Rapid-curing wave-absorbing edge sealing glue gun

A rapid curing and wave sealing technology, applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of uneven mixing, easy to block the glue dispensing pipeline, etc., and achieve labor-saving and convenient operation, simple structure, and glue coating process Simple and Flexible Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

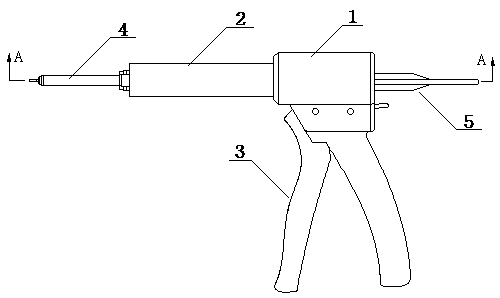

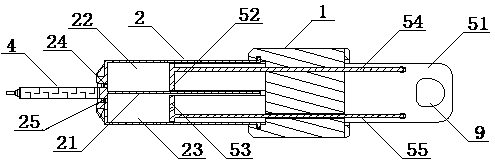

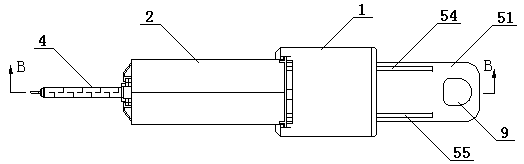

[0029] This embodiment discloses a fast-curing wave-absorbing edge-sealing glue gun, which includes a gun body 1, a rubber cartridge 2 fixed at the front end of the gun body 1, a trigger assembly 3 located below the gun body 1, communicated with the glue cartridge 2 and The mixing tube 4 fixed on the front end of the rubber cartridge 2 and the pushing part 5 that pushes the rubber cartridge 2 out of glue, the rear side wall of the gun body 1 is provided with a through hole 6, and the mixing tube 4 is a square mixing tube, including a square tube body 41. Connecting plate 42, mixing glue outlet 43 and tube core 44. The connecting plate 42 is integrally formed on one end of the square tube body 41, and the other end of the square tube body 41 is sealed and connected to the mixing glue outlet 43. The tube core 44 is inserted into the square tube body 41, and the inner side of the tube core 44 is provided with a plurality of mixing baffles 7 capable of cutting the mixed glue along ...

Embodiment 2

[0032] This embodiment discloses a fast-curing wave-absorbing edge-sealing glue gun, which includes a gun body 1, a rubber cartridge 2 fixed at the front end of the gun body 1, a trigger assembly 3 located below the gun body 1, communicated with the glue cartridge 2 and The mixing tube 4 fixed on the front end of the rubber tube 2 and the pushing part 5 that pushes the rubber tube 2 out of glue, the rear side wall of the gun body 1 is provided with a through hole 6, the mixing tube 4 is a circular mixing tube, and the inner wall is provided with a There is a spiral groove 8 for mixing glue, and the nozzle at the front end of the circular mixing tube is circular.

[0033] As another most basic embodiment of the present invention, in this embodiment, the mixing tube is a circular mixing tube, and the inner wall of the mixing tube is provided with a spiral groove for mixing the glue, so that the mixed glue spirals in the process of advancing. It also plays the role of full mixing...

Embodiment 3

[0035]This embodiment discloses a fast-curing wave-absorbing edge-sealing glue gun, which includes a gun body 1, a rubber cartridge 2 fixed at the front end of the gun body 1, a trigger assembly 3 located below the gun body 1, communicated with the glue cartridge 2 and The mixing tube 4 fixed on the front end of the rubber cartridge 2 and the pushing part 5 that pushes the rubber cartridge 2 out of glue, the rear side wall of the gun body 1 is provided with a through hole 6, and the mixing tube 4 is a square mixing tube, including a square tube body 41. Connecting plate 42, mixing glue outlet 43 and tube core 44. The connecting plate 42 is integrally formed on one end of the square tube body 41, and the other end of the square tube body 41 is sealed and connected to the mixing glue outlet 43. The tube core 44 is inserted into the square tube body 41, and the inner side of the tube core 44 is provided with a plurality of mixing baffles 7 capable of cutting the mixed glue along i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com