Yarn drying equipment for textile

A technology for drying equipment and yarn, applied in drying, dryer, lighting and heating equipment and other directions, can solve the problems of residual moisture in yarn and incomplete drying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

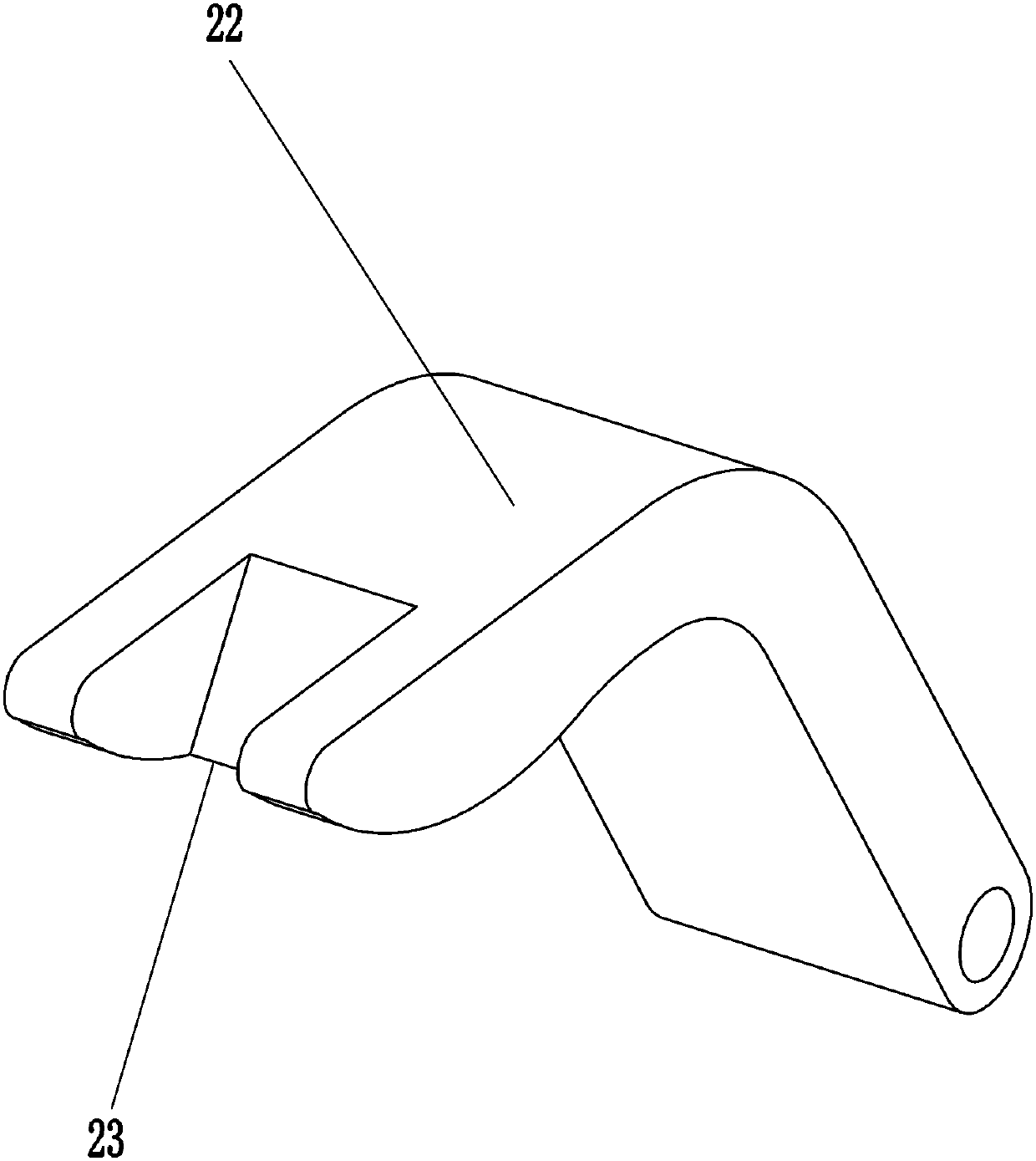

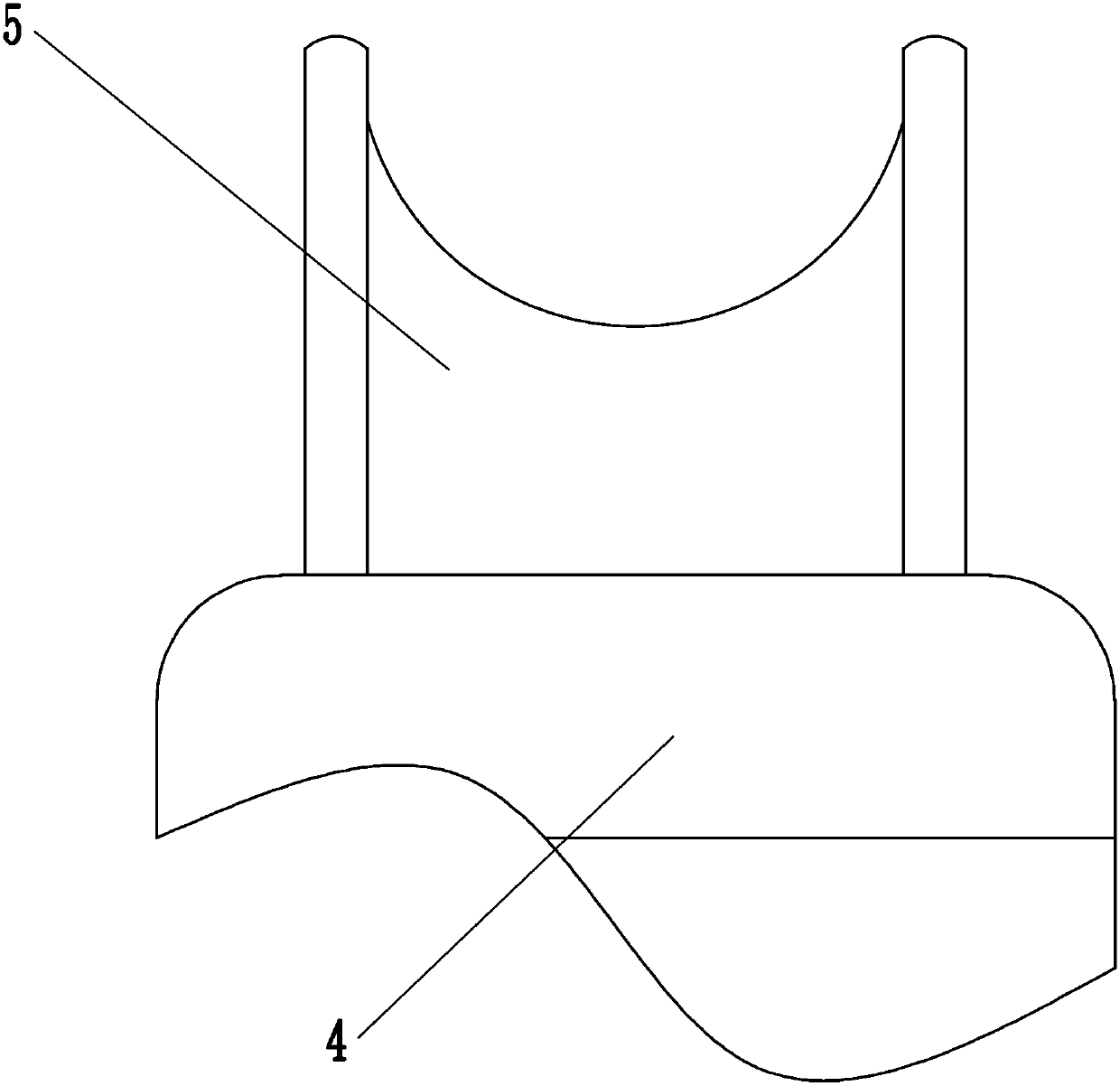

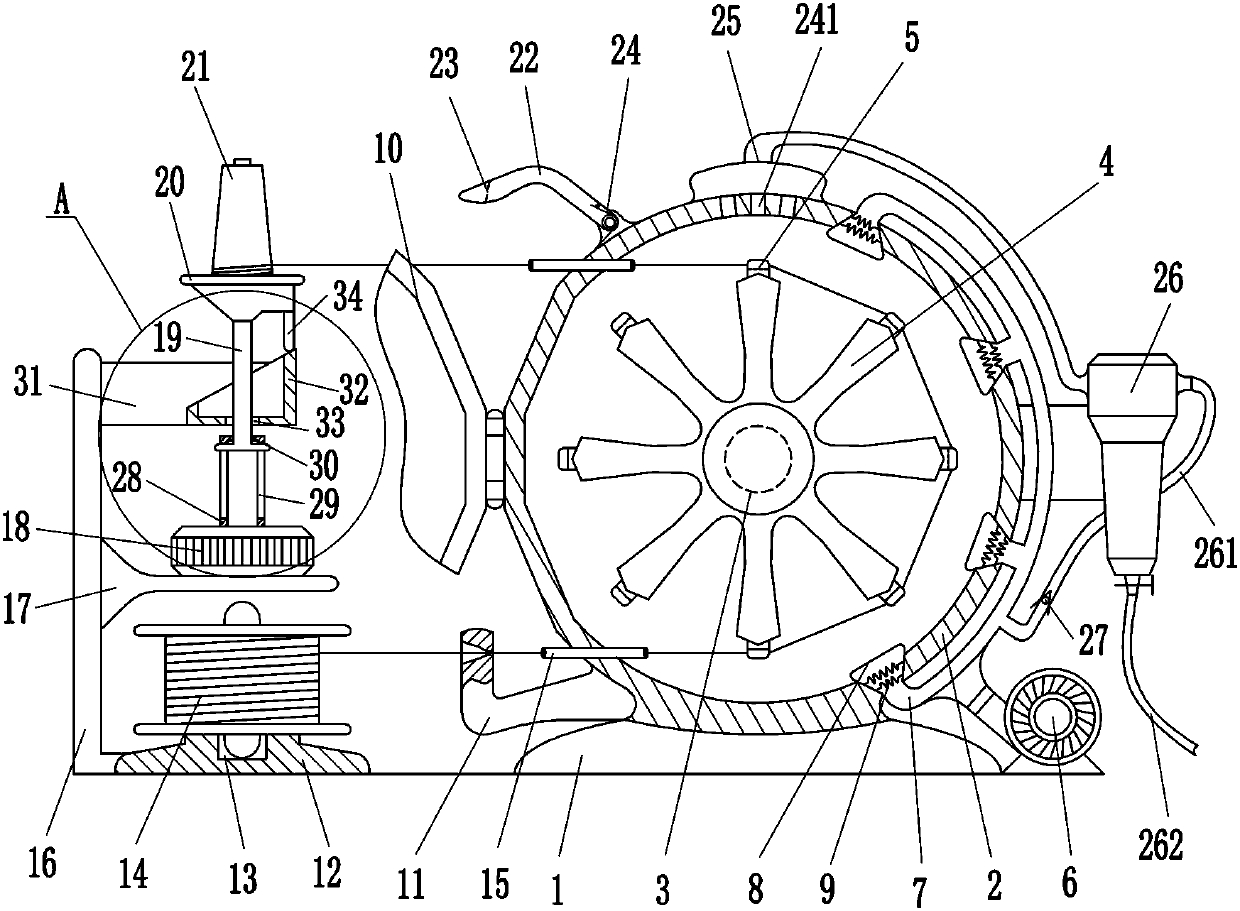

[0016] A kind of textile yarn drying equipment, such as Figure 1-2 As shown, it includes a first base 1, a box body 2, a first motor 3, a polygonal bracket 4, an arc-shaped support block 5, a blower 6, a multi-way pipe 7, a trumpet-shaped air inlet pipe 8, a heating wire 9, and a box door. 10. L-shaped water removal block 11, second base 12, raw material winding wheel 14, hose 15, first pole 16, second pole 17, second motor 18, first shaft 19, turntable 20 and finished product The winding wheel 21, the top of the first base 1 is equipped with a box body 2, the first base 1 is connected to the box body 2 by bolts, the first motor 3 is bolted to the middle of the back side of the box body 2, and the first motor 3 A polygonal bracket 4 is installed on the output shaft of the polygonal bracket 4, and eight arc-shaped support blocks 5 are evenly spaced on the outside of the polygonal bracket 4, and a blower 6 is bolted to the right side of the first base 1, and the blower 6 is con...

Embodiment 2

[0018] A kind of textile yarn drying equipment, such as Figure 1-4 As shown, it includes a first base 1, a box body 2, a first motor 3, a polygonal bracket 4, an arc-shaped support block 5, a blower 6, a multi-way pipe 7, a trumpet-shaped air inlet pipe 8, a heating wire 9, and a box door. 10. L-shaped water removal block 11, second base 12, raw material winding wheel 14, hose 15, first pole 16, second pole 17, second motor 18, first shaft 19, turntable 20 and finished product Winding wheel 21, box body 2 is installed on the top of the first base 1, first motor 3 is bolted to the middle part of the inner rear side of box body 2, polygonal bracket 4 is installed on the output shaft of first motor 3, and the outer side of polygonal bracket 4 is uniform Eight arc-shaped support blocks 5 are fixed at intervals, and a blower 6 is bolted to the right side of the first base 1. The blower 6 is connected with a multi-way pipe 7 for making air flow, and the right side of the box body 2...

Embodiment 3

[0021] A kind of textile yarn drying equipment, such as Figure 1-4As shown, it includes a first base 1, a box body 2, a first motor 3, a polygonal bracket 4, an arc-shaped support block 5, a blower 6, a multi-way pipe 7, a trumpet-shaped air inlet pipe 8, a heating wire 9, and a box door. 10. L-shaped water removal block 11, second base 12, raw material winding wheel 14, hose 15, first pole 16, second pole 17, second motor 18, first shaft 19, turntable 20 and finished product Winding wheel 21, box body 2 is installed on the top of the first base 1, first motor 3 is bolted to the middle part of the inner rear side of box body 2, polygonal bracket 4 is installed on the output shaft of first motor 3, and the outer side of polygonal bracket 4 is uniform Eight arc-shaped support blocks 5 are fixed at intervals, and a blower 6 is bolted to the right side of the first base 1. The blower 6 is connected with a multi-way pipe 7 for making air flow, and the right side of the box body 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com