Heat pipe envelope of heat exchanger

A technology of heat exchangers and heat pipes, which is applied in the field of heat pipe envelopes of heat exchangers, can solve problems such as installation, disassembly, cleaning and maintenance, and achieve the effect of increasing the installation density and improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

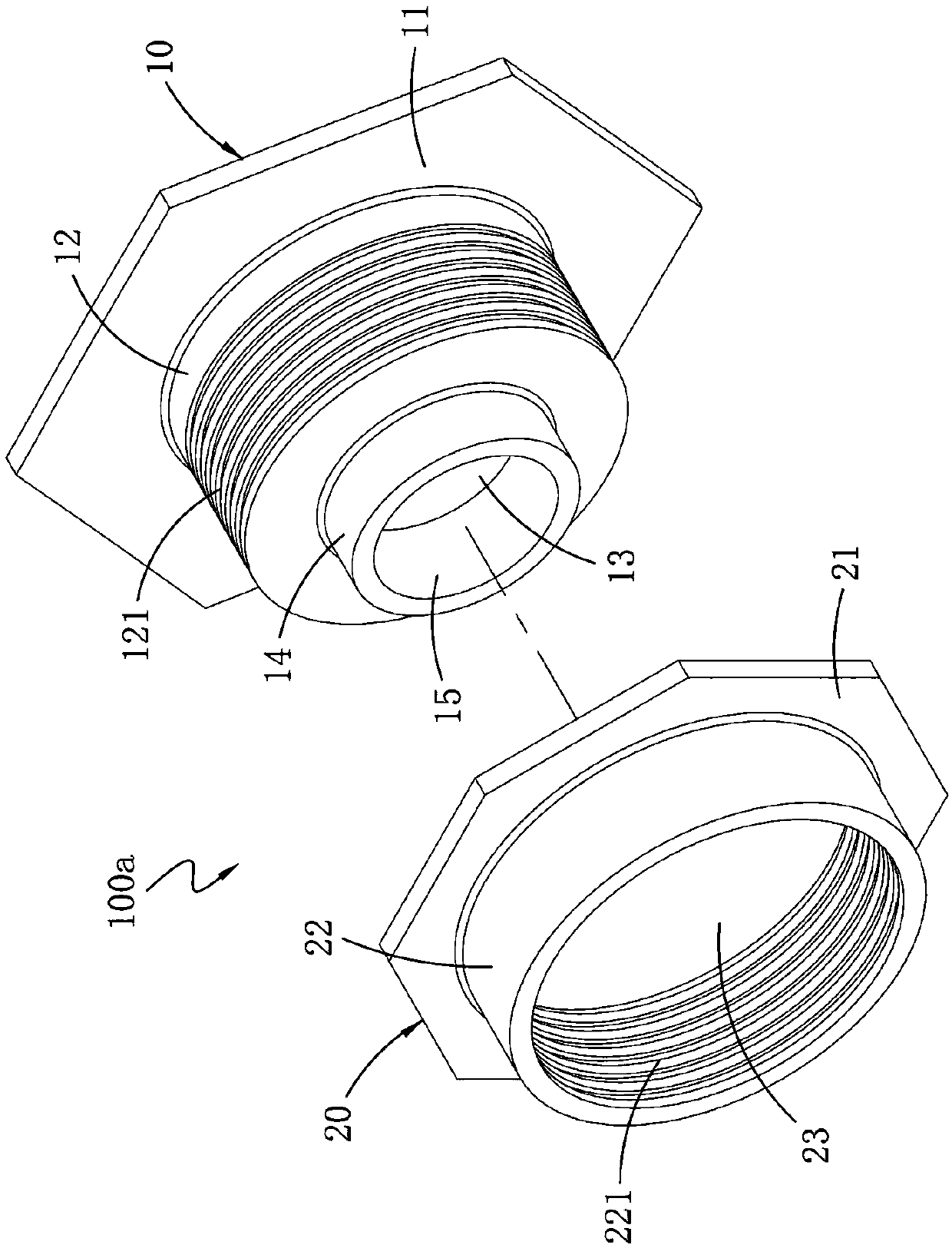

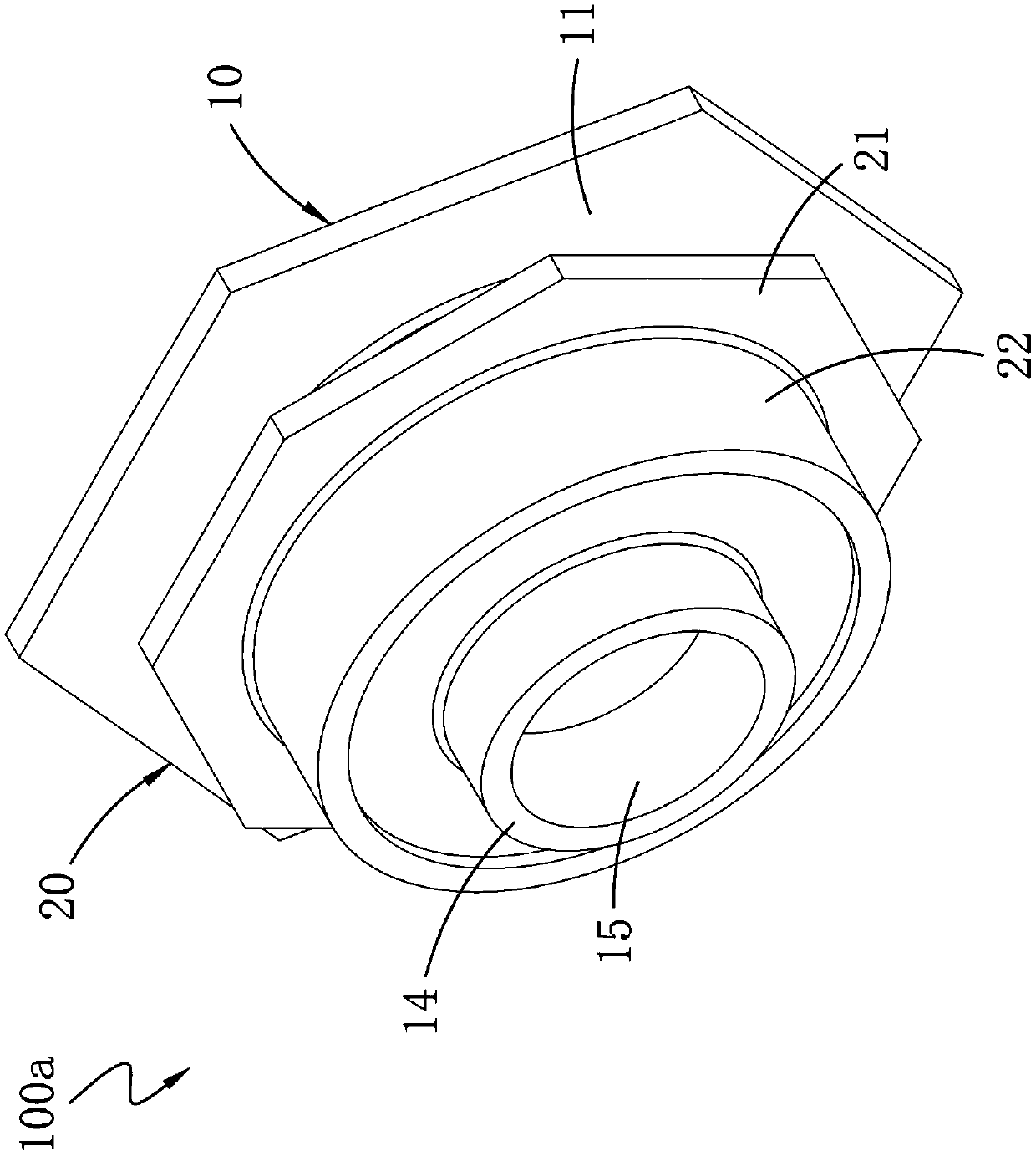

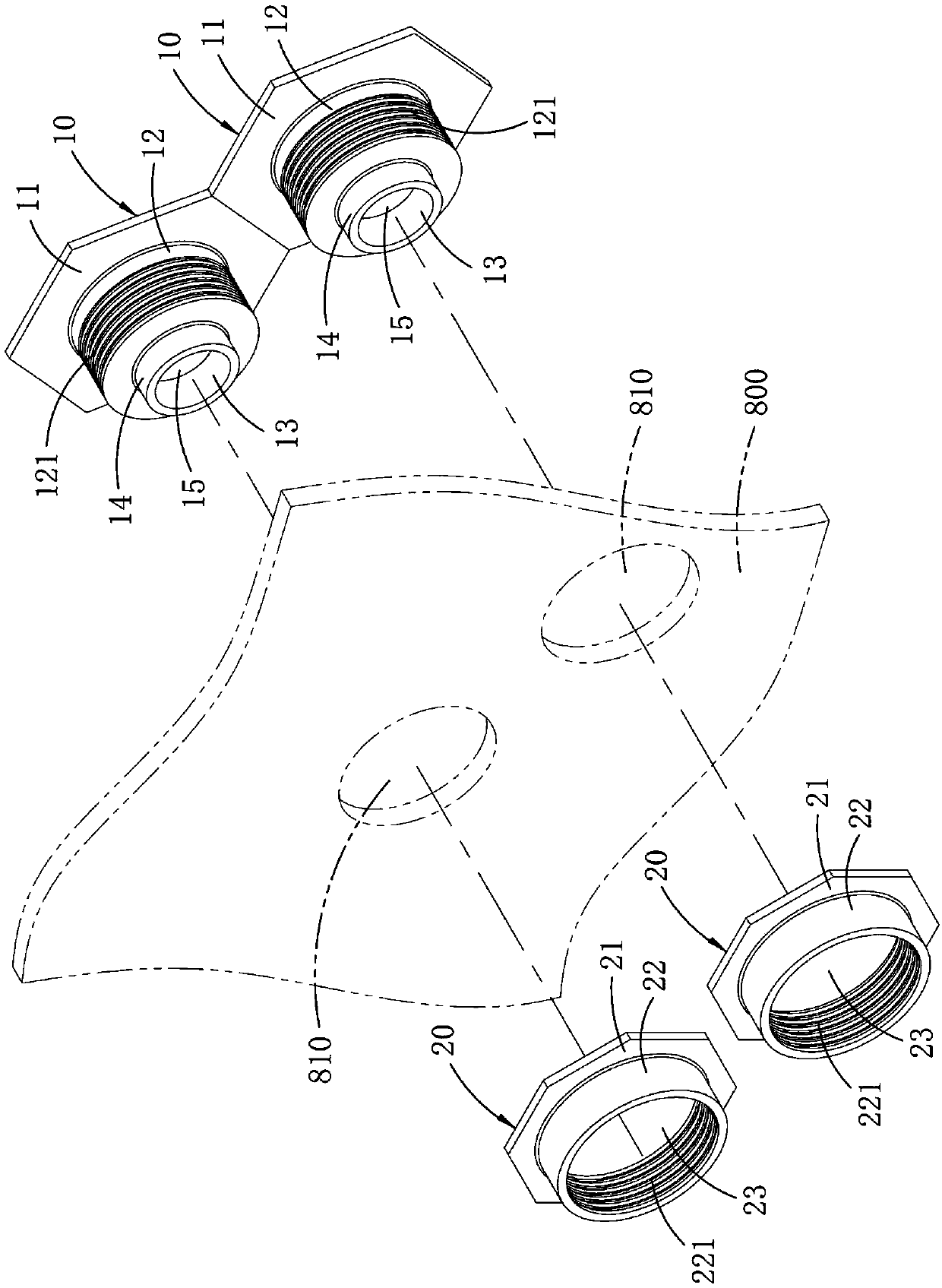

[0043] For the purpose of the present invention, please refer to Figure 1 to Figure 6 shown. The present invention provides a heat exchanger heat pipe envelope 100a, which is used in conjunction with a partition plate 800 and a heat pipe 900 passing through a hole 810 provided on the partition plate 800. Generally, a plurality of the setting holes 810 are formed on the partition plate 800 of the heat exchanger, and each of the setting holes 810 is respectively provided with the corresponding heat pipe 900 . Since the number of the heat pipes 900 in the heat exchanger can be designed according to requirements, the present invention is not limited herein. The heat pipe 900 is a heat conduction fluid with a pore structure inside and a liquid-vapor two-phase change fluid. However, the related technology of the heat pipe 900 has been accustomed to those skilled in the art. Therefore, the internal structure of the heat pipe 900 It will not be described in detail here.

[0044] S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com