A repairing structure and repairing construction method for foundation pit supporting and retaining piles

A foundation pit support and construction method technology, which is applied in the field of building foundations, can solve problems such as potential safety hazards, displacement inclination, and cracks in foundation pit support row piles, etc., to achieve high repair convenience, improve bending resistance, and avoid Effect of Reduction in Bending Resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

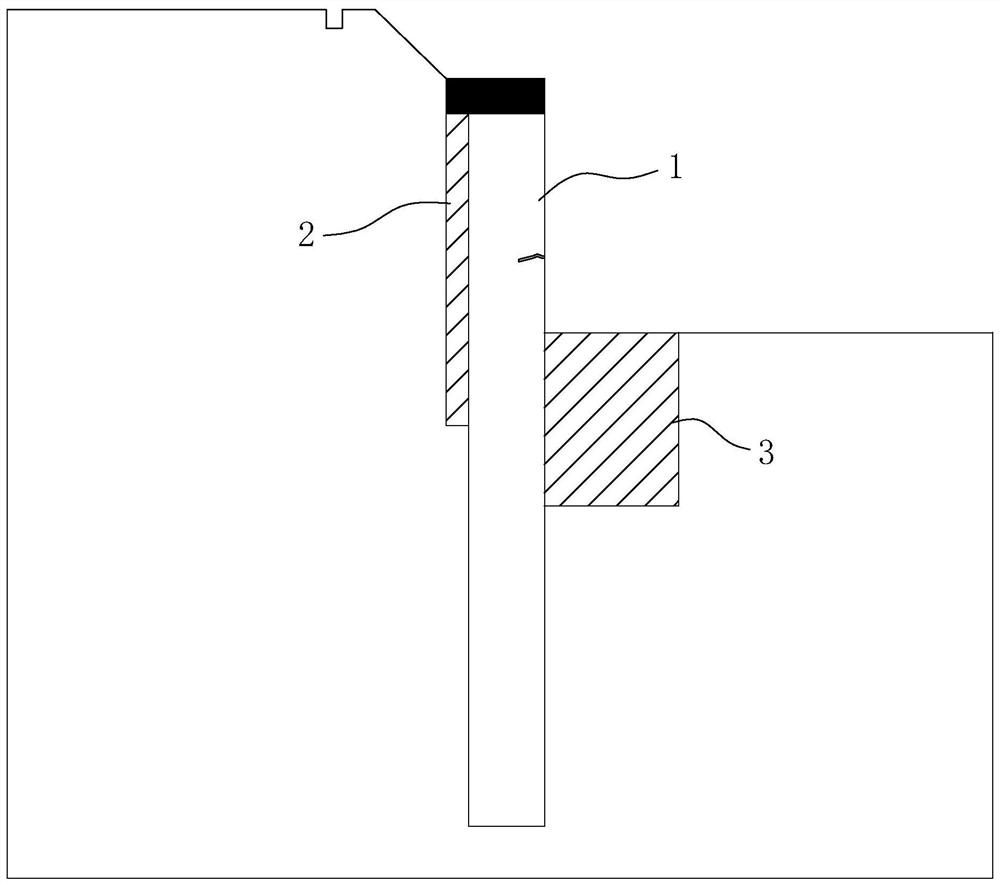

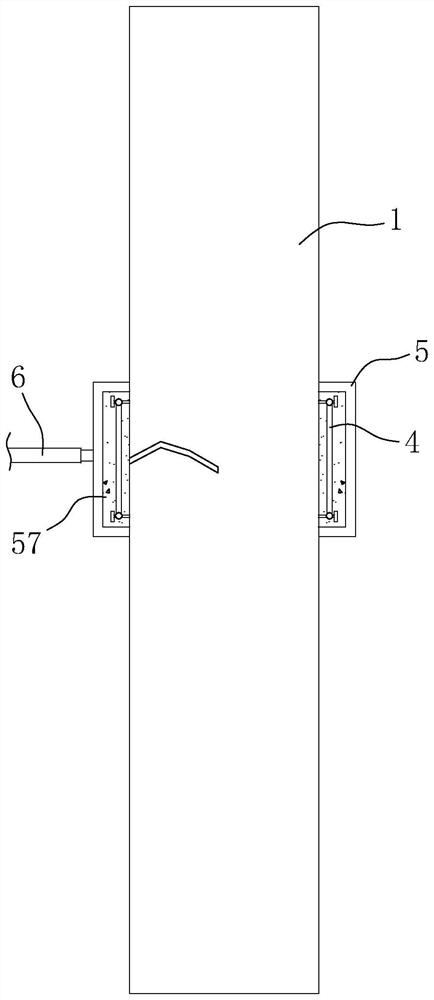

[0041] Such as figure 1 As shown, a repair structure for foundation pit support pile is applied to foundation pit support pile 1, and foundation pit support pile 1 is applied to foundation pit support, and foundation pit support pile 1 is made of cast-in-place concrete thin Wall pipe pile or immersed pipe grouting pile. When the excavator excavates the soil to form the foundation pit, the foundation pit support pile 1 can cling to the side wall of the foundation pit to achieve the purpose of supporting the side wall of the foundation pit and prevent problems such as soil slope slipping in the foundation pit. The support pile 1 is provided with a water-stop and soil-stop curtain 2 on the side corresponding to the periphery of the foundation pit. The distance between the water-stop and soil-stop curtain 2 and the foundation pit support pile 1 is set according to the space and soil quality requirements of the foundation pit location. . The foundation pit support pile 1 is provi...

Embodiment 2

[0051] A repairing construction method for applying the repairing structure of the foundation pit supporting pile 1 as described in the above technical scheme, comprising the following steps:

[0052] Step S1, excavating the soil around the cracks of the foundation pit support pile 1 on the side wall of the foundation pit, and cleaning the surface area where the foundation pit support pile 1 crack is located; specifically, cleaning the foundation pit support pile 1 The surface area where the crack is located includes the crack of the foundation pit support pile 1 , the upper part of the foundation pit support pile 1 crack, and the lower part of the foundation pit support pile 1 crack.

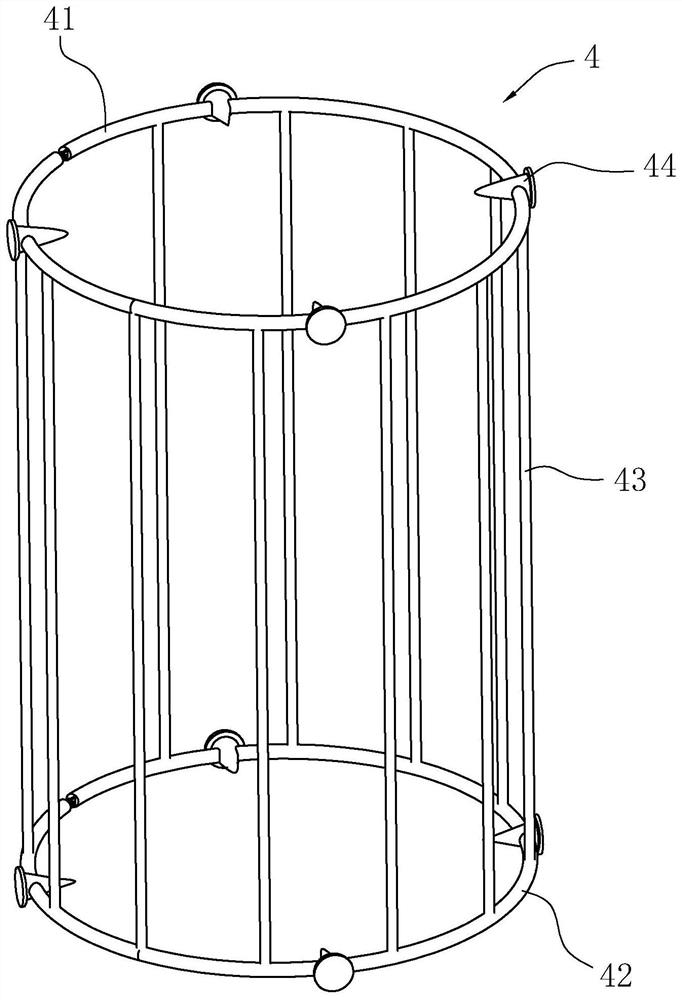

[0053] Step S2, fix the repair frame 4 around the crack of the foundation pit support pile 1; specifically, the first iron wire 41 and the second iron wire 42 are connected at the end to surround the foundation pit support pile 1, the first iron wire 41 and the second iron wire 42 are connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com