Clothes treatment device

A kind of clothing processing equipment and lint technology, applied in the field of clothing processing, can solve the problems of noise, inability to remove the lint filter device, and inappropriate removal of the lint filter device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

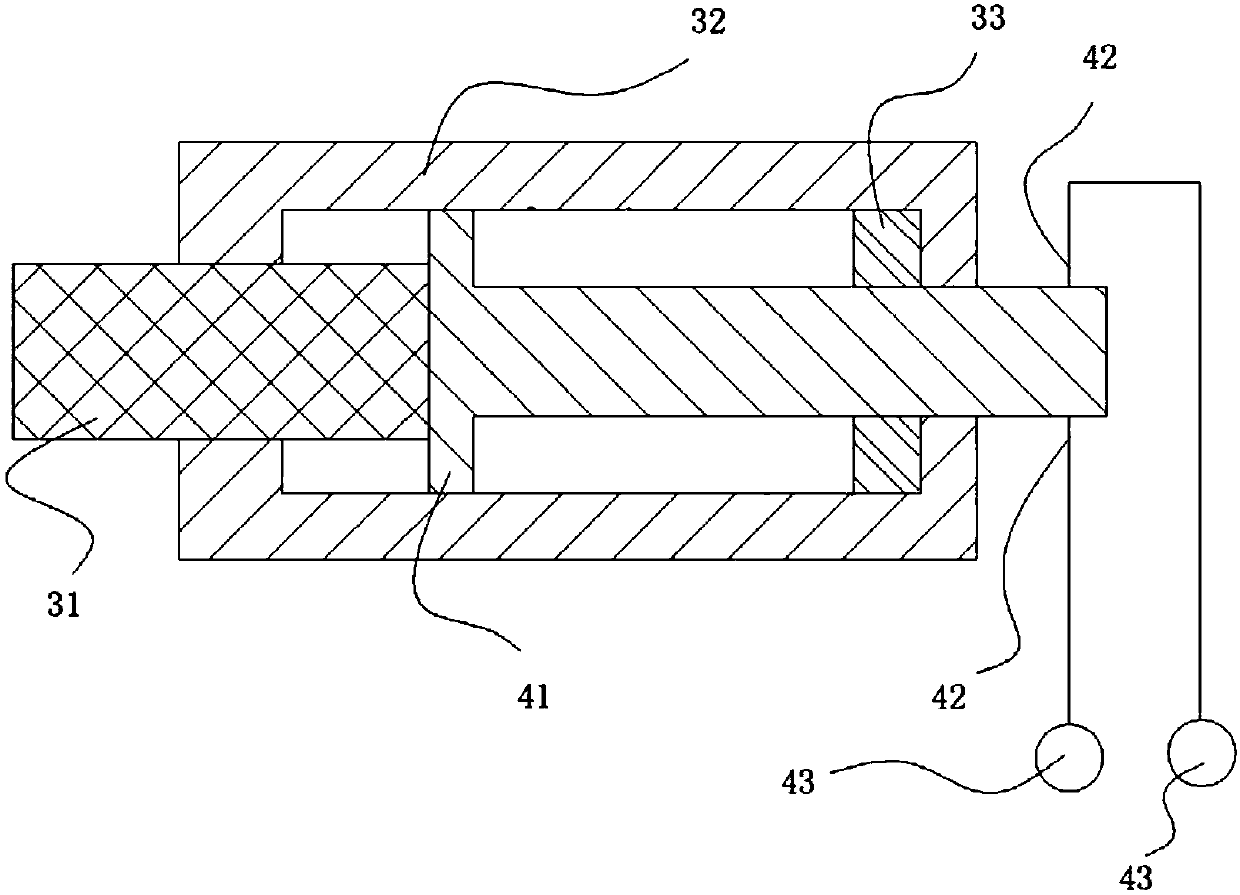

[0060] Such as figure 1 As shown, in the clothes processing device described in this embodiment, the cleaning device cleans the lint filtering device by spraying a cleaning medium. The position detection device is used to detect the relative position state between the lint filtering device and the clothes processing equipment, and generate a corresponding signal for adjusting the operation of the cleaning device;

[0061] The position detection device includes a detection connection part 41, a first detection point 42, and a controller 43 that cooperate with each other; the detection connection part 41 obtains the relative positional relationship between the lint filtering device and the clothes processing equipment, and mainly Based on this, control the communication relationship between the first detection point 42 and the controller 43 to generate corresponding signals, and then realize the detection of the position and state of the lint filtering device. One piece and the...

Embodiment 2

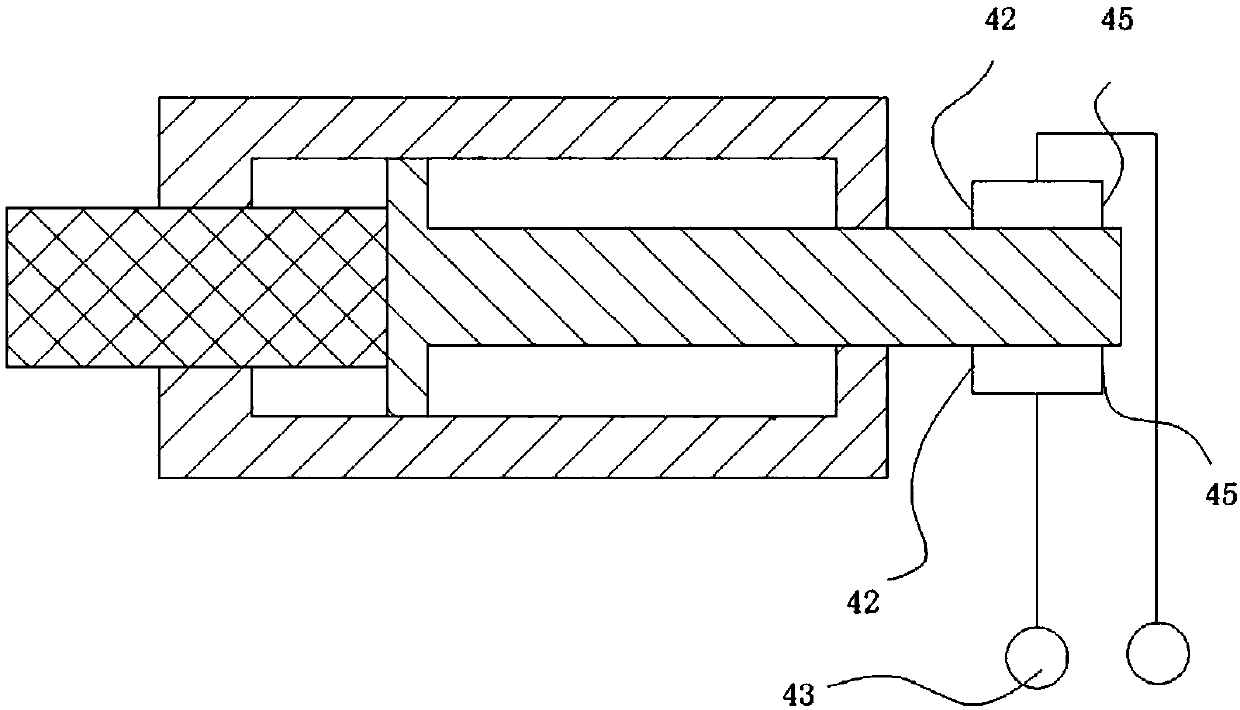

[0064] Such as figure 2 As shown, the difference between the clothes processing device described in this embodiment and the above embodiment is that there are multiple detection points, and the multiple detection points correspond to different detection values. When different detection points and control Different detection signals are generated when the device is connected; the detection connection part connects the corresponding detection point with the controller according to the relative positional relationship between the lint filtering device and the laundry processing equipment. Further, the detection connecting member is connected to the lint filtering device. The detection points in this implementation include at least the first detection point 42 and the second detection point 45. When the moving distance of the detection connecting piece is different, the connection conditions of the multiple detection points are different, and then different signals are generated ...

Embodiment 3

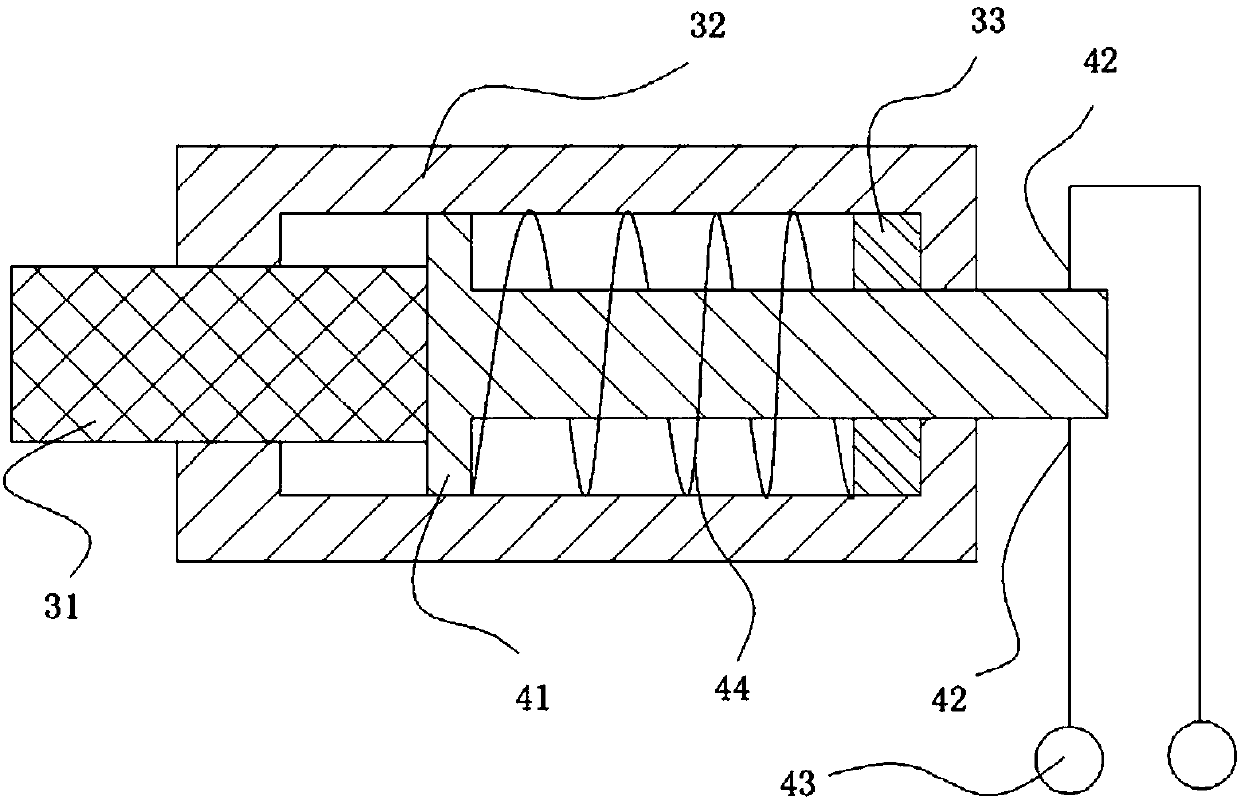

[0066] Such as image 3 As shown, the difference between the clothes processing device described in this embodiment and the above embodiments is that: the position detection device includes a reset member, which is used to restore the detection connecting member to the original position, thereby disconnecting the detection point from the controller, And generate a corresponding signal, so that the cleaning device adjusts the cleaning mode / ends the cleaning operation. The cleaning method includes cleaning angle and / or cleaning force and / or selection of cleaning medium.

[0067] Through the laundry processing equipment introduced in the present invention, a reset device is provided so that the position detection device can be reset after the detection is completed or after the clothing processing equipment stops working, so as to ensure the accuracy of the next detection and at the same time reset the lint filtering device, thereby enabling Users can easily remove it.

[0068]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com