Drying device

A drying device and drying cylinder technology, applied in drying, drying machine, drying solid materials and other directions, can solve problems such as unfavorable processing, rust, time-consuming, etc., and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

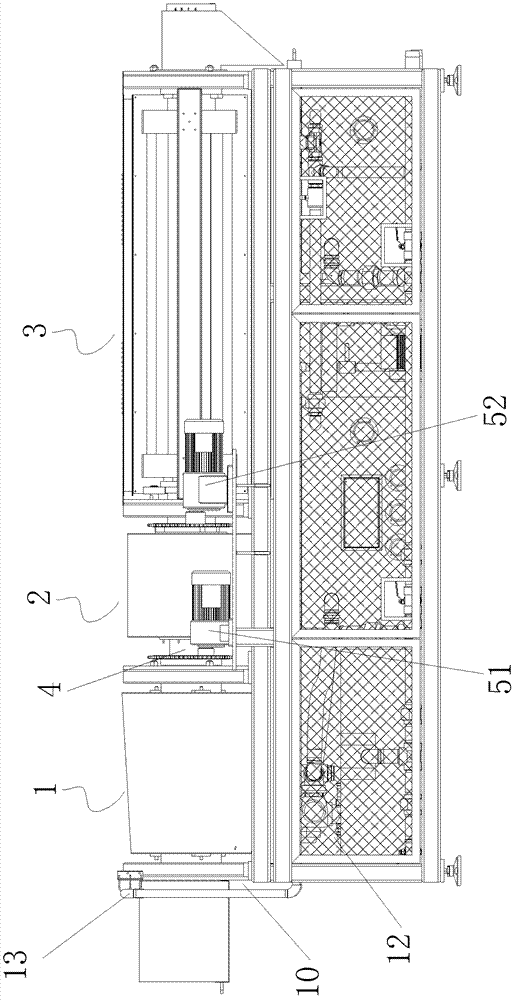

[0023] Embodiment: A cleaning machine includes a frame 10 and a cleaning device 1, a liquid removal device 2, and a drying device 3 which are sequentially installed on the frame 10.

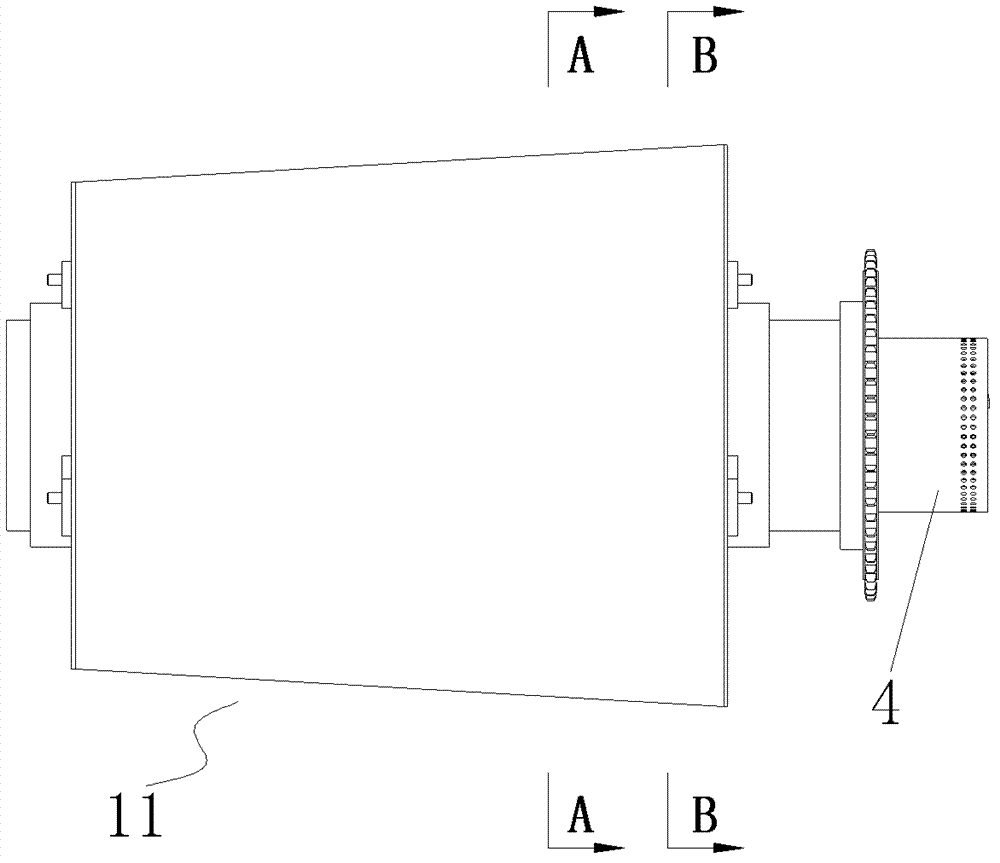

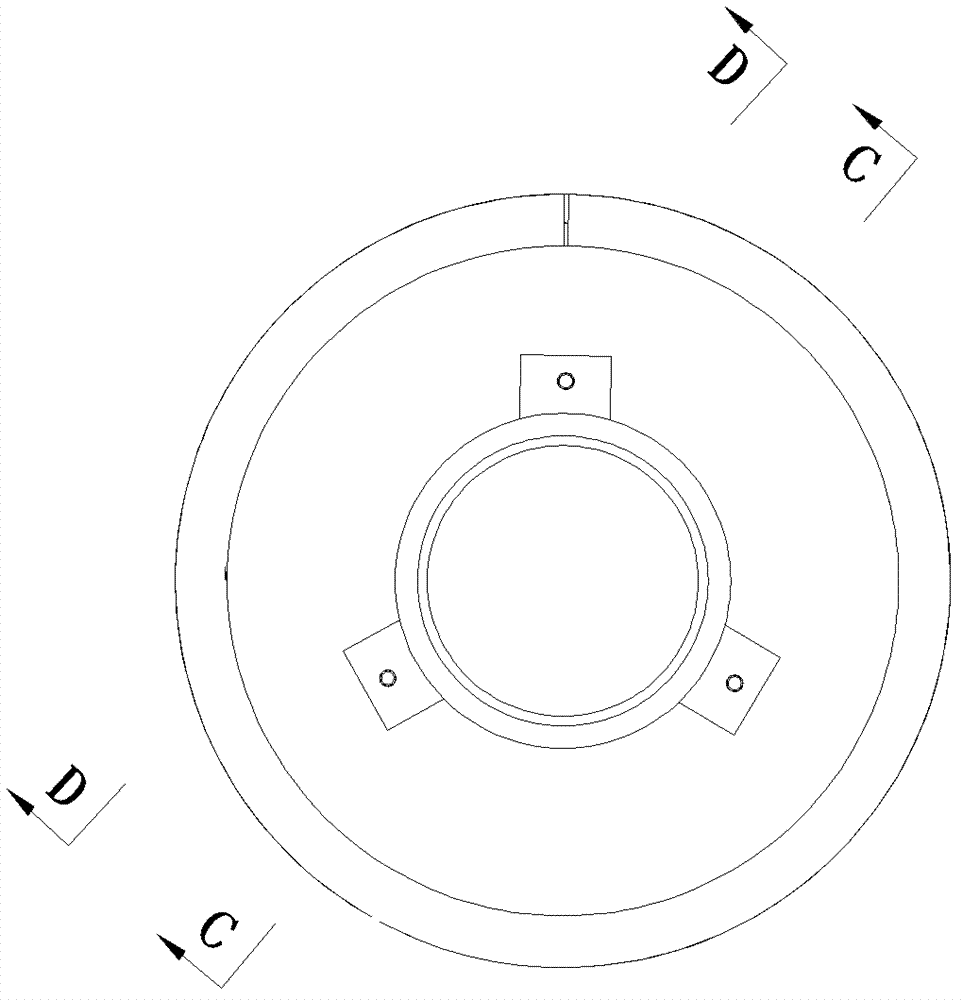

[0024] The cleaning device 1 includes a cleaning cylinder 11, which includes a cleaning cylinder 11-1 in the shape of a cone that can rotate around a horizontal axis, and a left end plate and a right end plate installed at both ends of the cleaning cylinder 11-1. The body 11-1 is evenly distributed with screen holes (not shown in the figure). The center of the left end plate on the smaller diameter side of the cleaning cylinder 11-1 is provided with a cleaning feed inlet 11-2, and the center of the right end plate is provided with a cleaning Outlet 11-3. A water tank 12 is installed under the cleaning cylinder 11, and a water spray pipe 13 extends from the cleaning feed inlet 11-2 and is suspended in the inner cavity of the cleaning cylinder 11-1. The cleaning machine is equipped with two water spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com