Jacking type locating device and material transferring system

A positioning device and jacking technology, applied in the direction of conveyor objects, transportation and packaging, conveyors, etc., can solve the problems of inability to meet the requirements of positioning accuracy and poor positioning accuracy, and achieve high-precision positioning of materials and ensure positioning accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

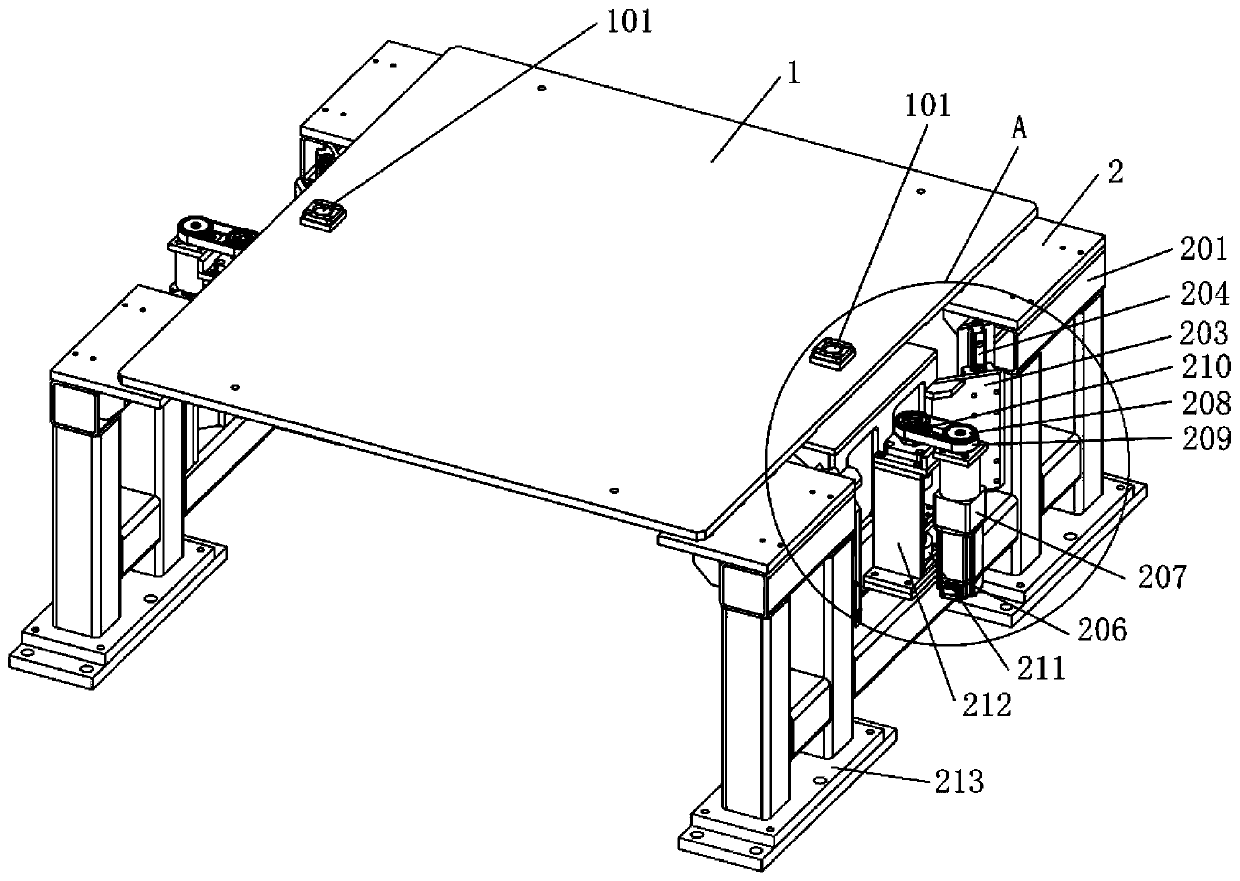

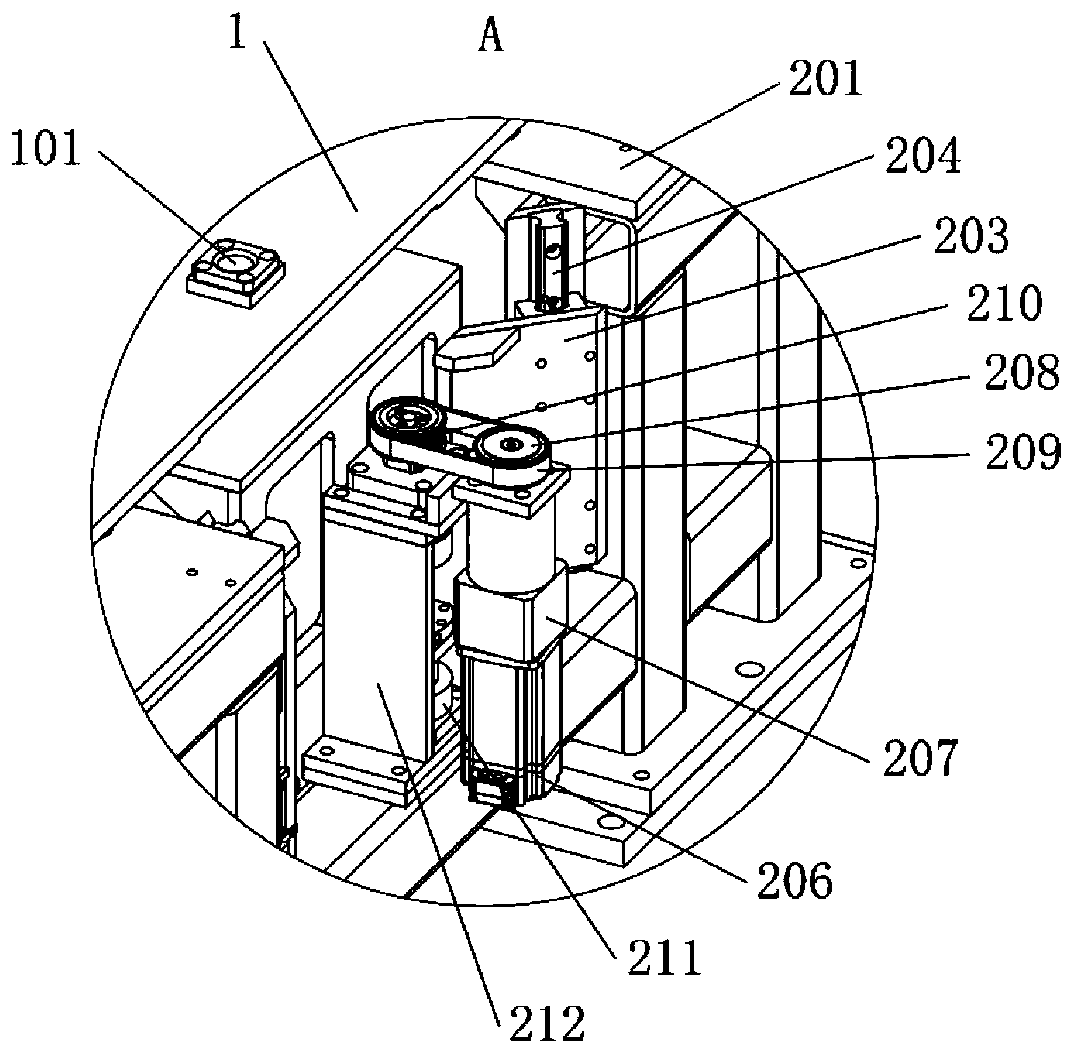

[0030] Such as Figure 1 to Figure 3 As shown, this embodiment provides a jack-up positioning device, which is used for secondary positioning of the materials transferred by the jack-up automatic guided transport vehicle, so as to meet the high precision of material positioning in industrial production need. The jack-up positioning device includes: a material transfer tray 1 and a positioning component 2 .

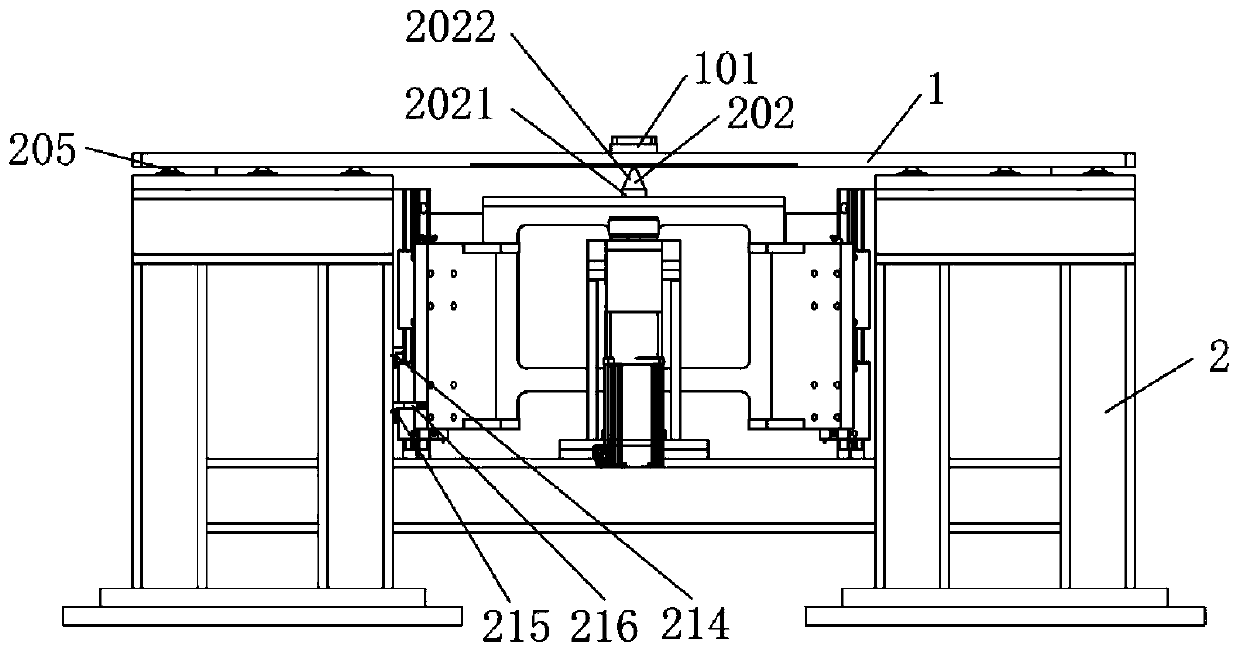

[0031] Wherein, the positioning assembly 2 includes a positioning bracket 201 and a jacking mechanism installed on the positioning bracket 201, the top of the positioning bracket 201 is provided with a rolling support 205, and the material transfer tray 1 can be placed on the rolling support 205 on the positioning bracket 201, A positioning pin 202 is provided on the jacking mechanism, and a guide bush 101 matching the positioning pin 202 is provided on the material transfer tray 1, and the positioning pin 202 cooperates with the guide bush 101. Translate to realize the ...

Embodiment 2

[0053] A material transfer system, comprising: a jack-up automatic guided transport vehicle and a jack-up positioning device according to the above embodiment, the jack-up positioning device includes a material transfer tray 1 and a positioning assembly 2, and the positioning assembly 2 includes a positioning bracket 201 And the jacking mechanism installed on the positioning bracket 201, the jacking mechanism is provided with a positioning pin 202, the material transfer tray 1 is provided with a guide bushing 101 matching the positioning pin 202, and the top of the positioning bracket 201 is provided with a rolling support 205 The jacking-type automatic guided transport vehicle is set to lift the material transfer tray 1 to move to the positioning assembly 2, and place it on the rolling support 205 on the positioning bracket 201, and the jacking mechanism lifts the material transfer tray 1, so that The material transfer tray 1 is raised, and the material transfer tray 1 transla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com