Asymmetric watertight corrugated bulkhead and bulk cargo ship heavy ballast tank

An asymmetric bulk carrier technology, applied in the direction of the hull, ship construction, and partial compartments in the hull, can solve the problems of excessive increase in the thickness of the transverse bulkhead, achieve weight reduction, reduce structural weight, and meet yield strength requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described by means of embodiments below in conjunction with the accompanying drawings, but the present invention is not limited to the scope of the following embodiments.

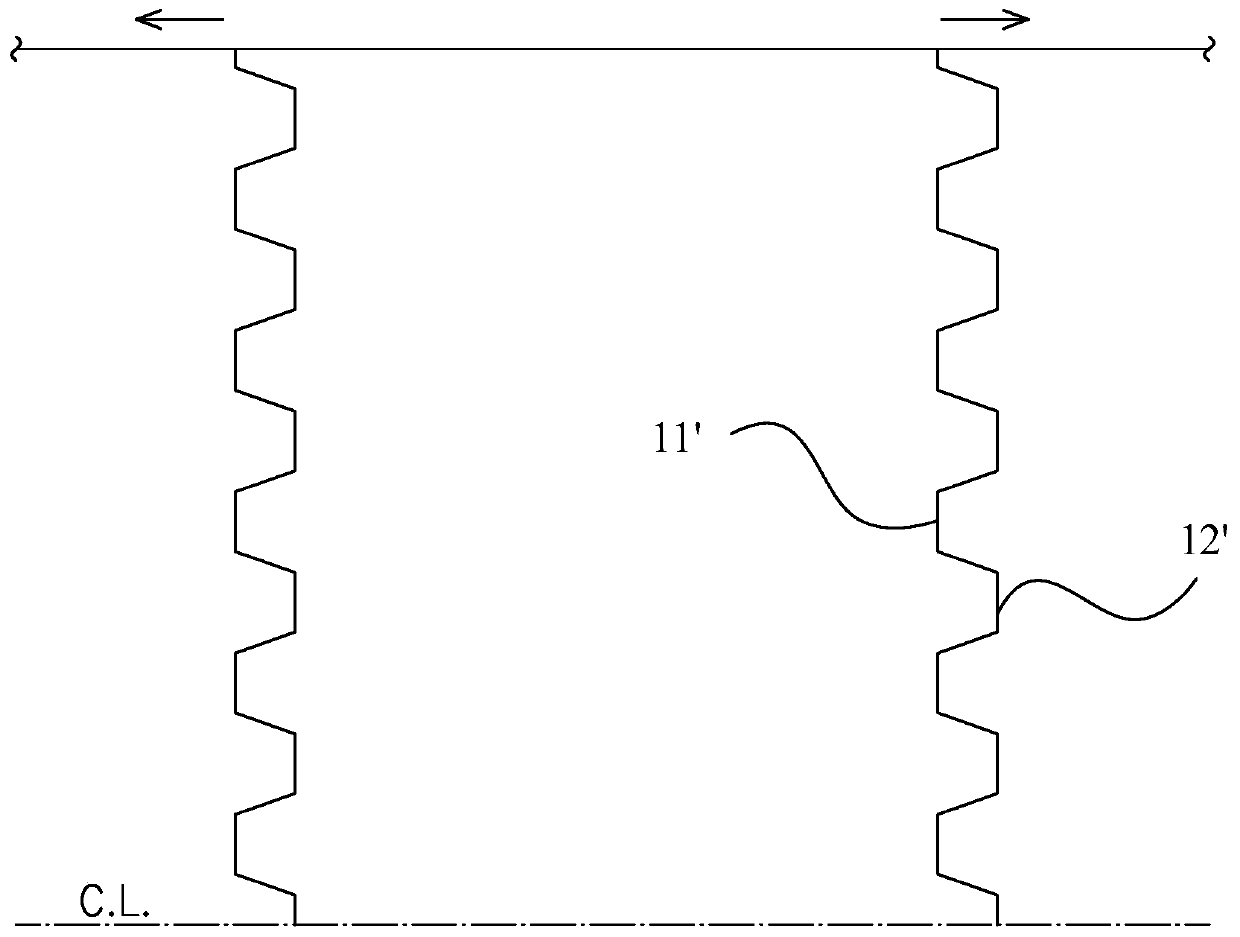

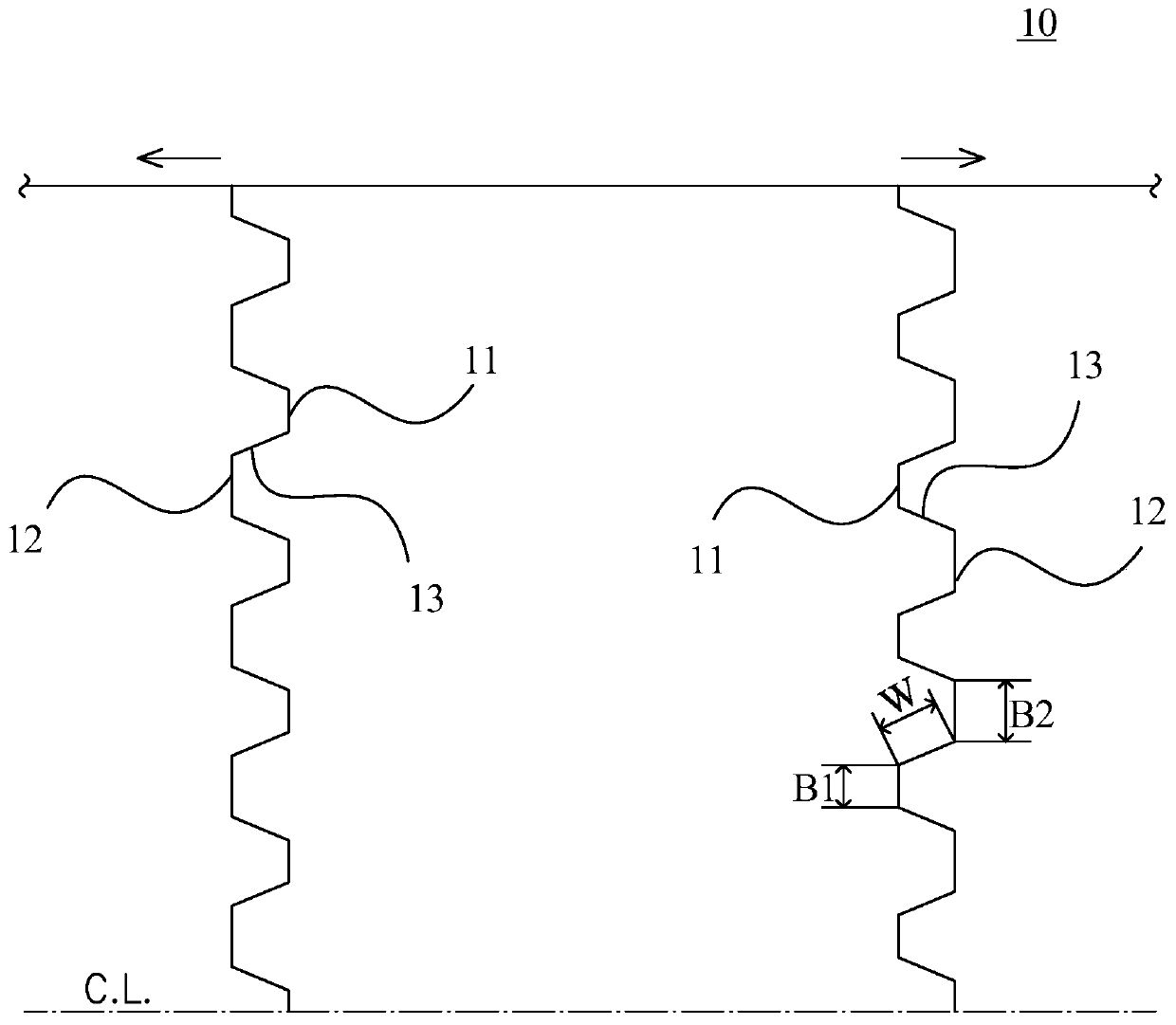

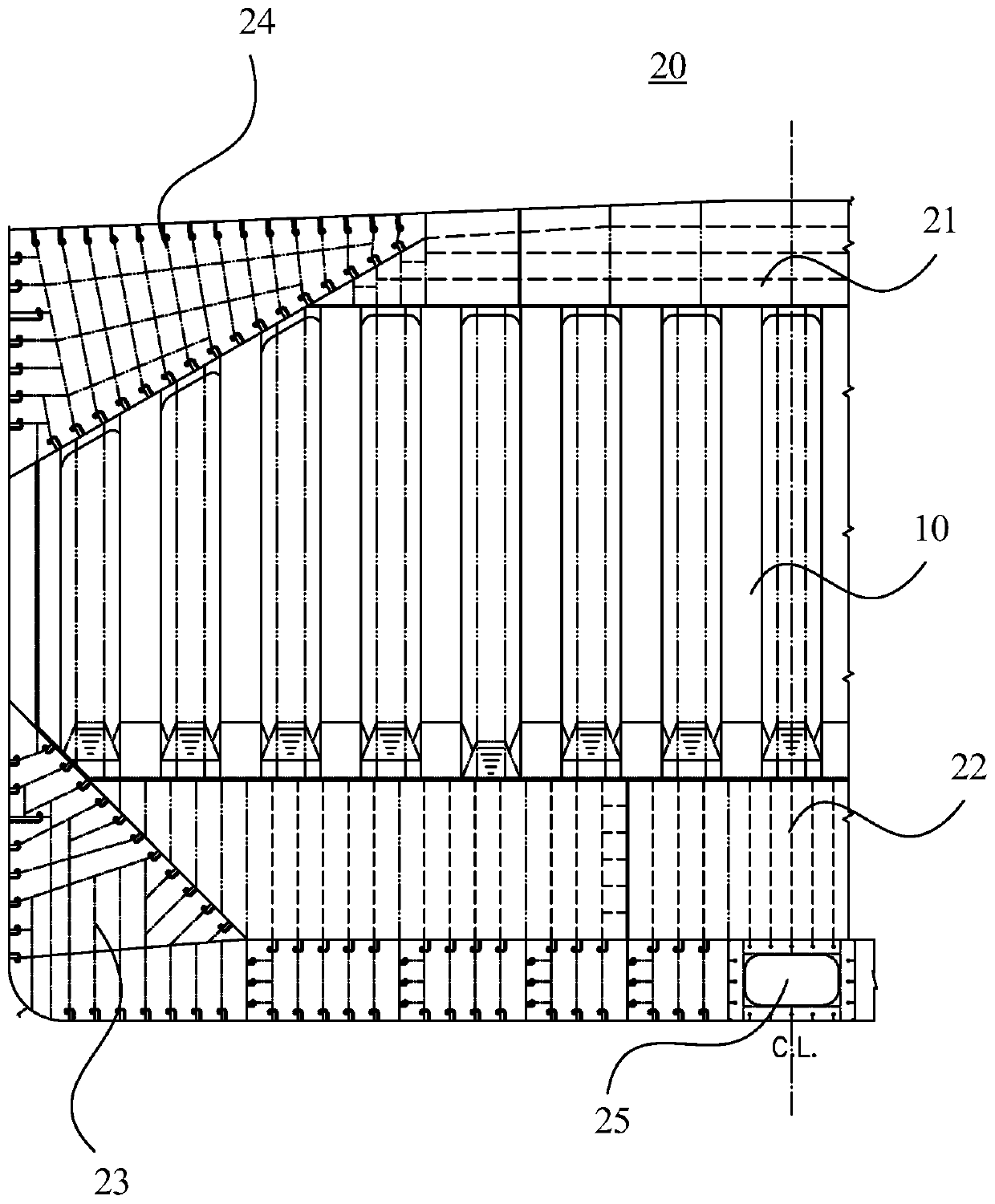

[0037] like Figure 2-3 As shown, the asymmetric watertight corrugated bulkhead 10 includes: a first panel 11 , a second panel 12 , and a web 13 .

[0038] The first panel 11 faces the interior of the cabin, and the second panel 12 faces the outside of the cabin; the width B1 of the first panel 11 is smaller than the width B2 of the second panel 12 , and the width W of the web 13 is equal to the width B2 of the second panel 12 .

[0039] The panel of the watertight grooved bulkhead is set asymmetrically, and on the premise of ensuring its bending capacity, it meets the requirement of yield strength and enhances the buckling resistance, so as to achieve the purpose of reducing the structural weight. The width W of the web 13 is set to be equal to the width B2 of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com