Solar cell silicon wafer drying equipment

A technology for solar cells and drying equipment, applied in the field of solar cells, can solve problems such as easy tilting of cells when moving up and down, inaccurate stacking positions, and reduced drying efficiency, so as to reduce the time used for drying and improve the efficiency of drying. Efficiency, improve the effect of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

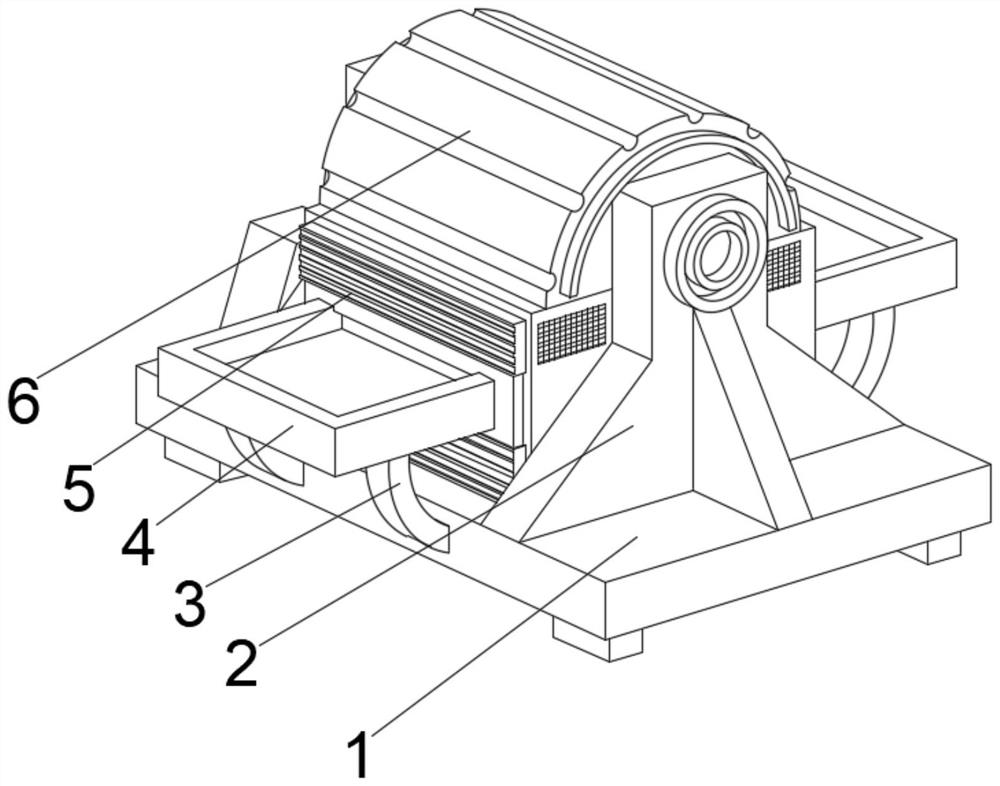

[0040] see Figure 1-6 , the present invention provides a technical solution: a solar cell silicon wafer drying equipment, including a fixed base 1, a drying device 6 is fixedly connected to the middle position of the top of the fixed base 1, and the middle part of the outer wall on both sides of the drying device 6 is provided with The opening and closing baffle 5, the middle part of the side of the opening and closing baffle 5 away from the drying device 6 is provided with a conveying line 4, both sides of the bottom of the conveying line 4 are fixedly connected with arc-shaped brackets 3, and the top of the fixed base 1 is located at the drying Both sides of the device 6 are fixedly connected with connecting support plates 2 .

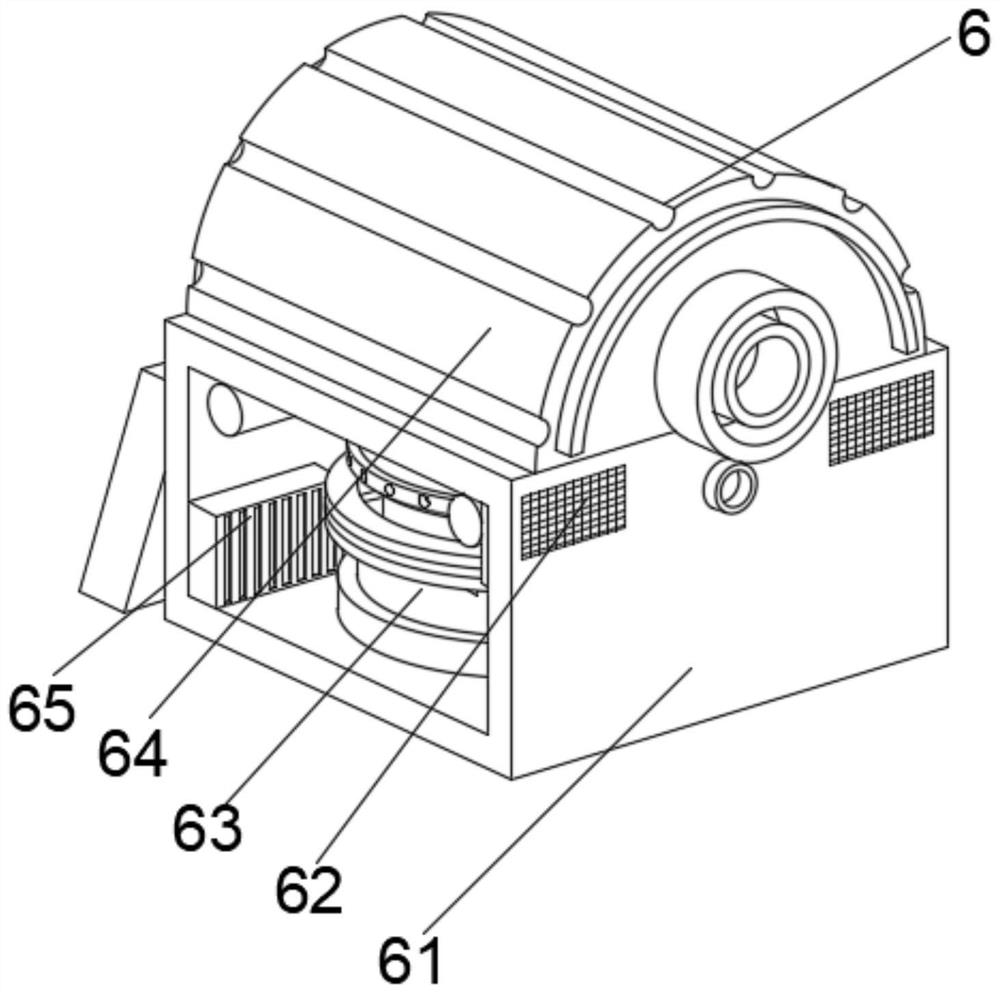

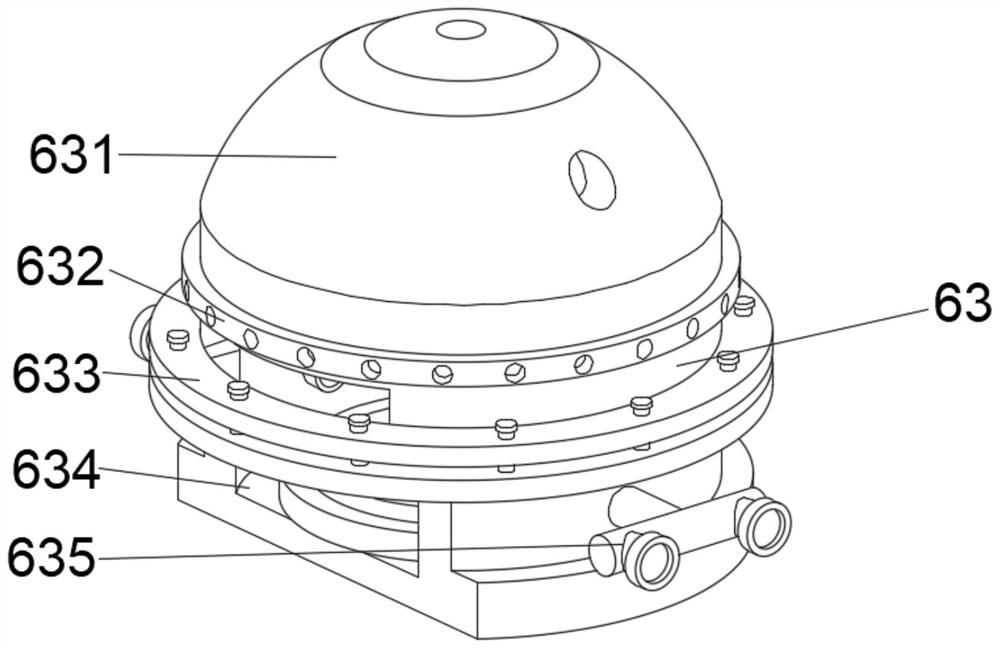

[0041] Wherein, the drying device 6 includes a drying box 61, the top of the drying box 61 is fixedly connected with an auxiliary mechanism 64, the top of the right side outer wall of the drying box 61 is provided with a ventilating plate (62), and ...

Embodiment 2

[0047] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using solar cell silicon wafer drying equipment, which is characterized in that: Step 1: Place the equipment in a stable position, and connect the conveying line 4 with the The assembly line for cell production is connected, and the equipment is started, so that when the cells placed on the surface of the conveying line 4 touch the sensor, the opening and closing baffle shrinks to create a space for entry and exit, and the conveying line extends to the inside of the drying device 6;

[0048] Step 2: The cells are dried, the internal temperature is increased, the vacuum valve 65 and the air-permeable plate (62) control the internal vacuum, and the middle part of the drying mechanism 63 can be separated when entering the cell for drying, realizing Drying of the front and back of the cell;

[0049] Step 3: After receiving the signal of battery entry, the clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com