A carbon dioxide blaster

A carbon dioxide and blaster technology, applied in blasting cylinders, weapon accessories, offensive equipment, etc., can solve the problems of separation, push rod damage, deformation, etc., and achieve the effect of increasing force and increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

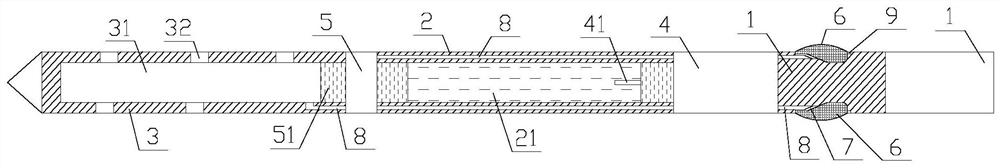

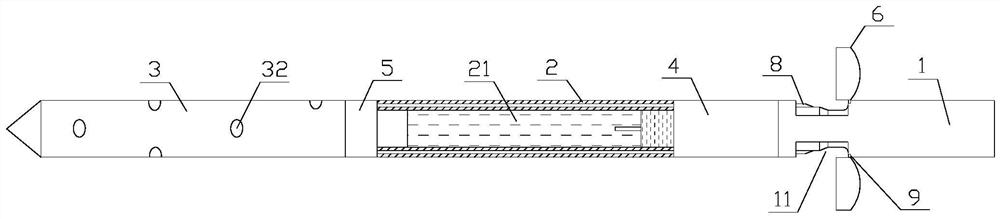

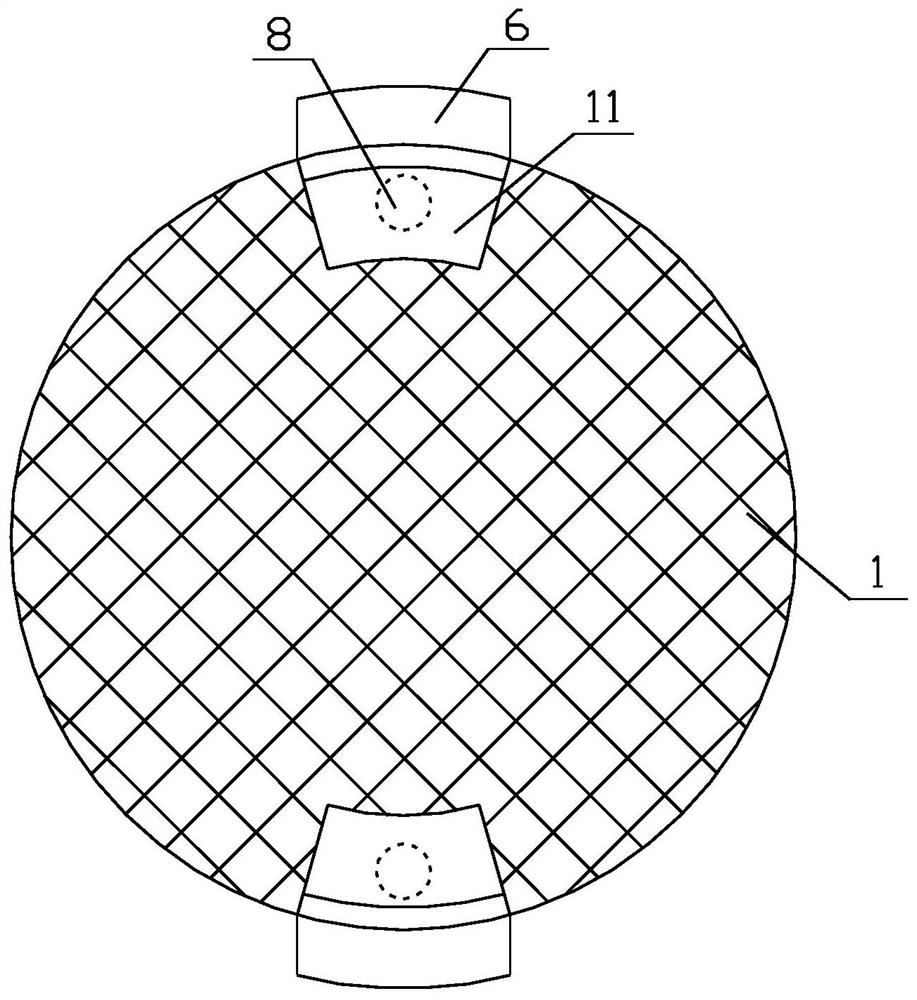

[0036] Such as Figure 1-5 As shown, a carbon dioxide blaster of the present invention includes a push rod 1, a liquid storage pipe 2 and an exhaust pipe 3, the liquid storage pipe 2 is provided with a liquid storage chamber 21, and the exhaust pipe 3 is provided with an exhaust chamber 31. The surface of the exhaust pipe 3 is provided with an exhaust hole 32, and the exhaust hole 32 communicates with the exhaust chamber 31. The push rod 1 and the liquid storage pipe 2 are connected through the first connector 4, and the liquid storage pipe 2 is connected to the exhaust chamber 31. The air pipes 3 are connected through the second connector 5, a heater 41 is arranged on the first connector, and a constant pressure shear piece 51 is arranged on the second connector 5, and the constant pressure shear piece 51 is arranged between the liquid storage chamber 21 and the exhaust gas. Between chambers 31.

[0037] Further, the push rod 1 is provided with several grooves 11, the groove...

Embodiment 2

[0042] Such as Figure 1-5 As shown, a carbon dioxide blaster of the present invention includes a push rod 1, a liquid storage pipe 2 and an exhaust pipe 3, the liquid storage pipe 2 is provided with a liquid storage chamber 21, and the exhaust pipe 3 is provided with an exhaust chamber 31. The surface of the exhaust pipe 3 is provided with an exhaust hole 32, and the exhaust hole 32 communicates with the exhaust chamber 31. The push rod 1 and the liquid storage pipe 2 are connected through the first connector 4, and the liquid storage pipe 2 is connected to the exhaust chamber 31. The air pipes 3 are connected through the second connector 5, a heater 41 is arranged on the first connector, and a constant pressure shear piece 51 is arranged on the second connector 5, and the constant pressure shear piece 51 is arranged between the liquid storage chamber 21 and the exhaust gas. Between chambers 31.

[0043] Further, the push rod 1 is provided with several grooves 11, the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com