Pressure-driven type anti-backflow microporous atomizing device

A technology of microporous atomization and anti-backflow, which is applied in nebulizers for treatment, other medical devices, respirators, etc., and can solve problems such as increasing the risk of infection, affecting gas pressure and flow, and failing to achieve the effect of treatment , to reduce the chance of infection, ensure the pressure and flow, and reduce the effect of liquid residue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

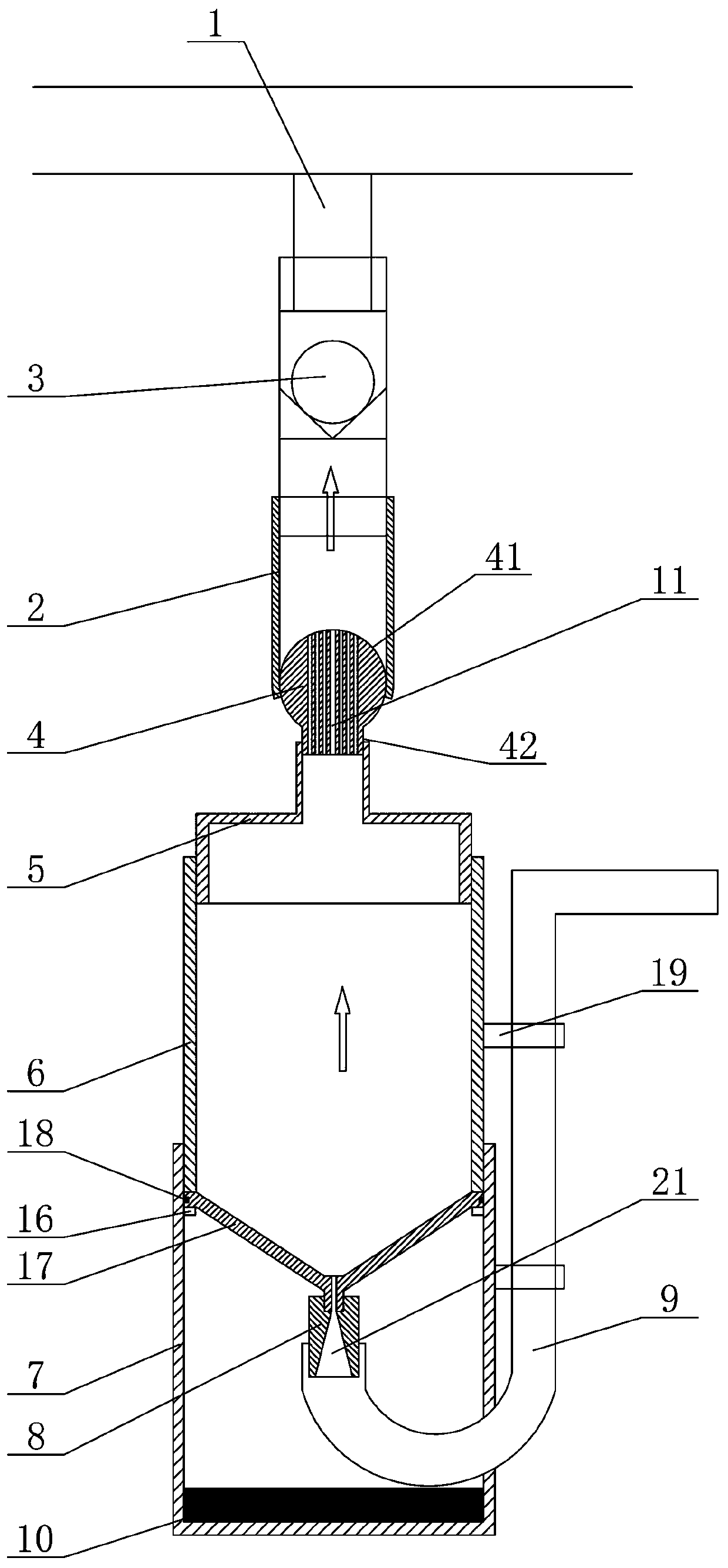

[0043] Such as figure 1 As shown, a pressure-driven anti-backflow microporous atomization device includes an upper joint 1, an upper connecting pipe 2, a one-way valve 3, a hinged ball 4, an upper end cap 5, an atomization chamber 6, a lower end cap 7, an air inlet Joint 8, intake pipe 9 and counterweight 10, the upper joint 1 is a T-shaped three-way joint, including two horizontally connected interfaces and one vertical port, the two horizontally connected The interface is respectively connected to the ventilator and the artificial airway or the mask through the pipeline, the vertical port of the upper joint 1 is connected to the upper connecting pipe 2, and the upper end of the upper connecting pipe 2 is connected to the vertical port of the upper joint 1, and the upper The lower end of the connecting pipe 2 is connected to the hinged ball 4. The upper connecting pipe 2 is provided with a one-way valve 3. The hinged ball 4 includes a ball head 41 and a lower connecting porti...

Embodiment 2

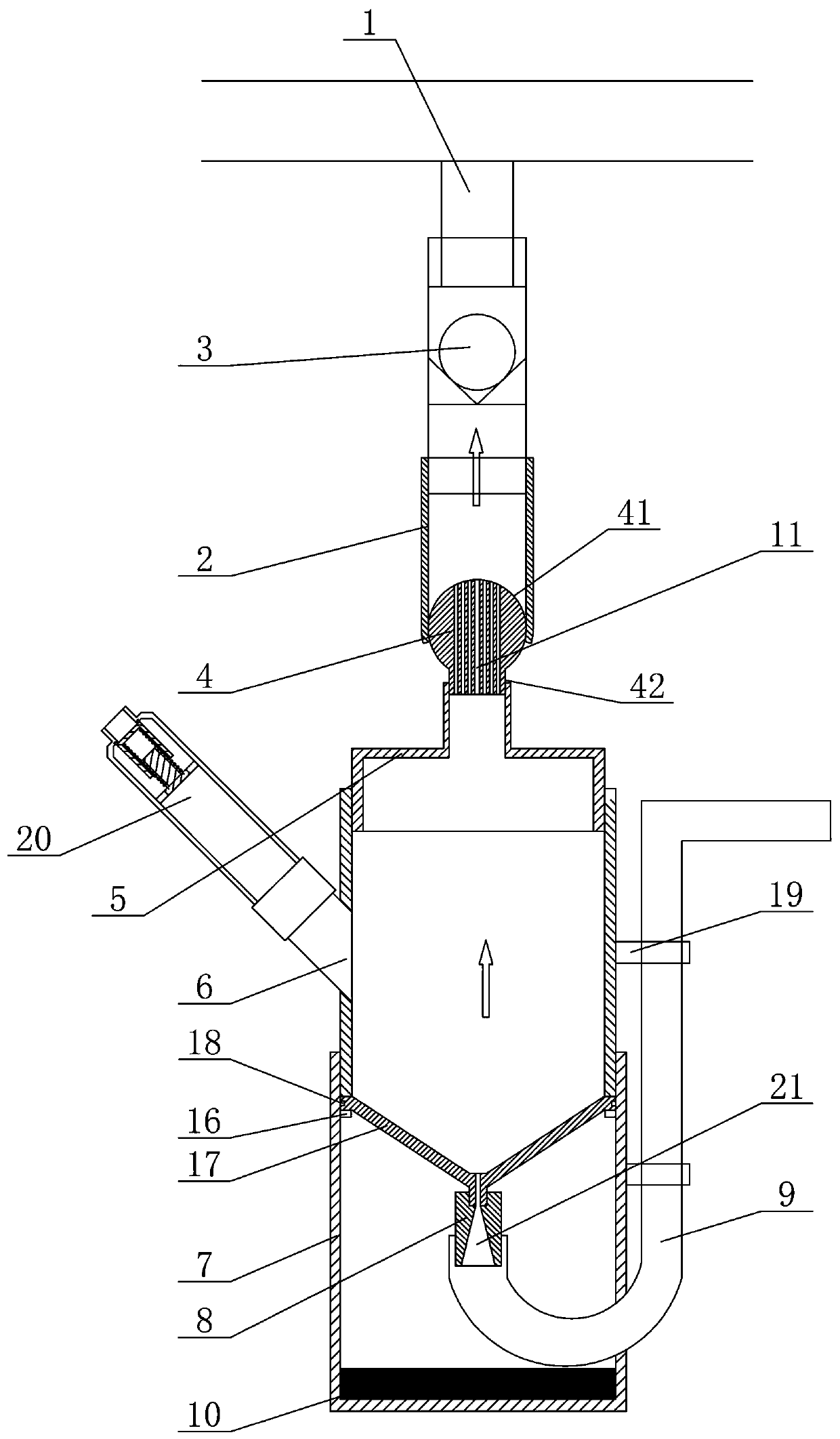

[0049] Such as figure 2 , Figure 5 As shown, Example 1 is repeated, with the following differences: the atomization chamber 6 is provided with a liquid inlet device 20, and the liquid inlet device 20 is arranged on one side of the atomization chamber 6, and the liquid inlet device 20 includes Liquid inlet pipe 201, piston device 202, sealing ring 203, spring 204 and spring seat 205, described liquid inlet pipe 201 comprises large-diameter pipe body section 207 and small-diameter nozzle section 206, and one end of nozzle section 206 is used for connecting In the syringe, the other end of the nozzle section 206 is screwed and fastened to one end of the tube body section 207, and the other end of the tube body section 207 is connected to the atomization chamber 6 and communicates with the inner cavity of the atomization chamber 6. The tube The body part 207 is provided with a spring seat 205, the spring seat 205 includes a seat plate and a sliding post of an integral structure...

Embodiment 3

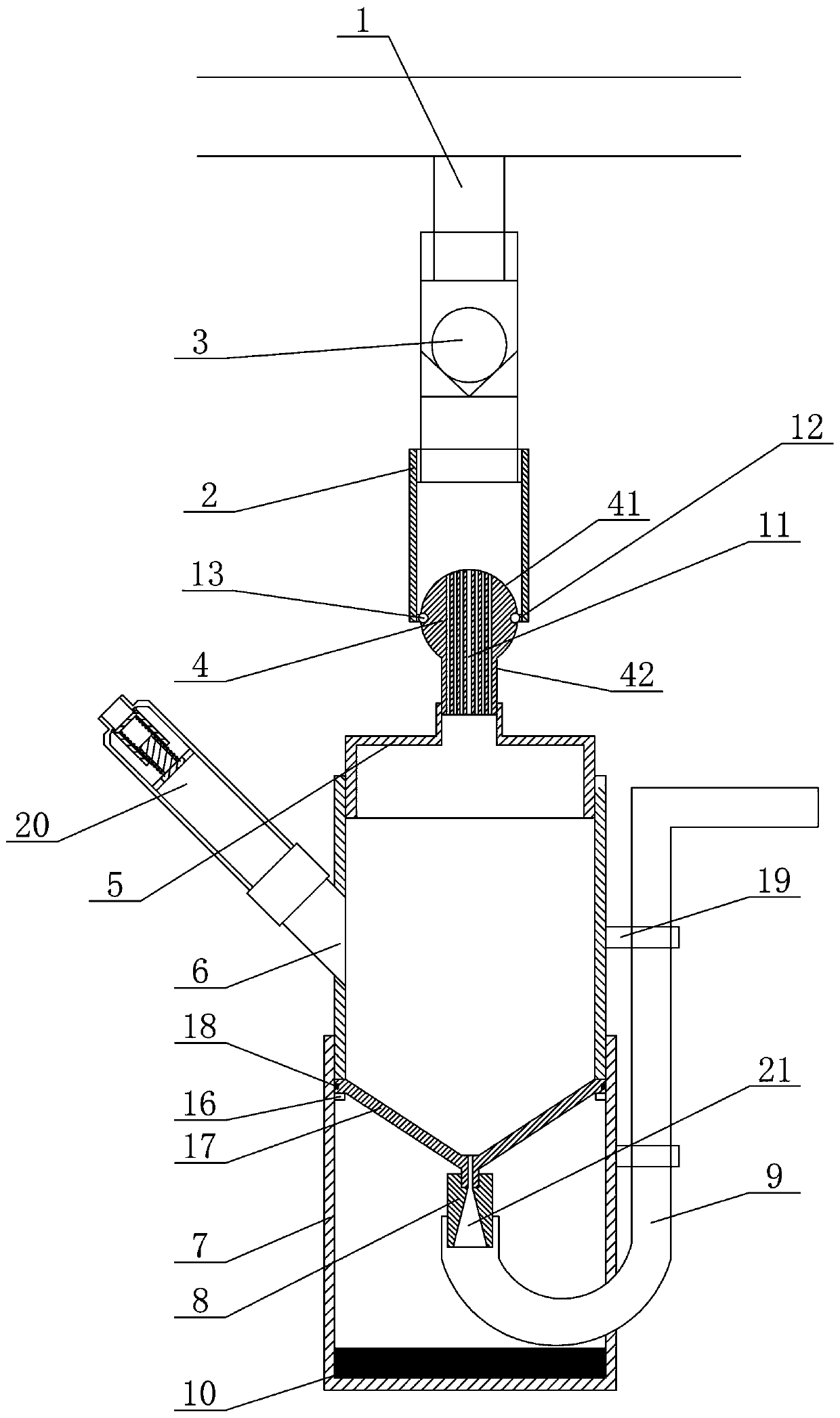

[0052] Such as image 3 , Figure 5 As shown, the second embodiment is repeated, with the following differences: blind holes 12 are symmetrically arranged on both sides of the ball head 41 of the hinged ball 4, and pin shafts are symmetrically arranged in the lower opening of the upper connecting pipe 2 13. The pin shaft 13 corresponds to the blind hole 12, and the pin shaft 13 is inserted into the blind hole 12, and the hinge ball 4 rotates relative to the upper connecting pipe 2 with the pin shaft 13 as the rotation axis. In this embodiment, the hinged ball 4 deflects and swings around the pin shaft 13 .

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap