Gluing machine system and gluing method

A gluing machine and gluing technology, applied in the direction of injection device, liquid injection device, etc., can solve the problems of cumbersome steps, complex structure of gluing machine, complex and huge structure, etc. Glue service, the effect of simple replacement steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

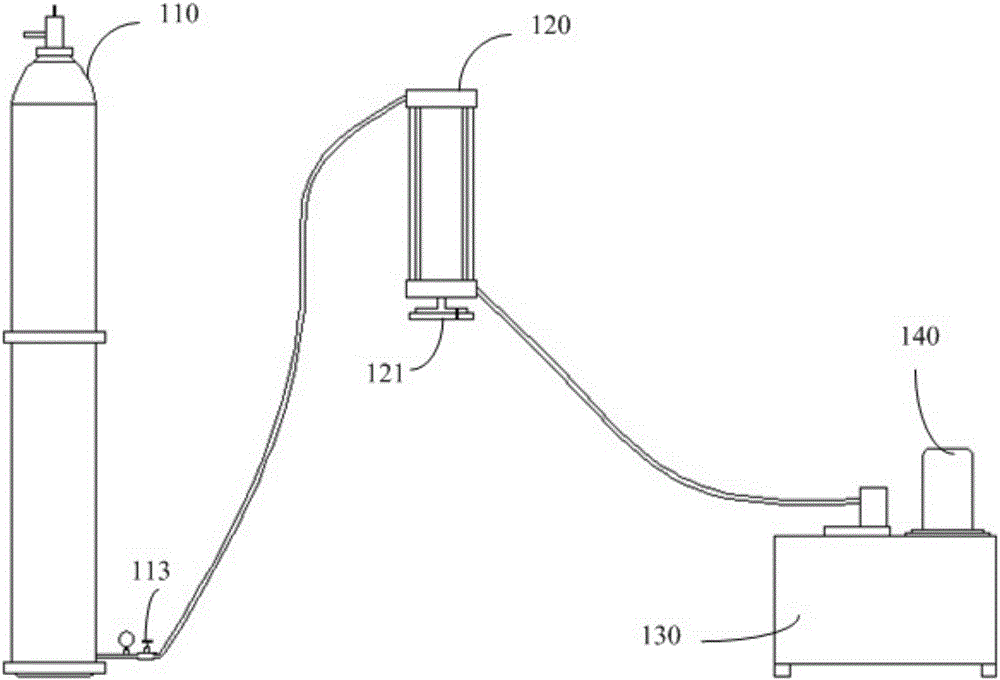

[0052] An embodiment of the present invention provides a glue applicator system, including:

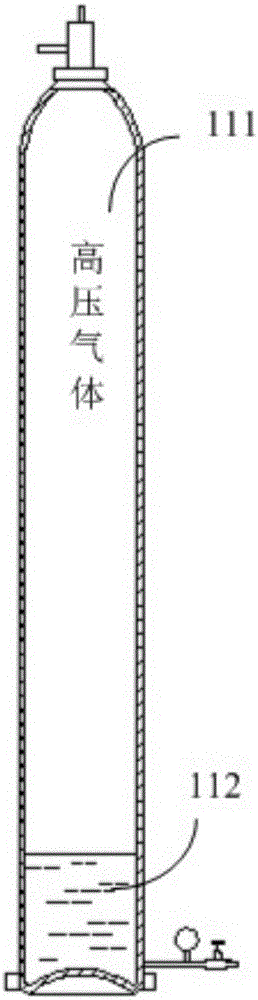

[0053] A pressure vessel containing high-pressure gas and hydraulic oil to provide a stable pressure source for hydraulic cylinders;

[0054] a bracket with slide rails for slidingly mounting the hydraulic cylinder;

[0055] The pressure detection and control device is used to realize the glue application control by measuring the pressure at the inlet and outlet of the metering pump for glue application.

[0056] It can be seen that the embodiment of the present invention achieves a stable pressure source through the pressure vessel containing the high-pressure gas, and the hydraulic cylinder can be easily removed through the bracket with the slide rail, so that the plastic bag can be replaced conveniently. Through the pressure detection and control device, the accurate control of glue output is realized.

[0057] figure 2 It is a schematic diagram of the overall structure of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com