A tree branch cutting and crushing device for gardening

A technology for crushing devices and branches, applied in heating devices, lighting and heating equipment, grain processing, etc., can solve the problems of increased labor intensity and no walking function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

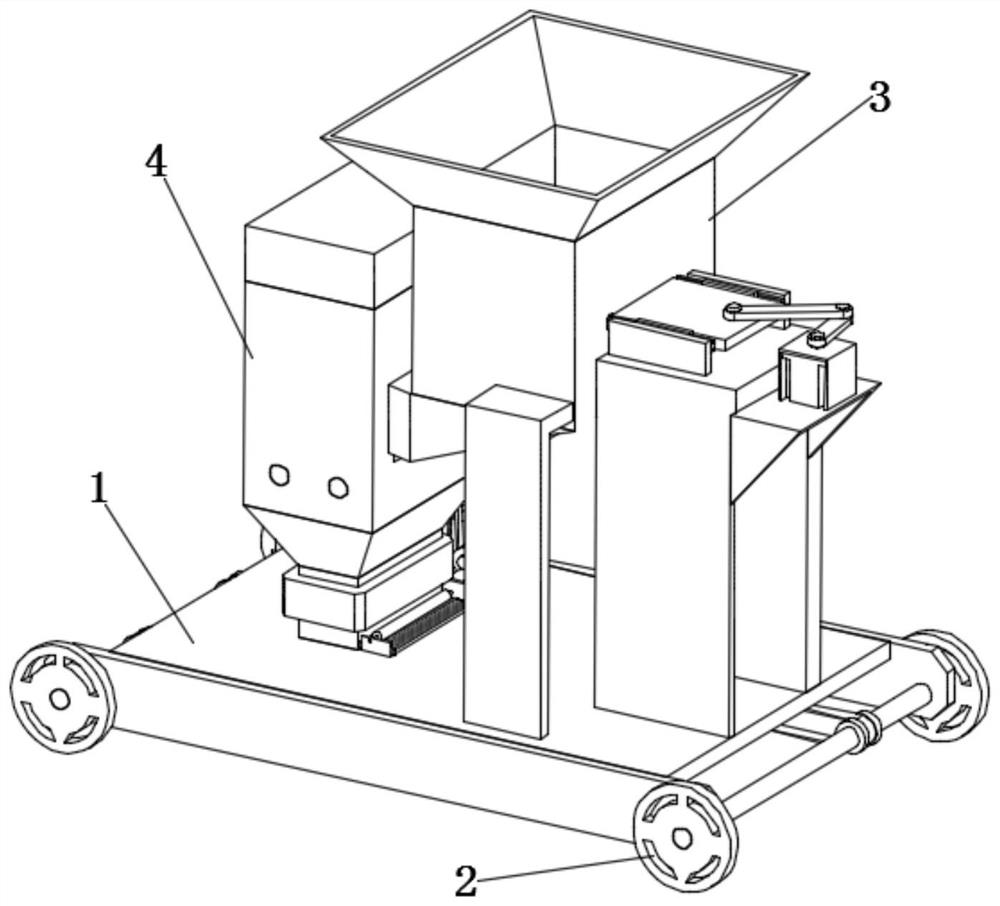

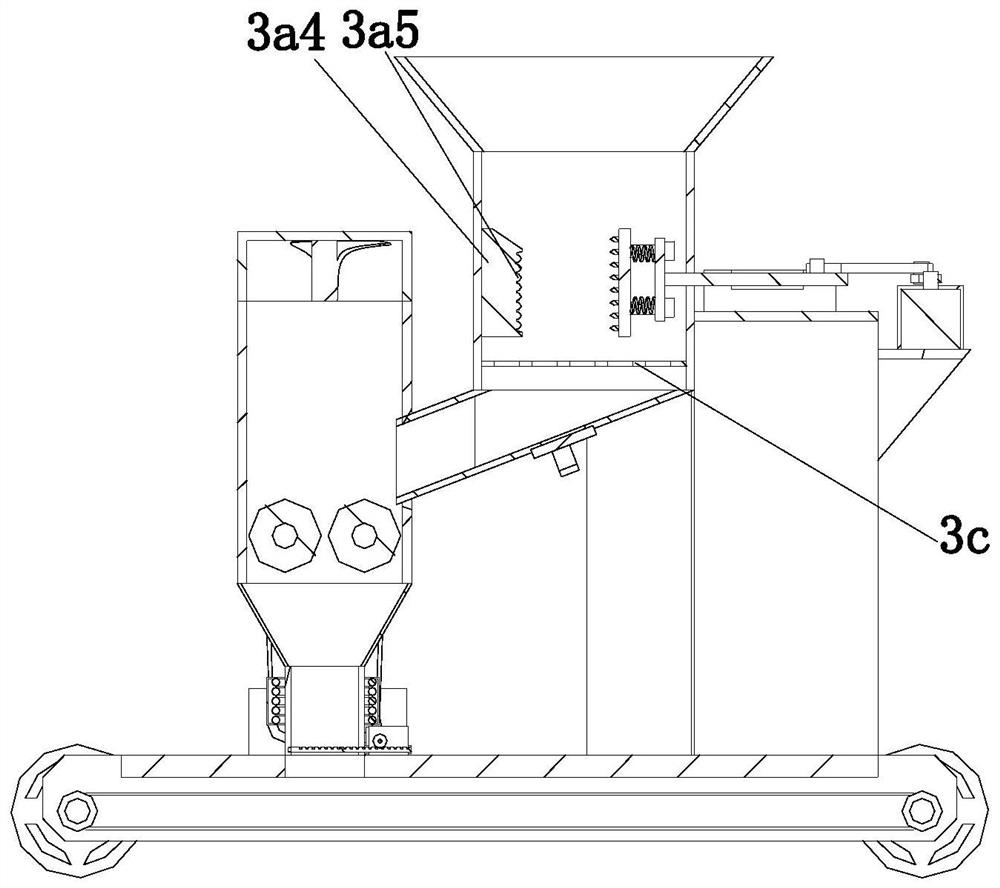

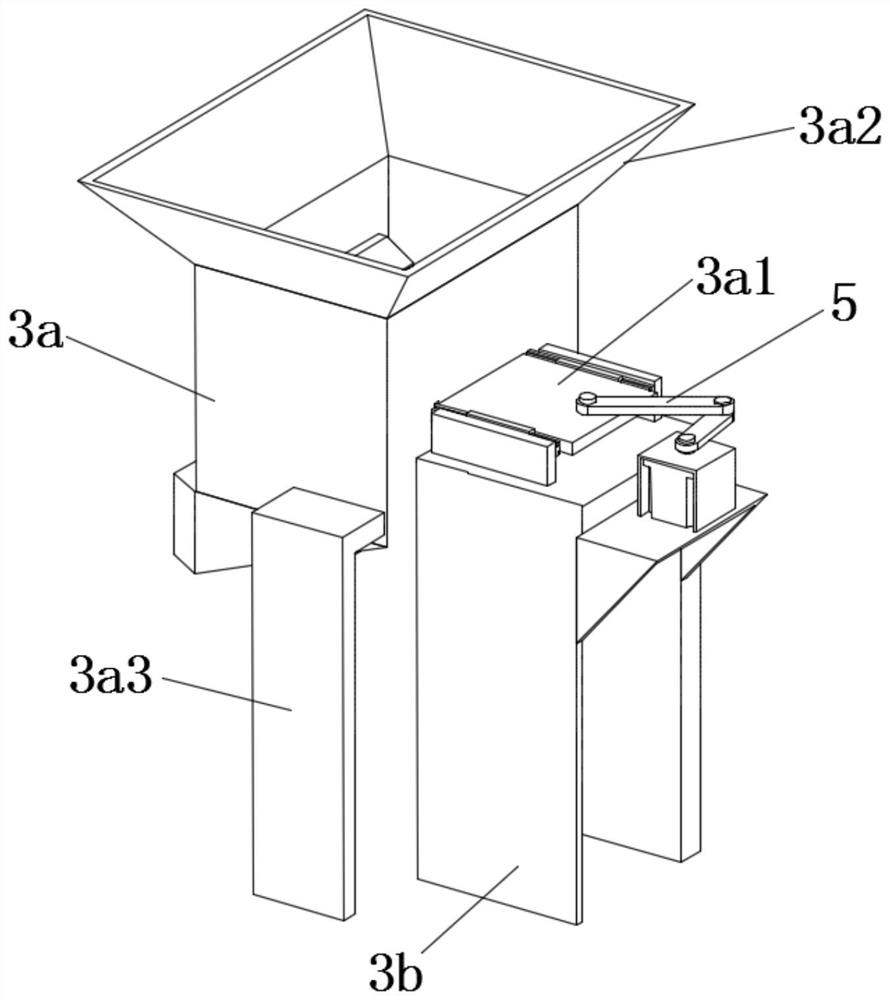

[0037] The present invention provides a kind of tree branch cutting and crushing device for gardens through improvement, such as Figure 1-Figure 10 As shown, it includes a supporting plate 1, a traveling assembly 2, a shearing assembly 3 and a crushing assembly 4, the traveling assembly 2 is located at the bottom of the supporting plate 1, and the shearing assembly 3 and the crushing assembly 4 are located at the top of the supporting plate 1 , the shearing assembly 3 includes a shearing cabinet 3a positioned directly above the supporting plate 1, a sliding plate 3a1 of a rectangular parallelepiped structure, and a drive assembly 5 for driving the sliding plate 3a1 to move in its own length direction, and the sliding plate 3a1 is located at Shear cabinet 3a side and with shear cabinet 3a sliding fit, described shear cabinet 3a top is provided with the feeding funnel 3a2 that is communicated with shear cabinet 3a, and described support plate 1 top is provided with two for The ...

Embodiment 2

[0049] The present invention provides another garden tree branch shearing and crushing device through improvement. Its general structure is the same as that of Embodiment 1, that is, it includes a supporting plate 1, a driving assembly 2, a shearing assembly 3 and a crushing assembly 4. Said driving assembly 2 is located at the bottom of the supporting plate 1, and the shearing assembly 3 and the crushing assembly 4 are located at the top of the supporting plate 1. The shearing assembly 3 includes a shearing cabinet 3a directly above the supporting plate 1, a The slide plate 3a1 and the driving assembly 5 used to drive the slide plate 3a1 to move in its own length direction, the slide plate 3a1 is located at the side of the shear cabinet 3a and is slidably matched with the shear cabinet 3a, and the top of the shear cabinet 3a is provided with The feeding funnel 3a2 that communicates with the shearing cabinet 3a, the top of the supporting plate 1 is provided with two L-shaped su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com