Through tubing perforating bullet case and through tubing perforating bullet

A technology of perforating shells and perforating bullets, applied in the field of perforating bullets, can solve the problems of easy deformation and high processing precision requirements, and achieve the effects of convenient processing, high assembly precision and fast installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

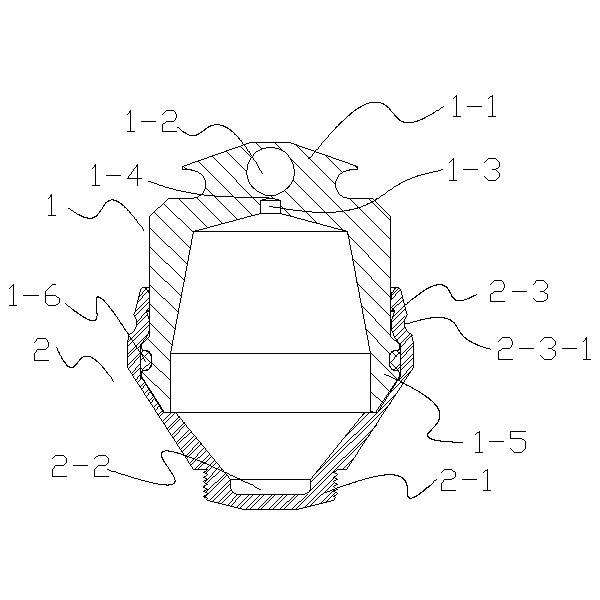

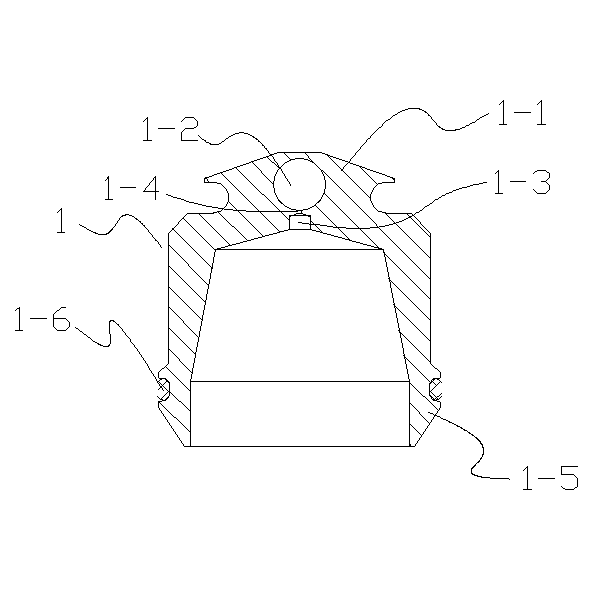

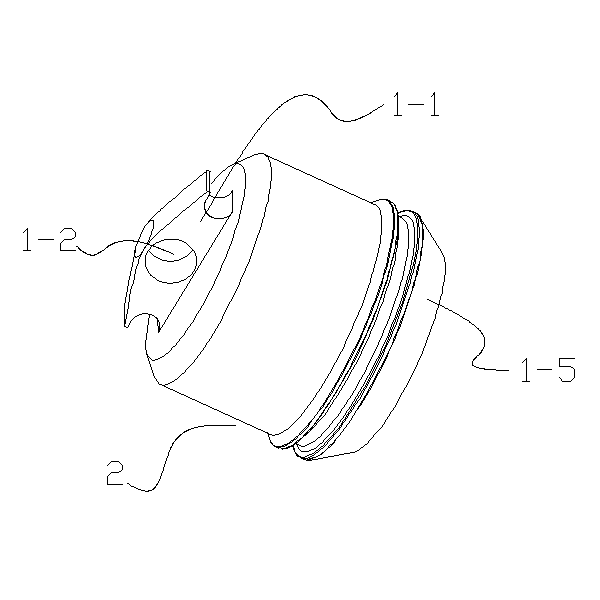

[0024] Embodiment 1: The casing of the perforating bullet through the tubing of this embodiment is as follows figure 1 , 2 , 3, 4, and 5, including perforating bullet casing 1 and perforating bullet cap 2, perforating bullet casing 1 and perforating bullet cap 2 are fastened together, and O Type sealing ring 1-6.

[0025] The opening end of the perforating bullet cap 2 is provided with a neck-shaped shell fastening part 2-3, and an annular elastic inner concave part 2-3-1 is pressed on the bullet case fastening part 2-3, and the inner concave part 2-3- The outer wall of 1 is concave inward to form a groove, the inner wall of the inner concave part 2-3-1 is convex inward to form a convex ring, and the outer wall of the opening end of the perforating cartridge case 1 is provided with a trapezoidal ring-shaped buckle cap 1-5 , the bullet cap fastening portion 1-5 is formed with a slot for installing a sealing ring, and an O-shaped sealing ring 1-6 is installed in the hole, and...

Embodiment 2

[0028] Embodiment 2: The casing of the perforating bullet through the tubing of this embodiment is as follows Figure 6 As shown, the perforating cartridge case 1 is made of 40CR material, and an inner cover 3 is provided on the wall of the inner cavity of the perforating cartridge case 1. The inner cover 3 is made of ZN material, and the inner cover 3 is closely attached to the perforating cartridge case 1. On the cavity wall of the inner cavity, the surface roughness of the joint between the cavity wall of the perforating cartridge casing 1 and the outer surface of the inner cover 3 is Ra6.3-12.5. Other technical features are the same as the perforating cartridge case 1 through the tubing of Embodiment 1.

[0029] The tubing perforating charge in this embodiment includes a tubing perforating charge casing, the inner cavity of the perforating bullet casing 1 is equipped with a liner cover 5 , and the inner cavity wall of the perforating case 1 and the liner cover 5 are press-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com