A kind of sock forming equipment

A technology for forming equipment and socks, which is applied in mechanical cleaning, textiles and papermaking, and sewing machine control devices, etc. It can solve the problems of large equipment footprint, increase intermediate links, and reduce production area, so as to achieve process concentration, quality assurance, and The effect of increasing productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

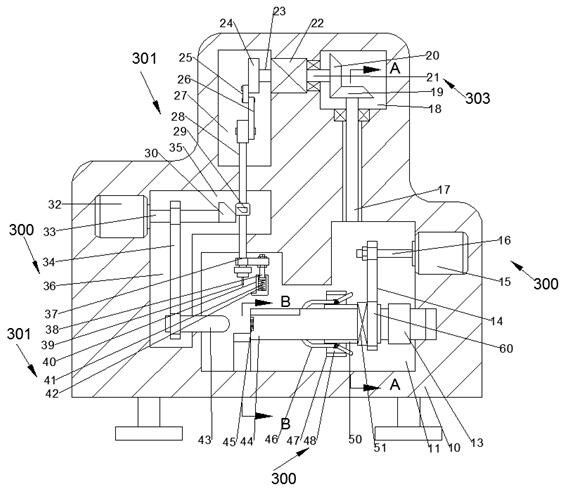

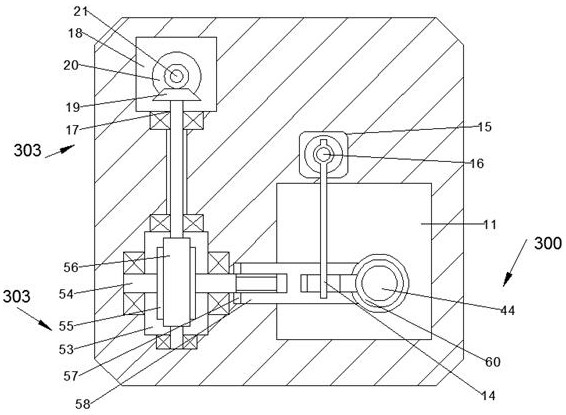

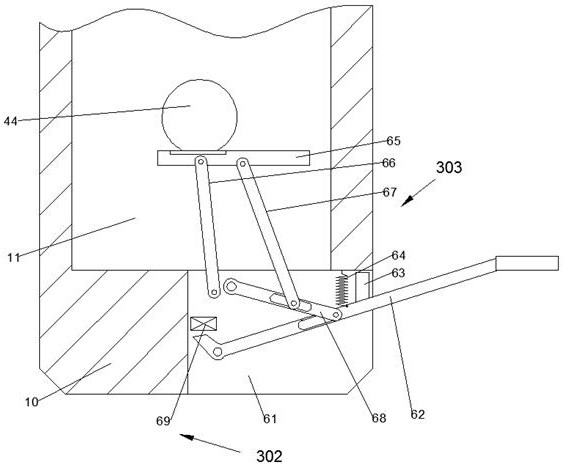

[0013] Combine below Figure 1-3 The present invention is described in detail, and for convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0014] refer to Figure 1-3 , a kind of sock forming equipment according to an embodiment of the present invention, comprising a device box 10, the device box 10 is provided with a sealing cavity 11, and the sealing cavity 11 is provided with a turning mechanism for turning over socks 300, the turning mechanism 300 includes a support platform 44 for supporting socks and a stretching rod 46 for pushing the socks to move, the turning mechanism 300 also includes a turning platform 43, and the upper side of the turning mechanism 300 is provided with Sealing mechanism 301, described sealing mechanism 301 comprises needle 39 and the clamping head 40 that clamps socks when sealing, and the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com