A kind of steel for prestressed concrete steel bar not easy to be brittle and its production method

A concrete steel rod and prestressing technology, applied in the field of alloy smelting, can solve the problems of stability risk, high fracture ratio, poor relaxation, etc., and achieve the effect of improving yield and production efficiency, increasing tempering temperature, and good surface quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

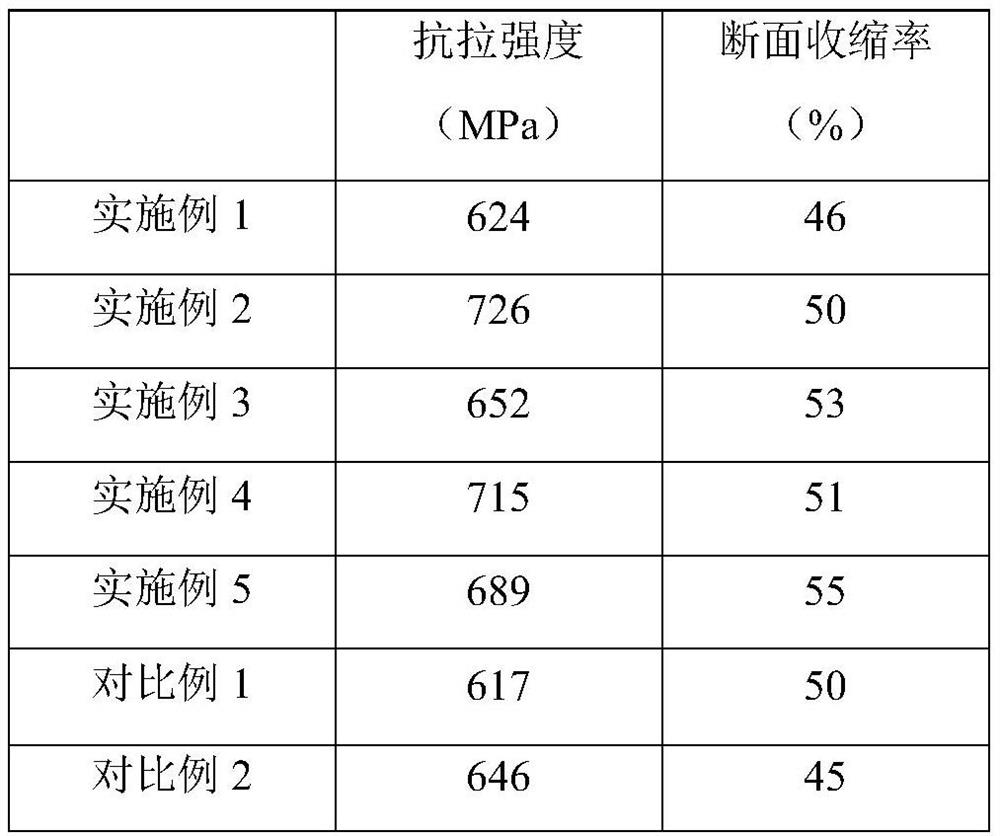

Examples

preparation example Construction

[0018] The method for preparing the steel for the prestressed concrete steel bar which is not easy to break easily comprises the following steps: (a) taking molten iron and steel scrap as raw materials to carry out converter steelmaking to obtain molten steel; the tapping temperature of the molten steel is 1600-1650°C, When the molten steel is tapped, 3-5kg of lime, 10-15kg of ferrosilicon and 8-10kg of silicon-manganese are added to each ton of molten steel, and the mass percentage content of C in the molten steel is controlled to be 0.05-0.15%, and the mass percentage of P The content is 0.001-0.020% and the mass percentage content of S is 0.005-0.030%; (b) performing LF refining on the molten steel, the LF refining includes using auxiliary materials to make white slag to deoxidize the molten steel, and the amount of the auxiliary materials added Add lime 4~5kg, fluorite 2~4kg and calcium carbide grain 0.5~1.5kg for every ton of molten steel; The temperature of described molt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reduction of area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap