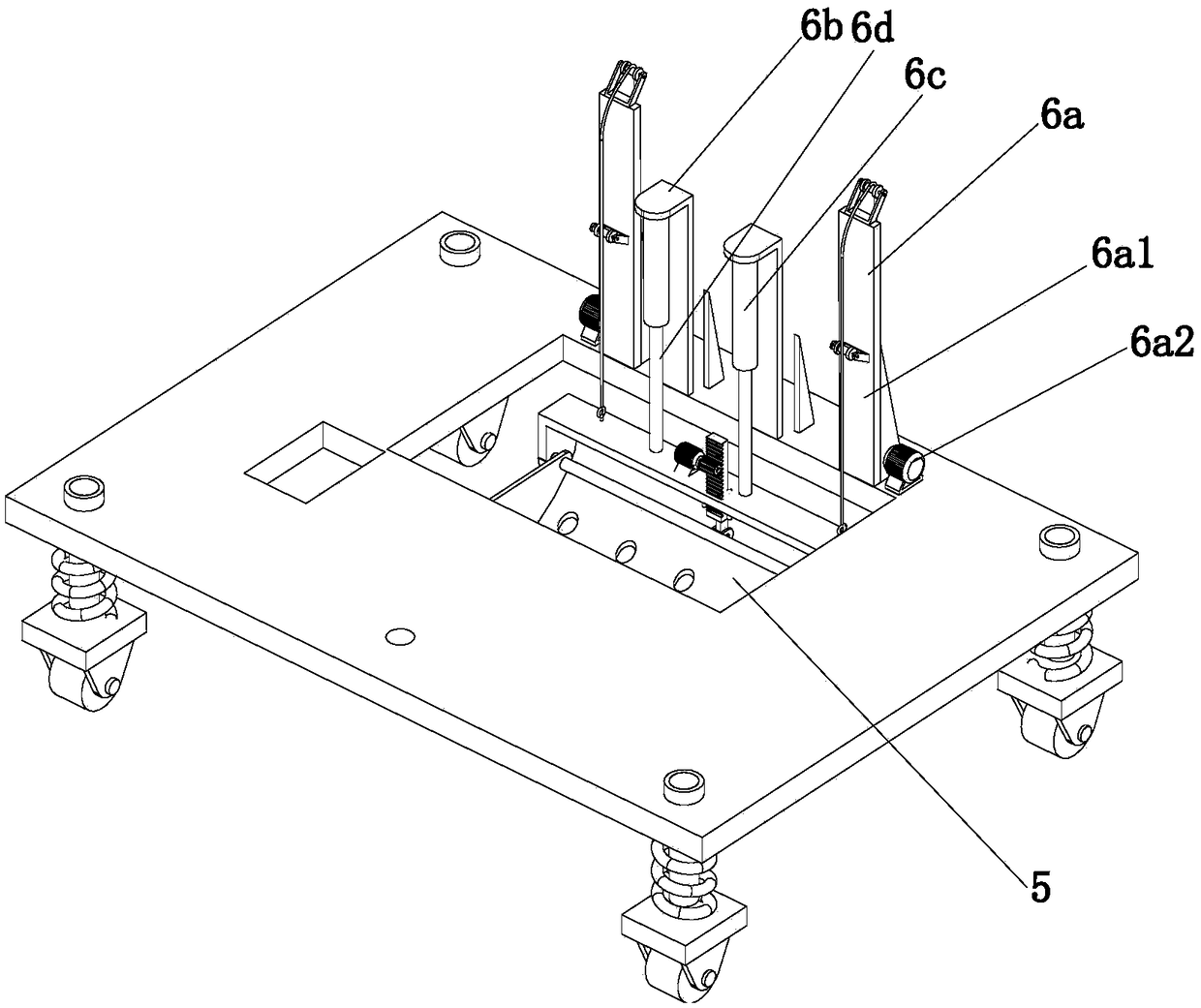

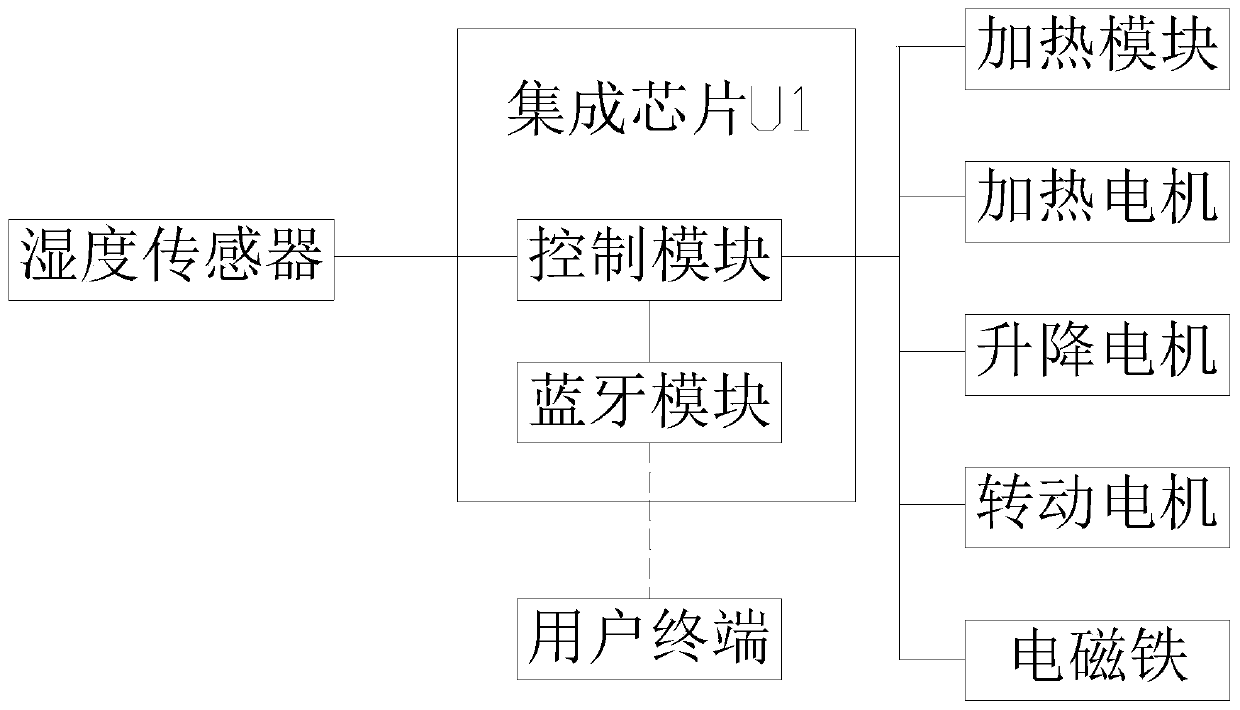

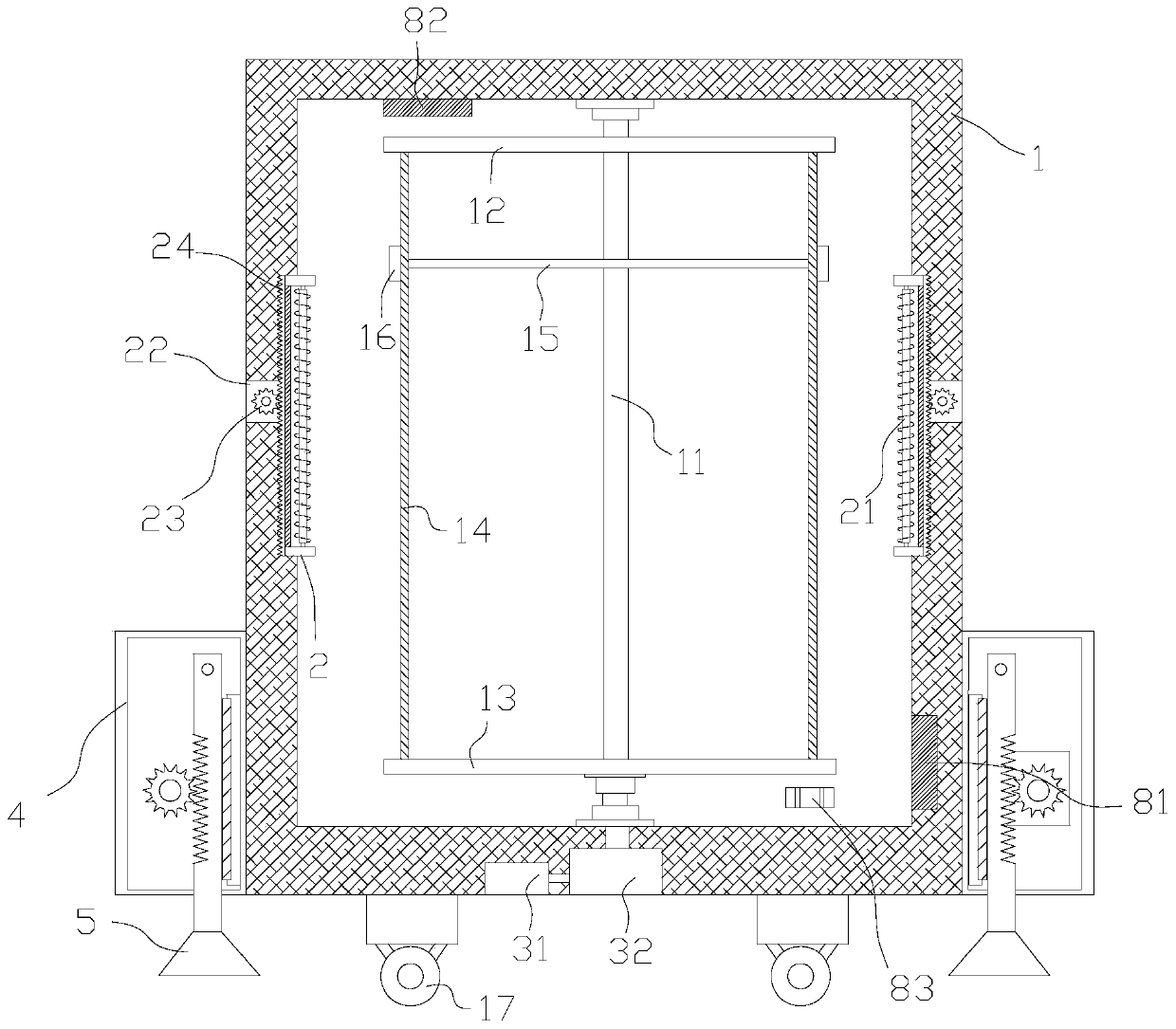

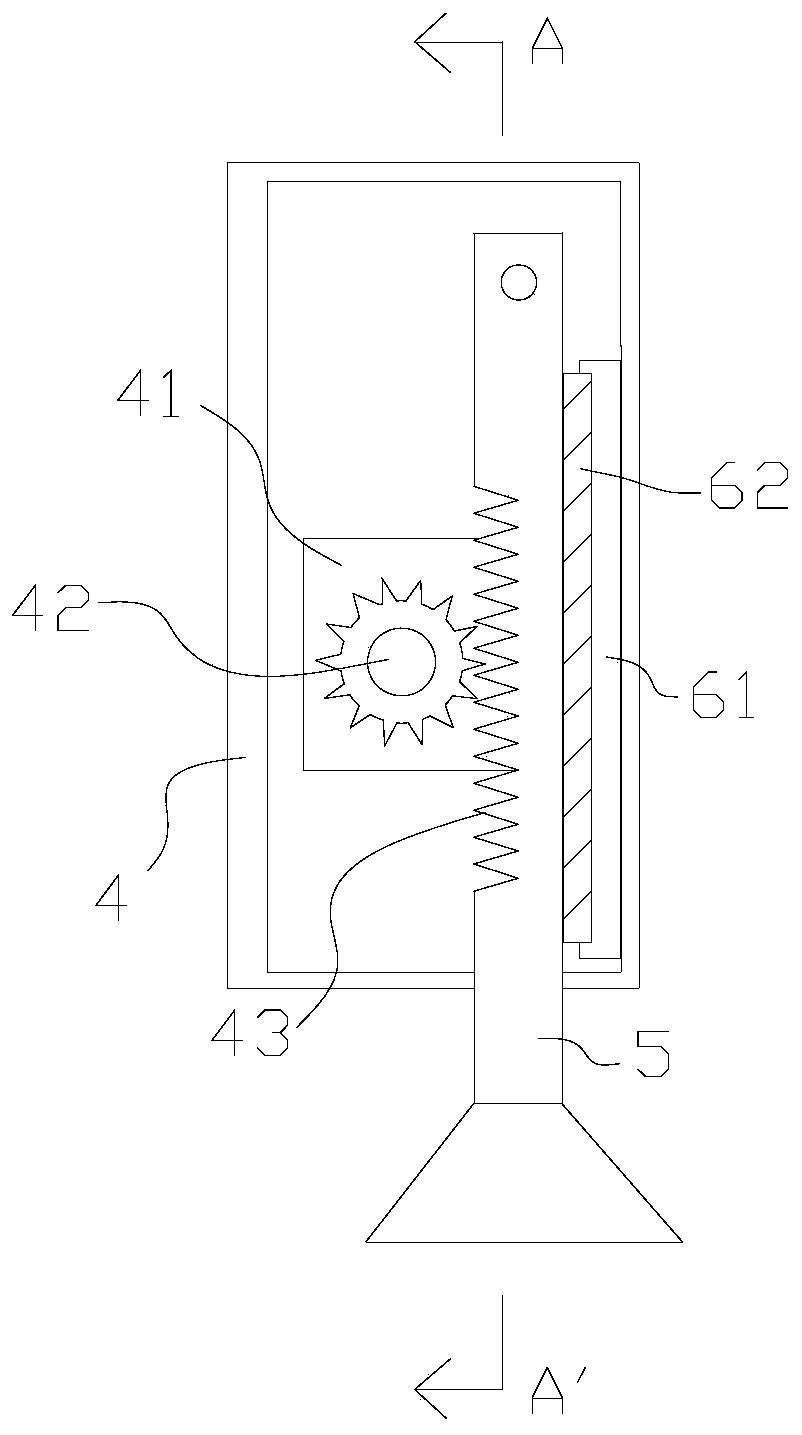

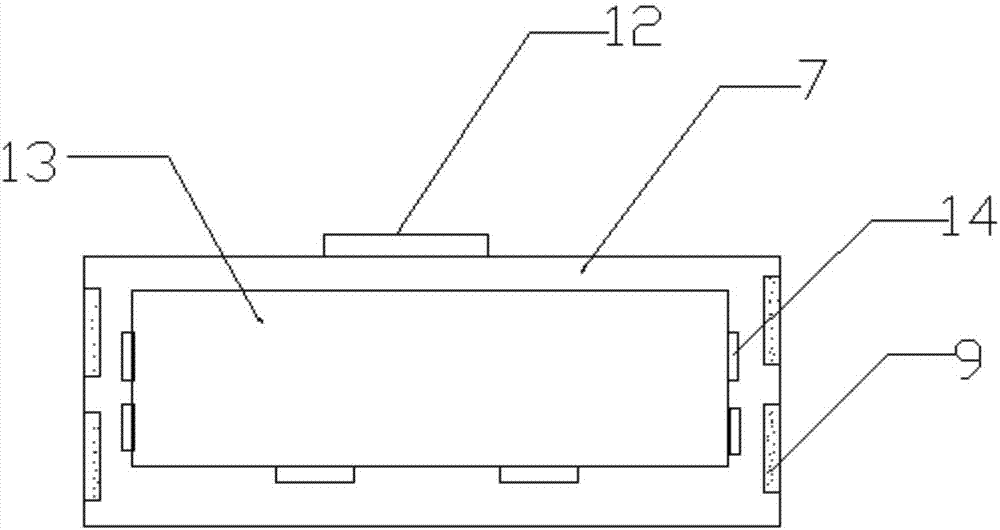

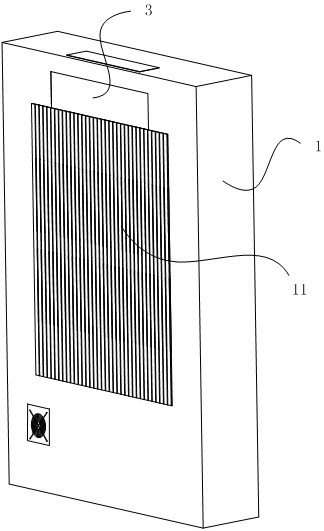

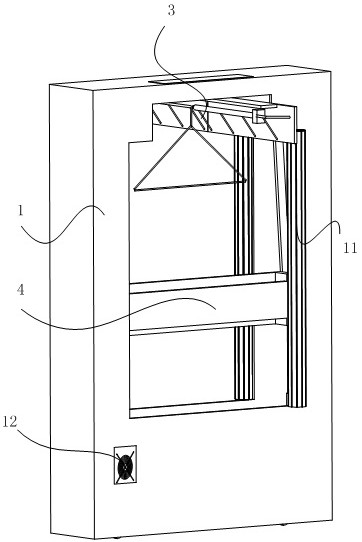

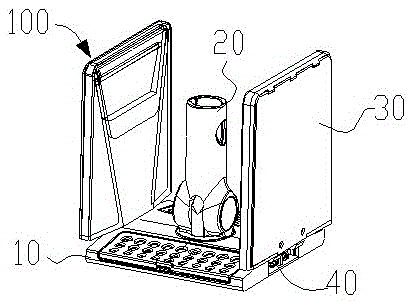

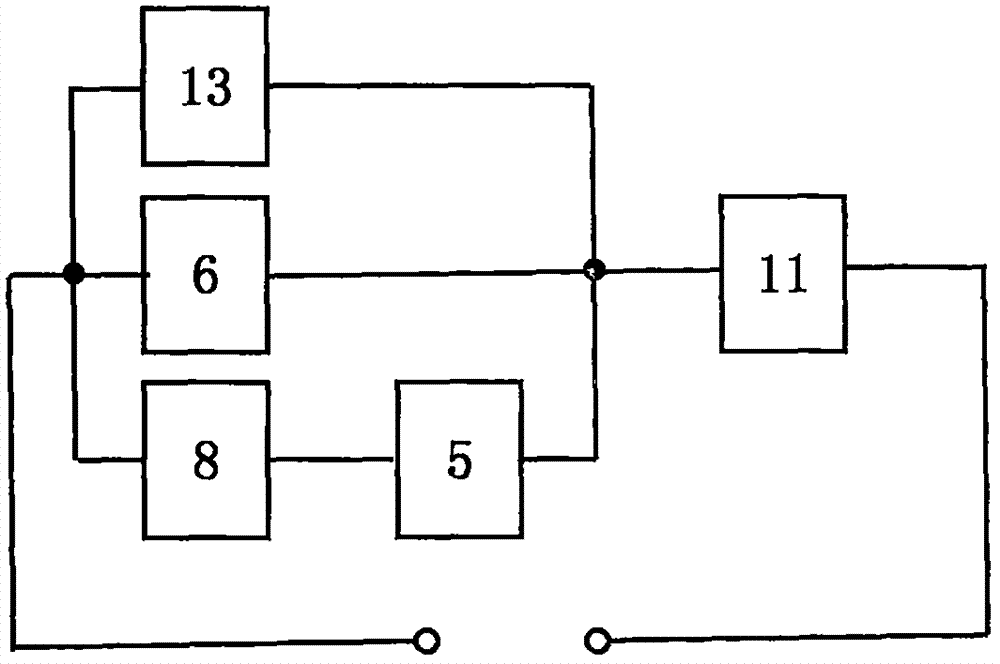

Intelligent wardrobe

PendingCN110833263AAutomatic dehumidificationAutomatic dryingWardrobesDispersed particle separationControl engineeringElectric machinery

The invention relates to the technical field of wardrobes, in particular to an intelligent wardrobe. The intelligent wardrobe comprises a cabinet body; heating modules are arranged on connecting bases; driving mechanisms are arranged in the cabinet body; a rotating motor is arranged in the cabinet body; the cabinet body is connected with a fixed base; the cabinet body is provided with universal wheels; the fixed base is movably provided with supporting feet; a lifting mechanism is arranged in the fixed base; the cabinet body is internally provided with a humidity sensor, a control module and aBluetooth module; and the output end of the control module is connected with the driving mechanisms, the rotating motor, the lifting mechanism, the Bluetooth module, the heating modules and the humidity sensor separately. Through the arrangement of the control module and the Bluetooth module, the Bluetooth module can control the cabinet body to perform the actions of dehumidifying, drying, rotating and supporting feet stretching and retracting by receiving a Bluetooth signal from a user terminal; and by arranging the humidity sensor, the cabinet body can automatically dehumidify and dry according to the humidity, thereby realizing intelligence.

Owner:GUANGDONG CACAR KITCHEN SCI & TECH CO LTD

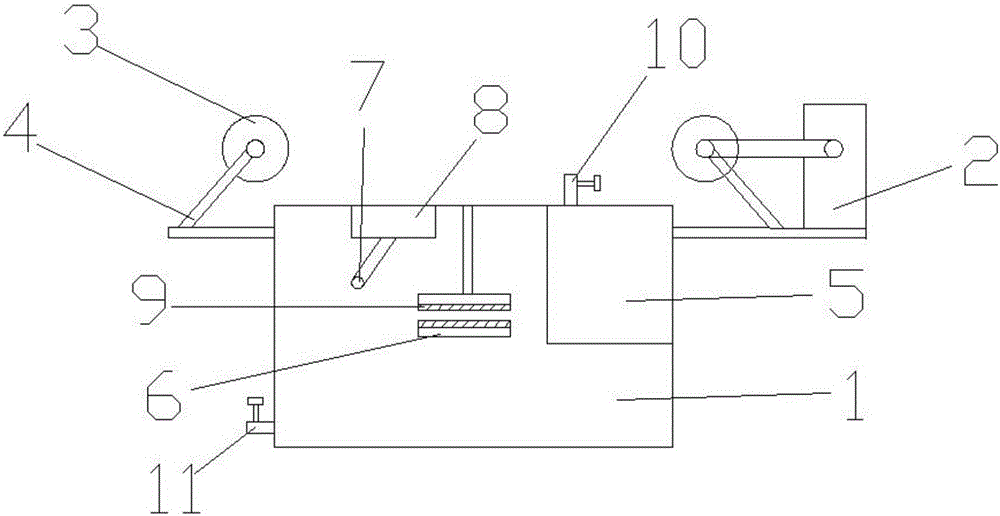

Plastic film washing device

InactiveCN106111584AAutomated cleaningAutomatic dryingCleaning using liquidsWater filterAssembly line

The invention discloses a plastic film washing device, and particularly relates to the technical field of plastic film processing. The plastic film washing device comprises a washing pool body, a motor, plastic film reels, plastic film supports, a drying box, a water filtering device, a high-pressure sprayer and a high-pressure water pump. The plastic film supports are arranged at the two ends of the washing pool body correspondingly and provided with the corresponding plastic film reels. The motor is connected with the plastic film reel located at one end of the washing pool body. The drying box, the water filtering device and the high-pressure sprayer are arranged in the washing pool body, and the high-pressure sprayer is connected with the high-pressure water pump. The plastic film washing device has the advantages that the structure is simple, and plastic films can be washed, dried and packaged automatically through assembly line work.

Owner:ANQING XINSHUN PLASTIC CO LTD

Special drying apparatus for shiitake mushrooms

The invention discloses a special drying device for shiitake mushrooms, which comprises a frame and a feeding frame fixedly installed on the frame. mouth, a first mesh belt and a second mesh belt are provided below the blanking port, a first heating box and a second heating box are respectively arranged in the middle of the first mesh belt and the second mesh belt, and the The two ends of the mesh belt are respectively connected with runners, the inside of the heating box is provided with a grid, the bottom and both ends of the grid are provided with heating pipes, and the top of the heating box is equipped with an exhaust fan; The special drying device for shiitake mushrooms can classify shiitake mushrooms of different sizes, and use uniform hot air of different sizes to dry shiitake mushrooms of different sizes. Water vapor, to avoid water vapor causing repeated pollution to dried shiitake mushrooms, further improving the efficiency of drying shiitake mushrooms.

Owner:无锡市广益中心小学

Spinning yarn storage barrel with drying and dust removing functions

InactiveCN108313461AEasy accessEasy and fast deliveryClosure with auxillary devicesContainers preventing decayYarnEngineering

The invention discloses a spinning yarn storage barrel with drying and dust removing functions. The spinning yarn storage barrel comprises a base with a cavity inside; support legs are reserved on thelower surface of the base near two sides; a first electric push rod and a second electric push rod are fixed on the inner walls of the bottoms of the two support legs through bolts; C-shaped rods arehinged to the top ends of extension rods of the first electric push rod and the second electric push rod; openings of the two C-shaped rods are opposite; the same base plate is welded between the twoC-shaped rods; a barrel body is clamped at the top end of the base; a temperature sensor and a humidity sensor are embedded in the inner wall of the bottom of the barrel body near two sides; and a heat dissipating fan is fixed on the outer wall of the bottom of the barrel body through bolts. The spinning yarn storage barrel can conveniently and quickly convey yarns remained at the bottom of the barrel body to a higher part, so that users are convenient to take, the labor intensity is reduced, the production efficiency is improved, and the internal environment of the barrel body can be precisely and conveniently detected.

Owner:江苏爱纺纺织有限公司

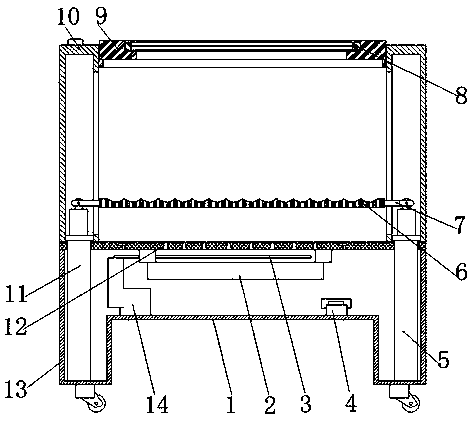

Automatic clothes ironing and drying equipment

ActiveCN112030494AImprove the quality and efficiency of ironingImprove user experienceTextiles and paperLaundry driersManufacturing engineeringAir drying

The invention discloses automatic clothes ironing and drying equipment. The automatic clothes ironing and drying equipment comprises a cabinet body, a clothes hanging mechanism, an air drying mechanism and an automatic ironing mechanism; the clothes hanging mechanism is mounted on the cabinet body and used for hanging to-be-ironed clothes; the air drying mechanism is provided with an air suction opening and an air exhaust opening, and the air drying mechanism is used for sucking wet air in the cabinet body through the air suction opening, drying and heating the wet air and then exhausting dryhot air into the cabinet body through the air exhaust opening; the automatic ironing mechanism comprises an ironing head, a lifting module and a steam generation module, the ironing head comprises a steam spraying plate and a supporting plate which are oppositely arranged, an ironing area used for ironing the clothes is formed between the steam spraying plate and the supporting plate, and the lifting module is used for driving the ironing head to move up and down in the cabinet body; and the steam generation module is used for generating steam and spraying the steam into the ironing area through the steam spraying plate. The automatic clothes ironing and drying equipment automatically irons and dries the clothes, and the user experience is improved.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

An electric drying rack

ActiveCN108166224BEasy to moveAutomatic dryingOther drying apparatusTextiles and paperEngineeringMechanical engineering

Owner:义乌市富顺箱包有限公司

Electronic vacuum device surface coating device capable of achieving uniform coating and automatic drying

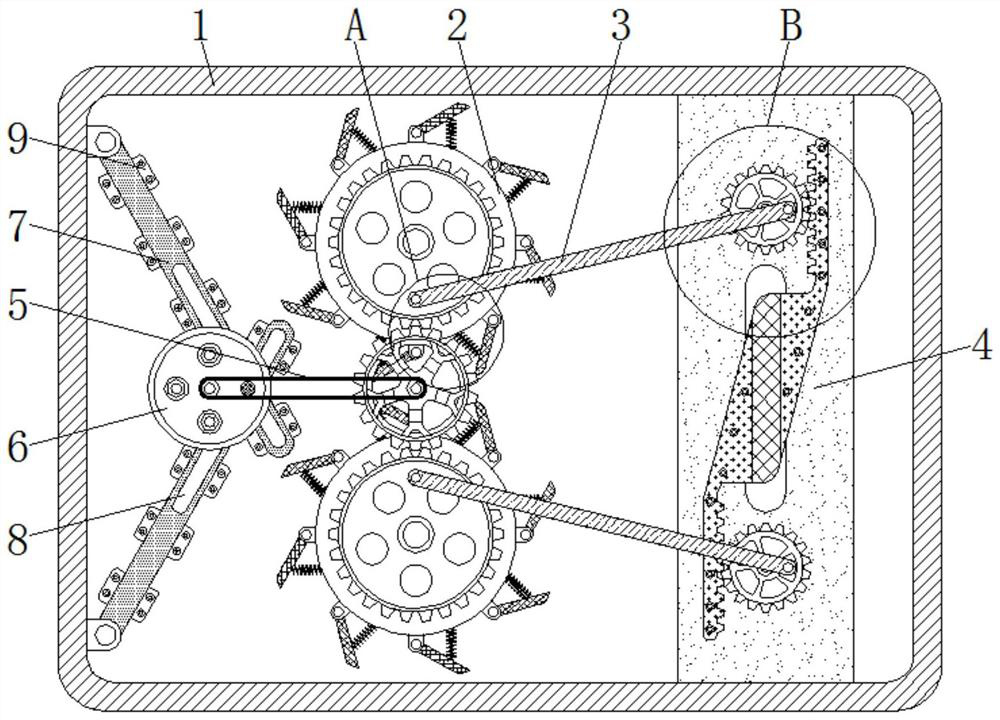

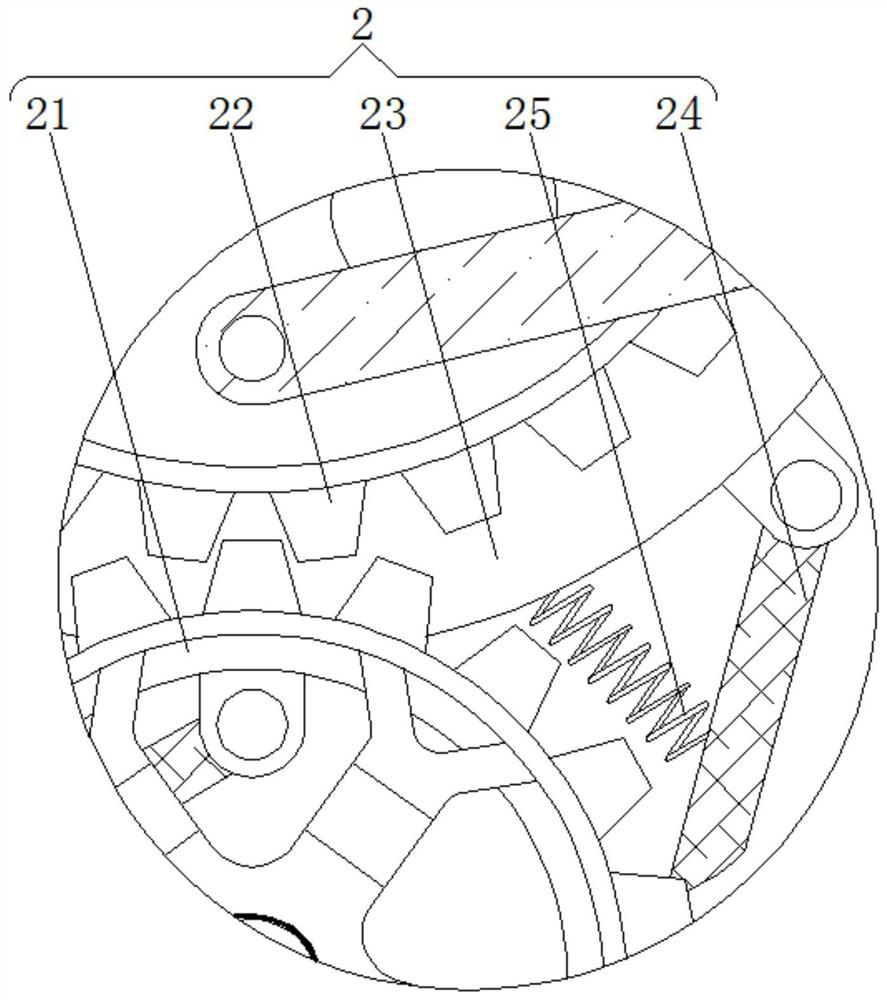

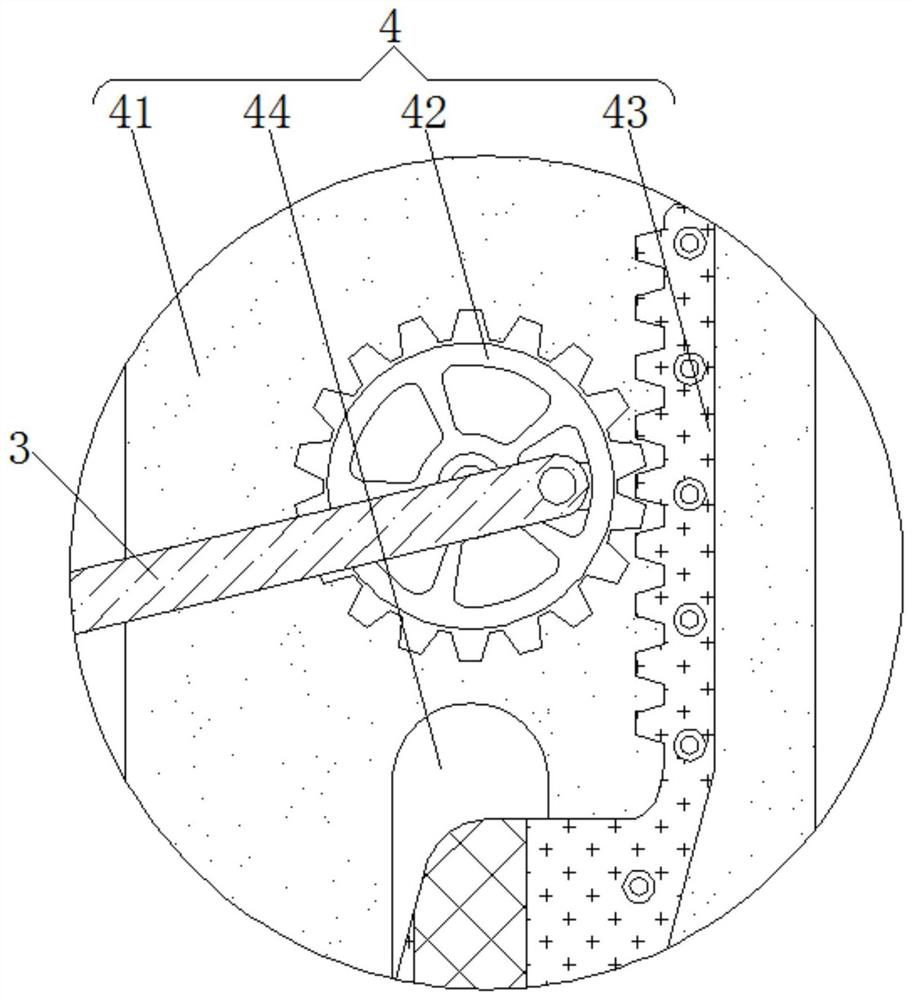

The invention relates to the technical field of electronic vacuum device coating equipment, and discloses an electronic vacuum device surface coating device capable of achieving uniform coating and automatic drying. The device comprises a bottom plate, the front surface of the bottom plate is rotatably connected with a coating mechanism, and the front surface of the coating mechanism is rotatably connected with a driving rod. The end, away from the coating mechanism, of the driving rod is rotationally connected with a discharging mechanism. According to the electronic vacuum device surface coating device capable of achieving uniform coating and automatic drying, a driving gear rotates to drive a reciprocating gear through the driving rod to rotate in a reciprocating mode, so that a sliding rack is driven to move up and down in a reciprocating mode, a film material is evenly sprayed to the surface of an electronic vacuum device, then the film material is scraped to be flat through a scraping plate, coating of the film material is more uniform, finally, a rotating disc rotates to drive the rotating rod to rotate in a reciprocating mode, the coated film material is evenly dried, operation is simpler, the working efficiency of film coating is greatly improved, meanwhile, the workload of workers is reduced, and more time and labor are saved.

Owner:济南滋朗戚光电科技有限公司

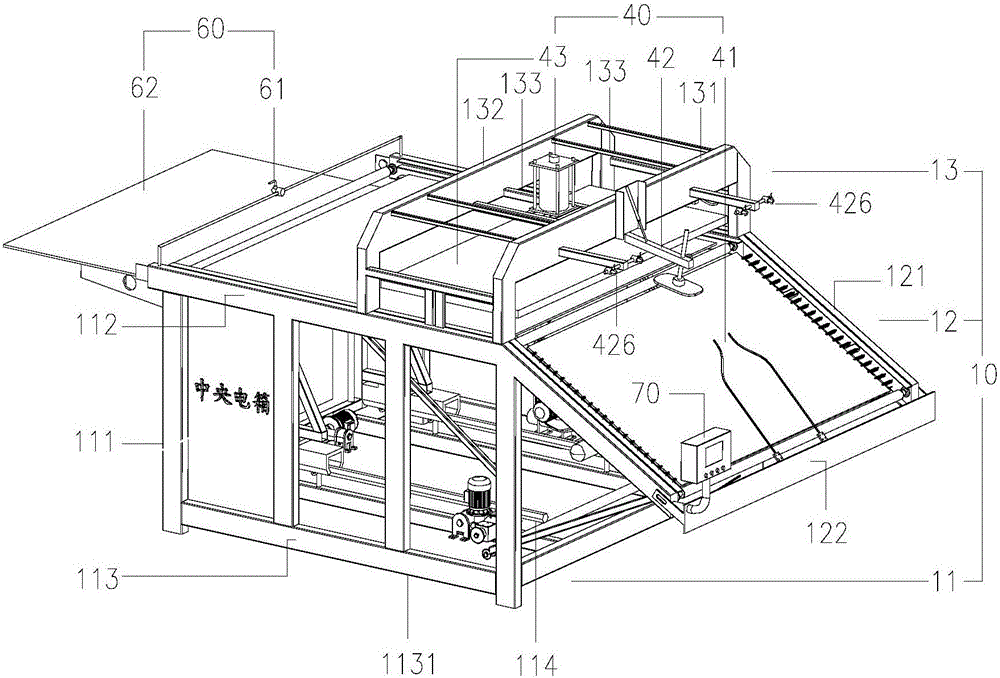

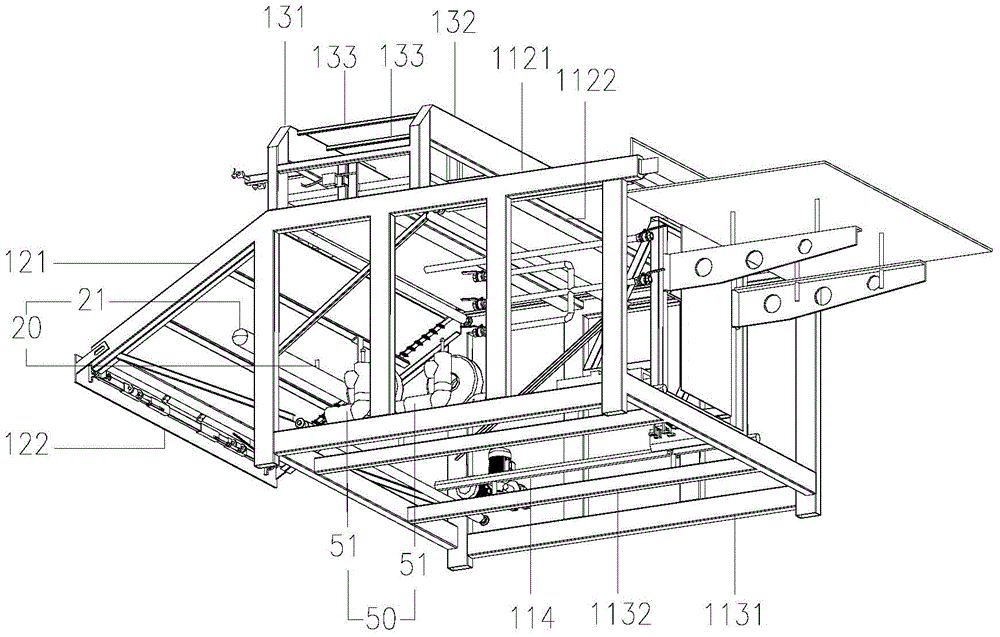

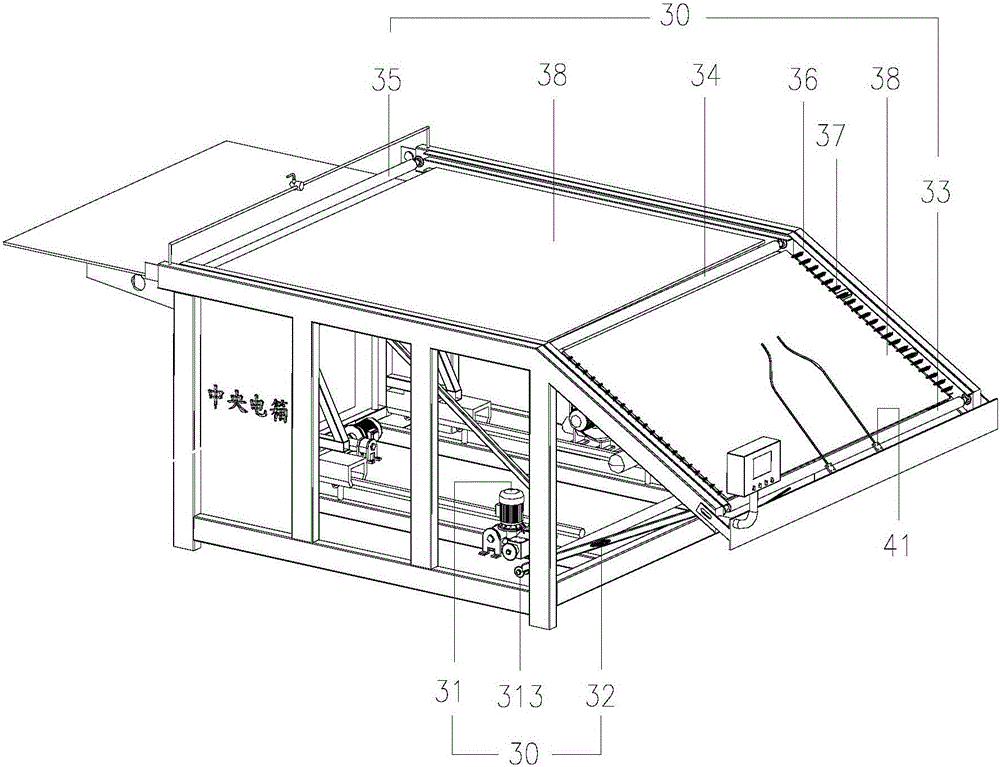

A wool fabric steaming and ironing setting machine

InactiveCN104805666BAchieve ironing and settingAvoid out of shapeHeating/cooling textile fabricsIroning apparatusSupport groupPulp and paper industry

The invention provides a woolen knitwear steaming setting machine. The woolen knitwear steaming setting machine comprises a machine frame, a steam evaporating group, a transmission group, an ironing positioning group, a ventilating dehumidifying group, a counting clothes supporting group and an electric control group, wherein the machine frame comprises a main frame part, an inclined frame part and a top frame part; the main frame part is provided with a main rod, an upper frame and a lower frame; the inclined frame part is combined with the front side of the upper frame body and is provided with a surface beam; the top frame part is arranged on the upper frame body; the steam evaporating group comprises a steam temporary storage device; the steam temporary storage device is communicated with the ventilating dehumidifying group through a pipeline; the transmission group drives a first roller, a second roller, a third roller and a conveying cloth belt of the transmission group by adopting chain transmission; a transmission chain used for the chain transmission is provided with ear holes; the first roller is overlapped to the second roller and the third roller through the conveying cloth belt; metal rings are arranged on the two side peripheries of the conveying cloth belt corresponding to the ear holes; the ear holes are connected with the metal rings through springs. Through the structure, the technical problems about woolen knitwear steaming and setting are solved; good effects that the operation is facilitated, and the steaming efficiency is improved are achieved.

Owner:郑野

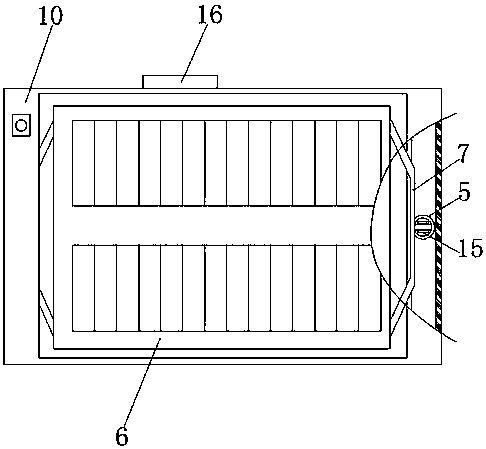

Solar cell silicon wafer drying equipment

PendingCN114383388ANot easy to reachAvoid burnsDrying gas arrangementsDrying solid materialsSolar cellDrying time

The invention discloses solar cell silicon wafer drying equipment which comprises a fixed base, a drying device is fixedly connected to the middle of the top of the fixed base, opening and closing baffles are arranged in the middles of the outer walls of the two sides of the drying device, and a conveying line is arranged in the middle of the side, away from the drying device, of each opening and closing baffle. Arc-shaped supports are fixedly connected to the two sides of the bottom of the conveying line, and connecting supporting plates are fixedly connected to the positions, located on the two sides of the drying device, of the top of the fixed base. According to the solar cell silicon wafer drying equipment, the conveying line and the clamping baffles guarantee the position accuracy and the internal sealing performance of the cell pieces, workers are not prone to making contact with the equipment, the situation that the workers are scalded by high temperature on the surface of the equipment is avoided, meanwhile, the drying mechanism is tightly matched with the auxiliary mechanism, the drying time is shortened, and the drying efficiency is improved. And the phenomenon that the stacked battery pieces are broken due to uneven stress caused by the fact that the positions of the dried battery pieces move is prevented.

Owner:馬明陽

A kind of textile yarn drying equipment

ActiveCN110230921BAutomatic dryingAutomatic windingFilament handlingDrying gas arrangementsYarnElectric machinery

The invention relates to drying equipment, in particular to a yarn drying equipment for textile. The invention aims to provide the yarn drying equipment for the textile which can automatically wind updried yarn and completely dry the yarn. According to the technical scheme, the yarn drying equipment for the textile comprises a first base, a box body, a first motor, a polygonal support, arc-shapedsupporting blocks, an air blower, a multi-way pipe, a trumpet-shaped air inlet pipe, an electric heating wire, a box door and the like; the top of the first base is provided with the box body, the first motor is connected to the middle of the inner rear side of the box body through a bolt, an output shaft of the first motor is provided with the polygonal support, and the eight arc-shaped supporting blocks which are uniformly spaced are fixedly connected to the outer side of the polygonal support. According to the yarn drying equipment for the textile, air can be heated into hot air through the electric heating wire, so that the yarn can be dried; and due to the fact that the yarn is wound around the arc-shaped supporting blocks, the hot air can be uniformly sprayed on the yarn, and then the yarn can be completely dried.

Owner:SUZHOU ZHIRUI PHOTOELECTRIC MATERIAL TECH CO LTD

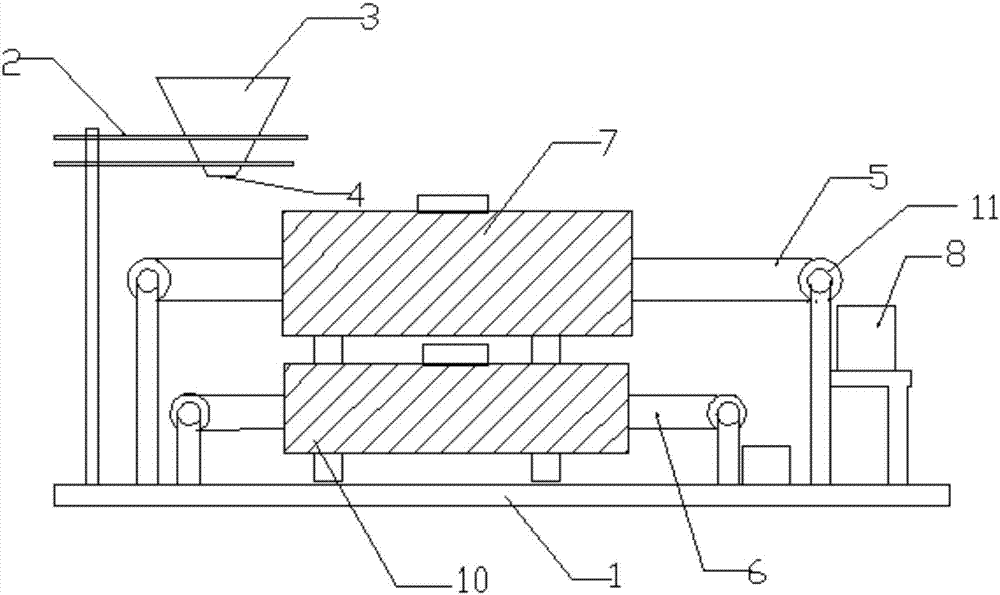

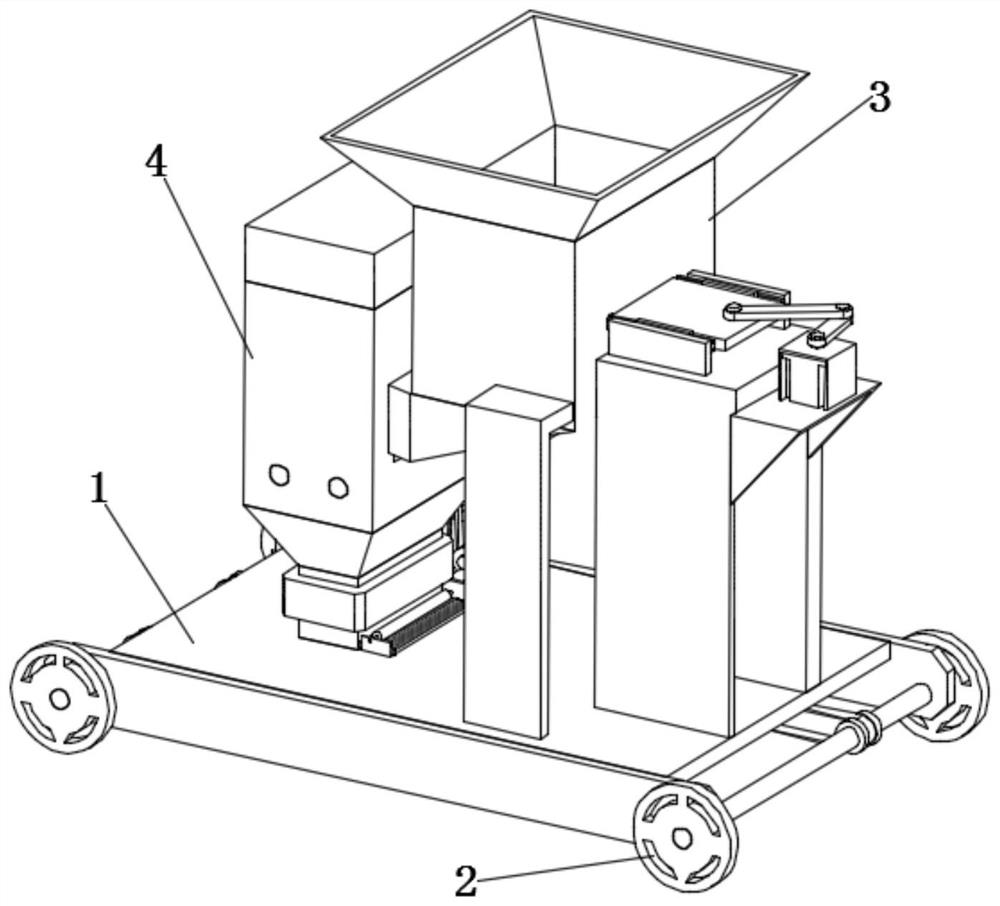

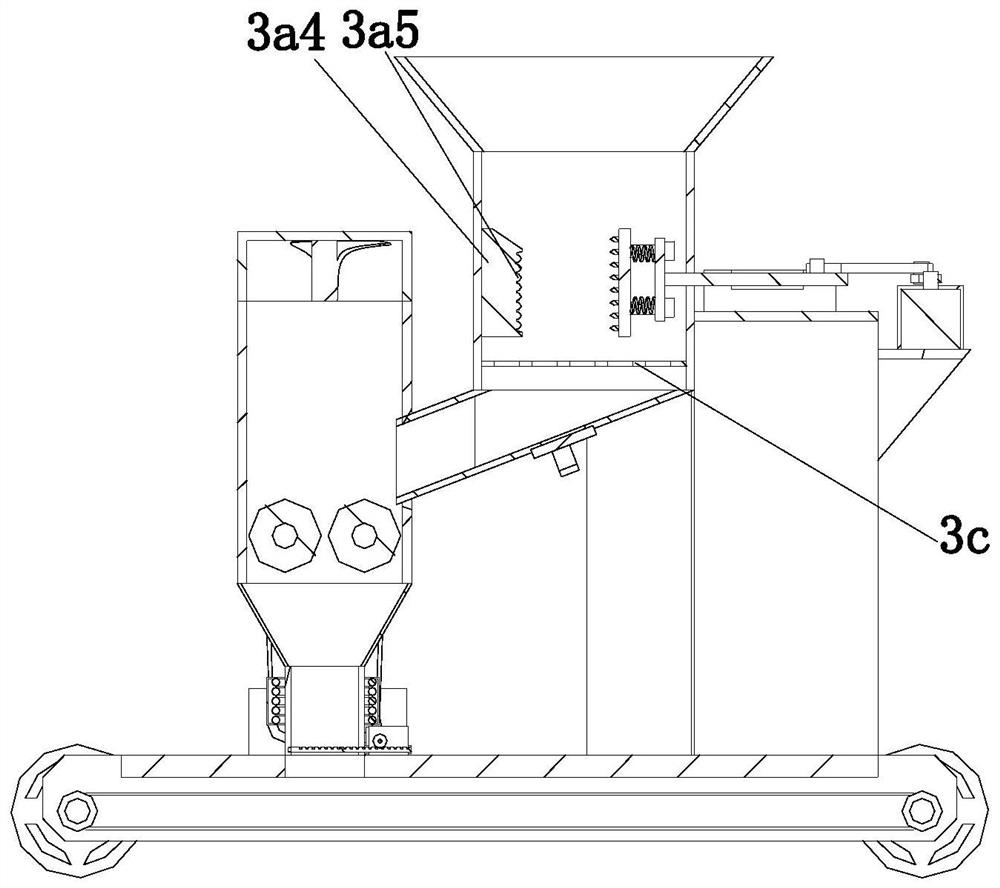

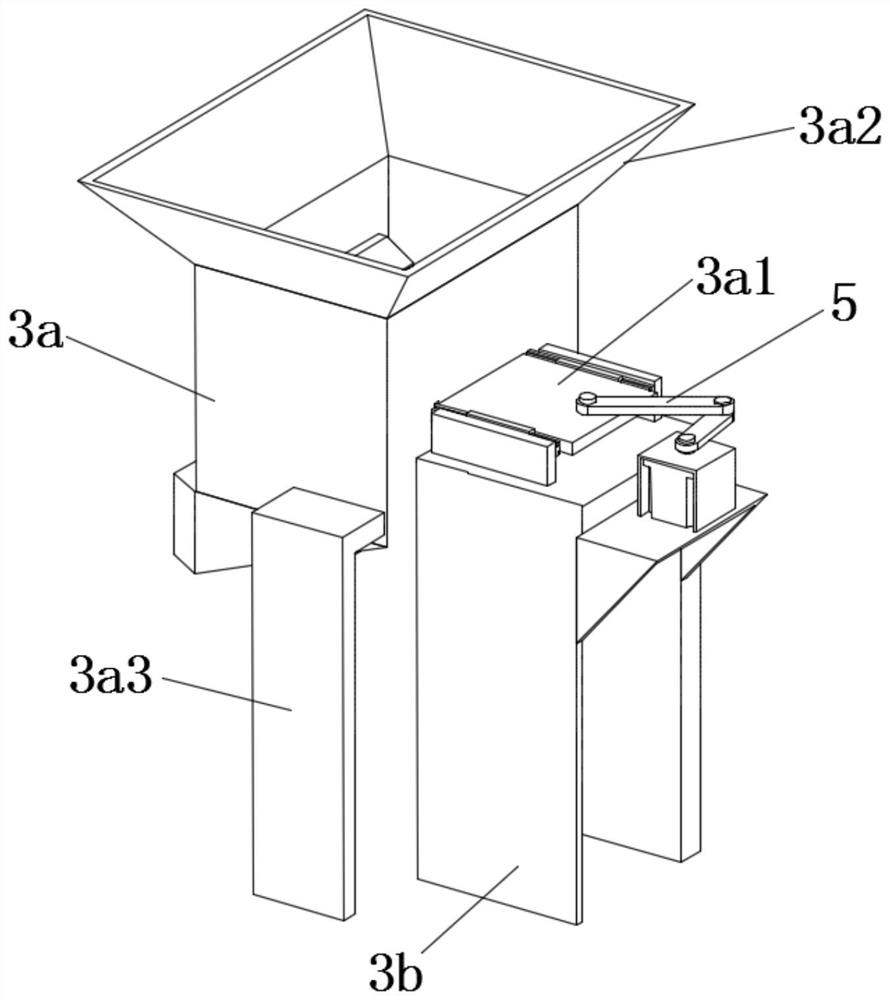

A tree branch cutting and crushing device for gardening

InactiveCN109078687BMeet needsNo need for manual handlingGrain treatmentsHeating arrangementAgricultural engineeringSlide plate

A tree branch shearing and crushing device for gardens provided by the present invention includes a supporting plate, a driving assembly, a shearing assembly and a crushing assembly, the shearing assembly includes a shearing cabinet, a sliding plate with a cuboid structure and a driving assembly, the sliding plate It is located next to the shearing cabinet and is slidingly matched with the shearing cabinet. The top of the shearing cabinet is provided with a feed funnel connected with the shearing cabinet. There are two L-shaped support plates on the top of the supporting plate. The crushing assembly includes a The crushing cabinet above the board, the crushing cabinet and the shearing cabinet are connected through the feed box. The beneficial effect of the present invention is that the cutting assembly and the crushing assembly can process the branches into broken branches and branch chips respectively to meet the needs of different users, the drying assembly can automatically dry the branch chips, and the driving assembly enables the device to Automatically walk to the desired location without manual handling.

Owner:江苏健达交通工程有限公司

Dust removal device for aluminum alloy door and window production

InactiveCN113578820AAutomate cleaningAutomatic dryingDrying gas arrangementsCleaning using toolsDust controlEngineering

The invention discloses a dust removal device for aluminum alloy door and window production. The dust removal device structurally comprises a fixing base, track grooves, a drain valve, a first servo motor and a supporting base are arranged on the fixing base, the track grooves are located on the left side and the right side of the interior of the fixing base, the drain valve is fixedly connected to the middle right ahead the fixing base, the first servo motor is fixedly connected to the left side right ahead the fixing base, the supporting base is fixedly connected to the right end of the fixing base, the number of the track grooves is two, a first lead screw is movably connected to the interior of the track groove on the left side, and a metal guide rod is fixedly connected to the interior of the track groove on the right side. According to the dust removal device for aluminum alloy door and window production, dust attached to aluminum alloy doors and windows is automatically removed, the speed of removing the dust attached to the aluminum alloy door and window is increased, in addition, the cleaned aluminum alloy doors and window can be automatically dried, the phenomenon that the aluminum alloy doors and windows are stained again after being cleaned can be prevented, and the convenience of the dust removal device in the using process is improved.

Owner:徐州市固塑建筑材料有限公司

A retractable wall brushing device

The invention discloses a retractable wall painting device, which comprises a support plate, at least one wall painting plate movably connected with the support plate, and assembly parts installed inside both the support plate and the wall painting plate; The assembly part includes a number of moving parts and springs equal in number to the wall painting board; one end of the moving part is fixedly connected to the support plate, and the other end is fixedly connected to the wall painting board; the spring includes a first A spring segment, a helical spring segment and a second spring segment, the first spring segment is connected to the wall-washing board, the helical spring segment and the second spring segment are installed in the support plate; through the moving part The wall brushing board is flexibly connected with the support board with a spring. Since the wall-painting board can rotate along the support plate, the wall-painting board can be shrunk during storage, reducing the occupied space, and at the same time, the wall painting can be carried out in a small space, and can also be cleaned and dried automatically.

Owner:会同会泓新材料科技有限公司

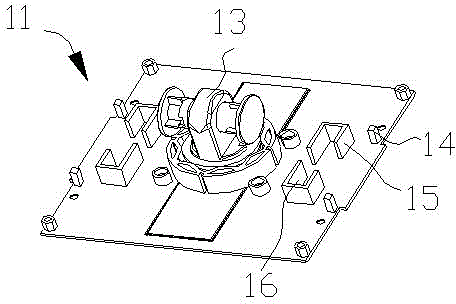

Device for separating melting impurities during pig iron separation and reduction

ActiveCN112475282AImprove work efficiencyLow amount of molten ironCasting cleaning apparatusPhysicsEngineering

The invention relates to a device for separating melting impurities, in particular to a device for separating melting impurities during pig iron separation and reduction. The invention provides the device for separating melting impurities during pig iron separation and reduction, which is good in impurity removal effect and is high in work efficiency. The device for separating melting impurities during pig iron separation and reduction comprises a bottom plate and a servo motor as well as a filter mechanism and a knocking mechanism, wherein the servo motor is arranged at one side of the top ofthe bottom plate; the filter mechanism is arranged between one side of the top of the bottom plate and the output shaft of the servo motor; and the knocking mechanism is arranged between one side ofthe top of the bottom plate and the filter mechanism. An indirect discharge mechanism, the knocking mechanism and the filter mechanism are matched, so that intermittent discharge and filter operationof molten iron can be automatically accomplished, work efficiency of people is improved, amount of molten iron filtered every time is less, and filter effect on molten iron is good; and a cooling mechanism can automatically cool the filtered impurities, so that a knocking block conveniently knocks off the impurities adhered onto a filter plate.

Owner:江苏长实基业电气科技有限公司

Integrated device capable of synchronously removing dust in polishing process

InactiveCN112933849AReduce the spread of dustReduce wear and tearCombination devicesDirt cleaningPhysicsGrinding

The invention relates to the technical field of metal, and discloses an integrated device capable of synchronously removing dust in the polishing process. Through cooperative use of a water storage chamber, a push rod, a first gear and a second gear, water is automatically sprayed during grinding, and therefore dust diffusion is reduced; and meanwhile, the grinding tool can be cooled through cold water, and the loss of the tool is reduced. Through cooperative use of a roller shaft, a first rotating rod, a second rotating rod and a disc, dust collection is automatically conducted through negative pressure during novel water spraying, and the dust collection strength is automatically improved in the later period of grinding; so that on one hand, the situation that dust is difficult to adsorb due to the fact that the weight of the dust is increased after water suction is avoided, and on the other hand, mobility of air is accelerated through negative pressure, so that the workbench is automatically dried, and rusting is avoided; and through cooperative use of the swing rod, the filter plate and the scraper blade, the filter plate is automatically and intermittently cleaned by using the scraper blade. The device does not need to be cleaned manually, blockage of the filter plate is avoided, and more time and labor are saved.

Owner:SHENZHEN ACHIEVE TECH & ENGI

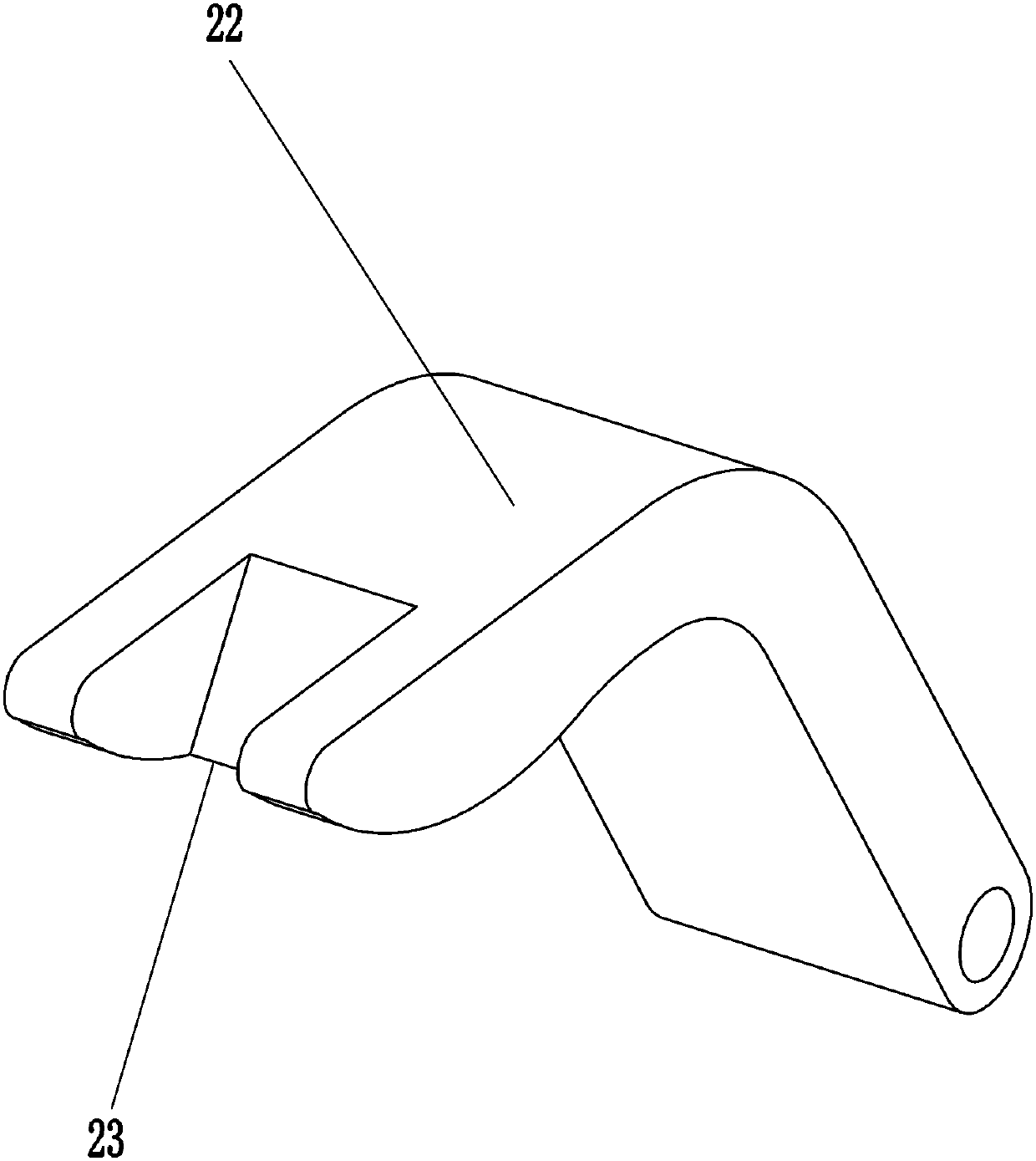

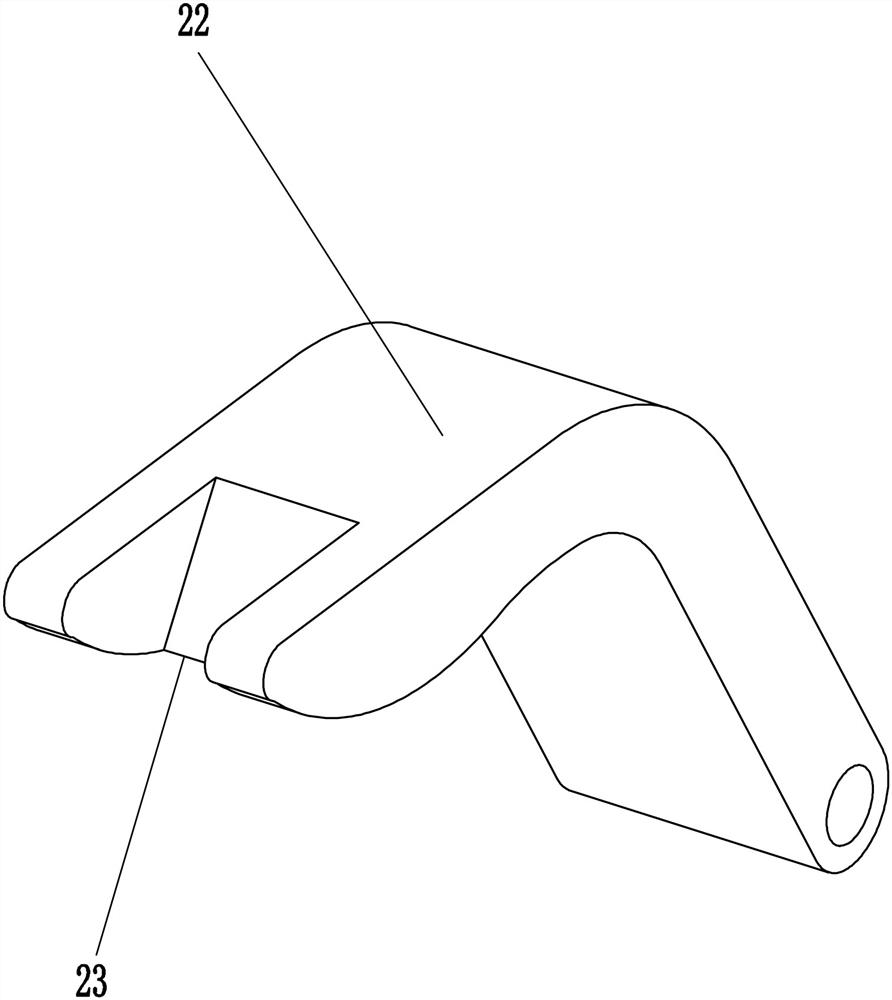

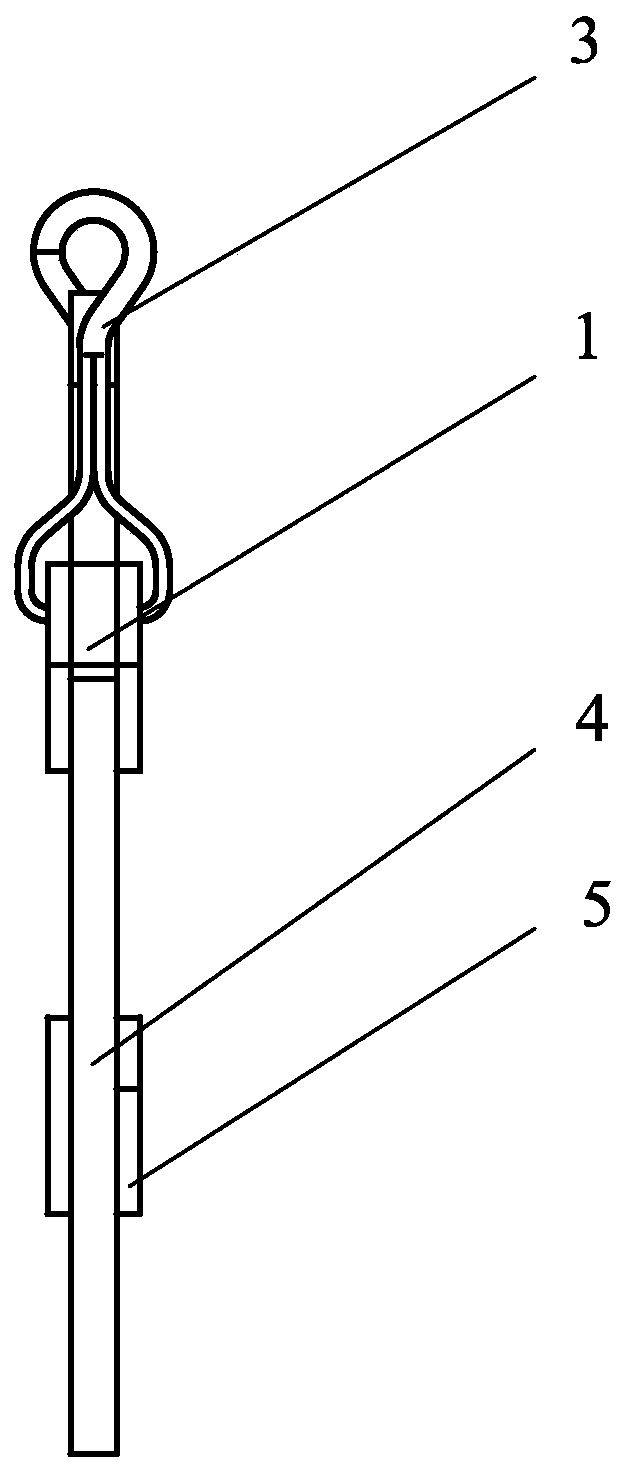

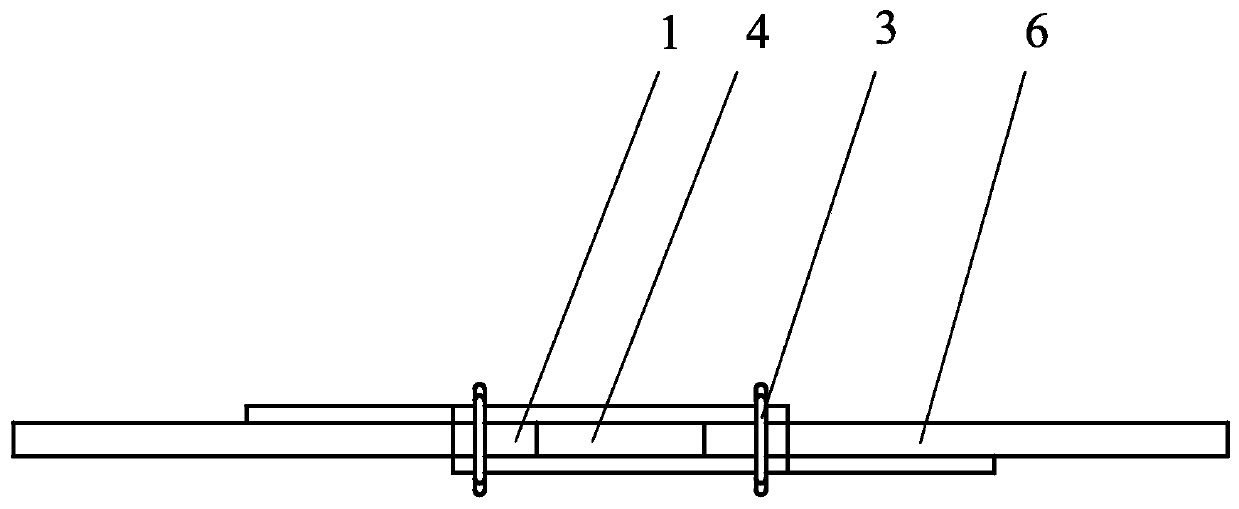

Self-locking telescopic clothes hanger with pure mechanical structure

InactiveCN111166142AImprove efficiencyReduce labor consumptionApparel holdersClothes hangerEngineering

The invention, whichbelongs to the field of self-locking hanger manufacturing, discloses a self-locking telescopic clothes hanger with a pure mechanical structure, thereby solving a problem that a clothes hanger in the prior art is inconvenient to air and pick up clothes with small collars and thus more time is consumed in the airing process. The clothes hanger comprises a hanging mechanism, a supporting mechanism and an adjusting mechanism; the supporting mechanism is arranged below the hanging mechanism, the supporting mechanism is hinged to the hanging mechanism, the adjusting mechanism isinserted into the hanging mechanism, the adjusting mechanism is in sliding connection with the hanging mechanism, and the adjusting mechanism is hinged to the supporting mechanism. The clothes hangeris mainly applied to airing and displaying of clothes with small collars.

Owner:HARBIN INST OF TECH

Domestic multifunctional chopstick dryer

InactiveCN107024111ADry evenlyAutomatic dryingDrying solid materialsDrying machines with local agitationHome useMetal sheet

The invention belongs to the technical field of chopsticks drying, and specifically relates to a household multifunctional chopsticks dryer, which includes a frame body and a water receiving tray arranged at the lower part of the frame body. The chopsticks basket is equipped with a blowing device and a vibration switch. The blowing device includes a housing with an air inlet and an air outlet. The housing is equipped with a motor, blades and heating wires. The motor is connected to the blades, and the blades The fan blade adopts an eccentric design, the heating wire is located near the air outlet of the housing, and the heating wire is electrically connected to the vibration switch; an insulating groove is provided on the water tray, and the insulating groove There are two metal sheets oppositely arranged in the groove, and the two metal sheets are connected in series on the motor circuit to form an open circuit; the household multifunctional chopsticks dryer adopting the technical solution of the present invention has low energy consumption and is suitable for family use, and It has fast drying speed and meets the needs of intelligent modern family life.

Owner:樊霞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com