Air-cooled blow needle mechanism

An air-cooled, needle-body technology is applied in the field of air-cooled needle blowing mechanisms and plastic hollow containers to achieve the effects of improving heat dissipation, improving production efficiency and shortening inflation time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

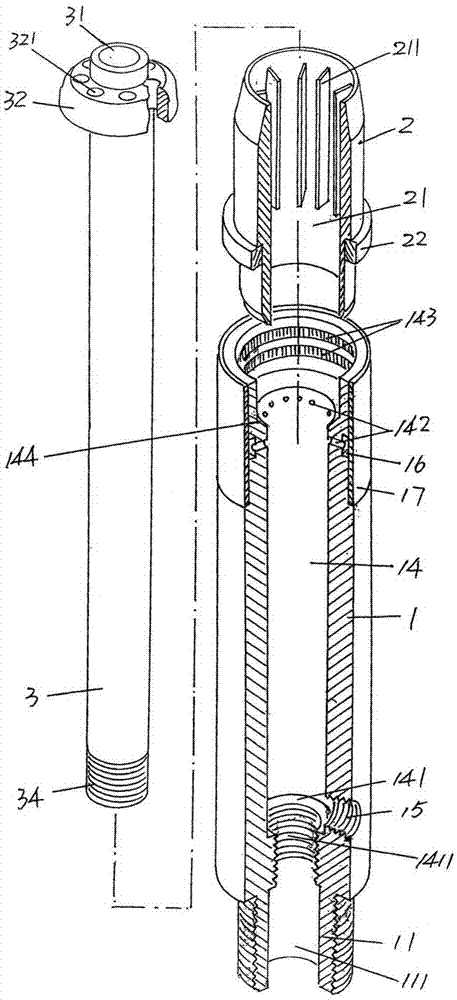

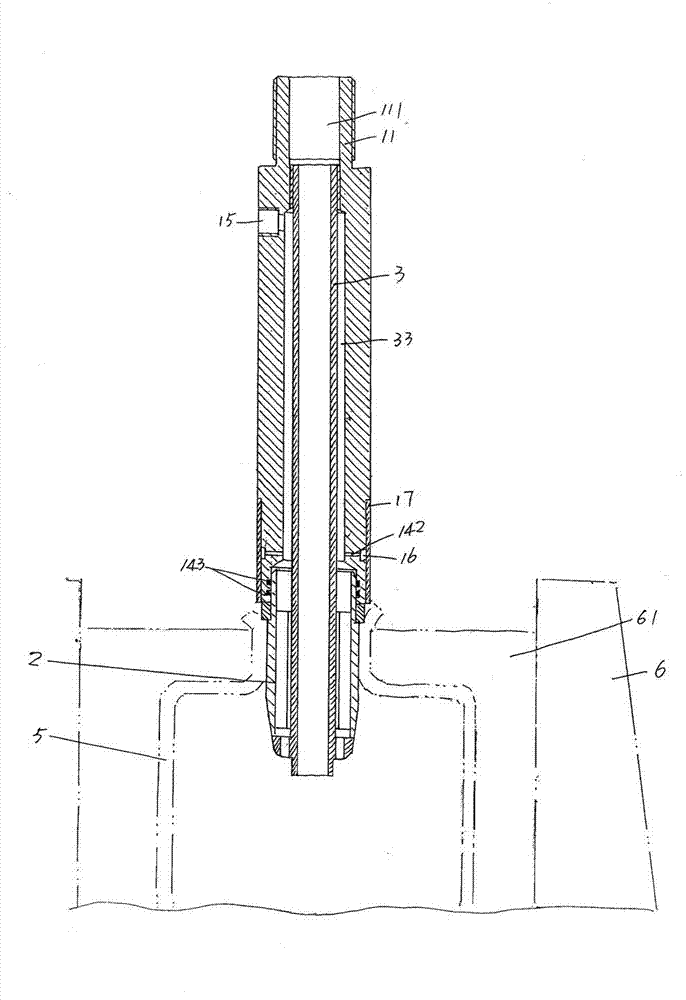

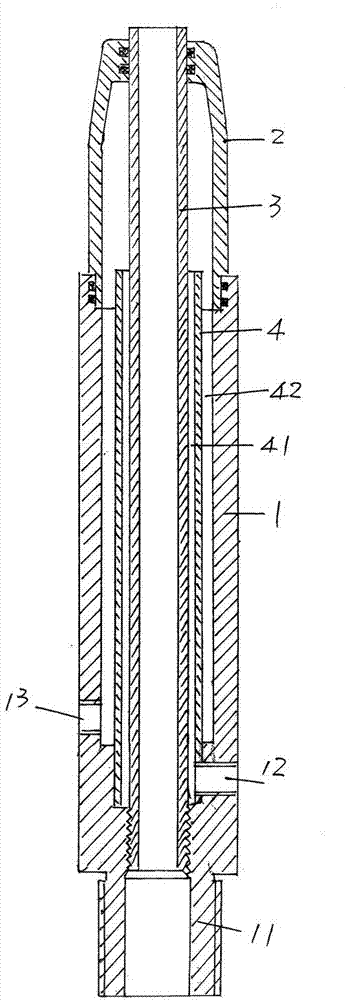

[0016] See figure 1 , a blowing needle body 1 whose material is metal and preferably stainless steel is provided, the blowing needle body 1 is hollow, more specifically, the blowing needle body 1 is formed with a hollow cavity 14 penetrating from one end to the other end, At one end of the blowing needle body 1 that is figure 1 The lower end shown is extended with an inlet pipe fitting 11 , and a cooling air inlet 15 is opened on the side of the end, and the cooling air inlet 15 communicates with the aforementioned hollow cavity 14 . In the state of use, the aforesaid inlet pipe fitting 11 is connected with an air source pipeline providing an air source device, such as an air compressor or an air pump. In the hollow cavity 14 and toward one end of the air inlet pipe fitting 11 is formed a blowing pipe fitting seat 141 with an internal thread 1411 , and the cooling air inlet 15 is located above the blowing pipe fitting seat 141 . At the other end of the blowing needle bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com