Steering transverse pull rod with composite constant pressure cavity provided with one-way oil conveying protection function

A technology of steering tie rods and constant pressure chambers, applied in steering tie rods, steering mechanisms, transportation and packaging, etc., can solve problems such as excessive wear on one side of the tire, influence of tie rods, impurities entering the ball shaft, etc., and achieve the goal of reducing the impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

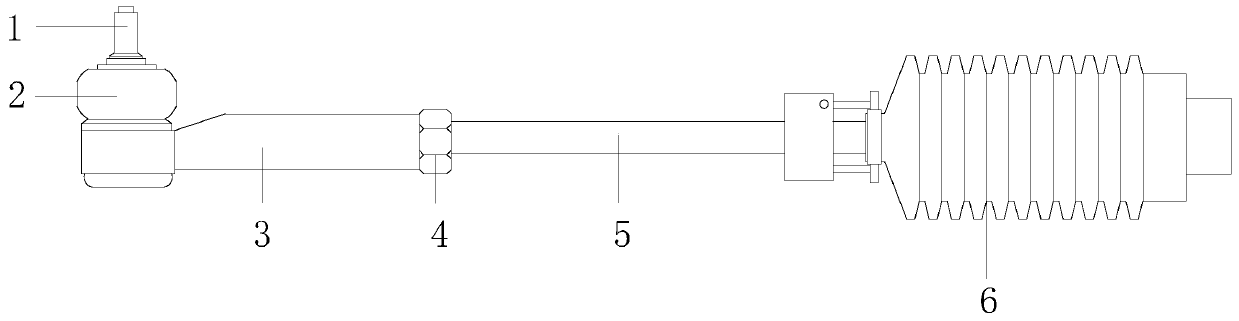

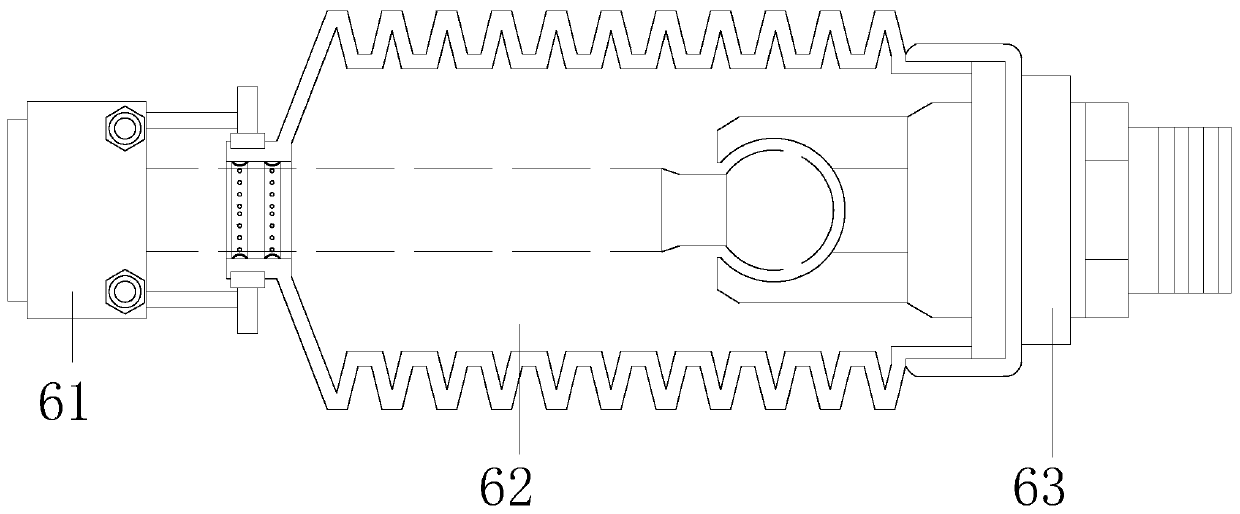

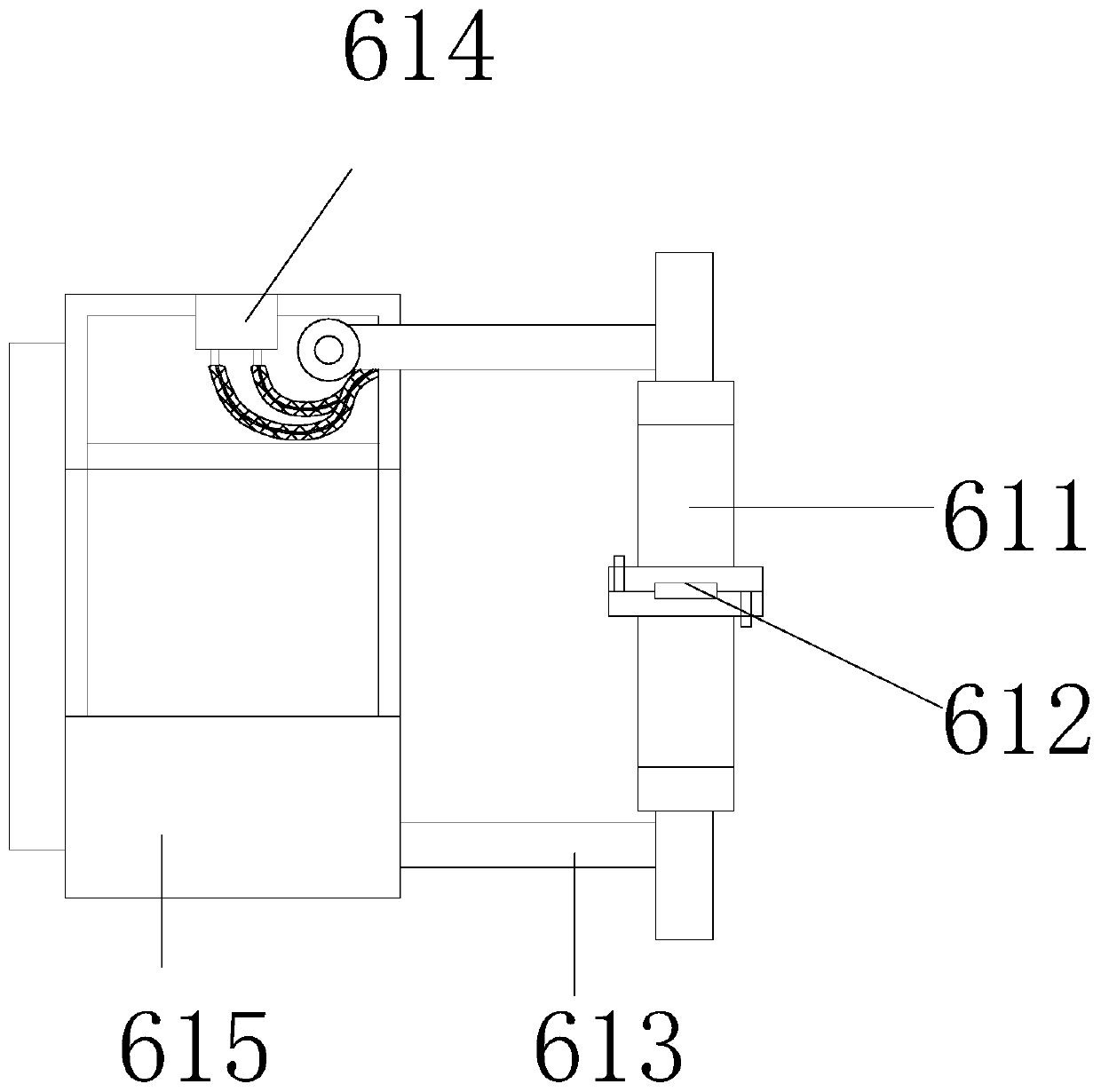

[0031] Such as Figure 1-Figure 10 As shown, the present invention provides a steering tie rod with a composite constant pressure chamber and one-way oil delivery protection, and its structure includes: a ball head 1, a dust cover 2, a connecting screw seat 3, a regulator 4, a tie rod 5, and a tie rod Fitting 6, the ball head 1 is vertically fixed to the top of the connecting screw seat 3, and the middle part of the two is protected by a dust cover 2, the internal thread of the connecting screw seat 3 and the external thread of the regulator 4 on the left side of the pull rod 5 Closely fit, the tie rod 5 vertically runs through the center of the tie rod assembly 6, and the internal structure of the tie rod assembly 6 includes: a constant pressure sensing head 61, a sealing coil 62, a connecting rod head 63, and the constant pressure sensing head 61 is tightly fastened in the end groove on the left side of the sealing coil 62 , and the connecting rod head 63 is horizontally fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com