Antiskid glazed tile surface spraying device

A technology for surface spraying and glazed tiles, which is applied to the surface coating device, spray device, liquid spray device, etc., can solve problems such as low work efficiency, save time, improve spray efficiency, and maintain cleanliness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

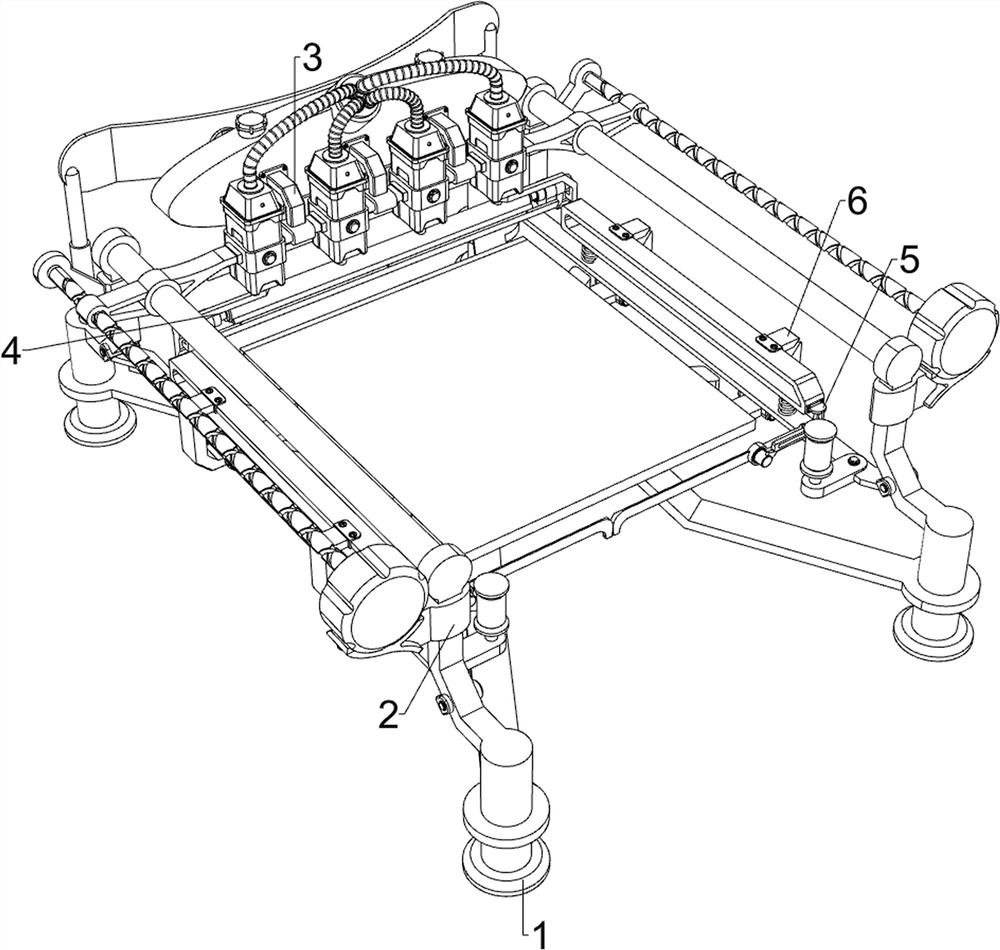

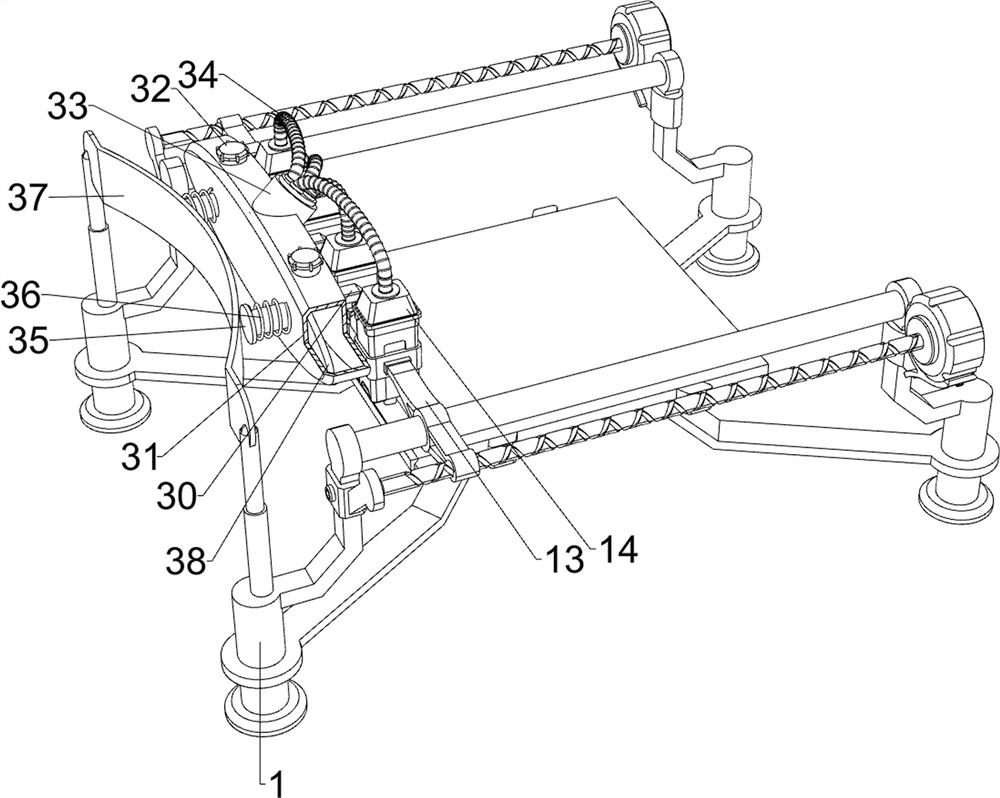

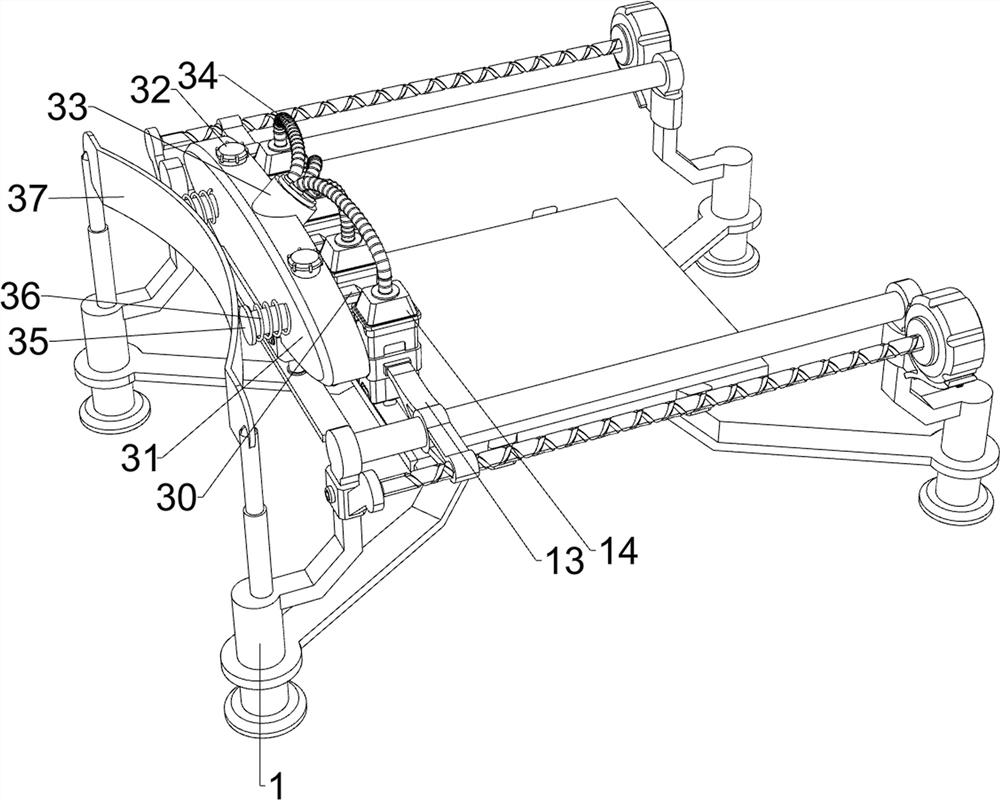

[0035] A non-slip glazed tile surface spraying device, such as Figure 1-7 As shown, it includes a mounting frame 1, a material bracket 11, a guide rod 12, a moving frame 13, a sprayer 14, a spray pipe 15, a reciprocating mechanism 2 and a feeding mechanism 3, and there are materials between the four mounting frames 1. Bracket 11. Glazed tiles can be placed on the material bracket 11. Guide rods 12 are provided between the two mounting brackets 1 on the left and between the two mounting brackets 1 on the right. A moving frame 13 is slidably connected to the rear of the guide rod 12 , the moving frame 13 can move on the guide rod 12 , and four sprayers 14 are arranged on the moving frame 13 equidistantly. The sprayers 14 can provide power and also Anti-slip agent can be stored, and a spray pipe 15 is arranged between the lower parts of the four sprayers 14. The spray pipe 15 can spray the anti-slip agent on the glazed tiles. There is a feeding mechanism 3 for feeding the feede...

Embodiment 2

[0040] On the basis of Example 1, as figure 1 , figure 2 , Figure 8 and Figure 9 As shown, it also includes a blocking mechanism 4 to avoid waste of anti-slip agent. The blocking mechanism 4 includes a fixed rod 40, a blocking plate 41, a sponge rod 42, a first scroll spring 43, a first rotating block 44, a first The fixing plate 45, the first lifting block 46, the second spring 47 and the stopper 48, the left and right sides of the spray pipe 15 are provided with fixing rods 40, and the outer sides of the two fixing rods 40 are rotatably connected with the first rotating block 44, A first scroll spring 43 is sleeved between the first rotating block 44 and the adjacent fixed rod 40 , the first scroll spring 43 can be deformed by torsion, and a stopper is connected between the two first rotating blocks 44 Plate 41, the baffle plate 41 can collect the dripping anti-slip agent, which is convenient for recycling, avoids waste of resources, and can also prevent the anti-slip ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com