Anti-microbial and anti-skid health care sock

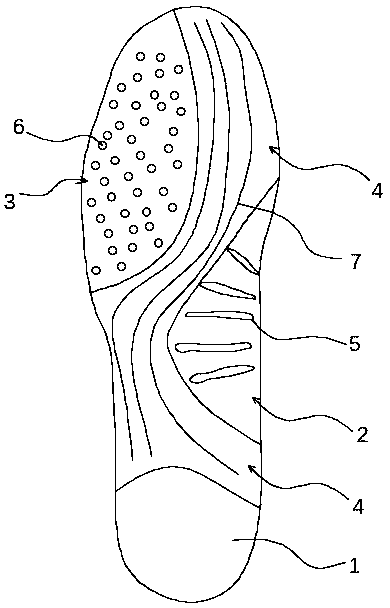

A health care socks and anti-skid technology, applied in socks, pantyhose, clothing and other directions, can solve problems such as lack of health care functions, and achieve the effects of relieving sole fatigue, reducing living environment and improving protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

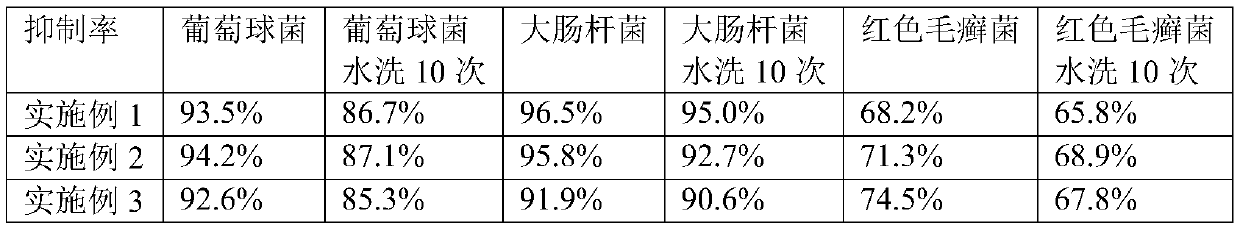

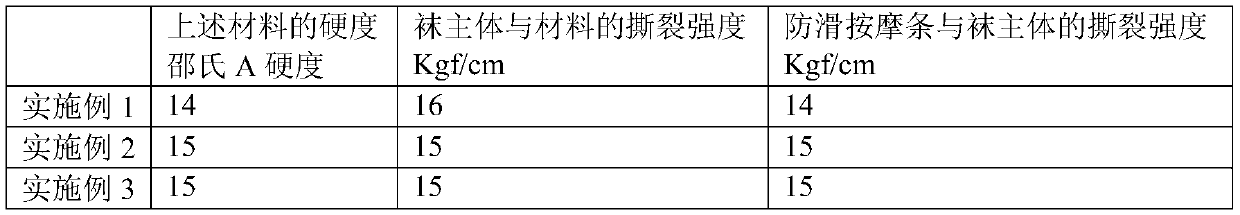

Embodiment 1

[0035] For the socks with the above structure, the materials used for the silica gel layer, the silica gel bumps 6 and the silica gel strip 7 include, in parts by weight: 100 parts of vinyl-terminated silicone oil, of which 30 parts have a viscosity of 400-500 mPa·s, The molar number of vinyl is 2.1-2.5%; the remaining viscosity is 1200-1500mPa·s, the molar number of vinyl is 0.9-1.3%; 20 parts of hydrogen-containing silicone oil, the mass fraction of active hydrogen is 0.6-0.8%; 5 parts of Silicon dioxide; 5 parts of alkoxysilane; 1 part of epoxy-containing organosiloxane; 18 parts of titanium dioxide; 0.5 part of cuprous oxide; 0.5 part of nickel phthalocyanine complex.

[0036] The adhesive used is prepared from the following components by weight: 60 parts of silicone adhesive; 0.5 parts of organic titanium chelate; 3 parts of crosslinking agent; 9 parts of catalyst; 10 parts of coupling agent; 3 copies. The crosslinking agent is hydroxyl polysiloxane, the coupling agent i...

Embodiment 2

[0038] For the socks with the above structure, the materials used for the silica gel layer, the silica gel bumps 6 and the silica gel strip 7 include, in parts by weight: 100 parts of vinyl-terminated silicone oil, of which 50 parts have a viscosity of 400-500 mPa·s, The vinyl molarity is 2.1-2.5%; the remaining viscosity is 1200-1500mPa·s, the vinyl molarity is 0.9-1.3%; 10 parts of hydrogen-containing silicone oil, the mass fraction of active hydrogen is 0.6-0.8%; 10 parts of Silicon dioxide; 3 parts of alkoxysilane; 2 parts of epoxy-containing organosiloxane; 10 parts of titanium dioxide; 2 parts of cuprous oxide; 0.3 parts of nickel phthalocyanine complex.

[0039] The adhesive used is prepared from the following components by weight: 75 parts of silicone adhesive; 0.2 parts of organic titanium chelate; 8 parts of crosslinking agent; 5 parts of catalyst; 15 parts of coupling agent; 1 serving. The crosslinking agent is hydroxyl polysiloxane, the coupling agent is titanate ...

Embodiment 3

[0041] For the socks with the above structure, the materials used for the silica gel layer, the silica gel bumps 6 and the silica gel strip 7 include, in parts by weight: 100 parts of vinyl-terminated silicone oil, of which 40 parts have a viscosity of 400-500 mPa·s , the number of vinyl moles is 2.1-2.5%; the remaining viscosity is 1200-1500 mPa·s, the number of vinyl moles is 0.9-1.3%; 15 parts of hydrogen-containing silicone oil, the mass fraction of active hydrogen is 0.6-0.8%; 6 Parts of silicon dioxide; 4 parts of alkoxysilane; 2 parts of epoxy-containing organosiloxane; 15 parts of titanium dioxide; 1 part of cuprous oxide; 0.3 parts of nickel phthalocyanine complex.

[0042] The adhesive used is prepared from the following components by weight: 70 parts of silicone adhesive; 0.3 parts of organic titanium chelate; 5 parts of crosslinking agent; 6 parts of catalyst; 12 parts of coupling agent; 2 servings. The crosslinking agent is hydroxyl polysiloxane, the coupling age...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com