Soft soil foundation reinforcement method

A soft soil foundation and soil layer technology, applied in soil protection, infrastructure engineering, sheet pile wall and other directions, can solve the problems of lack of connection relationship, inability to achieve good integrity of mixing piles, etc., and achieve the effect of improving connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

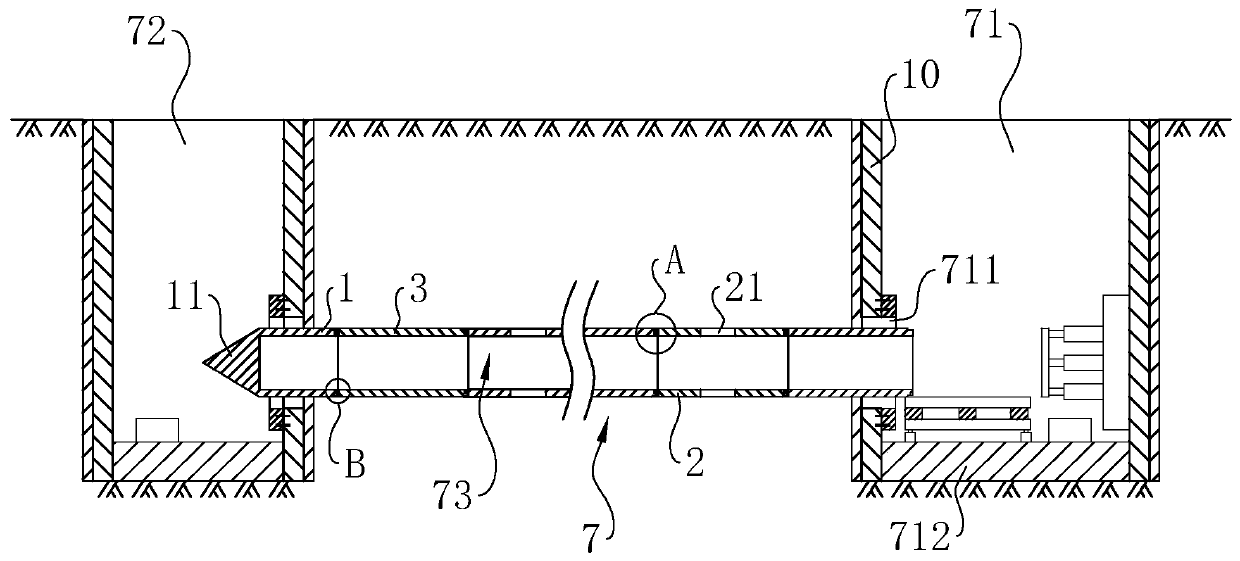

[0046] refer to figure 1 , is a kind of soft ground reinforcement method disclosed by the present invention, comprises the following steps:

[0047] S1, preparation before construction;

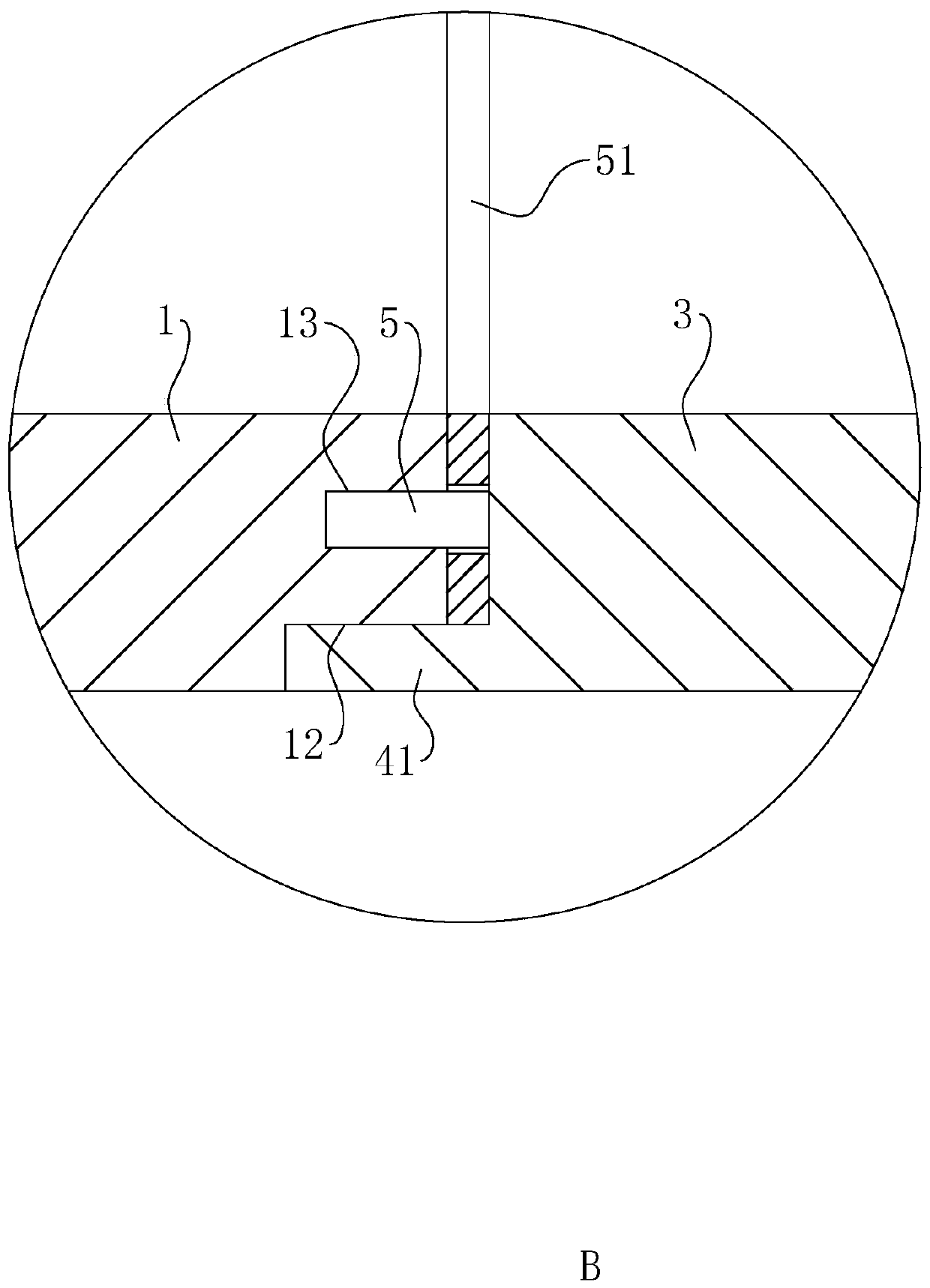

[0048] S1-1, prepare the head pipe 1, the unit pipe body 2 and the connecting pipe body 3. The diameter and wall thickness of the head pipe 1, the unit pipe body 2 and the connecting pipe body 3 are the same, and they are all made of steel. The head pipe 1 is a closed and hollow pipe at one end. The closed end of the head pipe 1 is provided with a conical tip 11 which is solid.

[0049] The unit pipe body 2 is a hollow pipe with open ends. The side wall of the unit pipe body 2 is provided with two opposite installation holes 21 . The connecting pipe body 3 is a hollow pipe with open ends.

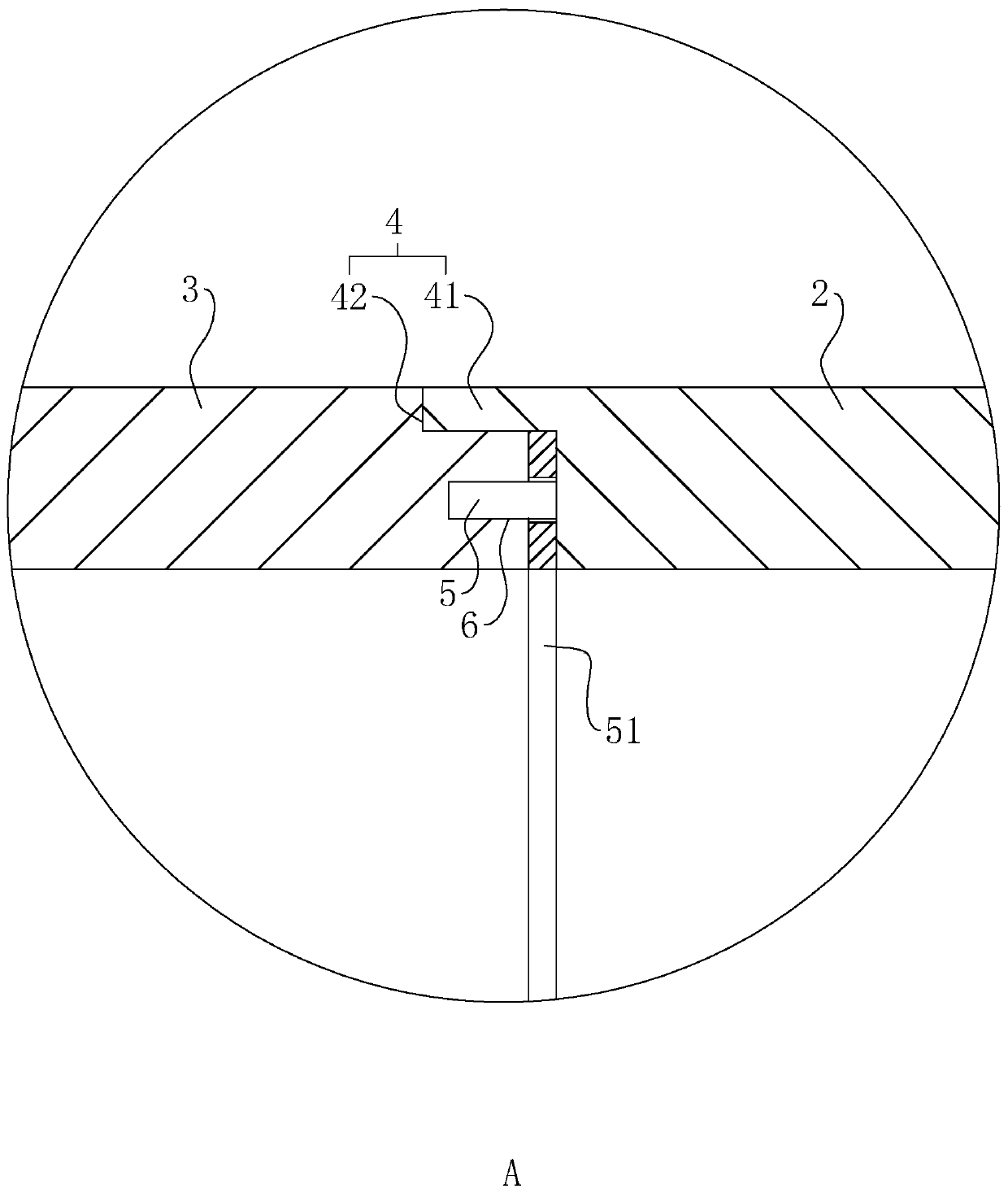

[0050] combine figure 1 and figure 2 , Both ends of the unit tube body 2 and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com