Square machine base with wire conduit

A technology for conduits and bases, which is used in electromechanical devices, casings/covers/supports, electrical components, etc., can solve the problems of increased stator core weight, large stress on welds, poor firmness, etc., and achieves increased installation. The effect of span, convenient hoisting and lowering of the center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The implementation of the present invention will be described in detail below with reference to the drawings and examples, so as to fully understand and implement the implementation process of how to use technical means to solve technical problems and achieve technical effects in the present invention.

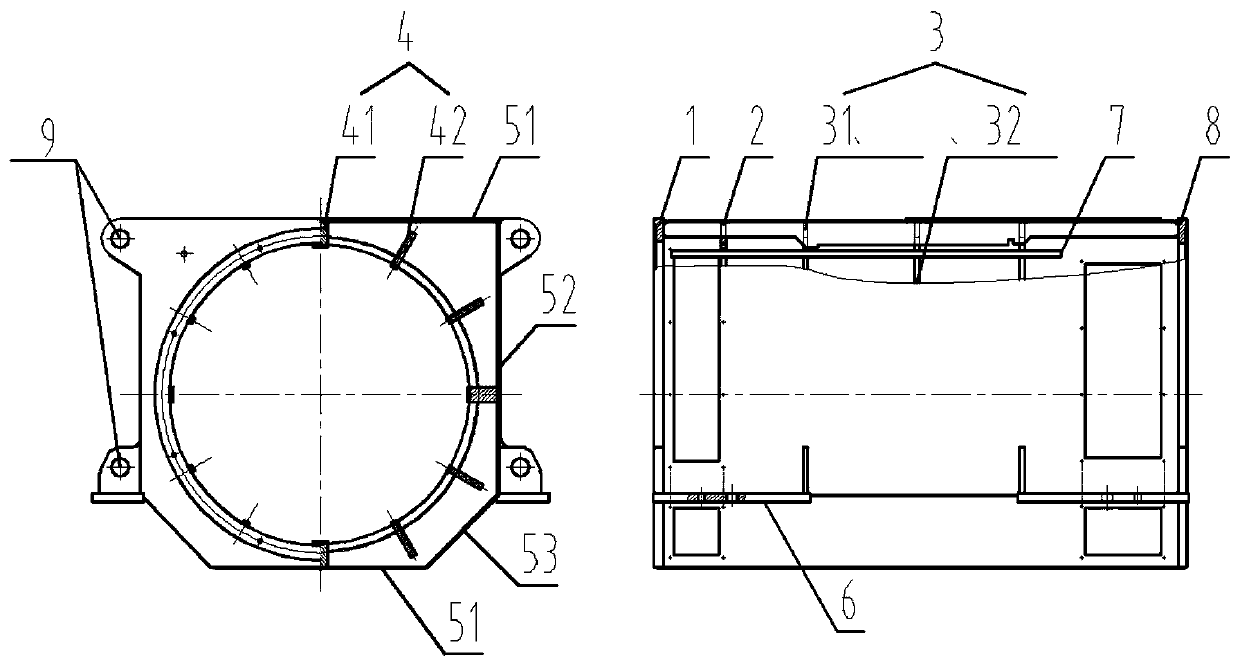

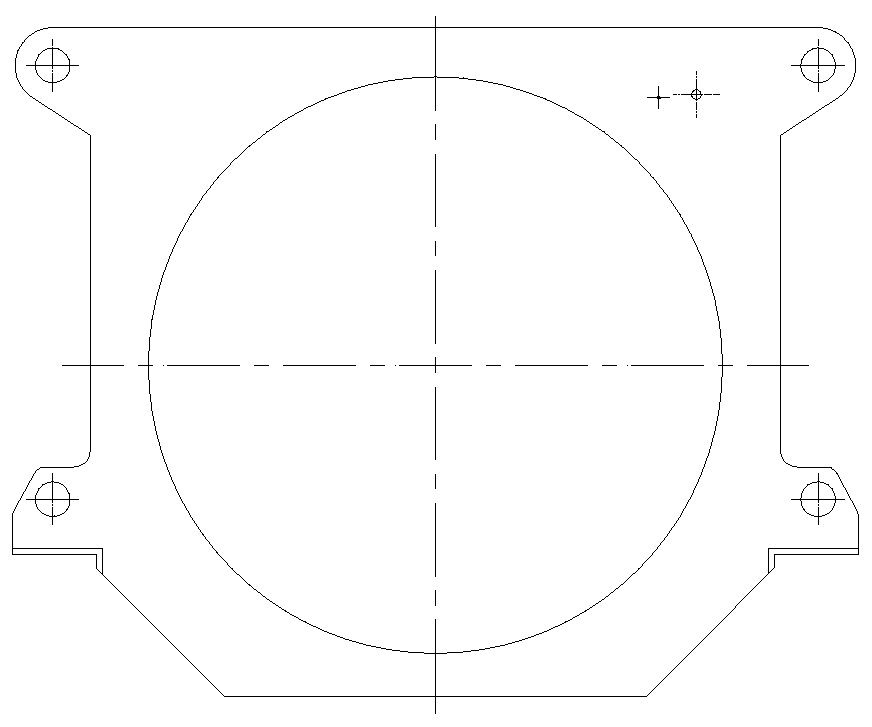

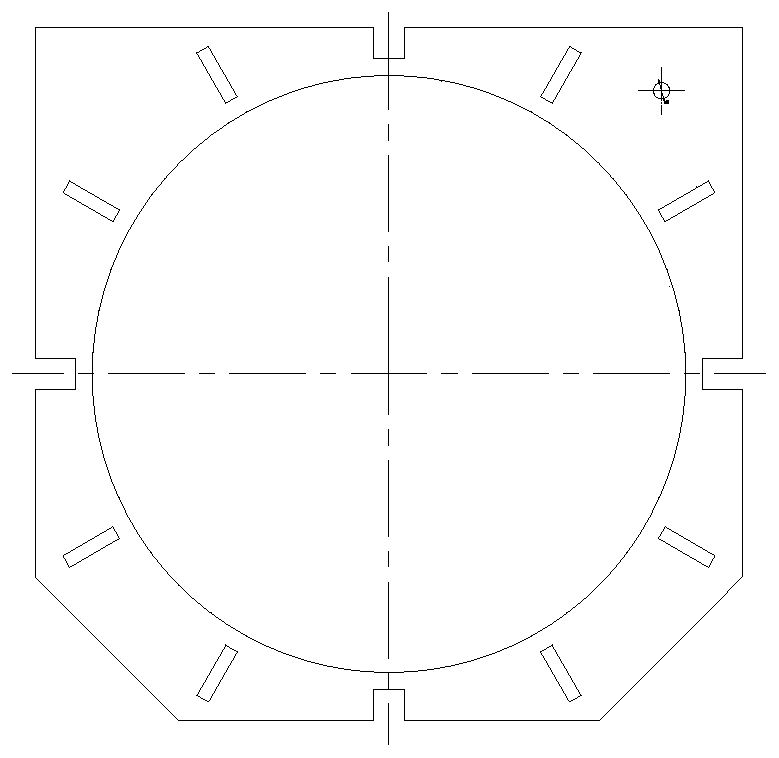

[0020] Specific embodiments of the present invention such as Figure 1 to Figure 6 As shown, a square machine base with a wire duct includes a front end plate 1, a windshield 2, a mesh base frame, a cover plate 5, a wire duct 7, a rear end plate 8 and a plurality of foot plates 6; The mesh base frame is composed of supporting plates 3 and ribs 4 interwoven. The front end plate 1 and the rear end plate 8 are respectively welded to the two ends of the mesh frame frame, and the cover plate 5 is paved and welded on the On the outer sides of the mesh base frame, the wire conduit 7 runs through the entire mesh frame frame, and a plurality of the foot plates 6 are respectively...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com