Floor overhead leveling device and laying method thereof

A floor and air-conditioning technology, which is applied to local access floors, floors, buildings, etc., can solve problems such as difficulty in meeting acceptance requirements, long leveling cycle, waste of resources, etc., to achieve shortened leveling cycle, high adjustment efficiency, and high flatness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The directional terms such as up, down, left, right, front, back, front, back, top, and bottom that are mentioned or may be mentioned in this specification are defined relative to the structures shown in the drawings. The words " "Inside" and "outside" respectively refer to the direction toward or away from the geometric center of a specific component. They are relative concepts, so they may change accordingly according to their different positions and different usage states. Accordingly, these or other directional terms should not be construed as limiting terms.

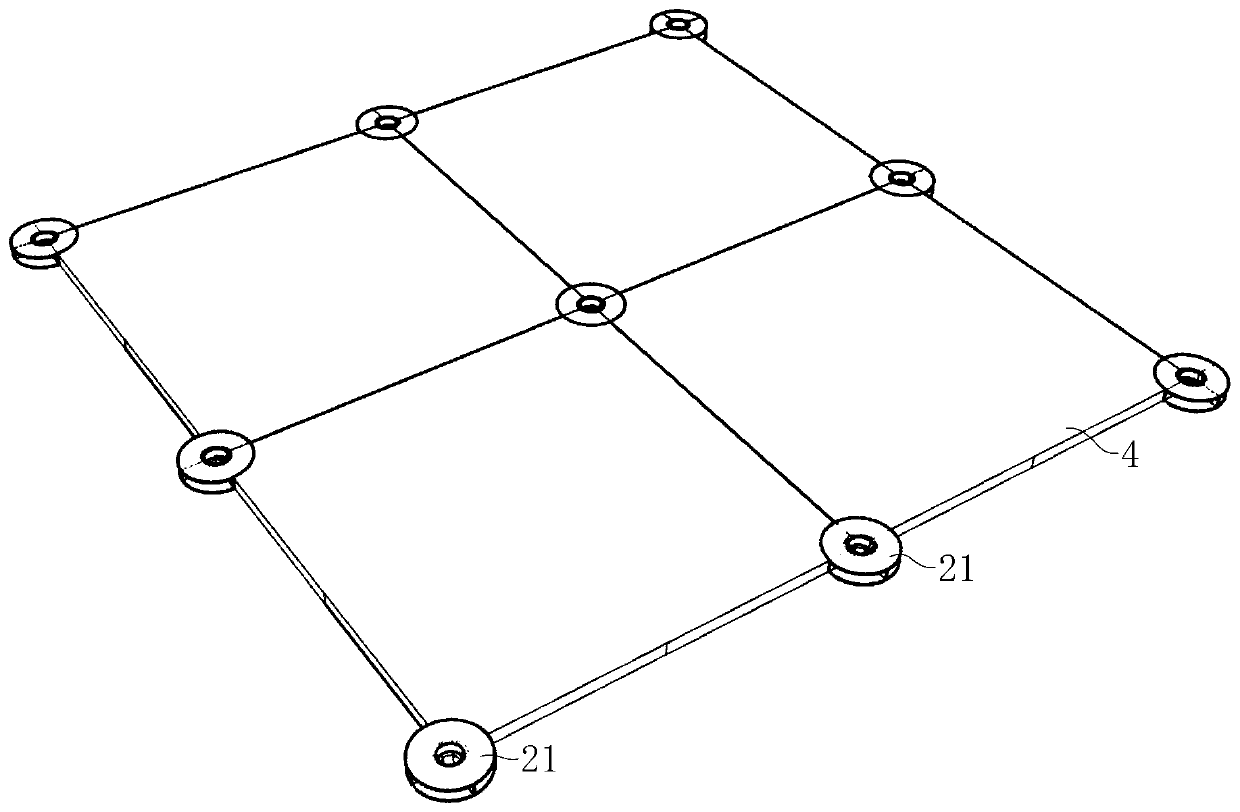

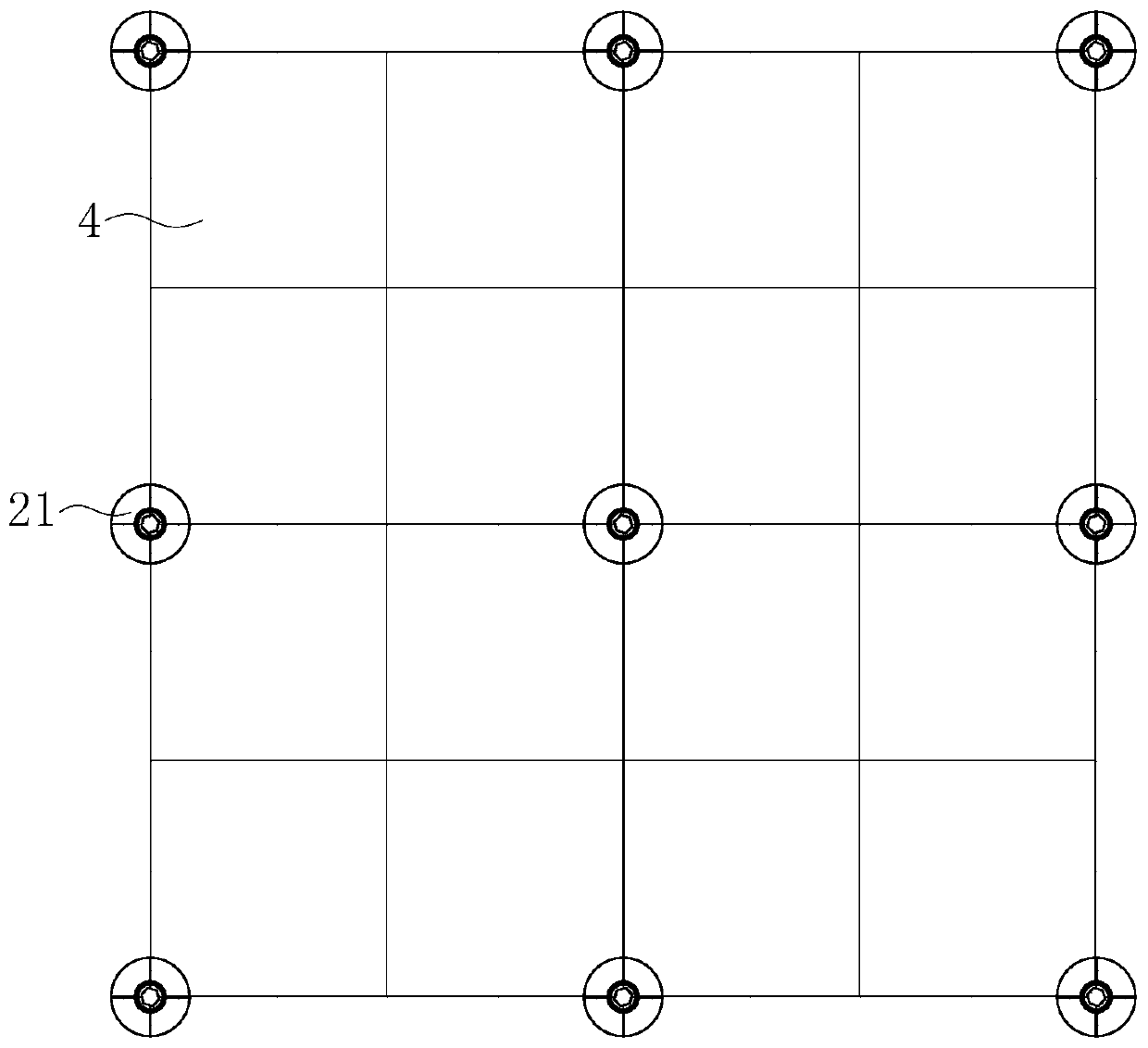

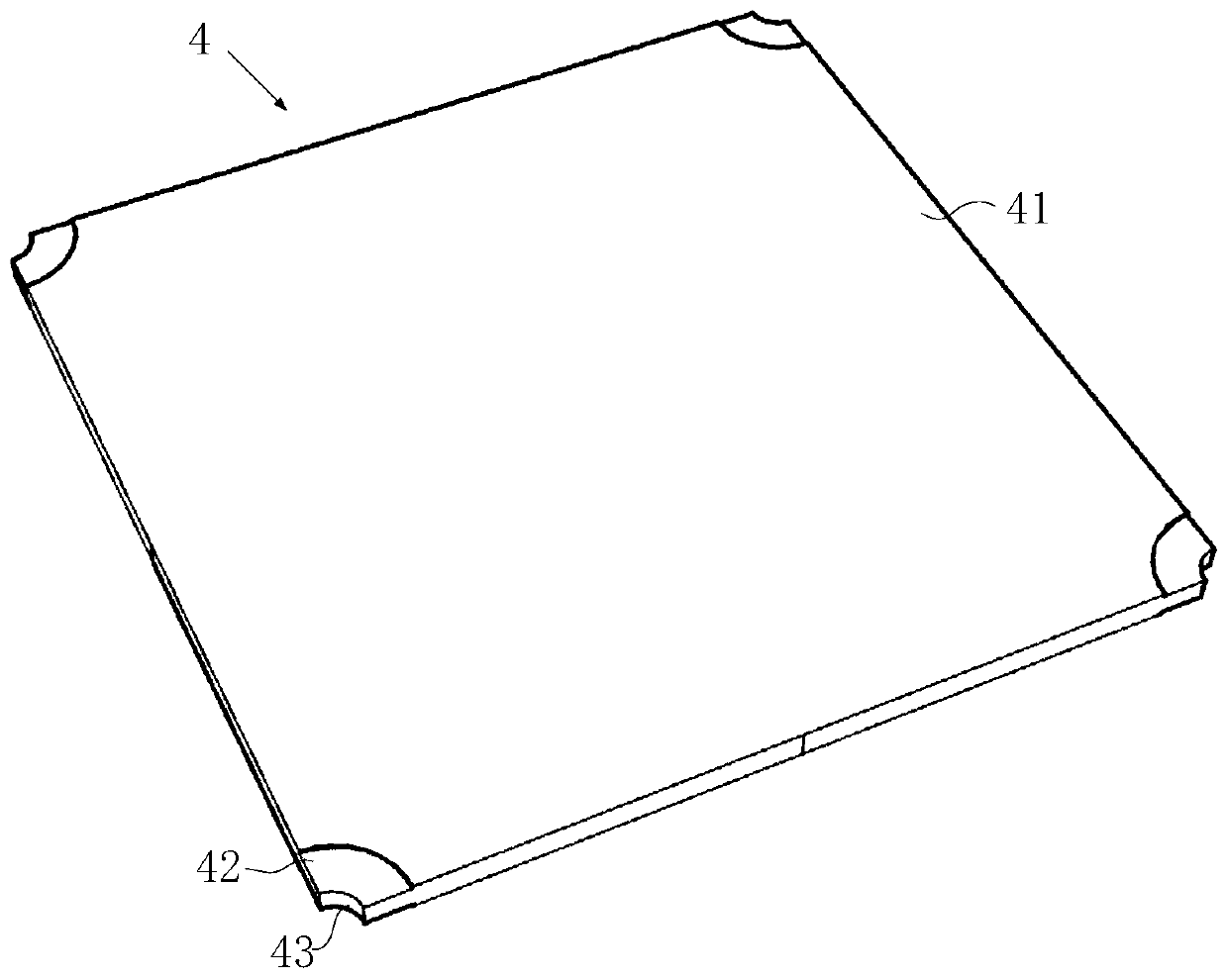

[0028] figure 1 A schematic structural view of a floor rack leveling device provided in an optional embodiment of the present invention, figure 2 for figure 1 top view of image 3 A schematic structural view of the floor provided in an optional embodiment of the present invention, Figure 4 A schematic structural view of the leveling foot provided for an optional embodiment of the present invention, Fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com