Metal heat treatment softening annealing treatment device

A metal heat treatment, softening annealing technology, applied in heat treatment furnaces, heat treatment equipment, dry goods processing, etc., can solve the problems of uneven hardness of sealing gaskets, insufficient heating degree, affecting the heating, heat preservation and cooling process of copper sealing gaskets, etc. Avoid copper gasket offset, improve efficiency, avoid the effect of uneven hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

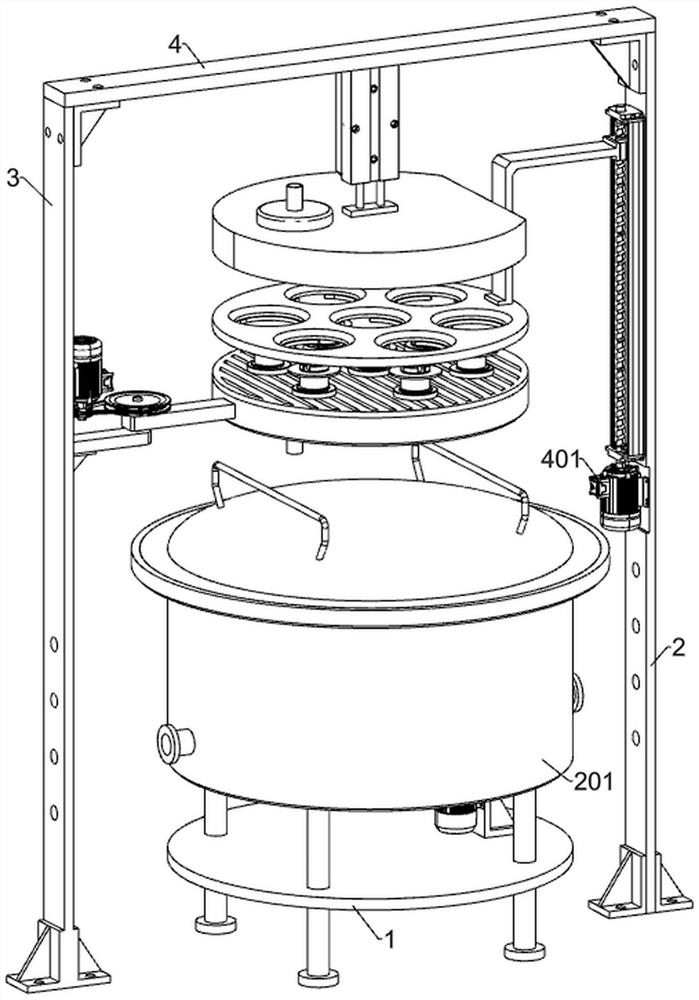

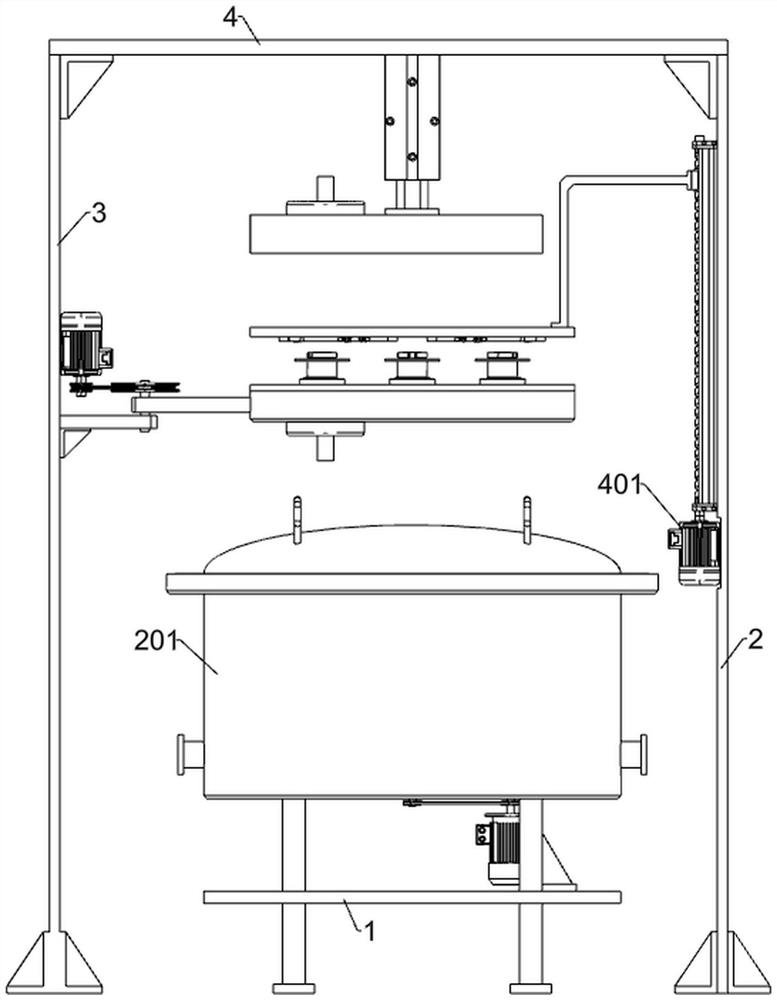

[0034] A metal heat treatment softening annealing treatment device, such as Figure 1-8As shown, it includes a support table 1, a first support frame 2, a second support frame 3, a third support frame 4, an annealing assembly and a first adjustment assembly; the right side of the support table 1 is provided with a first support frame 2; the support table 1. A second support frame 3 is provided on the left; a third support frame 4 is fixedly connected between the upper ends of the first support frame 2 and the second support frame 3; an annealing assembly is installed on the upper part of the support table 1; seven groups of First adjustment component.

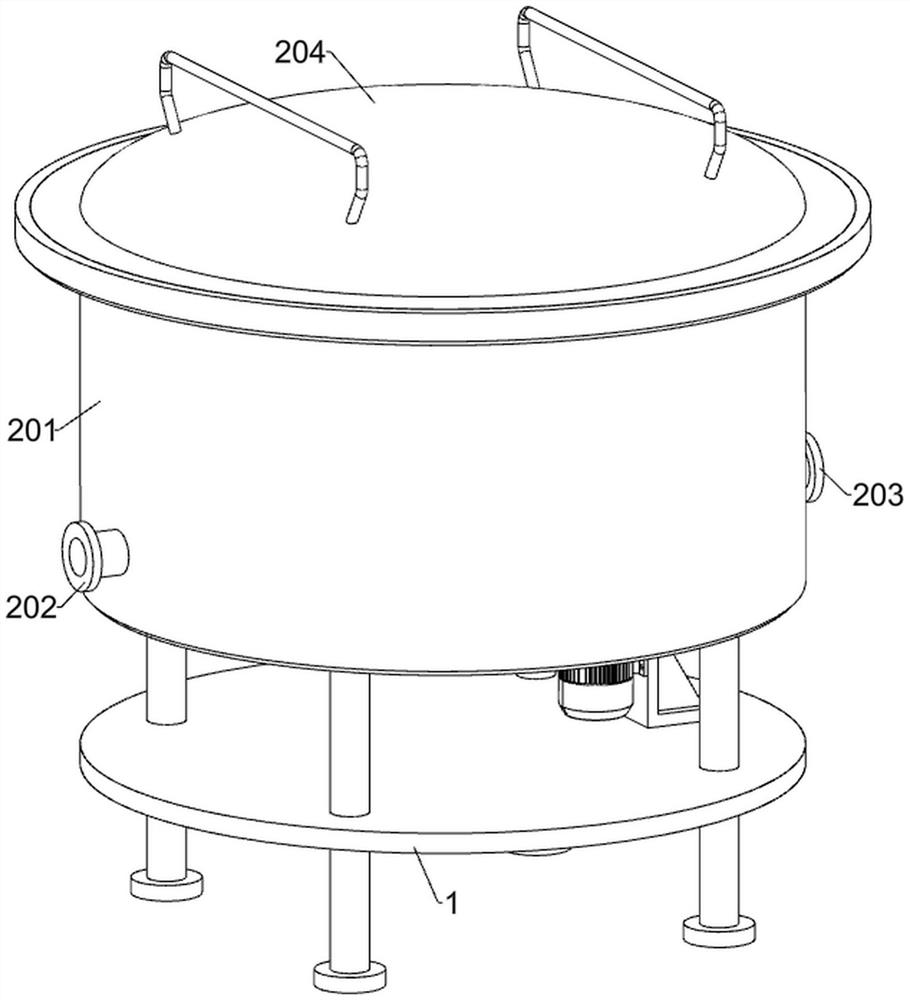

[0035] The annealing assembly includes a first annealing chamber 201, a first joint 202, a second joint 203, a first top cover 204, a first motor 205, a first connecting frame 206, a first guide rod 207, a first screw rod 208, a first A linkage plate 209, the first transmission wheel 2010, the first transmission rod 2011, the ...

Embodiment 2

[0041] On the basis of Example 1, such as figure 1 , Figure 9-11 As shown, a drying assembly is also included. The drying assembly is located under the third support frame 4. The drying assembly includes a second motor 401, a first guide rail 402, a second screw rod 403, a first slider 404, a first The linkage frame 405, the second receiving plate 406, the first telescopic cylinder 407, the first dryer 408, the third motor 409, the first linkage block 4010, the second dryer 4011, the third transmission wheel 4012 and the fourth transmission Wheel 4013; the middle part of the first support frame 2 is fixedly connected with the second motor 401; the upper part of the first support frame 2 is fixedly connected with the first guide rail 402; the middle part of the third support frame 4 is fixedly connected with the first telescopic cylinder 407; the second support frame 3 The upper part is fixedly connected with the third motor 409; the upper output end of the second motor 401 i...

Embodiment 3

[0046] On the basis of Example 2, such as figure 1 , Figure 12-13As shown, it also includes a second adjustment assembly. Seven sets of second adjustment assemblies are fixedly connected to the upper part of the second dryer 4011. The second adjustment assembly includes a first electric turntable 601, a first linkage column 602, and a third linkage block. 603, the first U-shaped block 604, the second limit rod 605, the second spring 606 and the first arc-shaped plate 607; the middle part of the upper surface of the second dryer 4011 is fixed with the first electric turntable 601; the first electric turntable 601 The rotating part is fixedly connected with the first linkage column 602; the middle part of the upper surface of the first linkage column 602 is fixedly connected with the third linkage block 603; the left and right sides of the third linkage block 603 are fixedly connected with a first U-shaped block 604; The middle part of each first U-shaped block 604 is slidingl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com