Glue spraying device and gluing method

A technology of spraying glue and nozzle, applied in the direction of spraying device, etc., can solve the problems of wasting labor, difficult to guarantee the quality of gluing, and difficult to gluing, etc., and achieve the effect of saving labor, improving quality, and being beneficial to aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

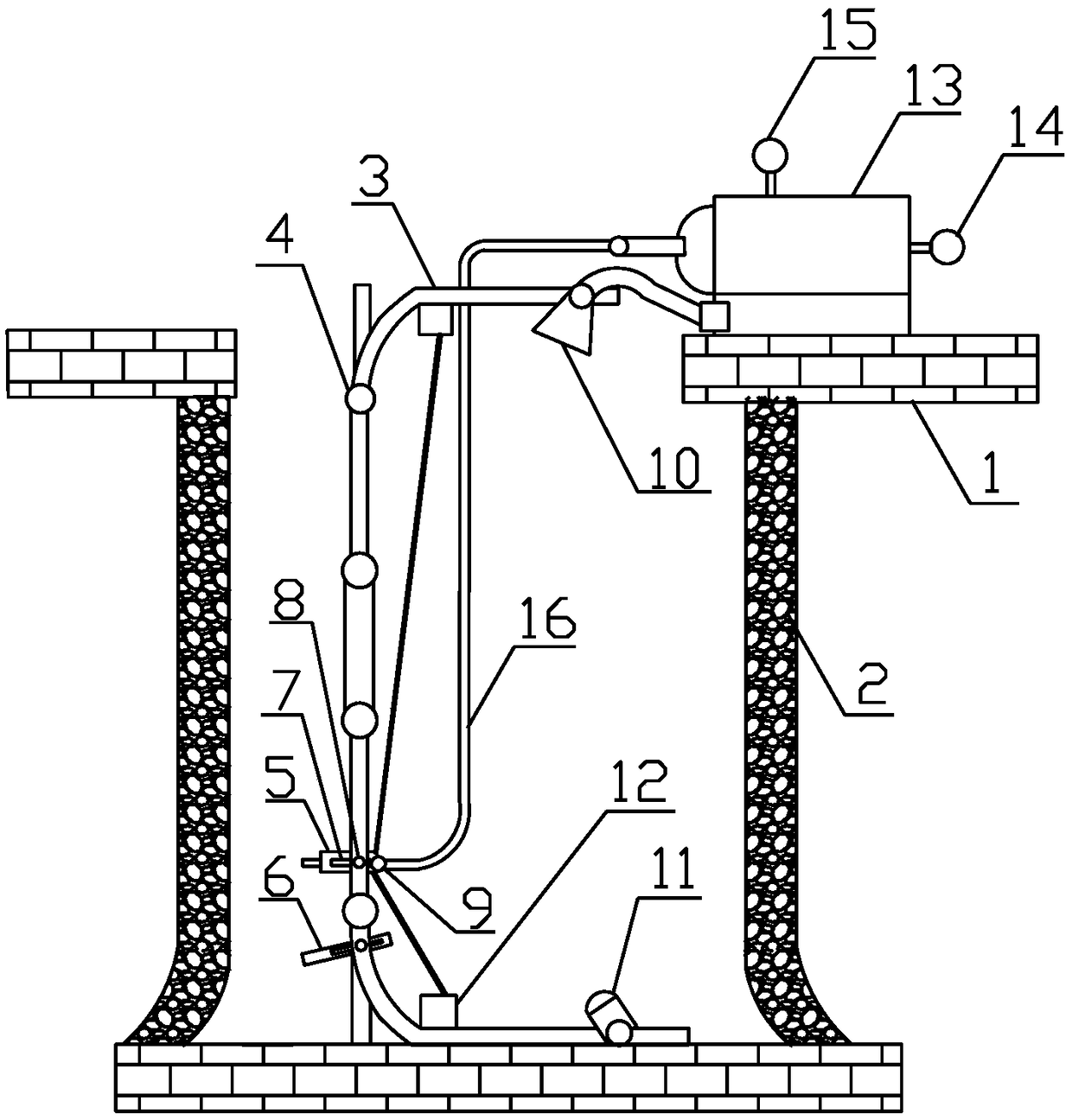

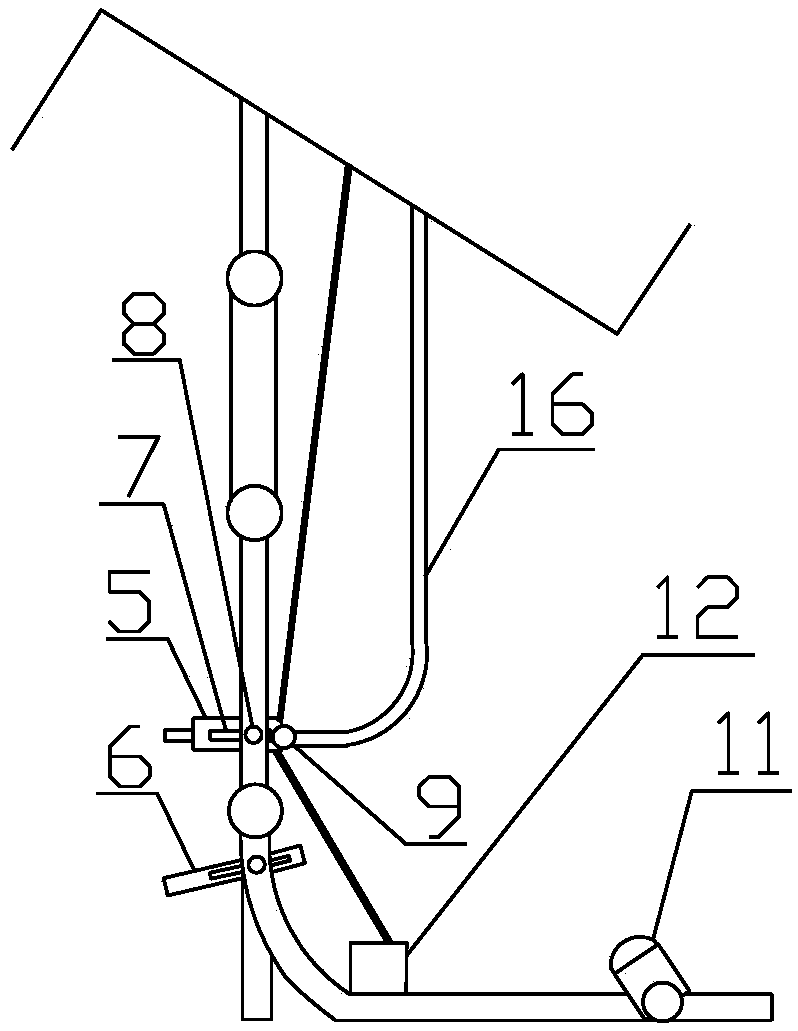

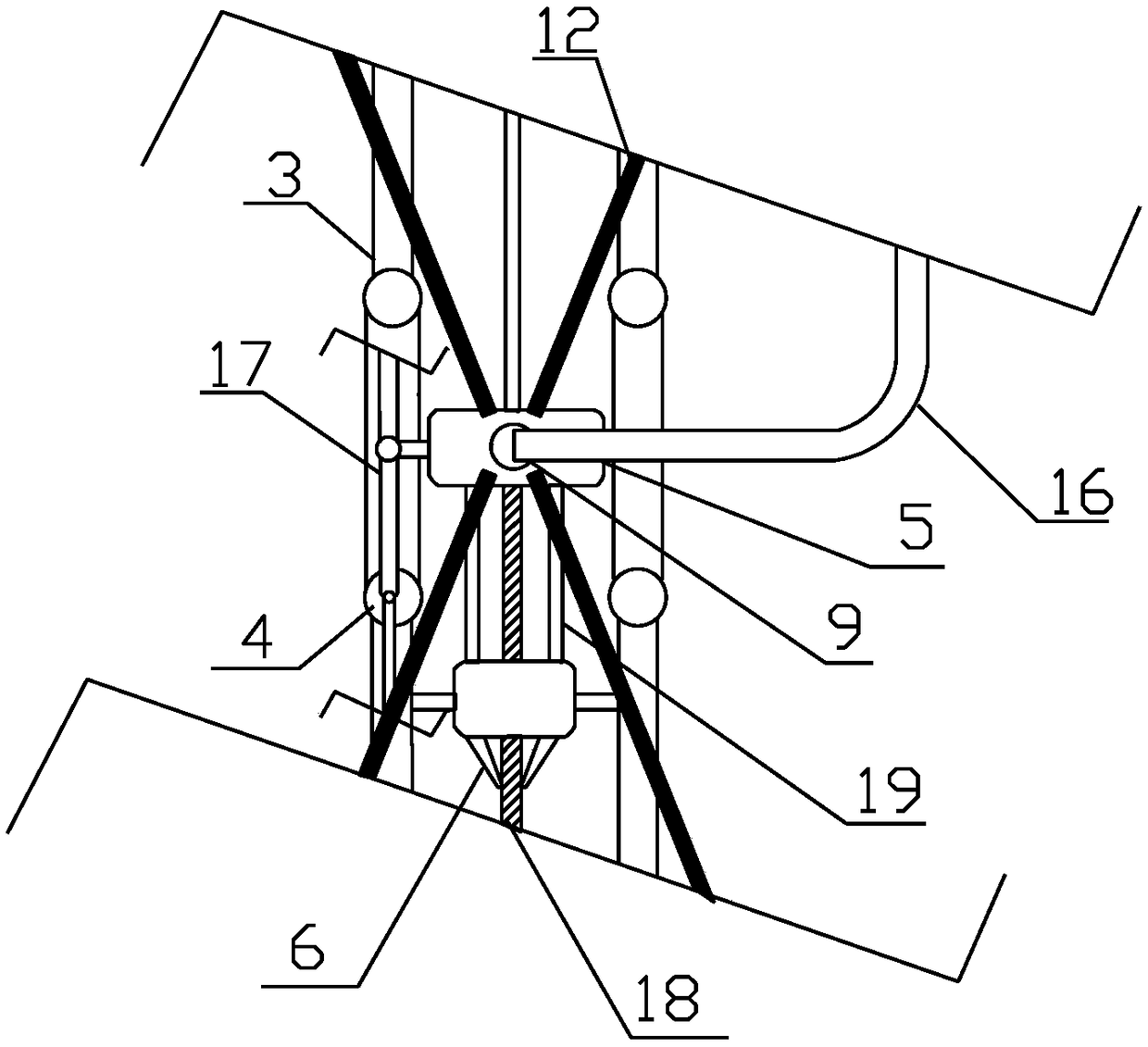

[0040] Combine below Figure 1 to Figure 3 The structural composition of the glue spraying device of the present invention will be described in detail.

[0041] Please refer to Figure 1 to Figure 3, a glue spraying device, arranged at the structural seam between the floor 1 and the color steel plate partition wall 2, it includes: an adjustable bracket 3, in order to realize the adjustable function of the bracket, the adjustable bracket 3 includes several fixed Point and bracket positioning key 4, the inside of the adjustable bracket 3 is provided with a bracket internal chute 17, which is convenient for the movement and positioning of the nozzle 5 and the scraper 6 during the glue spraying process;

[0042] Glue injection machine 13, a pressure gauge 15 and a glue gauge 14 are installed on the glue injection machine 13, during the glue spraying process, through real-time monitoring of the pressure gauge 15 and the glue gauge 14, the uniform speed glue in the glue spraying pr...

Embodiment 2

[0055] Please continue to refer Figure 1 to Figure 3 , the present invention also provides the gluing method utilizing aforementioned gluing device, and this method comprises the steps:

[0056] Step 1, provide the aforementioned glue spraying device for standby;

[0057] Step 2. In a relatively closed and clean environment, fill the glue injection machine 13 with sealant and observe the change of the glue meter 14, so that the glue injection machine 13 is filled with a suitable sealant; after the glue injection is completed, debug , focus on observing the glue output speed of the glue injection machine 13, the fluency of glue spraying, and the change of the pressure gauge 15 during the glue spraying pressure process, and observe whether there is any foreign matter in the inner flow channel of the nozzle 5; after debugging, put one end of the hose 16 It is connected with the glue injection machine 13, and the other end is fixed on the rear end of the nozzle 5 through the hos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com