Electronic vacuum device surface coating device capable of achieving uniform coating and automatic drying

An electronic vacuum device and surface coating technology, applied in spraying devices, spray booths, etc., can solve the problems of low work efficiency, uneven coating, cumbersome operation, etc., and achieve the effect of reducing workload, uniform coating and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

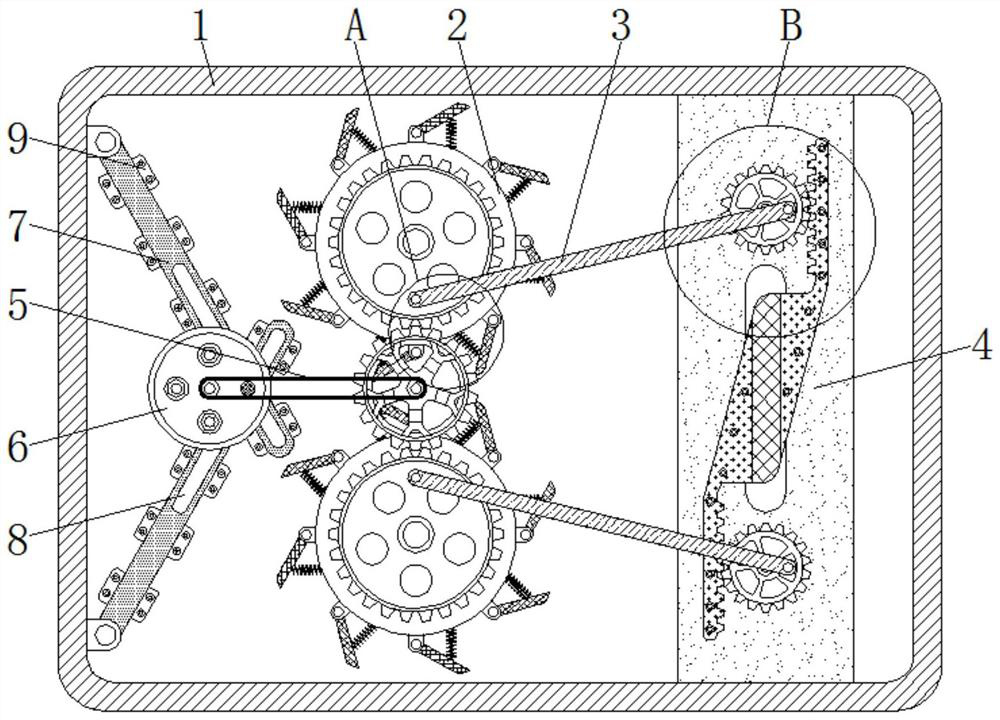

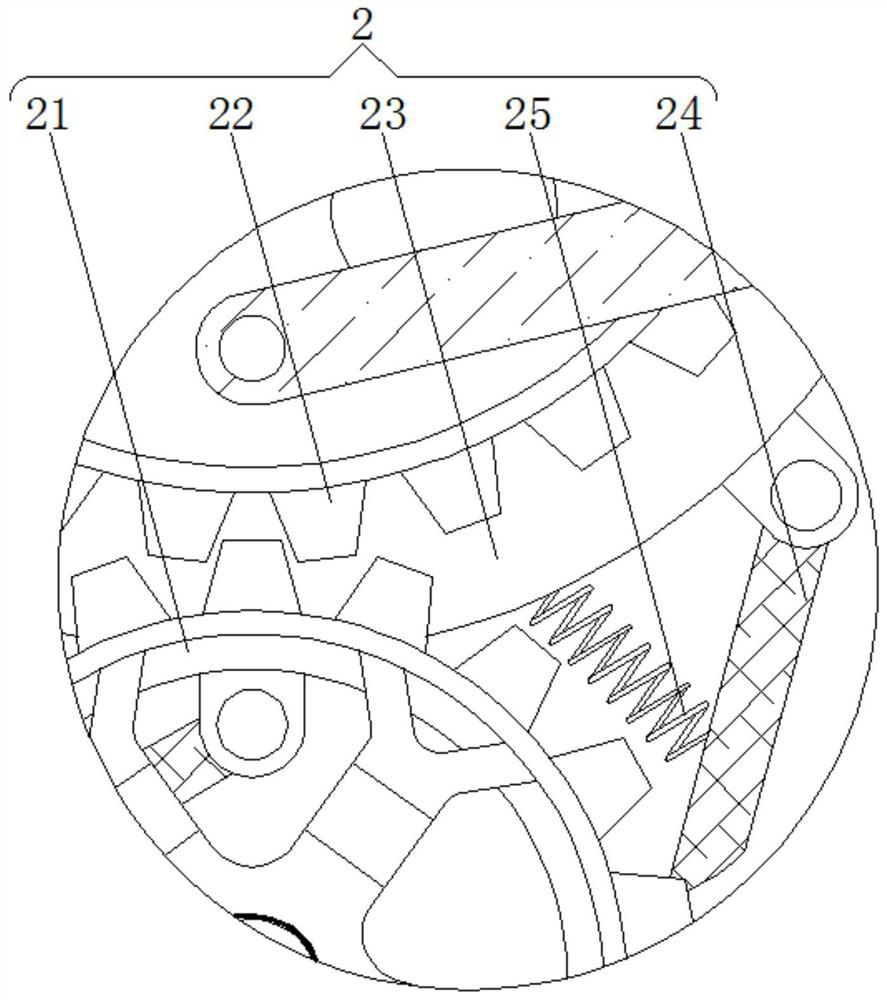

[0025] see figure 1 and figure 2 , an electronic vacuum device surface coating device capable of uniform coating and automatic drying, comprising a bottom plate 1, the front of the bottom plate 1 is rotatably connected to a coating mechanism 2, and the front of the coating mechanism 2 is rotatably connected to a driving rod 3, and the driving rod 3 The end far away from the coating mechanism 2 is rotatably connected with the unloading mechanism 4. There are two driving rods 3 with the same specifications, which are symmetrically distributed on the upper and lower sides of the coating mechanism 2. The two ends are respectively connected to the coating mechanism 2 and the bottom. The material mechanism 4 is connected in rotation, the front of the coating mechanism 2 is connected with a belt 5, and the side of the belt 5 far away from the coating mechanism 2 is connected with a turntable 6, and the side of the bottom plate 1 close to the turntable 6 is hinged with a rotation rod...

Embodiment 2

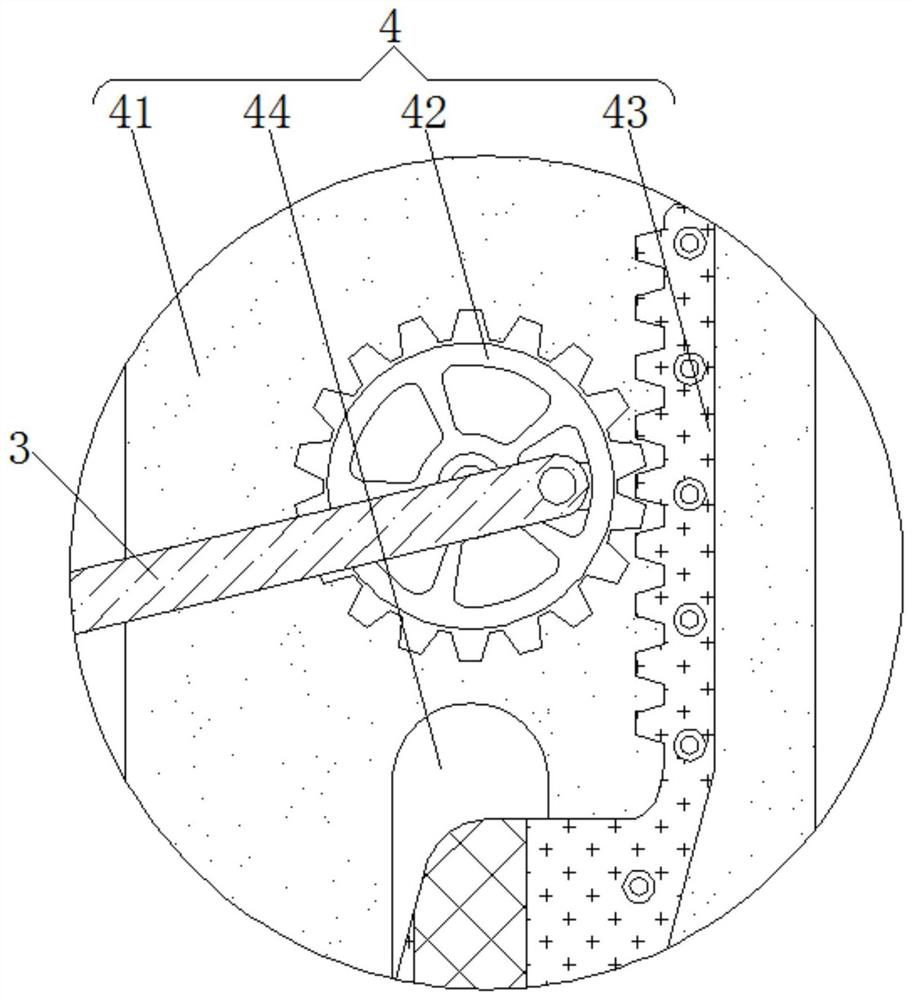

[0028] see figure 1 and image 3 , an electronic vacuum device surface coating device capable of uniform coating and automatic drying, comprising a bottom plate 1, the front of the bottom plate 1 is rotatably connected to a coating mechanism 2, and the front of the coating mechanism 2 is rotatably connected to a driving rod 3, and the driving rod 3 The end far away from the coating mechanism 2 is rotatably connected with the unloading mechanism 4. There are two driving rods 3 with the same specifications, which are symmetrically distributed on the upper and lower sides of the coating mechanism 2. The two ends are respectively connected to the coating mechanism 2 and the bottom. The material mechanism 4 is connected in rotation, the front of the coating mechanism 2 is connected with a belt 5, and the side of the belt 5 far away from the coating mechanism 2 is connected with a turntable 6, and the side of the bottom plate 1 close to the turntable 6 is hinged with a rotation rod ...

Embodiment 3

[0031] see Figure 1-3 , an electronic vacuum device surface coating device capable of uniform coating and automatic drying, comprising a bottom plate 1, the front of the bottom plate 1 is rotatably connected to a coating mechanism 2, and the front of the coating mechanism 2 is rotatably connected to a driving rod 3, and the driving rod 3 The end far away from the coating mechanism 2 is rotatably connected with the unloading mechanism 4. There are two driving rods 3 with the same specifications, which are symmetrically distributed on the upper and lower sides of the coating mechanism 2. The two ends are respectively connected to the coating mechanism 2 and the bottom. The material mechanism 4 is connected in rotation, the front of the coating mechanism 2 is connected with a belt 5, and the side of the belt 5 far away from the coating mechanism 2 is connected with a turntable 6, and the side of the bottom plate 1 close to the turntable 6 is hinged with a rotation rod 7, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com